Multi-Jet Printing (MJP) 3D Printing Service

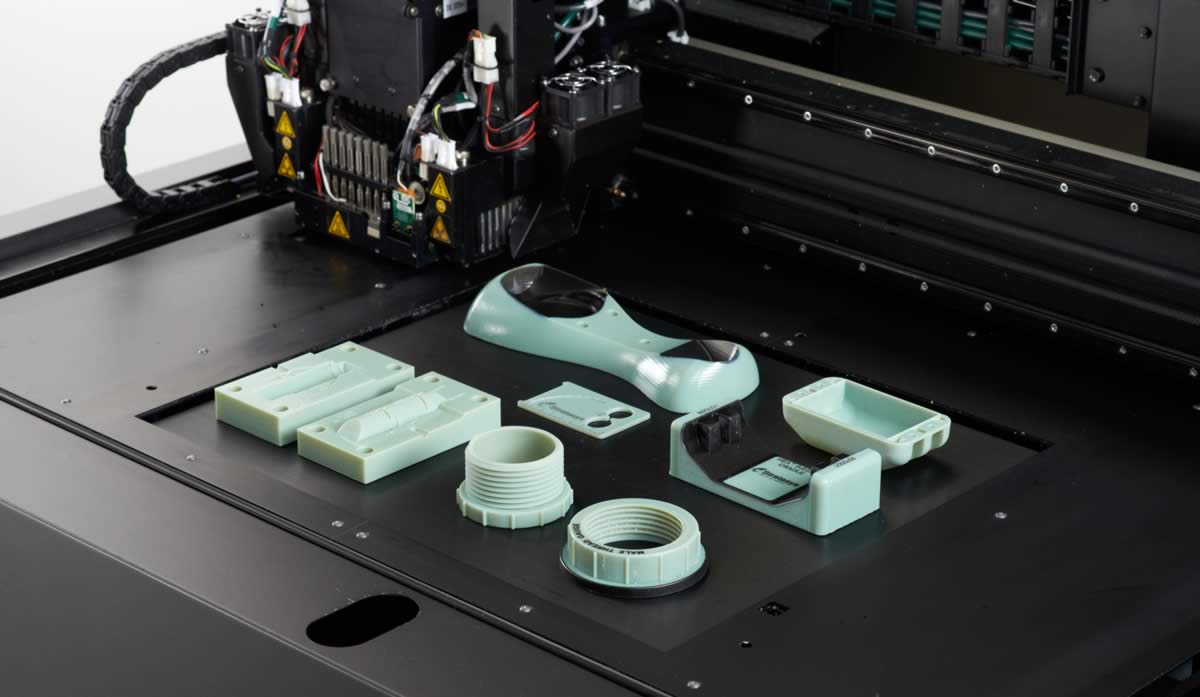

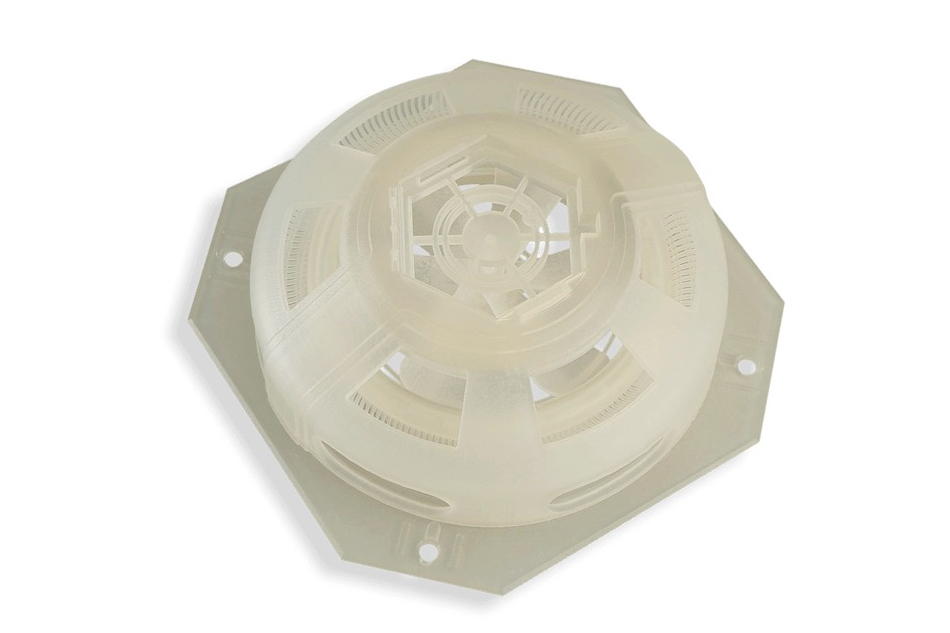

MultiJet Printing (MJP) turns your most intricate designs into high-precision reality—fast. This advanced 3D printing technology handles complex geometries and multi-material builds with ease, delivering prototypes and small-batch parts that look, feel, and function like the final product.

