MJF 3D Printing: What Is It & How Does It Work?

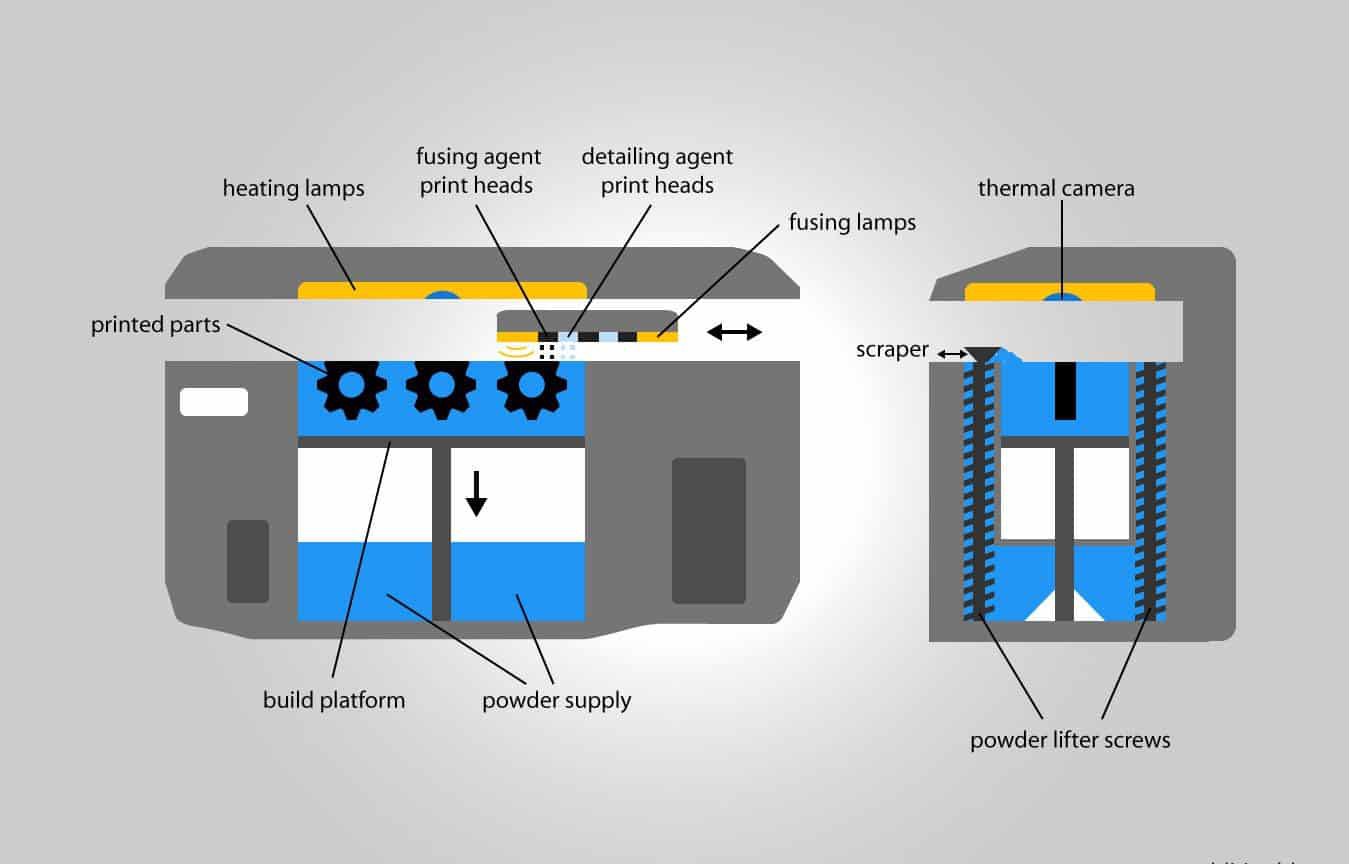

MJF (Multi Jet Fusion) 3D printing is an advanced additive manufacturing process developed by HP, which still holds patents for the technology. It creates parts by selectively fusing powdered material—typically nylon or similar polymers—using chemical agents and heat.

The process begins with a thin, even layer of powder spread across the build platform. Specialized printheads then deposit a fusing agent on areas meant to solidify, plus a detailing agent along edges to sharpen boundaries and boost precision. Next, a powerful infrared heating element passes over the layer: treated areas fuse into solid material, while untreated powder stays loose. This layering cycle repeats—new powder spread, selectively fused—until the part is fully built.

