Cooperative Partners

Customizable Medical Manufacturing Expertise

10+ Years of Medical Manufacturing Experience

Certified Material Selection & Traceability

Fast Turnaround for Custom Orders

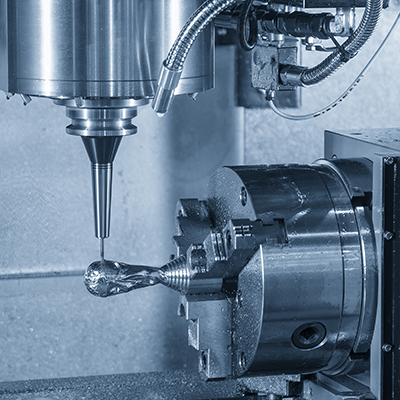

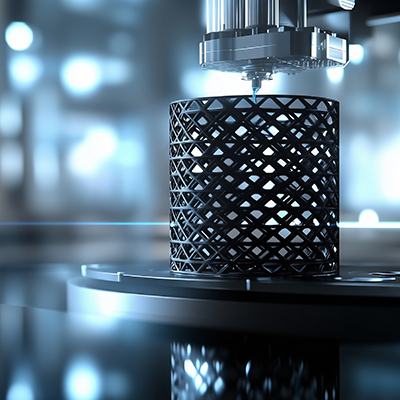

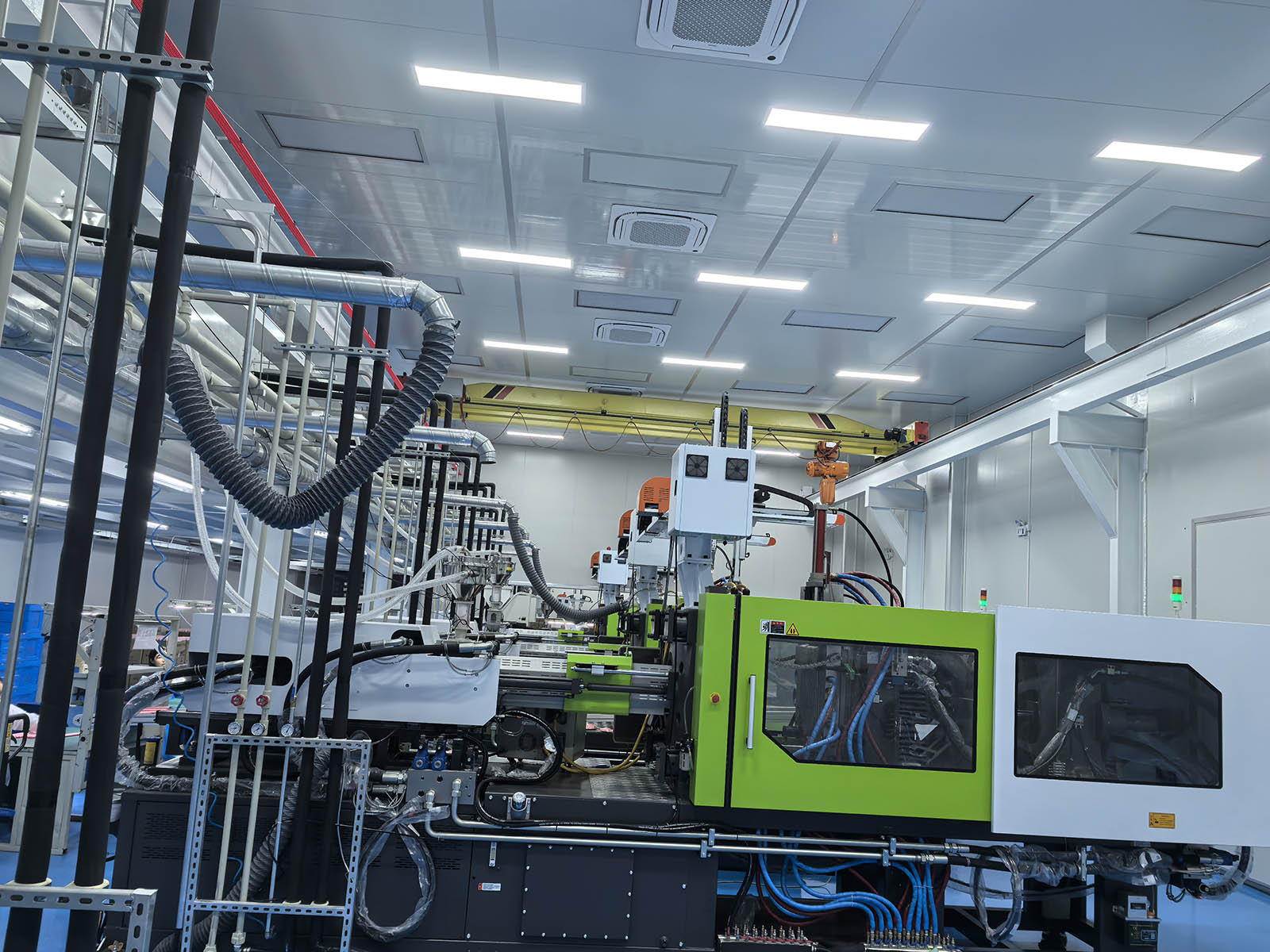

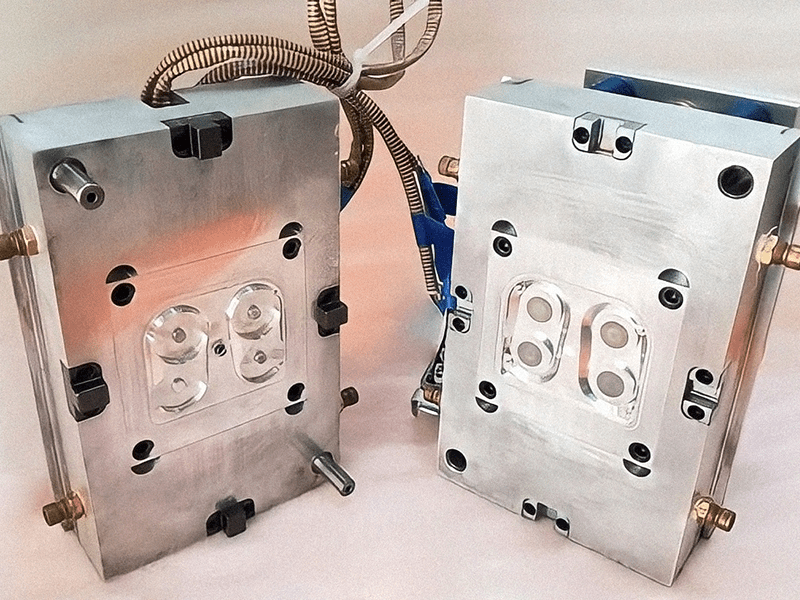

At KingStar Mold, our team of skilled professionals specializes in a wide range of services, including product design, mold design, injection molding, CNC machining, 3D printing and other advanced manufacturing processes. We provide a comprehensive one-stop solution for all your medical and pharmaceutical mold requirements.

We offer a variety of custom components for the medical & pharmaceutical industries, including:

KingStar Mold is a trusted manufacturer of medical and pharmaceutical products, specializing in using injection molding technology to create customized, high-precision molds. We offer a comprehensive solution for a wide range of medical device components, pharmaceutical packaging, and other critical applications.

How Do Medical Companies Cooperate with Us?

