Why We Start Providing OEM Service

We launched our OEM service to meet the increasing demand for customized manufacturing solutions across various industries. As businesses seek cost-effective, high-quality production options, we aim to be the trusted partner that delivers tailored products with precision and flexibility, supporting clients from design through full-scale manufacturing.

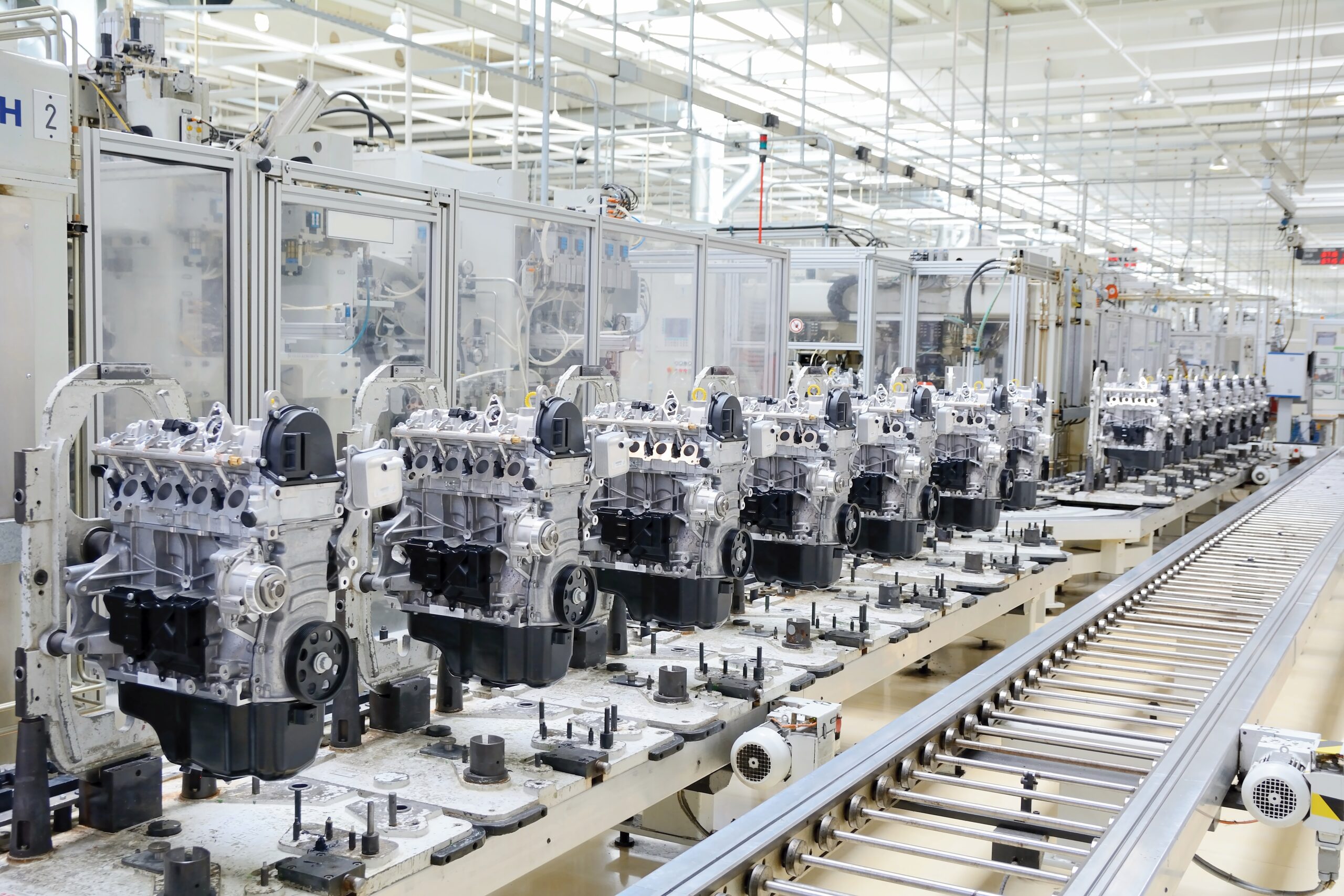

By leveraging our expertise in precision manufacturing, we help businesses achieve superior product quality and performance. With experience across sectors like automotive, furniture, and household goods, we can handle complex projects while streamlining the process, reducing time-to-market, and improving operational efficiency.

