KingStar Mold’s Advice on Choosing Your PA Product Supplier

Given the volume of projects we handle in the automotive industry, we often encounter product demands that require PA materials.

With over ten years of experience in mold design and injection molding, we are well-equipped to address the common defects encountered in PA injection molding.

Specializing in PA66+GF, PA6+GF and other materials, combined with high-precision injection molding machines and meticulous production management, KingStar Mold offers a variety of cooperation models tailored to meet your specific needs.

Automotive Applications

Packaging & Consumer Goods

Home Appliances Applications

Medical & Healthcare Applications

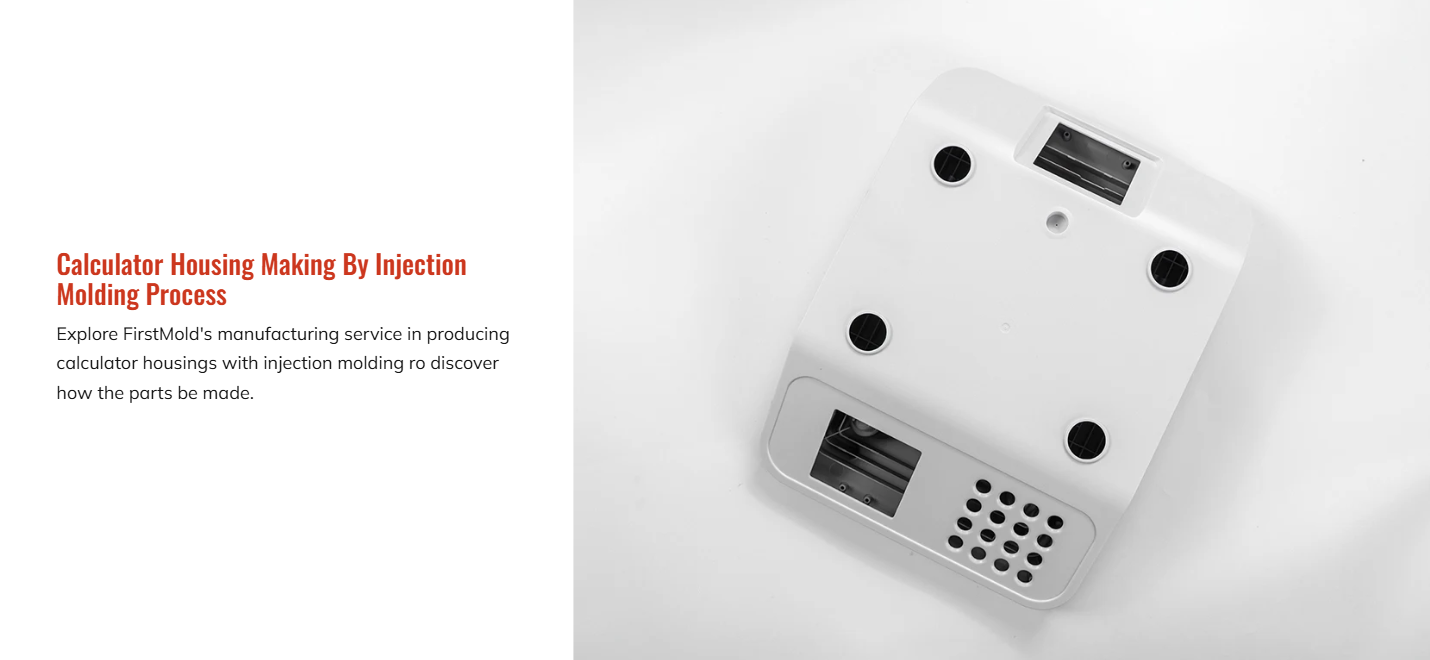

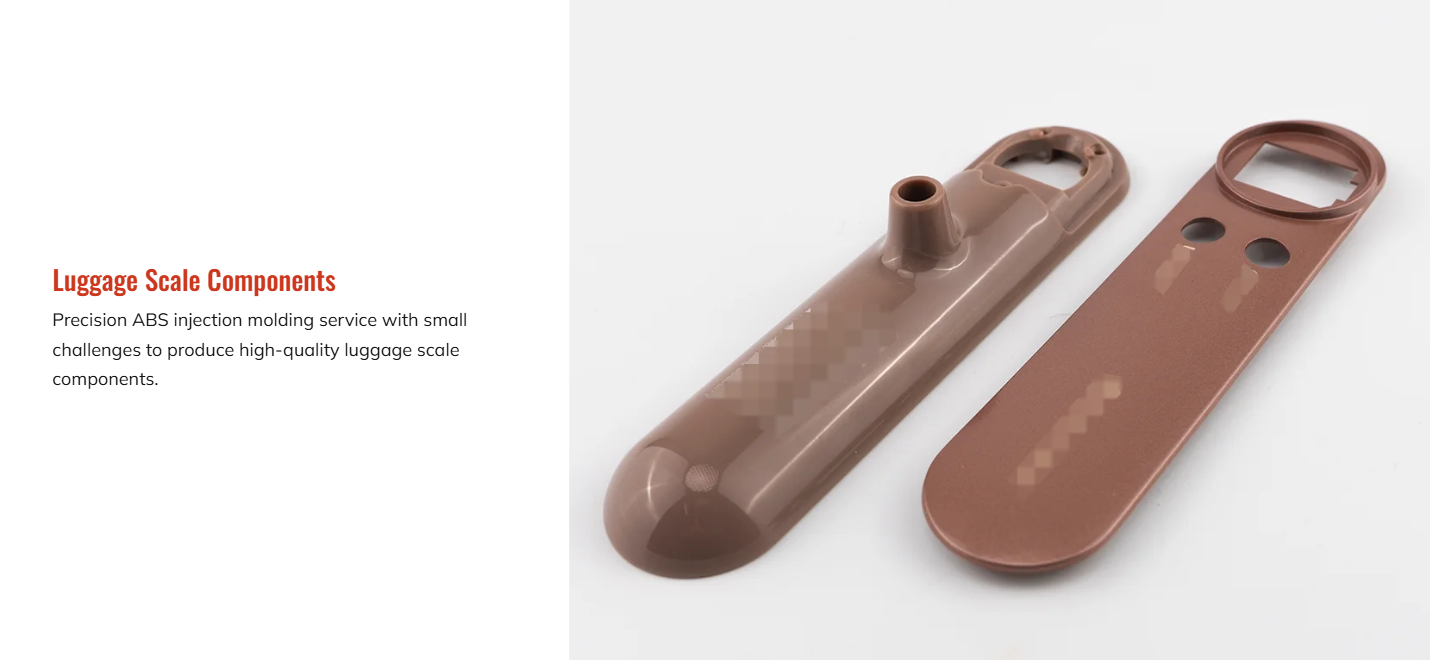

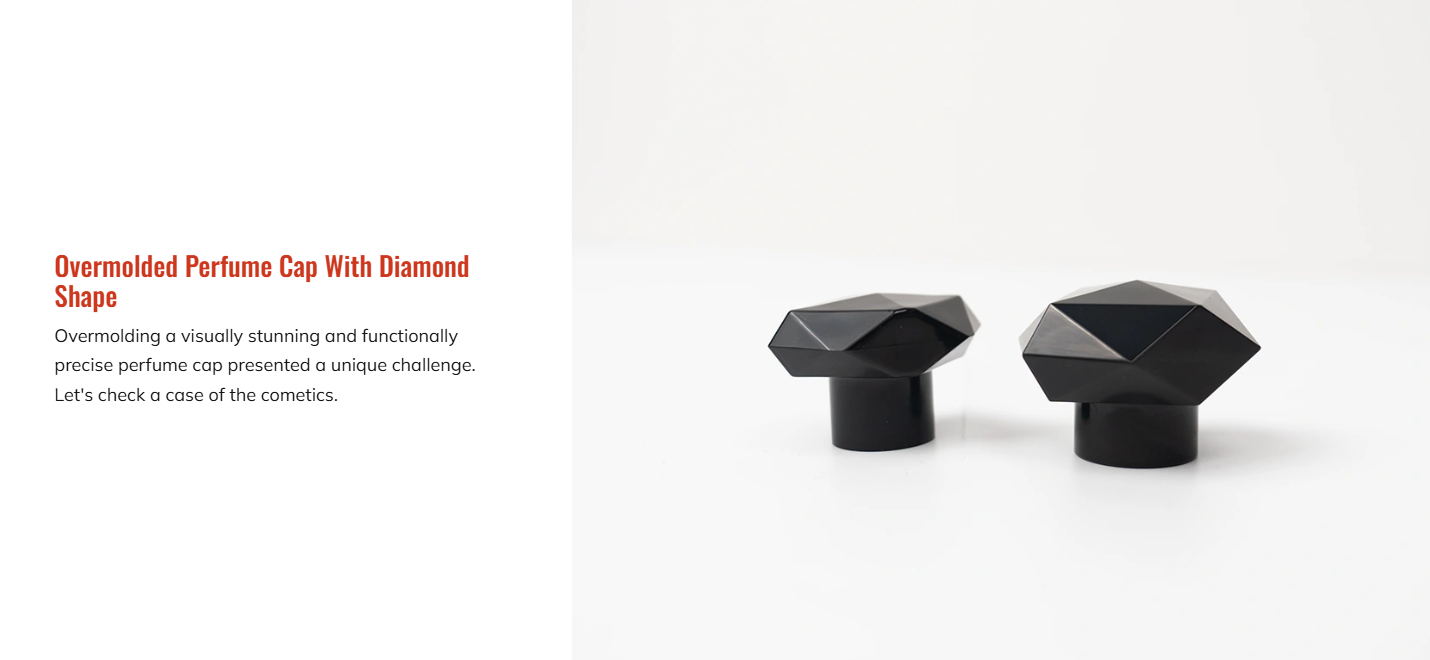

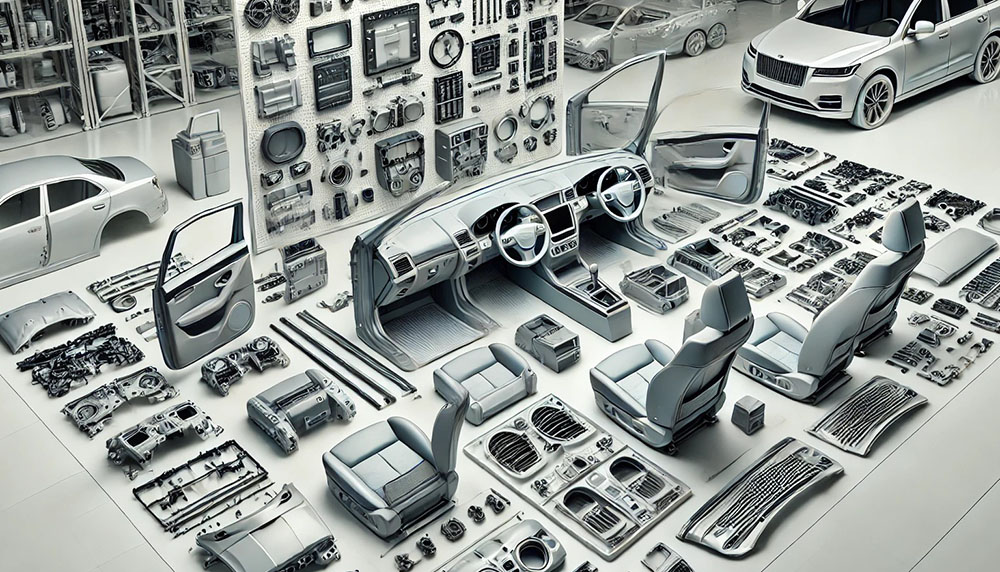

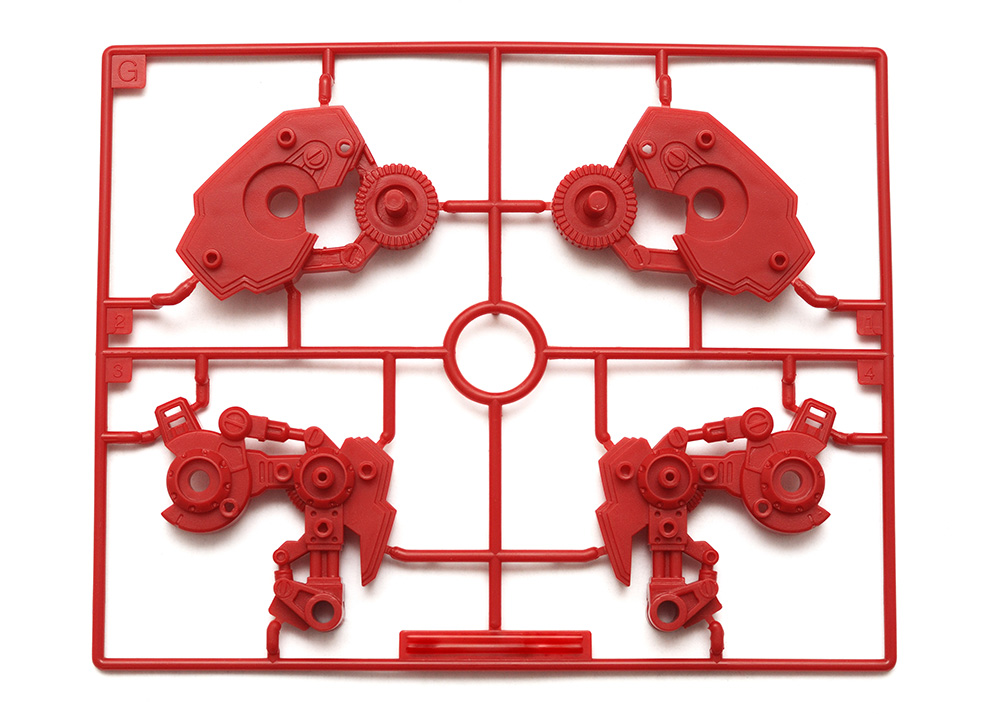

Here are a few case study images showcasing Nylon parts injection molded by KingStar Mold:

