Overmolding

Resources for The Complete Guide to Overmolding

What is Overmolding?

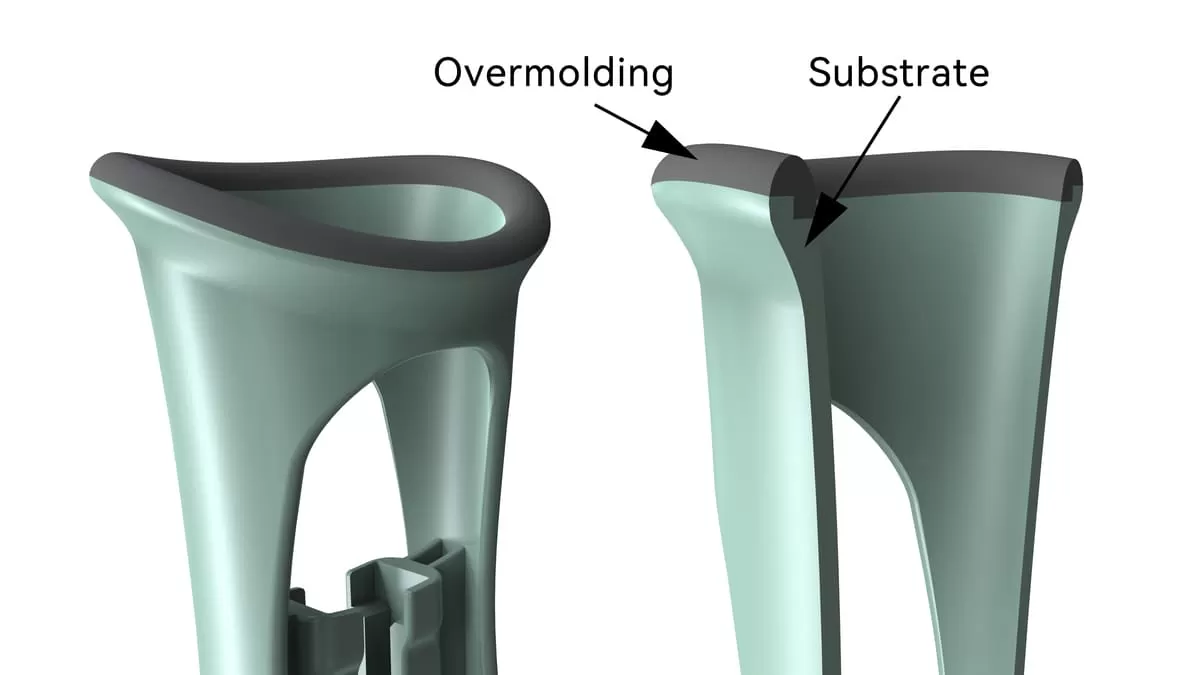

Overmolding is an injection molding process where you mold one material over top of another material or substrate. The first material is usually made of a different material or has a different shape than the second material. Overmolding is used in many industries including medical devices, automotive, aerospace, and consumer products.

To overmold, you first mold or make the first part. Then you mold the second material over top of the first part. The second material can be a different plastic, rubber, or other material that gives the part special properties like flexibility, durability, or looks.

How Does Overmolding Work?

Overmolding is a tricky process that has a bunch of steps and needs you to plan and do it right. Here’s a quick look at how overmolding works:

- Design and Prototype

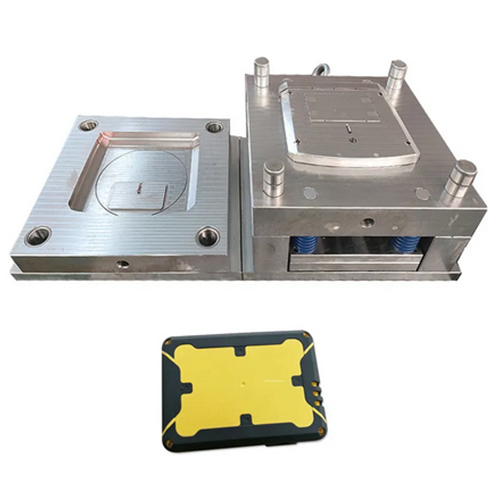

Create a 3D model of the primary part and secondary material, followed by prototypes to validate the design and specifications. - Tooling

Develop molds and necessary equipment for both the primary part and the overmolding material. - Main Part Production

Manufacture the primary part, typically made of a rigid material like PP, ABS, PA, or PC, using the main tooling. - Overmolding

Inject the secondary material into a mold containing the primary part. The material envelops the primary part, forming a secure bond. - Cooling and Ejection

Allow the mold to cool, solidifying the overmold. Eject the mold and remove the finished part. - Finishing

Inspect the overmolded part, trim excess material, clean, and prepare it for subsequent processes.

