What is On-Demand Manufacturing?

Why Choose On-Demand Manufacturing?

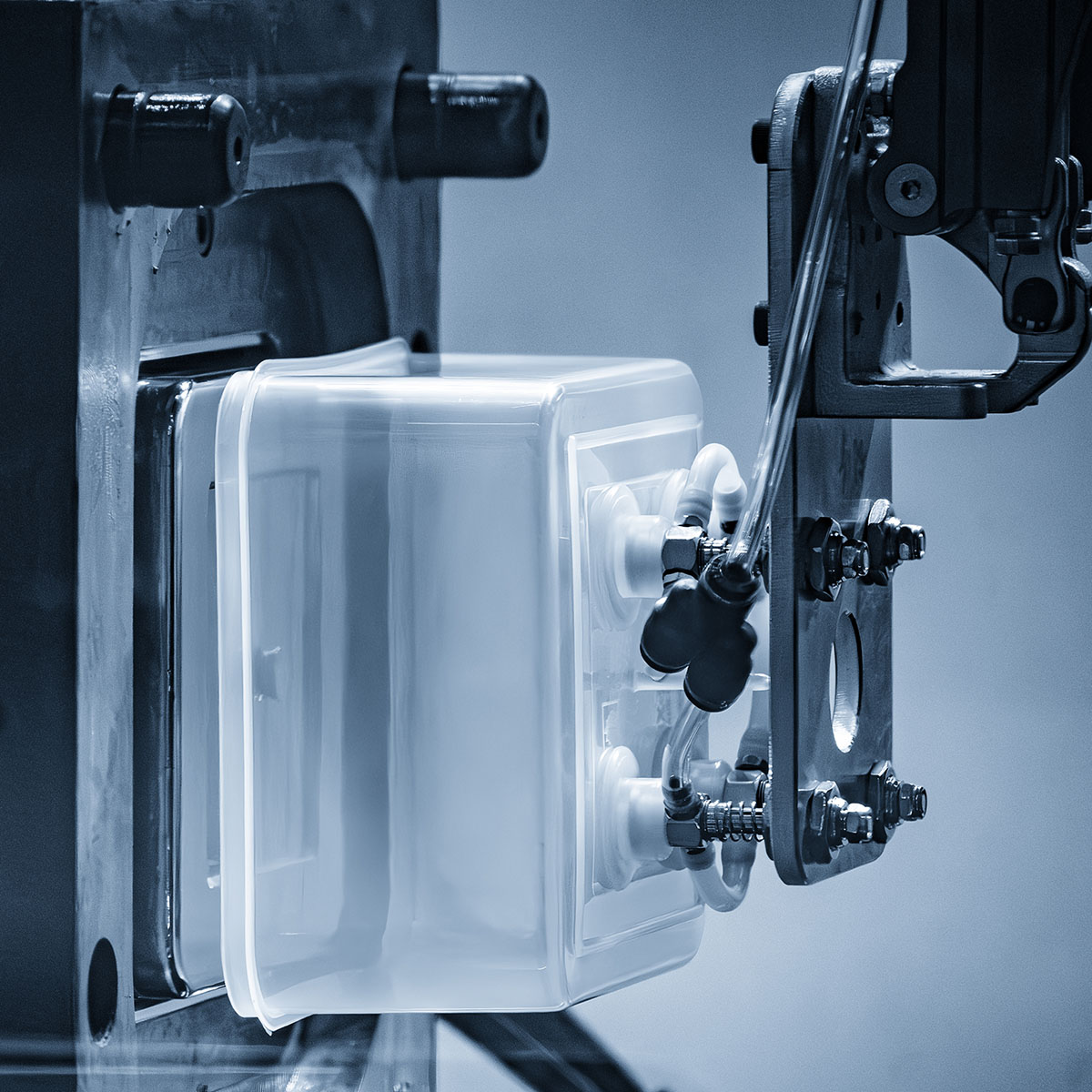

Plastic Injection Molding

Need custom plastic parts? Our injection molding gets the job done. We heat resin, inject it into precision molds under high pressure, and let it cool—turning out parts that are precise, consistent, and ready for use. Whether you need a small batch or 100,000+ units, it’s reliable for tight-tolerance work.