85%+

Fortune 500 Medical Companies Served

500 Million

Parts Manufactured

100,000+

Customers Served Globally

30+

Countries Served Worldwide

What We Can Make for You

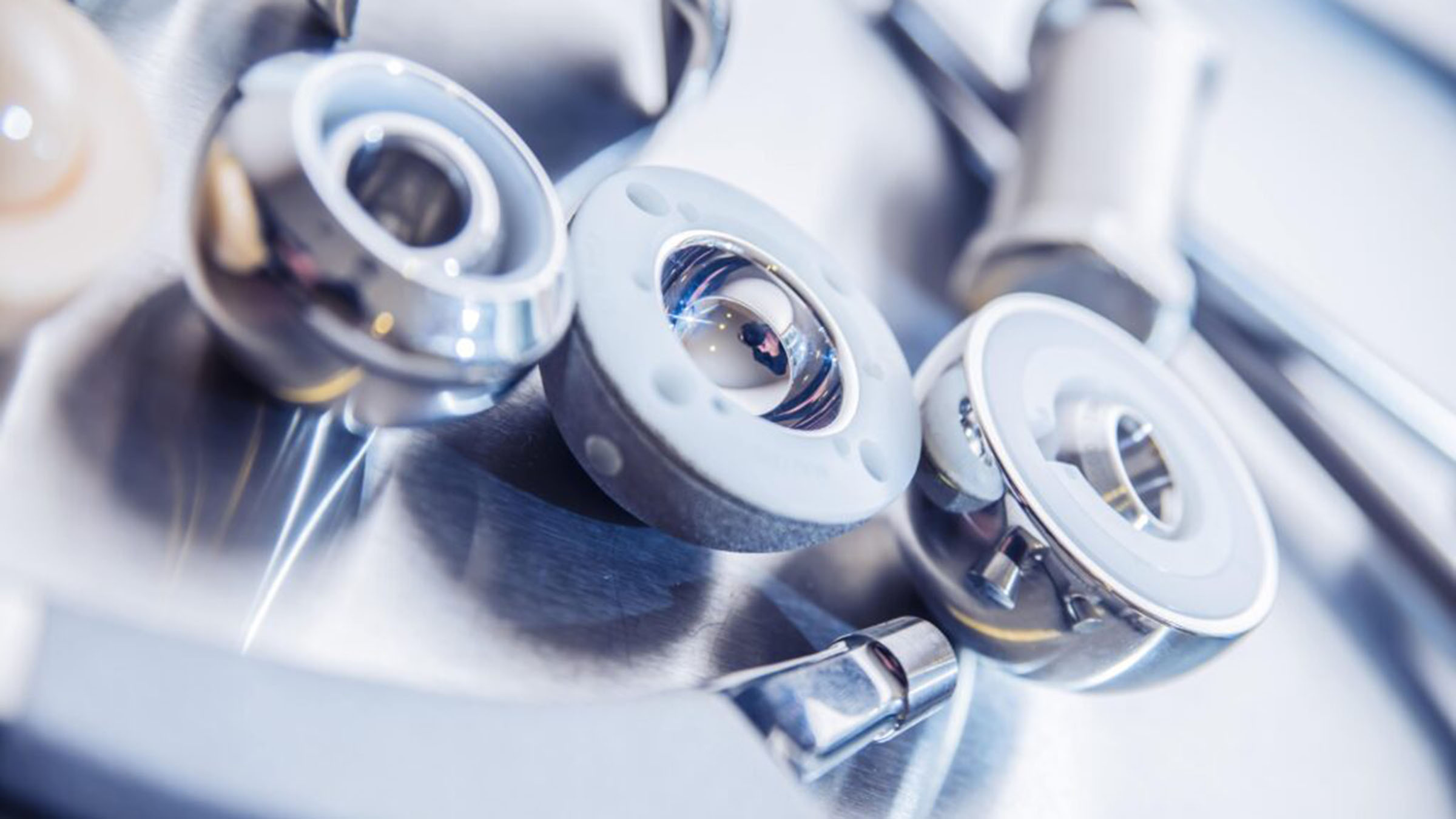

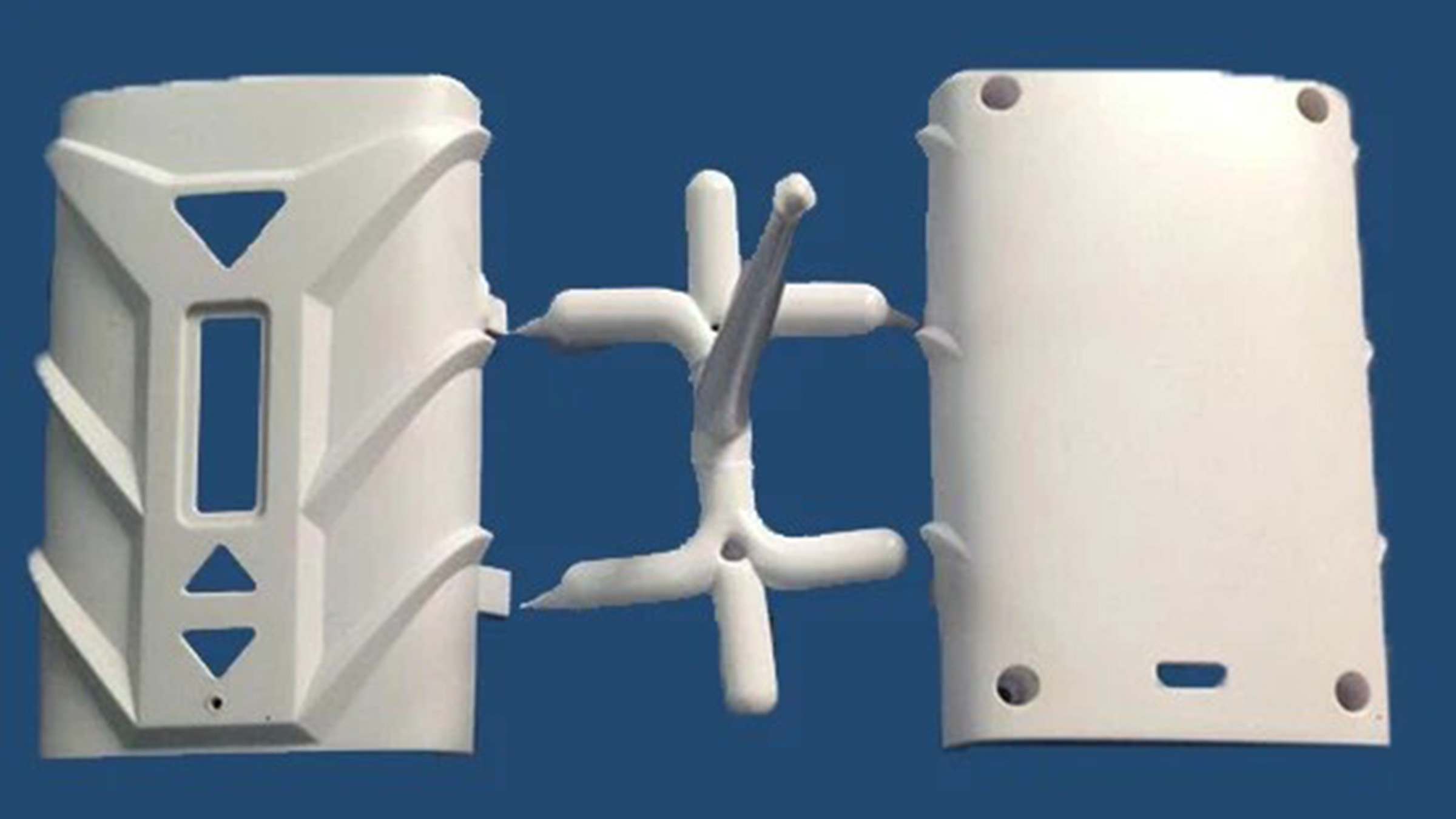

Medical Components Gallery

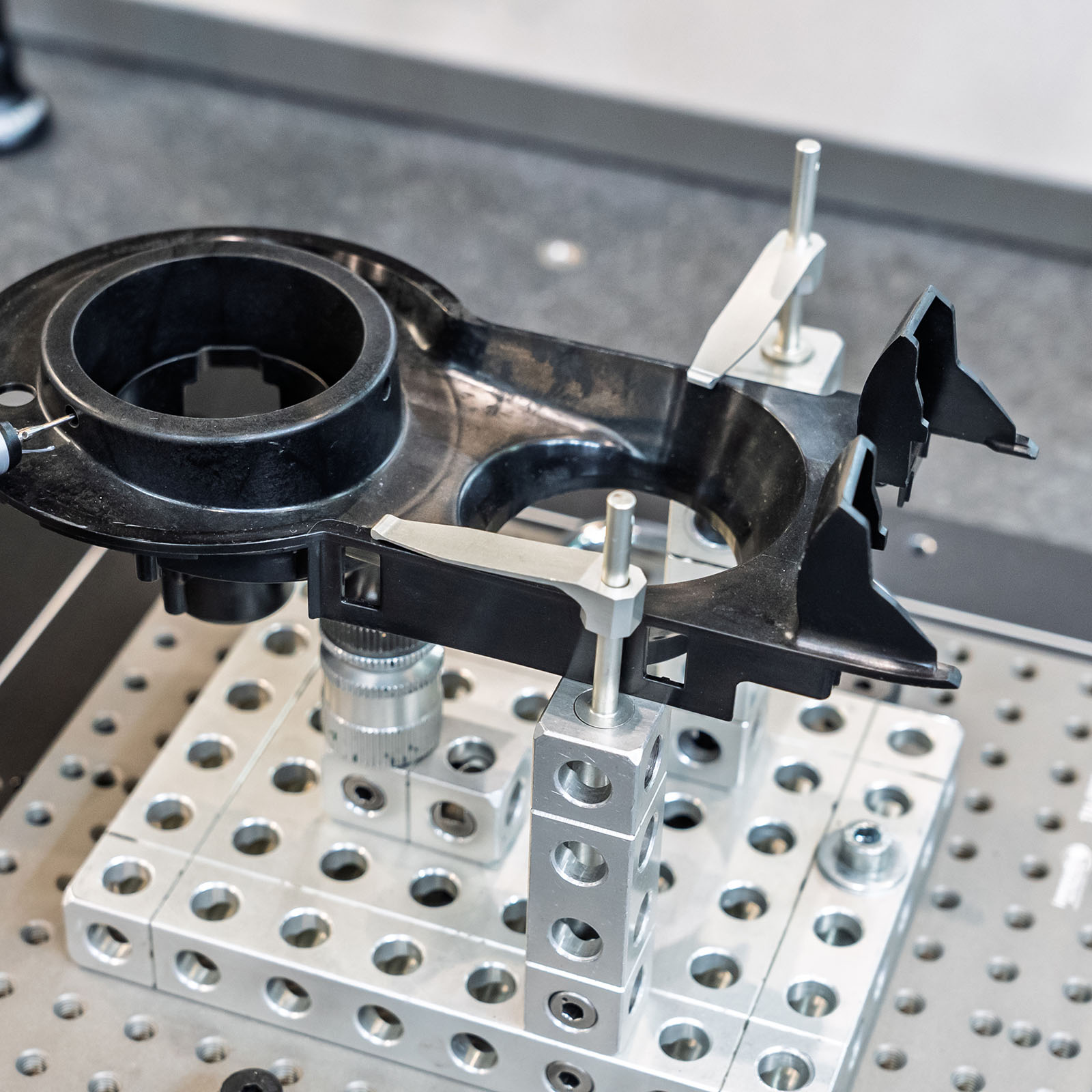

Parts of Support and Mobility Devices

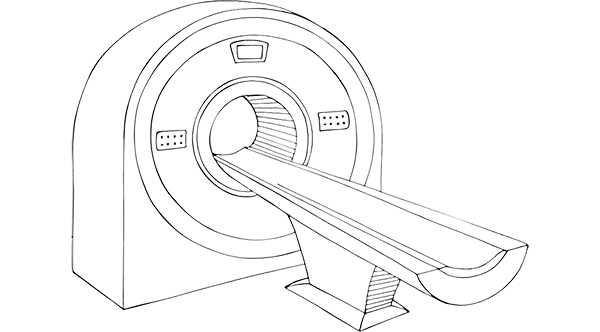

Parts of Diagnostic and Monitoring Devices

Dedicated Full-Scale Production Support

Our experienced manufacturing team oversees every stage of your production order, from start to finish. We handle the entire process with precision and efficiency—while keeping you informed with timely updates throughout.

Account Manager

Your dedicated account manager offers personalized assistance—from platform navigation to file uploads—ensuring smooth communication and project handling.

Application Engineers

Our in-house application engineers provide expert CAD support and design optimization, helping you reduce costs while maintaining performance and manufacturability.

Logistics

Our operations specialists manage global logistics with precision, ensuring fast, reliable delivery and streamlined supply chain coordination.