Overmolding Material Bonding Chart

You can bond overmolded materials together, but you need to make sure the materials work together to get the bond strength you want. If you really need the bond, you should definitely add a mechanical bond. An undercut is a good example of a mechanical bond.

| Overmolding Material | PP T30S | ABS DG417 | ABS/PC AC2300 | PC Makrolon® 2405 | PBT HR5330 | PA J2700 |

| TPE | C | M | M | M | M | M |

| TPR | C | C | C | M | M | M |

| TPU | M | C | C | C | C | M |

| TPV | C | M | M | M | M | M |

| TPC | M | C | C | C | C | C |

Overmolding is great because:

- Better Chemical Resistance: Overmolding can be used to make the primary part more resistant to chemicals, so it doesn’t get all corroded and messed up.

- Added Functionality: Overmolding can be used to add new features or functionality to the primary part, thereby increasing its utility and value.

- Simplified Assembly: Overmolding can help you avoid assembly by combining multiple parts into one, which makes manufacturing easier.

- Better Performance: Overmolding can be used to make the primary part better by adding new materials or properties that make it work better.

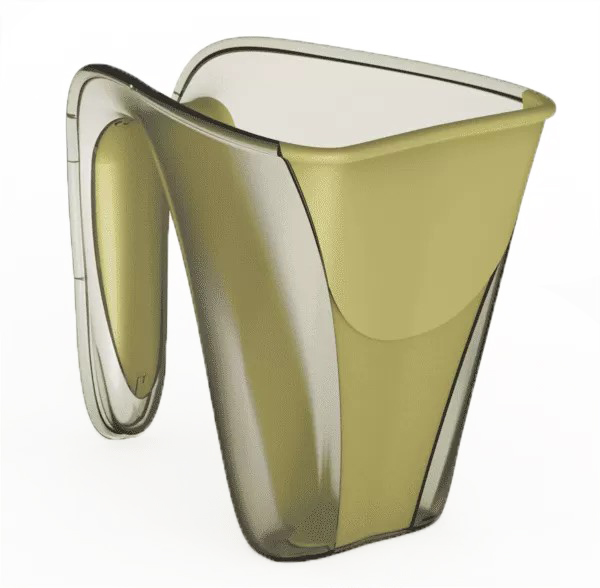

- Make it Look Good: Overmolding can make the main part look better. It makes it look nice.

- Lose Weight: Overmolding can help you lose weight. It makes your main part lighter, but still strong and tough. It makes it easier to carry and handle.

- Better Thermal Resistance: Overmolding can be used to make the primary part more resistant to heat, so it won’t get too hot or cold.

- Stronger and Tougher: Overmolding can make your part stronger and tougher, so it lasts longer and performs better.

- Better Electrical Insulation: Overmolding can be used to improve the electrical insulation of the main part, which helps protect it from electrical shock and damage.

- Better Looking: Overmolding can make the main part look better. It can be made to look more attractive.

What are the Applications of Overmolding?

Overmolding is a versatile manufacturing process that can be used to create complex parts with unique properties and functionality, making it applicable to a wide range of industries.

What are the Common Problems and Solutions for Overmolding?

The typical challenges in overmolding include incomplete filling of the overmold or substrate, flashing, and adhesion issues. Here’s how you can address these problems effectively.