Key Capabilities and Standards:

| Specification | Detail |

|---|---|

| Mold cavity precision | ±0.05 mm |

| Dimensional repeatability | ±0.1 mm between parts |

| Typical lead time | Within 15 working days |

| Suitable production volume | From 1 to 100,000+ cycles |

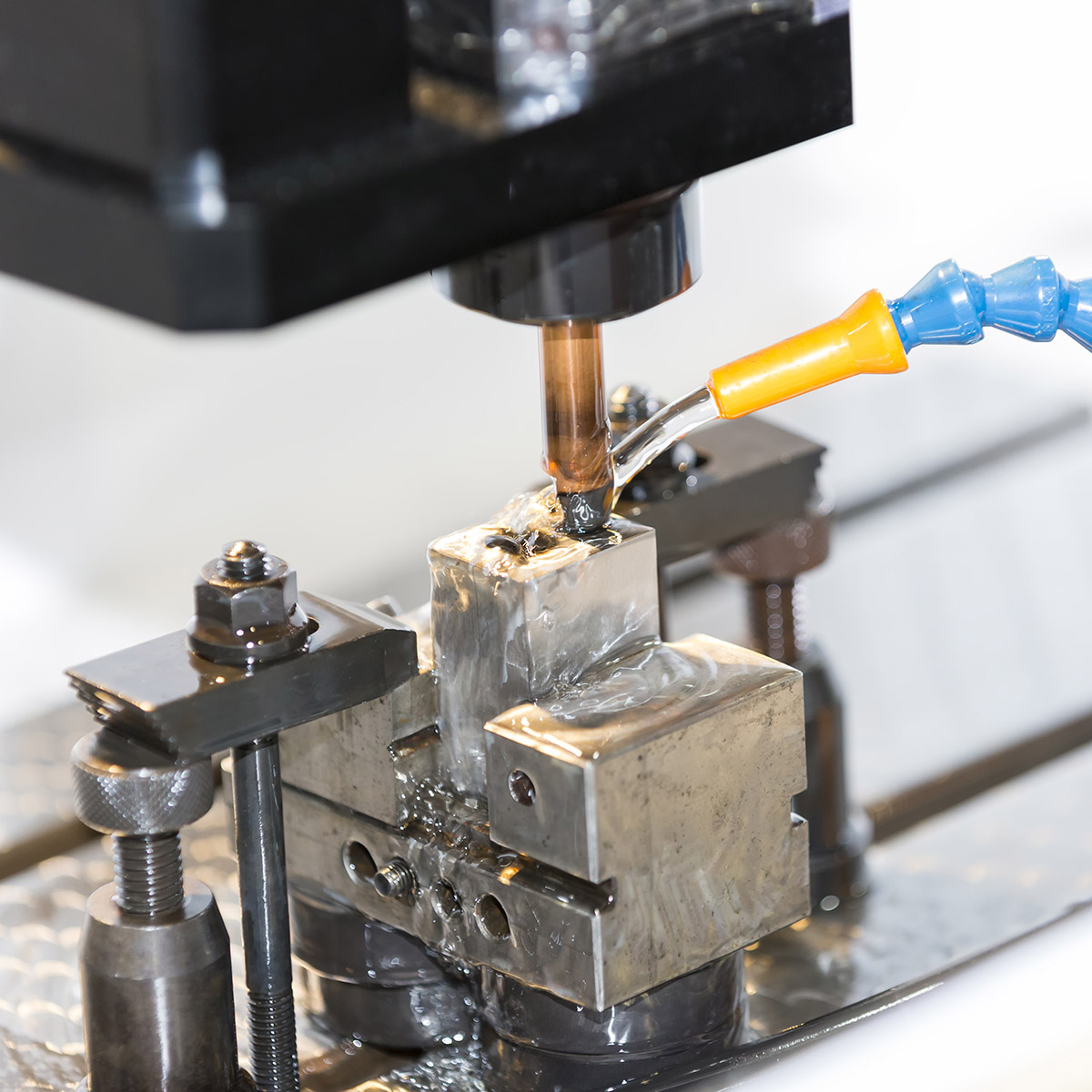

CNC Machining

Need custom parts with tight precision? Our CNC machining has you covered. We use computer-controlled tools to shape materials—whether you’re making small-batch prototypes or large production runs—so every part comes out consistent, accurate, and ready to use.