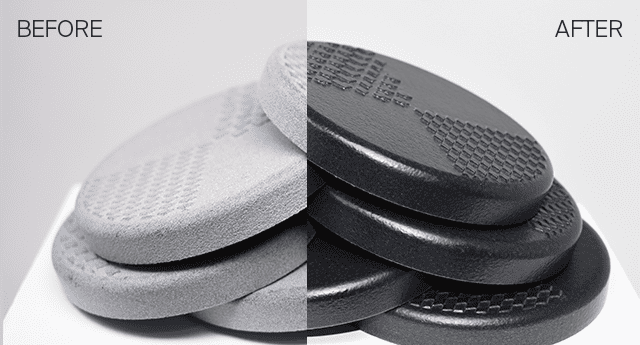

Known for high precision and efficiency, MJF produces complex geometries with consistent strength. After printing, parts are extracted from loose powder and may undergo post-processing (cleaning, dyeing, smoothing, coating) to enhance appearance and performance.

Our MJF 3D Printing Services

MJF Capabilities & Design Guidelines

| Design Parameter | US | Metric |

|---|---|---|

| Maximum Part Size | 11.1 x 14.9 x 14.9 in | 284 x 380 x 380 mm |

| Layer Thickness | 0.00315 in | 80 microns |

| Minimum Feature Size | 0.020 in | 0.5 mm |

| Wall Thickness | 0.020 in | 0.5 mm |

| Resolution | ± 0.012 in | ±0.3 mm |

| Dimensional Accuracy | ±0.3% (min. ±0.012”) | ±0.3% (min. ±0.3 mm) |

| Tolerance | ± 0.012 in + 0.1% per inch | ± 0.30 mm + 0.1% per 25.4 mm |

| Warpage Susceptibility | Parts >7 in prone to warping | Use ≥ 0.125 in thickness |

| Clearance for Assemblies | 0.006 - 0.010 in | 0.15 - 0.25 mm |

| Hole Diameter | ≥ 0.04 in | ≥ 1 mm |

| Embossed Features | ≥ 0.02 in height | ≥ 0.5 mm height |

| Engraved Features | ≥ 0.04 in depth & width | ≥ 1 mm depth & width |

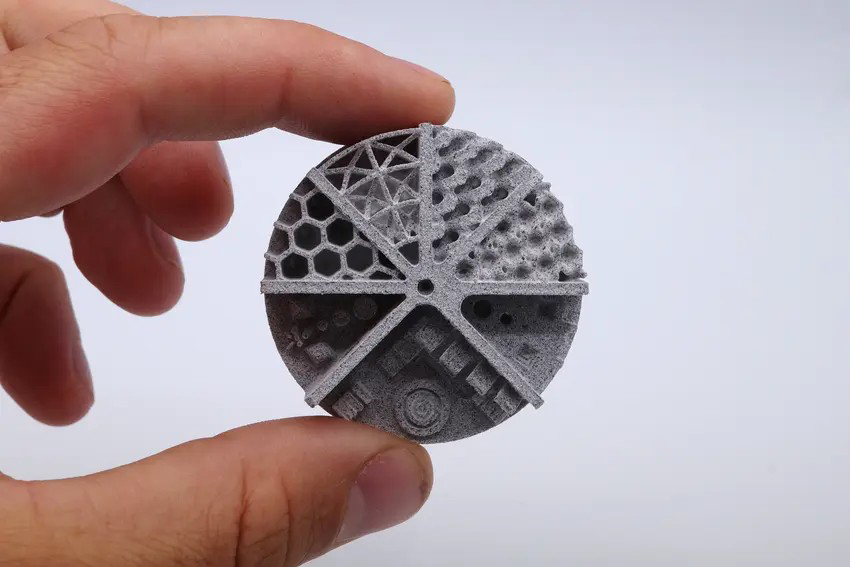

| Lattice Structure Gap Size | ≥ 0.04 in | ≥ 1 mm |

MJF Material Options

PA 12 is a high-tensile strength nylon known for its durability and smooth surface finish. The final parts are dyed black and offer slightly more isotropic mechanical properties compared to SLS materials. With a smaller minimum feature resolution of 0.02 in (versus 0.03 in for SLS), PA 12 Black is ideal for detailed designs and is the preferred choice for living hinges due to its flexibility and strength.