MJP 3D Printing Overview

MultiJet Printing (MJP) is a widely used 3D printing tech developed and patented by 3D Systems, marked by 16-micron Z-resolution, smooth surfaces, and unique single-build multi-material capability (rigid, flexible, colored resins).

Versus other methods, it outperforms single-resin SLA and single-material FDM in multi-material integration, with finer details and smoother surfaces than FDM—ideal for detailed prototypes.

Limitations: only uses photopolymers (narrower range than SLS’s nylons/composites), lower strength than SLS/metal prints, smaller build volumes, and higher costs for multi-material runs.

How Does MJP 3D Printing Work?

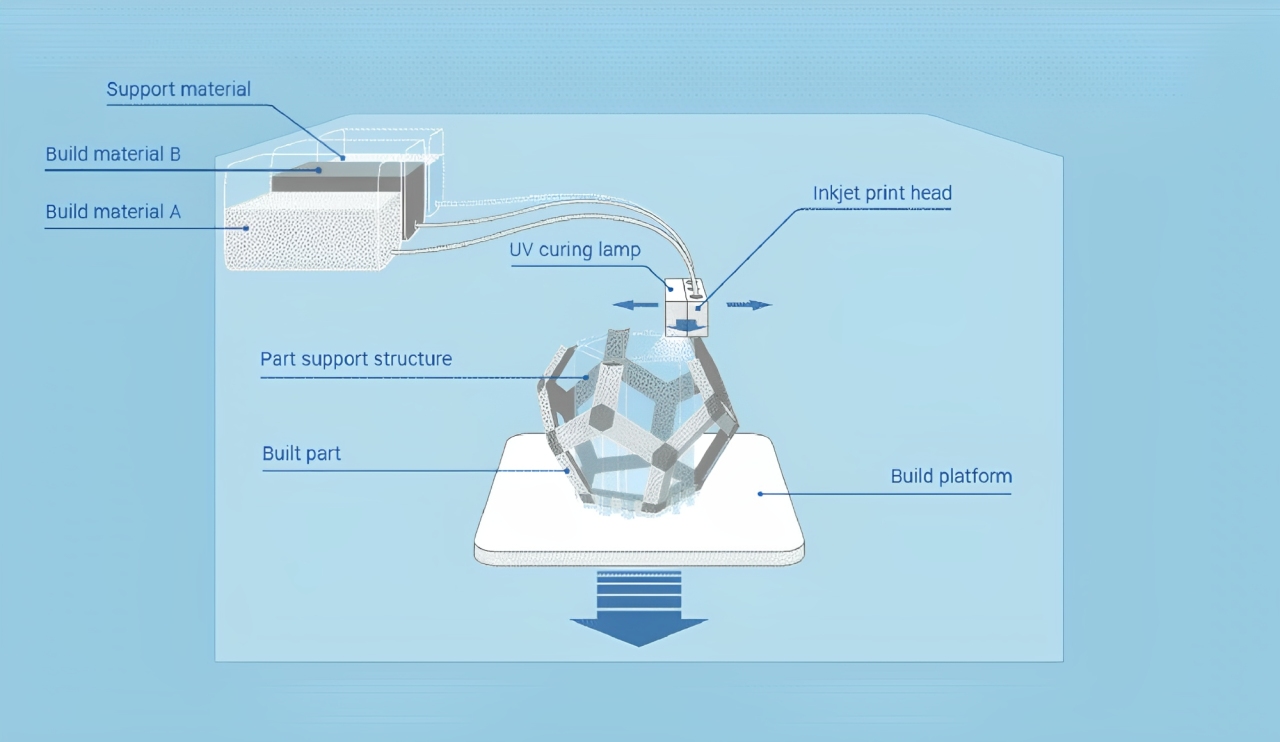

MJP 3D printing starts with prepping the CAD model: a 3D design is sliced into thin layers to create a digital blueprint. When jetting materials, the printer spreads small droplets of liquid photopolymer onto the build platform, while wax-based support material is added at the same time to hold up overhangs and complex sections. Each layer is cured right away with UV light to harden the material, slowly shaping the part as layers stack.