Our OEM service also strengthens customer relationships by offering flexible, adaptable support. We understand each business has unique needs, and our goal is to provide reliable, high-quality solutions that bring their product ideas to life while maintaining the integrity and standards KingStar Mold is known for.

Our ODM Product Solutions

Design and Customization

Tailored Product DevelopmentCollaborative design to meet client specifications.

Precision Manufacturing

High-Quality, Scalable ProductionEfficient, precise manufacturing for consistent results.

Quality Assurance and Delivery

Rigorous Testing and On-Time DeliveryComprehensive quality control and reliable delivery.

Appearance/Structure Design

Manufacturing Capability

What’s the Differences between ODM / OEM / Contract Manufacturing (CM)

Our OEM Product Innovation Design Process

1

Market Research and Trend Analysis

We begin by analyzing market trends and customer feedback to identify emerging demands and opportunities. This helps in aligning our design process with current market needs and future growth potential.

2

Concept Ideation and Brainstorming

Our team collaborates closely to generate creative product ideas based on research insights. We explore various possibilities to ensure the final design is innovative, practical, and aligned with customer expectations.

3

Preliminary Design and Prototyping

Using advanced CAD tools, we create preliminary design models for the product. These prototypes are tested to validate functionality and ensure the design meets performance and aesthetic goals.

4

Material Selection and Engineering Feasibility

We carefully select materials based on product requirements, considering factors like durability, cost, and manufacturability. This ensures that the chosen materials enhance both the product’s function and longevity.

5

Detailed Design Refinement

Our design team refines the product’s details, ensuring every component aligns perfectly with engineering specifications. This stage involves finalizing measurements, tolerances, and design aesthetics to ensure seamless production.

6

Testing, Validation, and Final Adjustments

We conduct rigorous testing to validate the product’s performance under real-world conditions. Any necessary adjustments are made based on test results, ensuring the product is both innovative and reliable before mass production.

Yes, we offer custom design services where we work with you to create a product that meets your exact specifications. This includes both aesthetic and functional aspects of the design.

Lead times vary depending on the complexity of the design and production volume, but typically range from a few weeks for simple products to several months for more complex or large-scale orders.

OEM products can be made from various materials, including plastics, metals, and composites. The choice of material depends on the product’s design, function, and industry requirements.

KingStar Mold provides precision manufacturing services to a wide range of industries, including automotive, furniture, household goods, solar panels, and baby products, ensuring tailored solutions for each sector.

At KingStar Mold, we implement stringent quality control measures at every stage of production. This includes rigorous testing, inspection, and the use of advanced manufacturing technologies to ensure that every product meets high standards.

OEM (Original Equipment Manufacturer) manufacturing involves producing products based on a company’s design and specifications. It allows businesses to outsource production while maintaining control over product quality and branding.

The cost of OEM manufacturing depends on factors like design complexity, material selection, production volume, and lead time. We provide detailed quotes based on your specific project requirements.

We use multiple quality control checks, including in-process inspections, automated testing, and final product inspections, to ensure every unit meets the required standards before delivery.

Yes, we offer small batch production for prototype testing or pilot runs. This allows you to evaluate the product’s design, functionality, and market acceptance before committing to larger quantities.

At KingStar Mold, we use flexible manufacturing systems that can scale to meet both small and large production volumes, ensuring consistent quality and timely delivery no matter the order size.

To begin, simply contact us with your product specifications and design ideas. We’ll guide you through the design, prototyping, and production phases to ensure your vision becomes a reality.

Our team of engineers at KingStar Mold will conduct a thorough analysis of your design, ensuring it’s feasible for manufacturing. We also provide feedback on any necessary adjustments to optimize the design for production.