Key Benefits:

- Near-isotropic mechanical properties for consistent performance

- Cost-effective material with high tensile strength

- Excellent for living hinges and fine-feature designs

PA 12 40% Glass-Filled is a nylon blend that adds 40% glass fibers to boost stiffness and heat resistance. Parts come dyed black, and it holds up to high temps really well—its heat deflection reaches 347°F (at 66 psi), making it the second-most heat-resistant MJF material (only behind PA 12 Mineral-Filled). It’s perfect for parts that need to be strong, stable, and handle warm conditions.

Key Benefits:

- Economical choice for strong, long-lasting parts

- Solid heat deflection for high-temperature uses

- More stiffness and better dimensional stability

PA 11 is a bio-based nylon made from castor oil—so it’s renewable, and it brings tough, flexible performance. It handles cold really well too: even at -40°C (-40°F), it still resists impact. It doesn’t absorb much water, so parts stay dimensionally stable in humid environments, and it stands up to oils and greases. With MJF, it delivers consistent strength across all axes, and it works with post-processing like dyeing or sanding—great for flexible parts like medical components or outdoor gear.

Key Benefits:

PP (Polypropylene) is a lightweight, budget-friendly thermoplastic that pairs well with MJF. It resists chemicals, doesn’t absorb much moisture, and balances rigidity with a little give—so it works in all kinds of settings, from general industrial use to consumer goods. MJF’s powder bed process makes consistent parts, and you can trim or polish them for a nicer finish. It’s ideal for non-load-bearing parts—think housings, containers, or light industrial fittings.

Key Benefits:

TPU 88A is a flexible elastic material that feels like rubber—great for absorbing impacts, and perfect for MJF-printed parts that need to be soft or deformable. It stretches well, stays flexible across moderate temperature ranges, and holds up to oils and greases. You can trim it easily post-print, so it’s a go-to for parts that need elasticity: gaskets, seals, soft grips, and other shock-absorbing pieces.

Key Benefits:

| Material | Tensile Strength | Elongation at Break | Tensile Modulus |

|---|---|---|---|

| PA 12 Black | 48 MPa/6960 psi at XY & Z | 20% at XY; 15% at Z | 1700 MPa/247 ksi at XY; 1800 MPa/261 ksi at Z |

| PA 12 40% Glass-Filled Black | 30 MPa/4351 psi | 10% | 2500 MPa/363 ksi at XY, XZ, YX, YZ; 2700 MPa/392 ksi at ZX, XY |

| PA 11 | 52 MPa/7542 psi | 55% at XY, XZ, YX, YZ; 40% at ZX, ZY | 1800 MPa/261 ksi |

| PP | 25-30 MPa/3626-4351 psi | 15-20% at XY; 10-14% at Z | 1300-1500 MPa/189-218 ksi |

| TPU 88A | 7-9 MPa/1015-1305 psi | 120-220% | 75-85 MPa/10.9-12.3 ksi |

These figures are approximate and influenced by various factors, such as machine settings and process parameters. As a result, the information provided is not binding or certified. For critical performance requirements, independent lab testing of additive materials or final parts is recommended.

MJF Post-processing Options

| Surface Finishing | Description |

|---|---|

| Sanding (Standard) | Bead blasting removes all excess powder, leaving a uniform texture. |

| Vapor Smoothing | Reduces surface roughness from 250+ μin RA (as-printed) to 64 – 100 μin RA. Applicable for all MJF printed materials. |

| Dyeing | A main way to color MJF parts (usually black). |

| Custom Finishing | Includes secondary options such as priming, tapping, and inserts for enhanced part functionality. |

Other post-processing services we provide are:

Why Choose MJF 3D Printing?

Typical Applications for MJP 3D Printing

Prototyping and Product Development

Functional Prototypes: Examples include mechanical test parts, housings, and brackets designed for product validation.

Rapid Prototypes: Concept models, form and fit prototypes, or parts to visualize design ideas quickly.

Design Iteration Parts: Parts used for multiple iterations in the product development process, such as prototypes for ergonomic testing.