| Observation | Potential Causes | Corrective Actions |

|---|---|---|

| Adhesion Problems | Incompatible materials or insufficient bonding area | Use compatible materials, increase bonding surface, optimize mold temperature. |

| Incomplete Filling | Low injection pressure or insufficient material flow | Increase injection pressure, adjust flow rate, or redesign mold gating. |

| Flashing | Excessive injection pressure or mold misalignment | Reduce injection pressure, inspect mold alignment, and repair damaged mold areas. |

| Surface Defects or Voids | Trapped air or uneven cooling | Add or optimize venting, adjust cooling time, and balance material temperature. |

| Shrinkage or Warping | Improper cooling or uneven material shrinkage | Ensure uniform cooling and use materials with low shrinkage rates. |

| Burn Marks or Discoloration | Overheating material or trapped gases | Lower injection temperature and improve mold venting to avoid gas buildup. |

| Inconsistent Overmolding | Variations in material flow or temperature | Standardize material preheating, monitor injection parameters, and maintain consistent cycle times. |

| Cracking or Brittle Parts | Material incompatibility or excessive stress | Choose compatible materials, reduce ejection force, and optimize mold design to minimize stress points. |

Resources for The Complete Guide to 2K Injection Molding

What is 2K Injection Molding?

2K injection molding, also known as 2K molding, is a manufacturing process where you inject two different materials or colors of plastic into a mold to make one part with unique properties and looks. This process is also known as “two-color injection molding” or “dual-color injection molding.”

In 2K injection molding, you usually inject the two materials at the same time, but separately, into the mold through two different gates. This is different from two-shot injection molding, where you inject the two materials one after the other.

How Does 2K Injection Molding Work?

2K injection molding, also known as two-shot injection molding, is a highly efficient manufacturing process that uses two different materials injected into the same mold during a single molding cycle. This innovative technique allows for the creation of complex parts that can combine multiple colors, textures, or material properties seamlessly in one piece. By eliminating the need for post-molding assembly, this process enhances production efficiency and reduces waste.

The entire process is carefully automated and controlled, ensuring consistent quality and precision. Automation also reduces labor requirements and minimizes the risk of human error, making it especially suitable for the high-volume production of intricate and functional components. From automotive and medical devices to consumer electronics, 2K injection molding is a versatile solution for producing sophisticated parts with superior performance and aesthetic appeal.

- 2K Injection Mold Design

A specialized mold is created with two cavities, one designated for each material or color. - Material Selection

The chosen materials should align with the desired aesthetics and functionality of the final product. Options may include plastics with varied colors, textures, or specific properties such as flexibility, durability, or transparency. - Material Preparation

Each material is prepped by heating it in separate hoppers or barrels to its optimal processing temperature, typically ranging between 150°C and 300°C (302°F to 572°F). - Injection

The molten materials are injected into the mold through distinct gates, with each material occupying its respective cavity. - Material Distribution

Initially, the first material partially fills the mold cavity. The mold then rotates (usually 180°), allowing the second material to fill the remaining cavity space, ensuring seamless integration between the two materials. - Cooling

The mold is cooled to solidify the materials, generally to a temperature between 20°C and 50°C (68°F to 122°F), forming a stable and bonded component. - Ejection

The mold opens, and the completed part is ejected. Excess material or flash is removed during post-processing, resulting in the final product.