Once printing finishes, the part is left to cool, then gently taken off the platform—with leftover wax supports still on it. Next, it goes through support removal: either in a heated bath or oven, where the wax melts away, leaving a detailed part with a smooth finish. Finally, you can add optional post-processing steps like polishing, painting, or dyeing to boost its look and surface smoothness.

KingStar’s MJP 3D Printing Services

Our MJP 3D Printing Capabilities

| Specification | Details |

|---|---|

| Maximum Build Size | 294 x 211 x 144 mm (11.6″ x 8.3″ x 5.7″) |

| Lead Time | 2-3 business days for most projects |

| Resolution | ± 0.03 mm (0.0012″) for fine features |

| Layer Thickness | 16-32 µm (0.0006″-0.0012″) per layer |

| Surface Finish | Smooth, polished appearance with minimal post-processing |

| Material Options | Rigid plastics, elastomers, and wax-like materials |

| Prototyping Applications | High-detail concept models, intricate geometries, and visually aesthetic prototypes |

| End-Use Applications | Low-volume, functional parts, detailed assemblies, and precision components |

| Tolerances | ± 0.1-0.2% of part dimensions, depending on size |

MJP Material Options

VisiJet Pearlstone dental material is crafted to produce precise, cost-effective dental models that closely resemble dental stone. Compatible with intraoral, impression, and plaster scanners, it’s perfect for creating models for crowns, bridges, orthodontic devices, implants, and partial dentures.

VisiJet® M3 Black is a standout material in the MJP family of professional printers, offering the look and feel of injection-molded plastic. Its black, durable finish makes it ideal for rigorous testing and functional use. This material is particularly suited for applications requiring snap-fit capabilities and enhanced strength.

VisiJet Procast Plastic Material offers the industry’s best direct micro-casting performance, making it ideal for applications such as small and delicate medical instruments, devices, and other custom metal casting applications.