Bridge and Short-Run Production

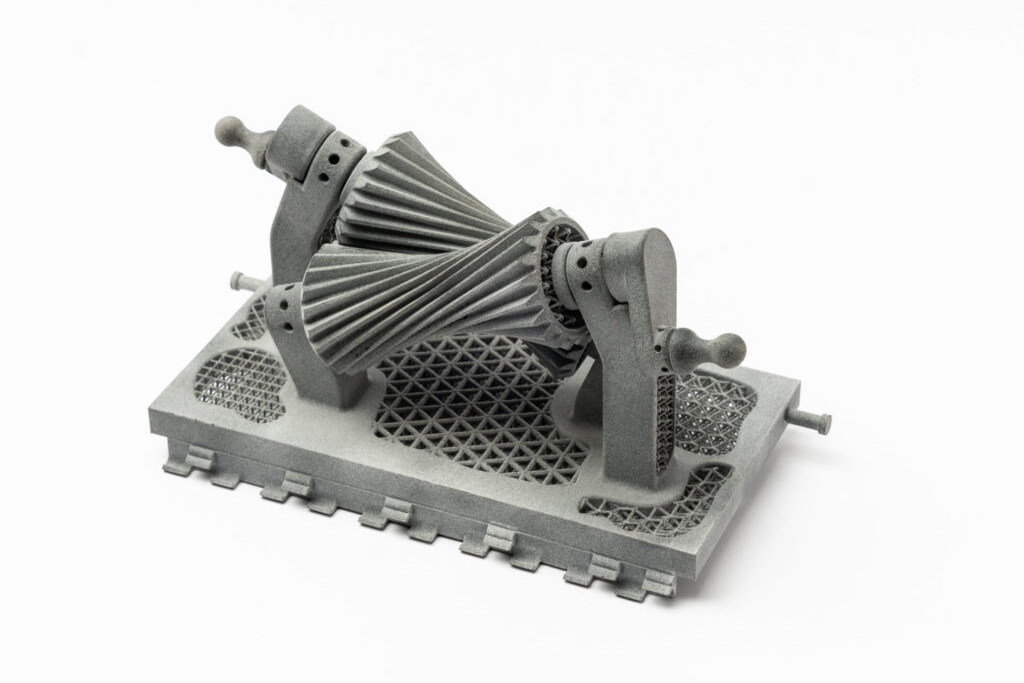

Small-Batch Production Parts: Low-volume production of custom gears, tools, or brackets for limited runs.

End-use Test Parts: Components produced for market testing or low-volume product introductions, such as custom enclosures or functional snap-fit parts.

Replacement Parts: Parts produced on-demand for replacement in ongoing production, such as machine components or tooling parts.

Durable End-Use Parts

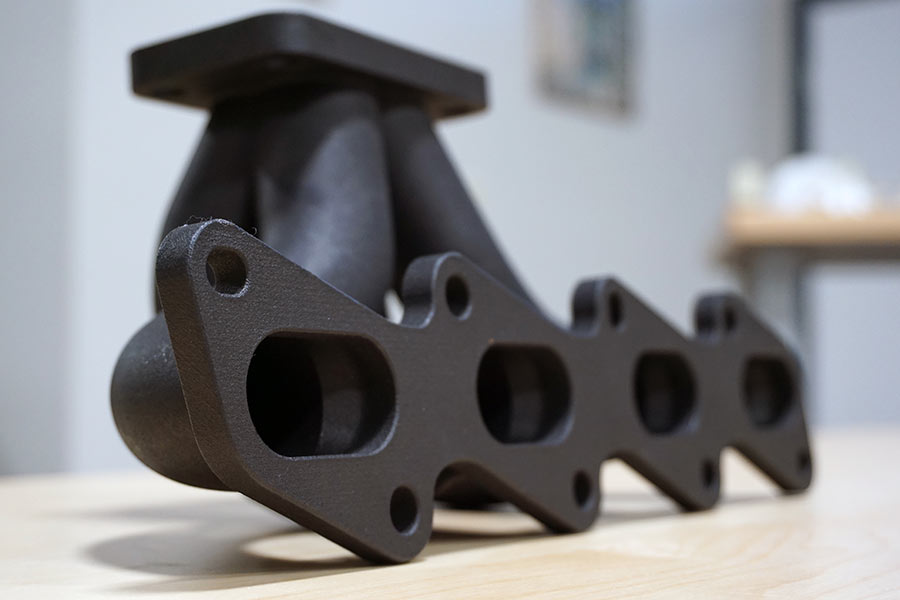

Automotive Components: Custom connectors, housings, or brackets that are used in functional automotive parts like interior components or engine enclosures.

Medical Devices: Surgical guides, anatomical models, or functional prototypes for implants and dental appliances.

Consumer Goods: Custom housings for electronics, wearables, or accessories that require both functionality and durability.