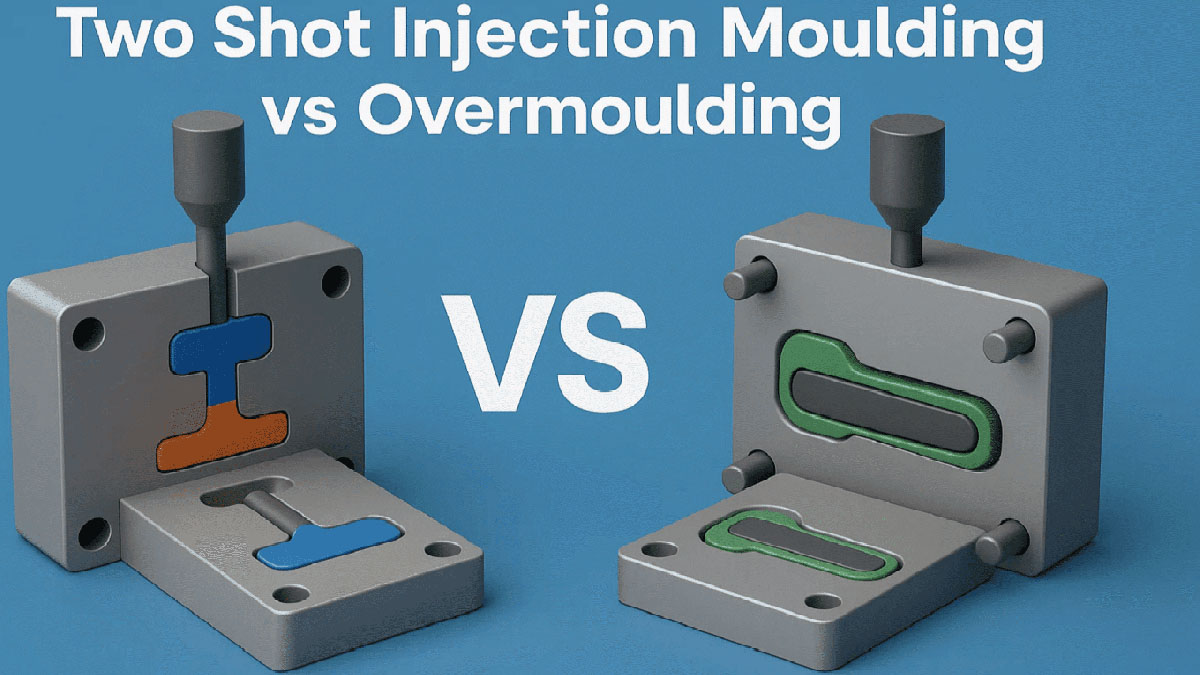

2K Injection Molding vs. Overmolding

2K injection molding and overmolding are two different manufacturing processes used to create complex plastic parts with multiple components. The choice between 2K injection molding and overmolding depends on the specific requirements of the part, including design complexity, material properties, and production volume.

| Specific Requirements | 2K Injection Molding | Overmolding |

| Design Complexity | ① Simple Geometries ② Limited design complexity | ① Complex Geometries ② Complex Designs |

| Production Volume | ① high-volume production | ① Medium and lower-volume production |

| Injection Machine | ① 2K injection molding machine ② Injection Machine Expensive | ① Single nozzle injection molding machine ② Injection Machine Cheap |

| Injection Process | ① Two materials are molded together in the same process | ① Two materials are molded separately |

What are the Benefits of 2K Injection Molding?

2K injection molding offers a bunch of benefits, including:

- Creative Aesthetics: Achieve eye-catching designs, unique color combinations, and intricate patterns that are unattainable with standard injection molding.

- Streamlined Assembly:By integrating materials during the production process, 2K molding removes the need for separate part assembly, saving labor costs and improving efficiency.

- Improved Part Quality: Parts benefit from increased strength, enhanced durability, and appealing aesthetics by combining two materials.

- Enhanced Functionality: Tailor materials to provide specific advantages, such as better grip, electrical conductivity, or superior thermal insulation.

- Greater Design Flexibility: Complex shapes and geometries become achievable, offering unparalleled design possibilities compared to traditional methods.

- Save money: By using a 2K mold, you can cut costs by not having to assemble separate parts and using less material.

- More complex designs: 2K molding allows you to create parts with intricate designs and shapes that would be tough to make with traditional molding.

- Better durability: The two materials can be made to be more durable and last longer.

What are the Applications of 2K Injection Molding?

2K injection molding has a wide range of applications across various industries like:

2K Injection Molding vs Overmolding: Which Is Better?

Here’s a price comparison of 2K Injection Molding and Overmolding for a specific project at quantities of 5,000, 10,000, 50,000, and 100,000 Pcs/Order.

Project Details:

① Mold Cavity: 1+1

② Product Weight: 58g and 18g

③Product Mateiral: PP M800E and TPE 60A

| Product Quantity/ PCS | Mold Cost/ $ | Part Price/ $ | Total Price/ $ | Average Part Cost/ $ | Mold Cost / $ | Part Price/ $ | Total Price/ $ | Average Part Cost/ $ | 2K Injection Molding Vs. Overmolding |

| 5000 | 18000 | 0.65 | 21250 | 4.25 | 12000 | 0.78 | 15900 | 3.18 | Overmolding |

| 10000 | 18000 | 0.63 | 24300 | 2.43 | 12000 | 0.76 | 19500 | 1.96 | Overmolding |

| 50000 | 18000 | 0.58 | 47000 | 0.94 | 12000 | 0.74 | 49000 | 0.98 | 2K Injection Molding |

| 100000 | 18000 | 0.54 | 72000 | 0.72 | 12000 | 0.72 | 84000 | 0.84 | 2K Injection Molding |