Capabilities and Tolerances:

| Specification | Standard Tolerance |

|---|---|

| Maximum part dimensions | 950 × 550 × 480 mm (37.0 × 21.5 × 18.5 in) |

| Tolerance – hole diameter (non-reamed) | ±0.025 mm (±0.001 in) |

| Tolerance – shaft diameter | ±0.025 mm (±0.001 in) |

| Tolerance – linear dimension | ±0.025 mm (±0.001 in) |

Sheet Metal Fabrication

Need strong, durable metal parts made from flat sheets? Our sheet metal fabrication gets it done. We take aluminum, steel, and other flat metals, then cut, bend, punch, and assemble them into finished components—sturdy, structurally solid, and built to last.

Tolerances and Dimensional Standards:

| Dimension Type | Tolerance |

|---|---|

| Hole-to-hole / edge-to-edge / edge-to-hole (same plane) | ±0.005 in |

| Bend to hole or edge (same surface) | ±0.010 in |

| Features across bends or multiple surfaces | ±0.030 in |

| Bend angle | ±1° |

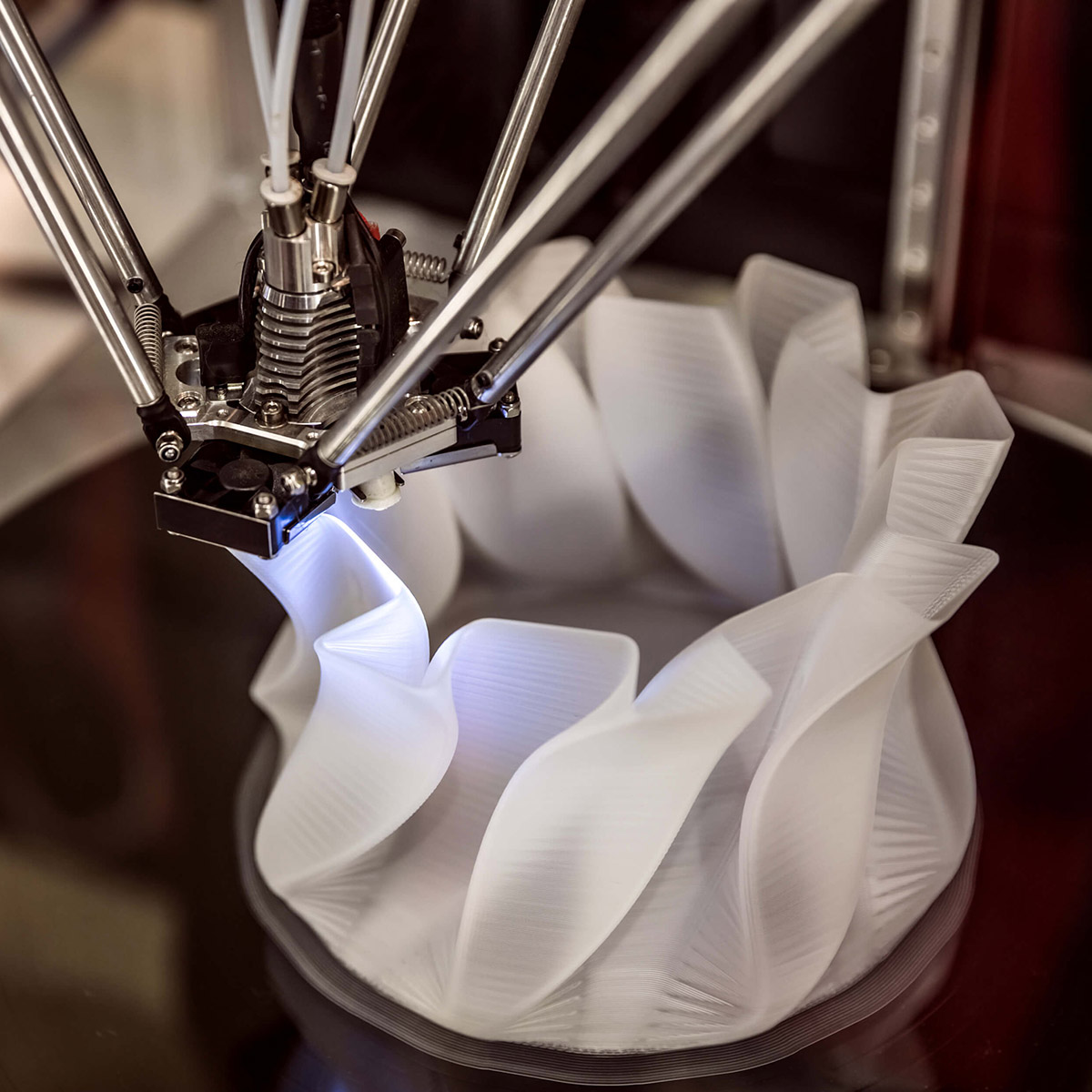

3D Printing

Need complex-shaped parts fast, without lots of tooling? Our 3D printing delivers. We build parts layer by layer from your CAD model—quick, with minimal setup, and perfect for tricky geometries that are hard to make with other methods.