Recommended Medical Manufacturing Solutions

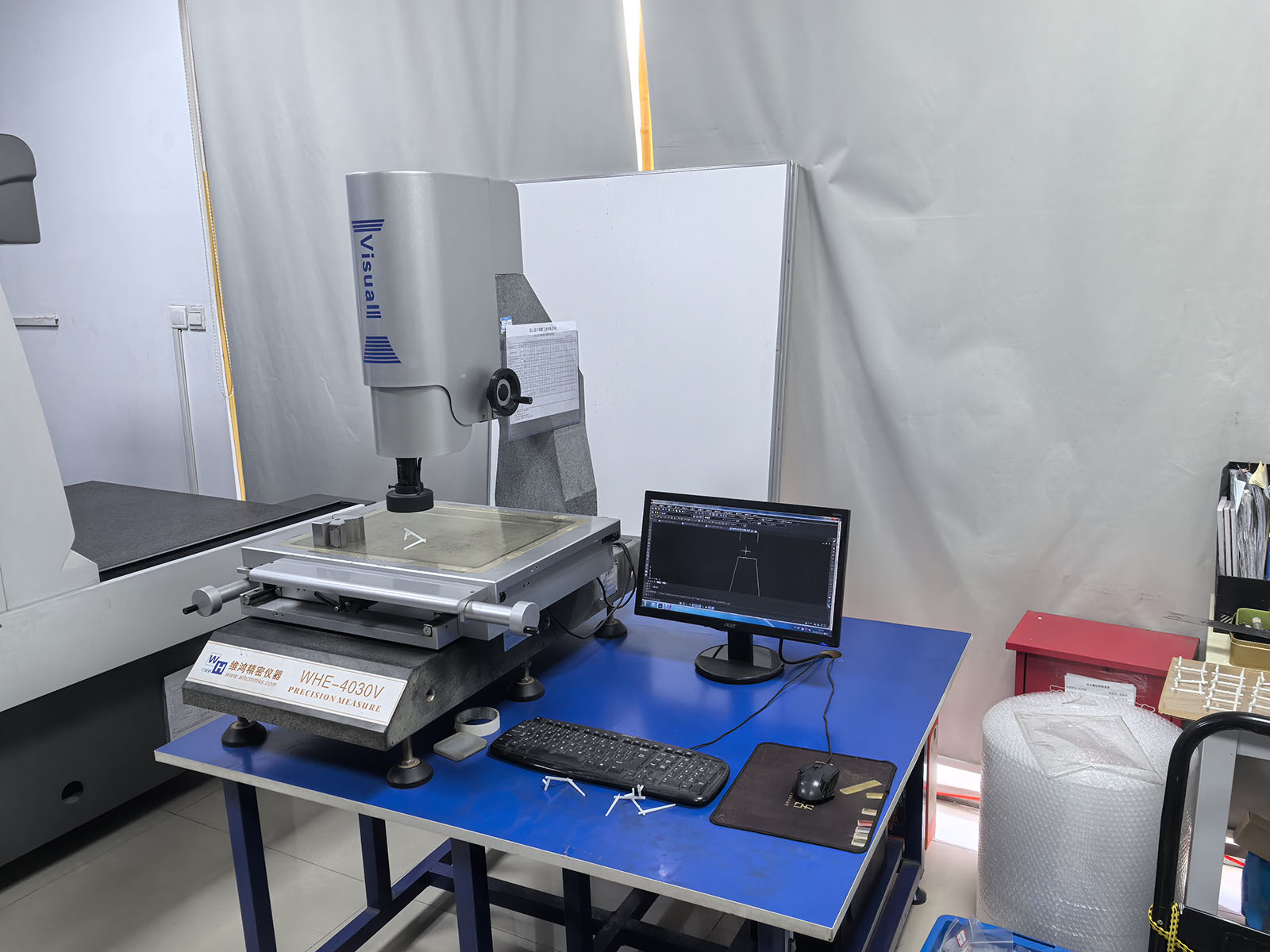

Quality Assurance in Medical & Pharmaceutical Industry

We follow strict quality assurance protocols, including ISO 13485 compliance, to ensure every medical and pharmaceutical component meets the highest standards of safety, precision, and regulatory reliability.

KingStar Mold’s commitment to quality gives you the confidence to trust us with even your most demanding medical components.

Materials For the Medical Components

The medical and healthcare industry holds unique responsibilities—many parts are used directly on or in the human body. To ensure safety and compliance, we strictly follow industry standards and never use recycled materials for injection molding, even at the cost of higher raw material usage. This standard also applies to all other industries we serve.

We can provide full material certifications and are happy to source from client-specified suppliers. Our expertise covers a wide range of certified materials:

Stainless Steel & Inconel

Medical-grade stainless steel and Inconel offer excellent corrosion resistance, high strength, and heat tolerance, making them ideal for precision surgical instruments. Their biocompatibility also makes them suitable for implants, including bone replacements, while ensuring easy sterilization in clinical environments.

