Pad Printing

What is Pad Printing?

To us, pad printing isn’t just a “printing method”, it’s the solution for surfaces other techniques can’t handle. Where screen printing struggles with curves, or laser engraving fails on soft plastics, pad printing shines.

Here’s how we make it work in our shop: A custom-molded silicone pad (we tweak its hardness to match your part’s shape: 30 Shore A for sharp edges, 70 for deep curves) picks up ink from a precision-etched plate, then presses it onto surfaces that feel “impossible”, like the rounded edge of an automotive dashboard button, the tiny 2mm recess of a medical device dial, or even the textured surface of a rubber grip.

We’ve built our process around real-world needs. Printing on ABS? We use a UV-cured ink that resists dashboard heat. On stainless steel? A primer-backed formula that passes 500+ wear tests. It’s why our clients come to us for logos that don’t fade on tool handles, serial numbers that stay legible on industrial parts, and tiny symbols that meet strict medical labeling standards.

Pad Printing: 6-Step Process Explained

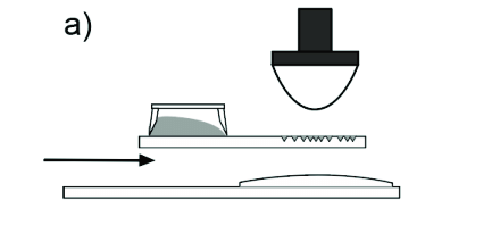

Step 1: Ink Plate Moves Beneath Pad

The ink plate (also called the cliché) containing the etched image slides into position directly under the silicone pad.

Step 2: Pad Picks Up Ink

The silicone pad presses down onto the ink-filled etched area, picking up a thin layer of ink in the shape of the design.

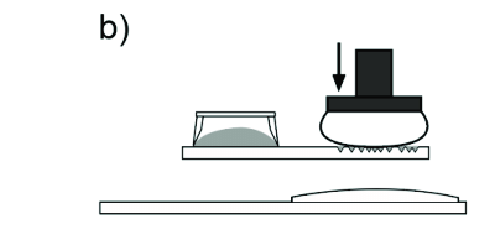

Step 3: Pad Lifts Off

The pad lifts straight up, carrying the inked image on its surface.

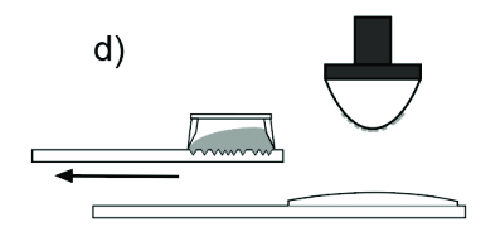

Step 4: Ink Plate Retracts

The ink plate moves out of the way to make room for the object being printed.

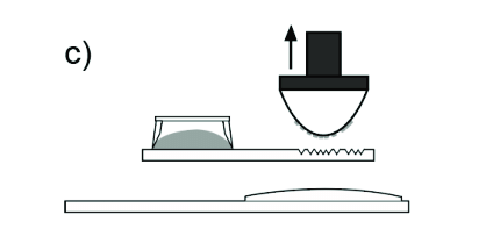

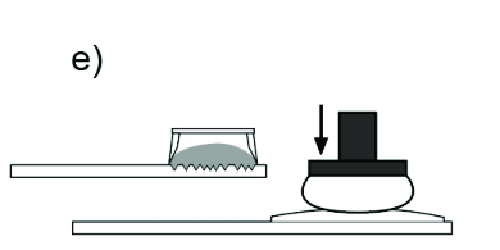

Step 5: Pad Transfers Image to Object

The pad presses down onto the object’s surface, transferring the ink from the pad to the product precisely.

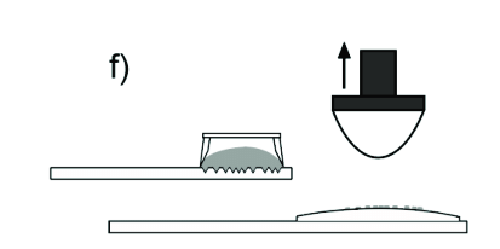

Step 6: Pad Lifts – Print Complete

The pad lifts away, leaving a clean, detailed image on the product. The print cycle is complete and ready for the next repetition.

Available Pad Printing Services

Advantages of Choosing Us to Pad Print Your Product

We Master the Tough Stuff

Our ±0.02mm registration precision ensures logos line up perfectly on curved surface (in one case, automotive trim) where something generic services can’t match. And for that trim project, we built a custom pad (70 Shore A, with a slight taper) that hugs the curves, and a slow-dry ink that soaks into the texture.

We Scale Seamlessly

From 100 prototypes (ready in 3 days) to 100,000 units, with zero drop in quality and no other shop balances speed and consistency like we do. A client needed 100 prototypes of a small electronics part on Monday, then 50,000 units by month’s end. We ran the prototypes on our manual press (done in 2 days), then swapped to our automated line with the same ink, same alignment, and zero rework.

Long-Lasting Results

Our pad-printed marks stand up to real-world abuse: tool handles with 1,000+ daily uses, outdoor gear baked under 3,000+ hours of sun. It’s not luck—our custom inks (tuned to your material) and pre-treatments (like flame-activating PP) lock in color, so the print outlasts the part.

We Back Every Print with Compliance

We back prints with proof. Medical clients get ink certs (ISO 10993, no phthalates). And for clients in automotives field, we send 3,000-hour UV test reports showing their logos won’t fade in sunlight. We replace empty promises with actual data.

Wide Color Range

From single-color logos to full-color graphics, pad printing supports a broad spectrum of color applications. A toy company needed a neon pink that matched their packaging. So we mixed 12 test swatches, let them pick, then locked that formula in. No surprises, just prints that make your parts look like you imagined.

What Do You Need to Prepare for Pad Printing?

*Note:

We’re continually expanding our pad printing capabilities. If you have questions or unique requirements, please reach out to your account representative for assistance.

Frequently Asked Questions

Yes. Accurate fixture design is critical for consistent pad printing—especially for multicolor applications or irregularly shaped parts. KingStar Mold designs and manufactures custom fixtures in-house, ensuring precise alignment and repeatability. We account for part geometry, ink transfer angles, and automation compatibility to support both manual and automated production workflows.

Lead times vary depending on part complexity, number of colors, and quantity. For standard single-color jobs on approved materials, lead time can be as short as 3–5 business days after artwork approval. Multicolor or custom automation setups may take 1–2 weeks. At KingStar Mold, we aim to minimize turnaround through efficient in-house tooling, fixture design, and print testing.

Yes—we’re ISO 9001:2015 certified, but that’s more than a certificate on the wall. It means every pad printing run gets logged: ink batches, pad hardness, cure times, even the pressure used on the press. We trace this data back to each part, so if a client needs to audit a 6-month-old batch of medical device dials, we can show exactly how the logos were printed (and that they met ISO 10993 ink standards). It’s how we keep consistency tight.