General Capabilities and Specifications:

| Feature | Specification |

|---|---|

| Build volume limits | FDM: 900 × 600 × 900 mmSLA: up to 1500 × 750 × 500 mmSLS: 750 × 550 × 550 mm |

| Dimensional accuracy | ±0.1 mm |

| Wall thickness minimum | FDM: ±1.0 mmSLA: ±0.2 mmSLS: ±0.7 mm |

| Lead time | Typically within 7 business days for quantities up to 50 parts |

| Scalable production | Suitable for batches exceeding 50 parts |

Vacuum Casting

Need detailed, high-quality parts for small batches or prototypes? Our vacuum casting gets it done. We use vacuum pressure to pull resin into silicone molds, creating complex shapes with crisp details—no heavy tooling required, perfect for tight runs.

Key Capabilities and Specifications:

| Specification | Detail |

|---|---|

| Tolerance (dimensional) | ±0.05 mm |

| Build size (max range) | ±0.025 mm (±0.001 in) |

| Typical layer thickness | Between 1.5 mm and 2.5 mm |

| Turnaround time | Up to 20 parts delivered in 15 days or less |

Aluminum Extrusion

Need complex aluminum parts with consistent cross-sections? Our aluminum extrusion delivers. We push aluminum through shaped dies to form detailed profiles, then refine them to fit your needs—strong, uniform, and ready for use.

Capabilities and Details:

| Specification | Description |

|---|---|

| Post-processing options | Includes CNC cutting, threading, slotting, face milling, and more |

| Press capacity | Ranges from 450 tons to 3000 tons |

| Lead times | Approximately 2 weeks for smaller molds, 4 weeks for larger ones |

| Minimum order quantity | 0.5 tons for small machines, 1 ton of 6063 aluminum for larger machines |

Die Casting

Need detailed, accurate metal parts in large quantities? Die casting is a manufacturing technique where liquid metal is forced into steel molds using high pressure, allowing for the creation of detailed and accurate metal components. It’s especially suited for producing large quantities of parts with uniform quality.

Key Specifications and Capabilities:

| Specification | Detail |

|---|---|

| Dimensional accuracy | ±0.05 mm |

| Maximum part size | 300 mm × 650 mm |

| Typical layer thickness | 1.5 mm to 2.5 mm |

| Lead time | Up to 20 parts within 15 days |

Frequently Asked Questions

Yep, we handle both scenarios:

First, mixing processes across different parts. Like, say you need a CNC-machined metal base, plus injection-molded plastic covers, or sheet metal brackets paired with 3D-printed bits. We can make each part with the best method for it.

Second, using multiple processes on a single part. For example, components produced by vacuum casting need to undergo further CNC processing to achieve some complex features. Or the plastic components produced by 3D printing may require surface treatment; Or you might need to add your own unique logo, brand name, etc. to the components.

All of this happens in-house. No need to juggle multiple suppliers. Whether it’s different parts with different methods, or one part needing several steps, we make sure everything fits right and saves you coordination time.

It depends on what you need: your part’s job, the material it requires, how many you need, and when you need them. For example:

High-volume plastic parts? Injection molding works best.

Tight-tolerance metal parts? Go with CNC machining.

Quick prototypes? 3D printing is ideal.

Sturdy enclosures? Sheet metal fabrication fits.

Our engineers can look at your design and point you to the fastest, most cost-effective option for your goals.

Absolutely. We offer custom aluminum extrusion services using your profile or we can help design one from scratch. Custom dies can be created quickly, and we also offer post-processing like CNC, anodizing, and assembly.

We accept most CAD formats including STEP, IGES, STL, and DWG. If you’re unsure, our engineers at KingStar Mold can help convert or adjust files to ensure compatibility and manufacturability before production begins.