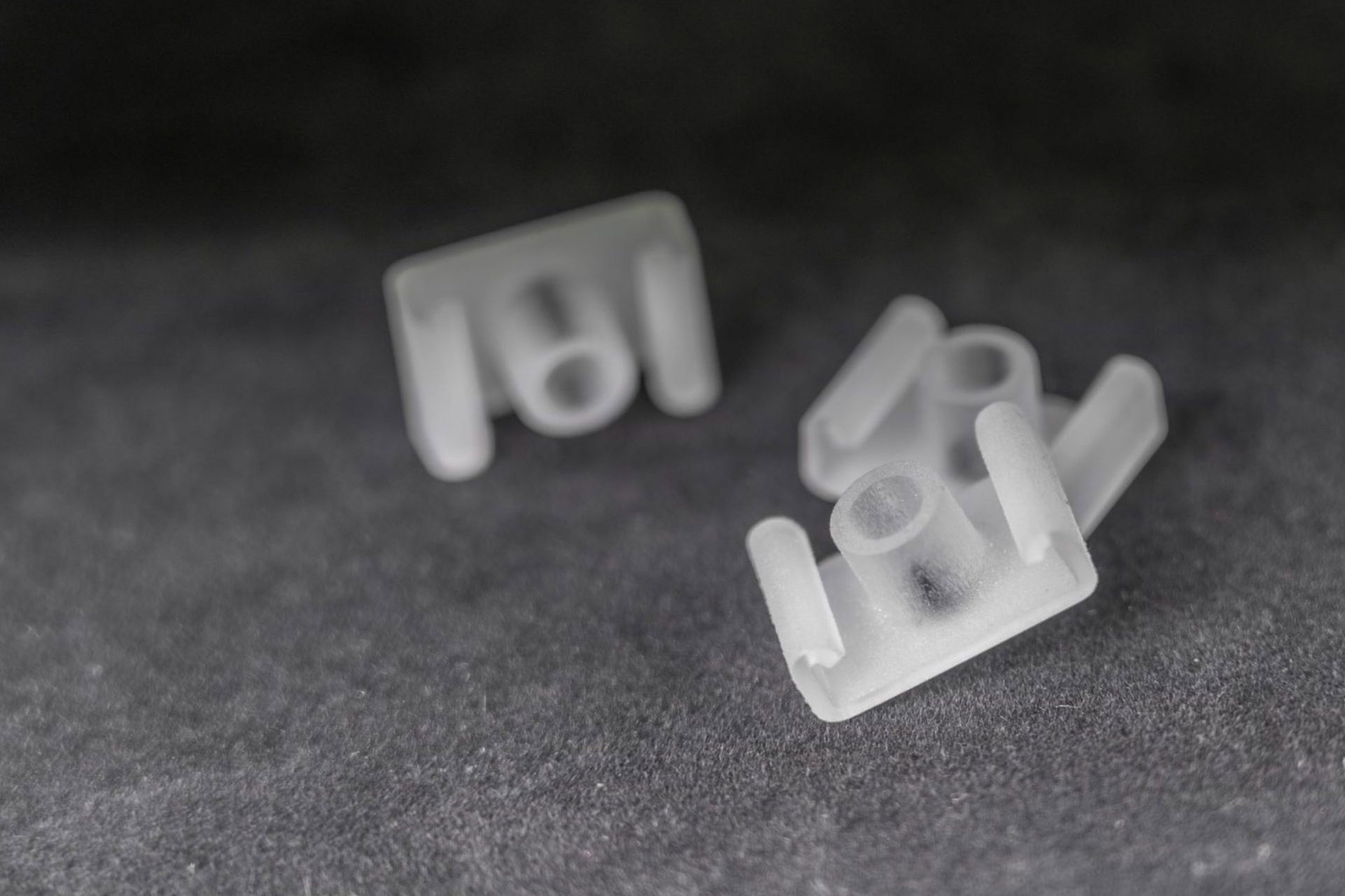

VisiJet Crystal is a high-performance engineered plastic built for toughness and consistent stability—traits that make it a go-to for functional testing and quick-turn tooling work. What sets it apart is its authentic plastic-like look and feel, which translates seamlessly to both prototyping needs and end-use parts across diverse applications. Notably, it holds USP Class VI certification, opening the door to use in select medical contexts where material safety is non-negotiable.