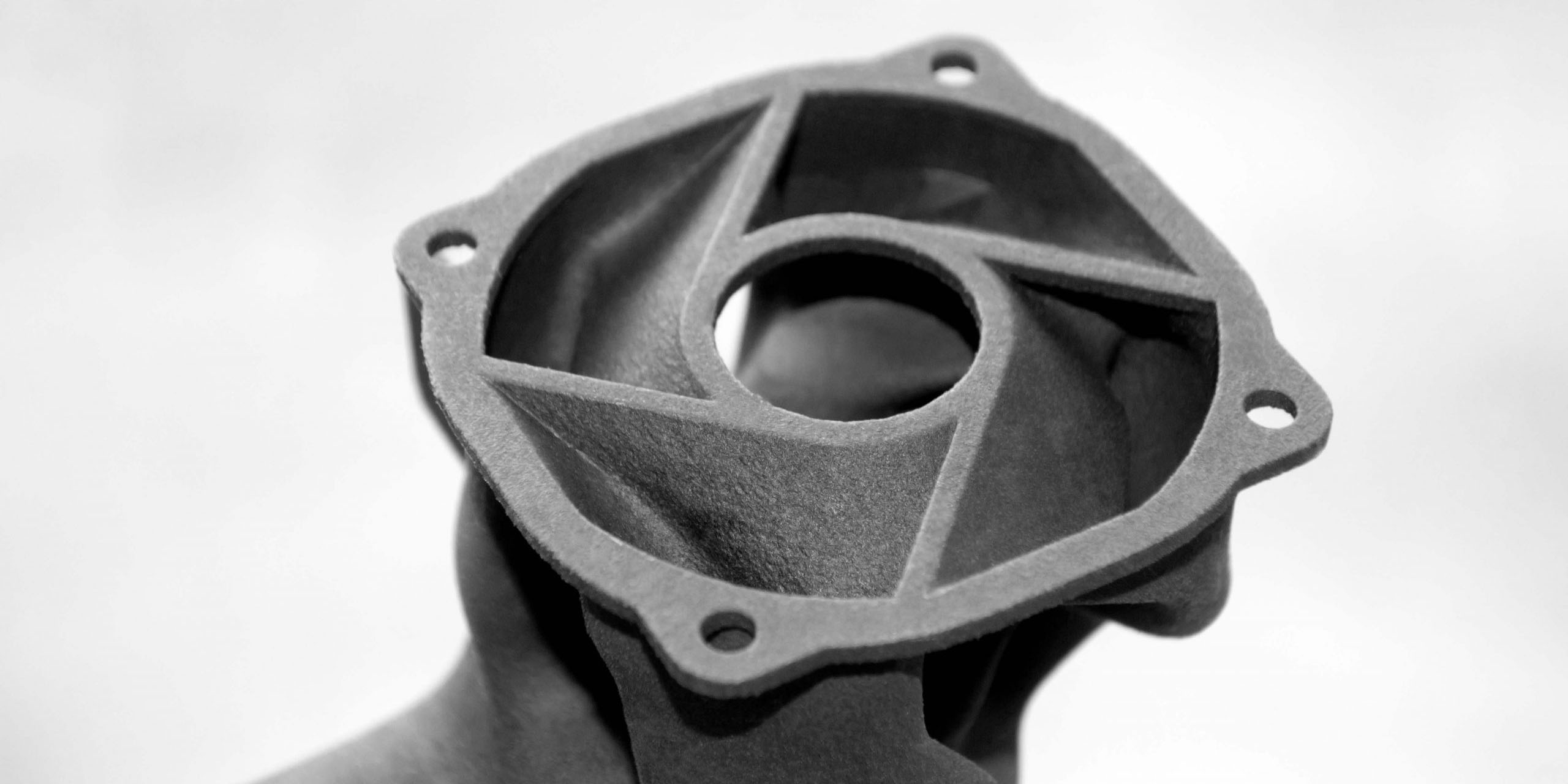

Complex Geometries and Fine Details

Organic Geometries: Medical models or prosthetics designed with intricate, organic shapes like complex bone structures or custom orthodontic devices.