Material Source Assurance

KingStar Mold has established a decade-long partnership with trusted material suppliers. We provide material certifications and are also flexible in sourcing materials from suppliers you recommend.

KingStar Mold utilizes a range of advanced equipment, including Coordinate Measuring Machines (CMM), material testing tools, quadratic element vision systems, and environmental testing devices, to guarantee that every injection molded part meets our stringent quality criteria.

Mold Design Assurance

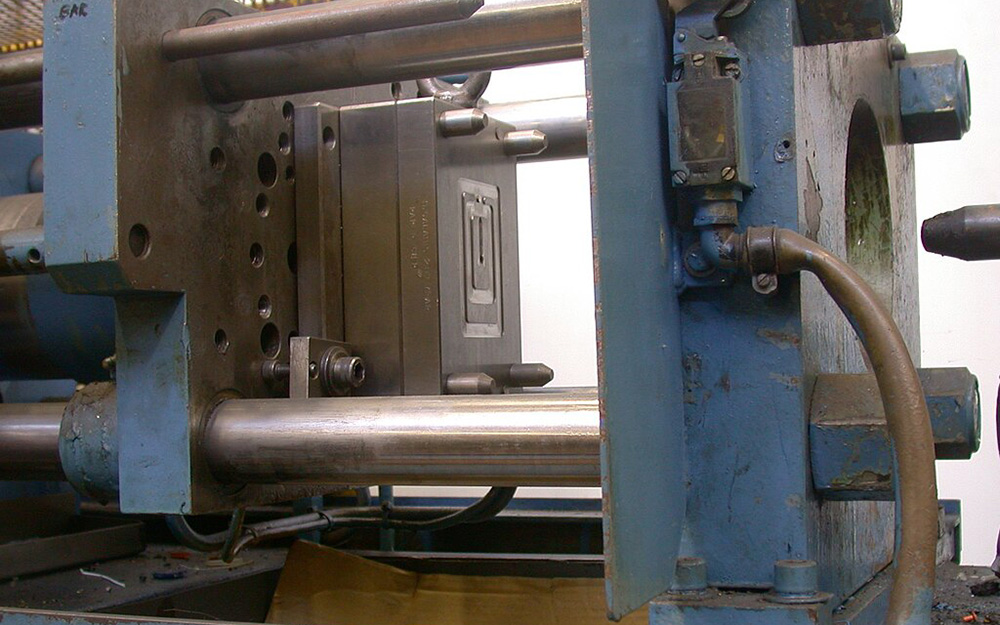

At KingStar Mold, our mold design and production teams collaborate closely. Through multiple professional team meetings, we finalize mold designs with zero risk, ensuring precision and reliability in every project.

PA Injection Molding Cases

PA materials outperform many plastics in terms of mechanical strength, durability, and resistance to harsh environments.

PA offers high strength, resistance to wear, and good heat and chemical resistance, making it suitable for demanding applications.

PA injection molding is widely used in automotive, aerospace, medical devices, consumer electronics, and industrial equipment.

Common types include PA6, PA66, glass-filled PA, and mineral-filled PA, each offering unique performance characteristics.

PA materials offer excellent mechanical strength, impact resistance, and durability, making them ideal for automotive, industrial, and consumer applications.

PA (Polyamide) injection molding is a process that uses PA-based materials to create durable, high-performance parts through injection molding.

KingStar Mold employs rigorous quality control processes, including real-time monitoring, mold inspections, and compliance with industry standards, ensuring consistently high-quality parts.

PA injection molding typically uses steel molds, which offer durability and the ability to handle high-pressure molding processes.

Yes, PA injection molding is highly versatile and can produce complex, intricate parts with fine details and tight tolerances.

Glass-filled PA increases material strength, stiffness, and dimensional stability, making it ideal for high-performance parts.

PA materials need to be dried to a specific moisture content before molding to prevent defects such as bubbling or inconsistent part quality.

PA materials can absorb moisture, affecting the molding process and part quality, requiring precise drying and careful material handling.