Titanium

With its exceptional strength-to-weight ratio and natural biocompatibility, titanium is ideal for orthopedic implants and internal joint components. It resists corrosion in bodily environments and can be precisely machined or 3D printed to meet tight medical tolerances.

Medical Alloys

Specialty medical alloys, such as cobalt-chrome and nickel-titanium (Nitinol), are engineered for demanding applications like stents, implants, and surgical tools. They offer unique combinations of biocompatibility, flexibility, fatigue resistance, and long-term durability in the human body.

Nylon & ABS

Durable and versatile, Nylon and ABS are commonly used in medical devices, housings, and equipment components. Both materials are compatible with 3D printing, making them ideal for rapid prototyping and low-volume production of functional, on-demand parts.

Silicone & TPE

Silicone and thermoplastic elastomers (TPE) are ideal for components that come into frequent contact with skin, such as wearables, seals, and handheld devices. They offer excellent flexibility, skin-friendliness, and chemical resistance, making them perfect for medical-grade applications.

High-Temp Plastics

Materials like PEEK and PEI (Ultem) deliver excellent heat resistance, dimensional stability, and creep resistance. They’re ideal for medical applications that demand repeated sterilization and long-term performance under mechanical stress.

Microfluidics

Materials like Watershed (ABS-like) and Accura 60 (PC-like) are ideal for microfluidic devices and transparent components such as lenses, covers, and diagnostic housings. Their clarity and fine-detail resolution make them well-suited for fluid flow visualization and precision applications.

Carbon RPU & FPU

Carbon DLS technology utilizes rigid (RPU) and flexible (FPU) polyurethane materials to produce strong, functional parts suitable for late-stage prototyping and end-use medical devices. These materials combine durability with excellent surface finish and mechanical performance.

Medical Components Surface Treatment

In the medical device industry, many components are not just functional—they’re also appearance-critical. Aesthetic standards are often just as important as performance, especially for parts used in patient-facing instruments and diagnostic equipment. At KingStar Mold, we offer a full range of surface treatment services to meet these expectations.

With an integrated supply chain and in-house capabilities, we handle everything from basic silk screening to complex electroplating. For parts without specific surface requirements, we typically apply high-gloss finishes or follow industry-standard treatments to ensure both visual and functional excellence. When your product arrives, you’ll immediately notice the precision and polish that set our work apart.

Laser Etching

Polishing

Passivation

Factory Gallery

Frequently Asked Questions

Yes, KingStar Mold specializes in rapid prototyping services for medical and pharmaceutical components. We use a range of technologies such as CNC machining, 3D printing, and soft tooling to produce high-precision prototypes quickly. These prototypes help clients validate part designs, perform functional testing, and accelerate regulatory approval processes. Whether it’s a handheld diagnostic device, a drug delivery system, or a surgical tool component, our rapid prototyping capabilities ensure fast turnaround while maintaining medical-grade quality standards. We also offer material options that mimic final production materials to provide more accurate performance testing results.

Absolutely. Our engineering team collaborates closely with clients to optimize designs for manufacturability without compromising functionality or regulatory compliance. We help adjust wall thicknesses, radii, draft angles, and parting lines to improve production efficiency and part durability.

- ISO Certifications: We operate under ISO 9001:2015 and ISO 13485 quality management systems.

- In-Process Inspections: Each stage of manufacturing undergoes strict dimensional and visual inspections.

- Advanced Testing: Final products can be subjected to functional testing, leak testing, and dimensional validation based on client requirements.

Yes. We specialize in both low-volume and pilot production runs, especially important for clinical trials, regulatory testing, and early-stage device launches. Our flexible tooling solutions allow rapid iterations with minimized cost and lead time.

- Medical-Grade Plastics: Materials like PEEK, POM, PC, PP, and medical-grade ABS are often used for surgical instruments, drug delivery systems, and housings.

- Stainless Steel and Titanium: Selected for implants, surgical tools, and devices requiring high strength and corrosion resistance.

- Silicone: Frequently used in flexible tubing, seals, and implantable devices for its biocompatibility and flexibility.