What is PA 12 White?

PA 12 White (PA650) for SLS

| Property | Test Standard | Value |

|---|---|---|

| Density | DIN 53466 | 0.95 g/cm³ |

| Heat Deflection (0.45 MPa) | ASTM D648 | 180.85°C |

| Heat Deflection (1.8 MPa) | ASTM D648 | 115.4°C |

| Tensile Strength | ASTM D638 | 50 MPa |

| Tensile Modulus | ASTM D638 | 2000 MPa |

| Elongation at Break | ASTM D638 | 11.5% |

| Flexural Strength | ASTM D790 | 60 MPa |

| Flexural Modulus | ASTM D790 | 1900 MPa |

| Notched Impact Strength | ASTM D256 | 21 J/m |

| Unnotched Impact Strength | ASTM D256 | 294 J/m |

PA 12 White (PA650) for MJF

| Property | Test Standard | Unit | Value |

|---|---|---|---|

| Density | ISO 1183 | g/cm³ | 1.01 |

| Tensile Strength | ISO 527 | MPa | 44 |

| Elongation at Break | ISO 527 | % | 21 |

| Tensile Modulus | ISO 527 | MPa | 1600 |

| Bending Strength | ISO 178 | MPa | 70 |

| Bending Modulus | ISO 178 | MPa | 1800 |

| Impact Resistance (Charpy) | ISO 179 | kJ/m² | 45 |

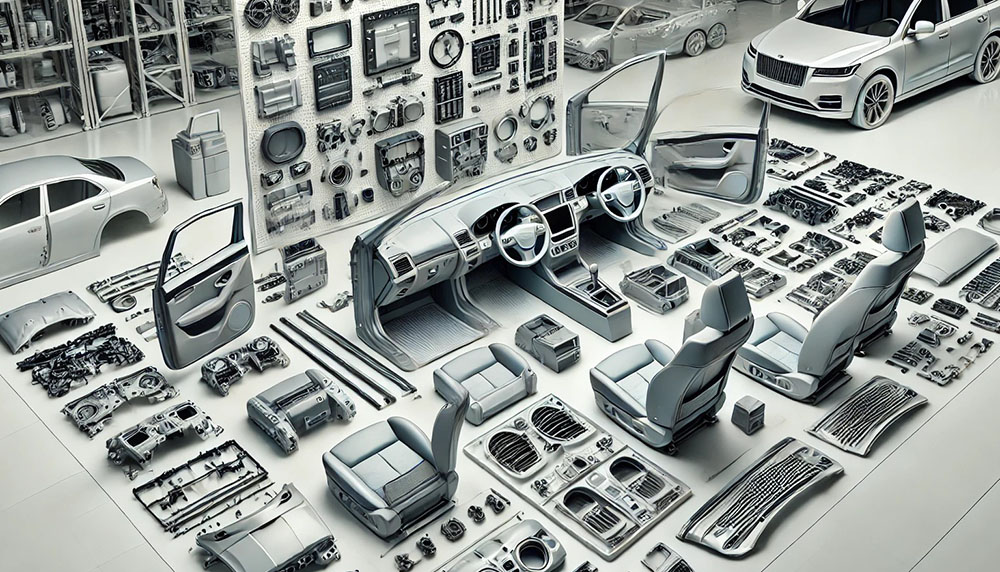

PA 12 White (PA650) is widely used in SLS and MJF 3D printing due to its excellent mechanical properties, durability, and fine detail resolution, making it ideal for functional prototypes that require strong, impact-resistant parts for testing and validation.

Gears & Mechanical Parts

Consumer Goods

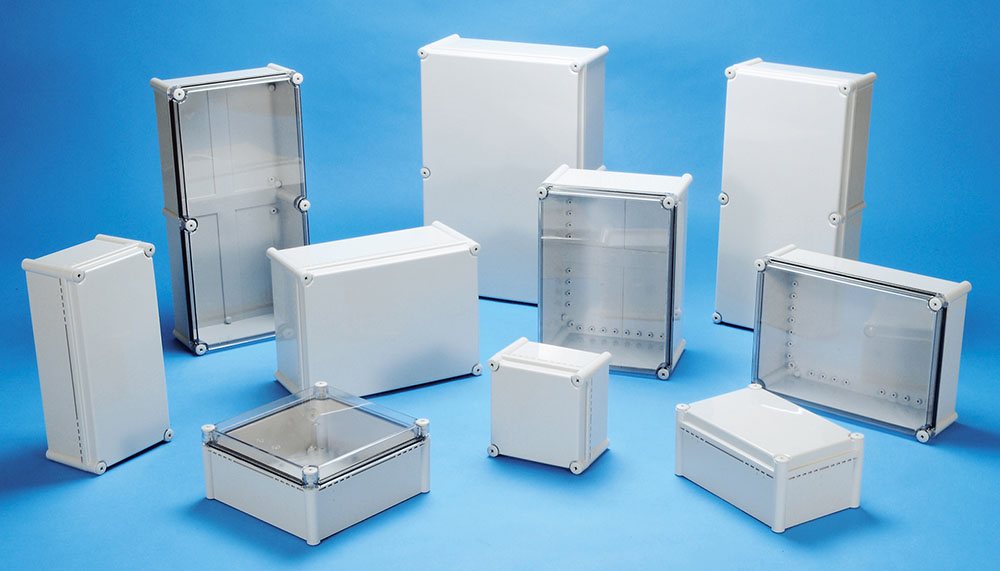

Custom Housings & Enclosures

Medical Devices

Frequently Asked Questions

How does PA 12 White (PA650) compare to other materials used in 3D printing?webadmin2025-07-15T07:44:35+00:00

How does KingStar Mold utilize PA 12 White (PA650) in manufacturing?webadmin2025-07-15T07:37:08+00:00