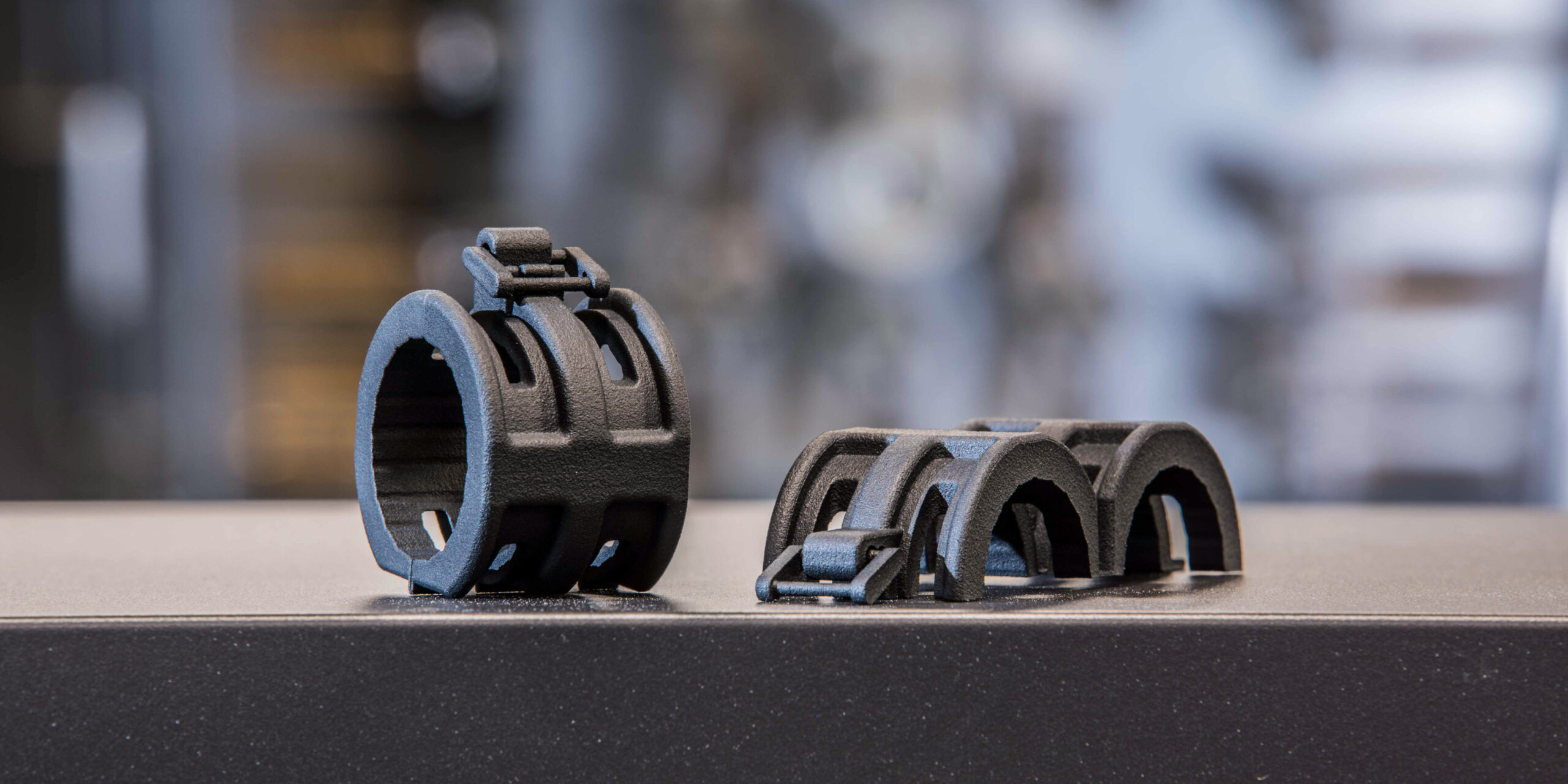

Parts with Fine Features: Small components with fine features, such as clips, brackets, or detailed electronics enclosures, requiring high resolution and surface finish.

Thin-Walled Parts: Lightweight structures for applications like drone parts, small housings, or intricate components where weight and strength are critical.

Case Studies

Frequently Asked Questions

MJF 3D printing is used across key industries for functional parts: it makes robotics joints, industrial brackets, medical surgical tools and swabs, consumer electronics casings, and automotive interior trim—all leveraging its speed, precision, and durable polymer performance.

No, MJF doesn’t need support structures. Its powder bed acts as a natural support for complex geometries—like undercuts, lattices, or hollow parts—so you can print intricate designs directly without extra material or post-processing to remove supports.

It depends on the material and post-processing. Unfinished MJF nylon (PA11/PA12) parts have slight water absorption (around 1-2% for PA12), which can affect dimensions over time. For water-resistant needs, add post-processing like vapor smoothing (seals surface pores) or a hydrophobic coating—making parts suitable for applications like outdoor gear components or mild water-exposed industrial parts.