View Datasheet

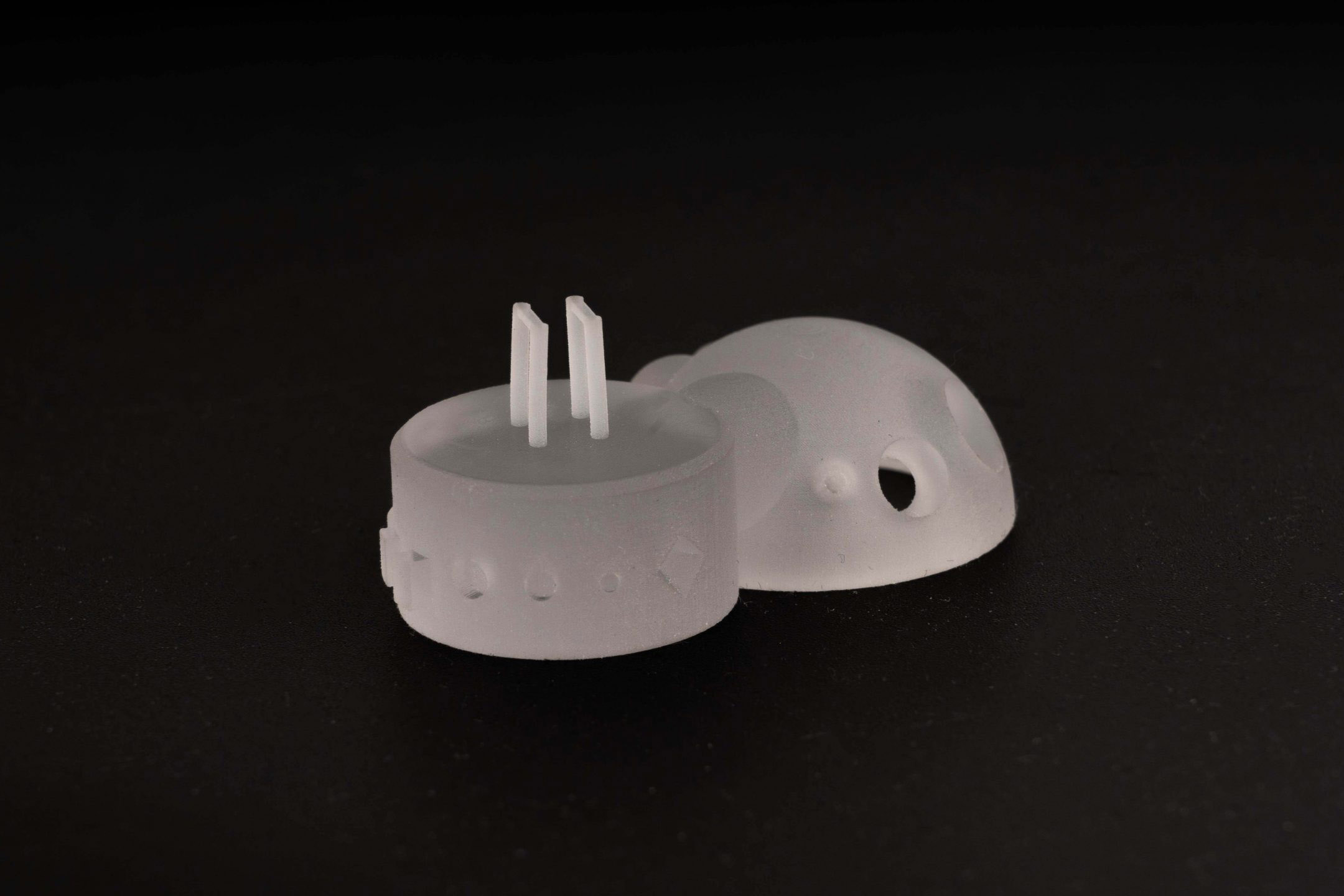

VisiJet Techplast Plastic Material (gray) offers an economical solution for general modeling needs. It is also commonly used for sacrificial patterns in various direct casting applications, providing versatility and cost-effectiveness.

Offers the look, feel, and performance of injection-molded ABS plastic, making it ideal for prototyping and product mockups. Suitable for end-use applications demanding exceptional toughness and high-temperature resistance, with a sleek, stunning white finish.

VisiJet Hi-Cast shines when it comes to high-end lost-wax casting, thanks to its standout sharp resolution—perfect for crafting fine-detail items like jewelry, tiny medical devices, and intricate electrical components. It’s designed to work only with ProJet CPX 3500 3D printers, and in terms of feature clarity, accuracy, and precision, it’s set the bar for what’s possible in this space.

VisiJet Proplast Plastic Material (white/natural) offers an economical solution for general modeling needs. It is also commonly used for sacrificial patterns in various direct casting applications, providing a cost-effective and versatile option.

VisiJet Prowax Material provides 100% RealWax patterns for lost-wax casting in mid-sized and large foundry applications across various industries. These RealWax patterns can seamlessly replace traditional casting waxes in standard casting processes without the need for special modifications.

MJP Surface Finishing Options

| Finishing Method | Applicable Materials | Color | Description |

|---|---|---|---|

| As Printed | – | Transparent | MJP parts are often left as printed, as they naturally have an aesthetic, smooth finish. |

| Painting | All | Black, Pantone/RAL colors | Enhances aesthetics by adding color with a smooth, even coat. Ideal for visual prototypes. |

| Dyeing | All | Black, Pantone/RAL colors | A fast, cost-effective method to color MJP parts, primarily for aesthetic improvement. |

| Polishing | All | N/A | Refines surface texture, reducing layer lines for a smoother, shinier finish. |

| Spray Painting | All | Custom colors | Adds a uniform, glossy finish with custom color options, improving visual appeal. |

| Vapour Smoothing | Select plastics | N/A | Chemical process that smooths surfaces, enhancing gloss and reducing layer lines. |

Why Choose MJP 3D Printing?

Typical Applications for MJP 3D Printing

Medical & Healthcare

Automotive

Consumer Electronics

Aerospace & Defense

Dental

Industrial Design & Product Development

Comparison between Different 3D Printing Services

| Feature | SLA | SLS | DMLS | MJP | FDM | SLM | MJF |

|---|---|---|---|---|---|---|---|

| Range of Material Options | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ |

| Geometry Complexity | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Batch Discount | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐⭐ |

| Scalability | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐⭐ |

| Precision Tolerance | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| Fine Details | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| Large Parts | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ |

Frequently Asked Questions

No, MJP 3D printing is mostly built to work with plastic, elastomeric, and composite materials—while it can make high-precision parts for fields like automotive, aerospace, and healthcare, it isn’t set up for metal part production. If you need metal 3D printing, you’d turn to technologies like DMLS or SLM, since these are specifically designed to handle metal powders and create the high strength needed for industrial uses.

The MJP 3D printing technology is renowned for its high precision and fine details – often surpassing technologies such as FDM or SLA in terms of surface smoothness and dimensional accuracy. Its jetting process combined with precise ultraviolet curing ensures that the components have extremely high resolution, making it highly suitable for industries such as aerospace and medicine that require precise tolerances and complex shapes. However, for larger components, its accuracy is not as good as that of DMLS or SLM technologies – and these two are more suitable for metal applications that require extremely high precision.