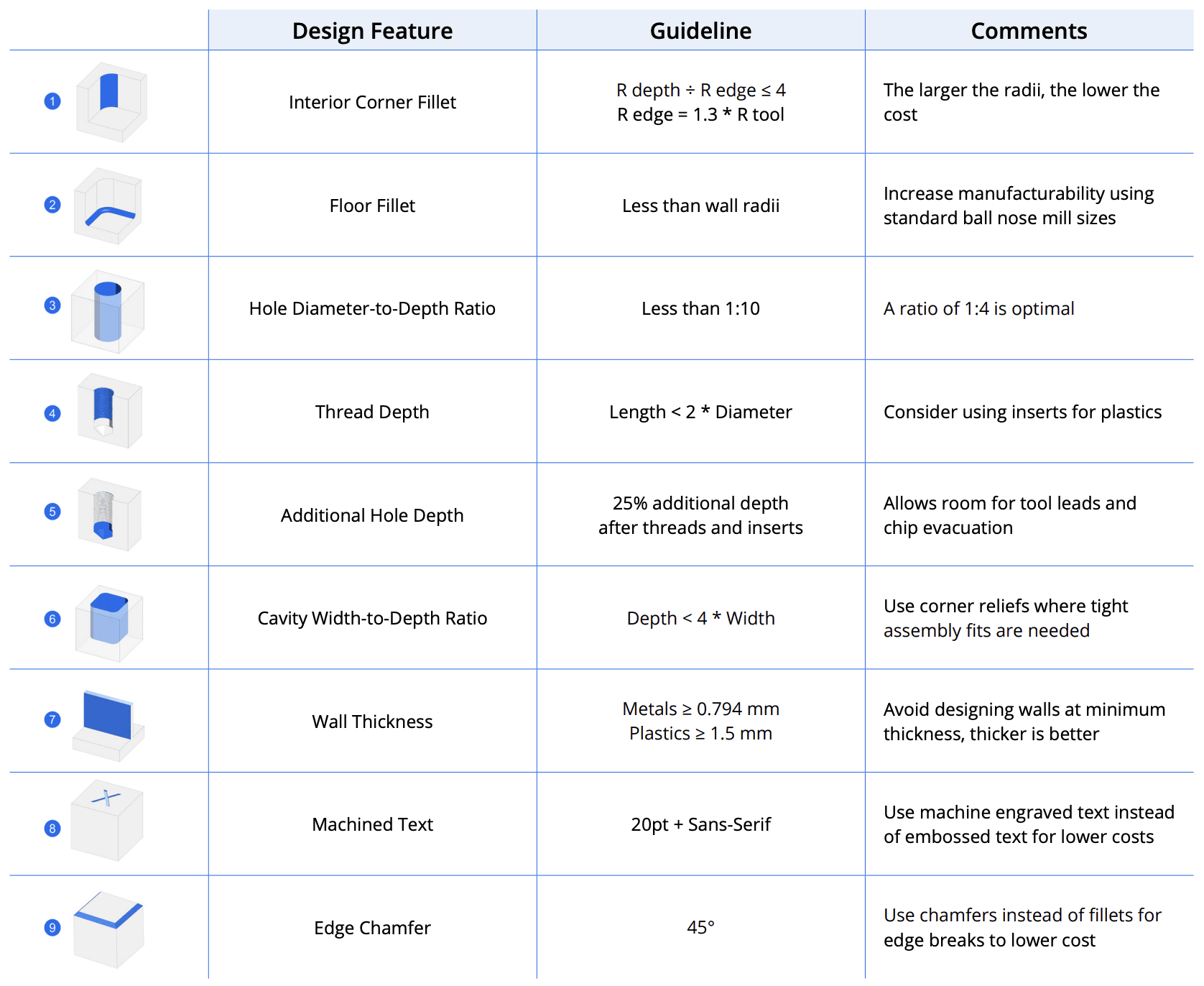

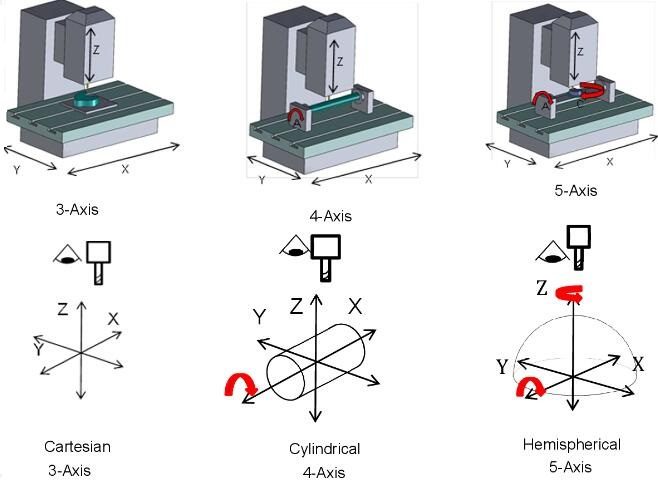

The three-axis movement of a CNC milling machine

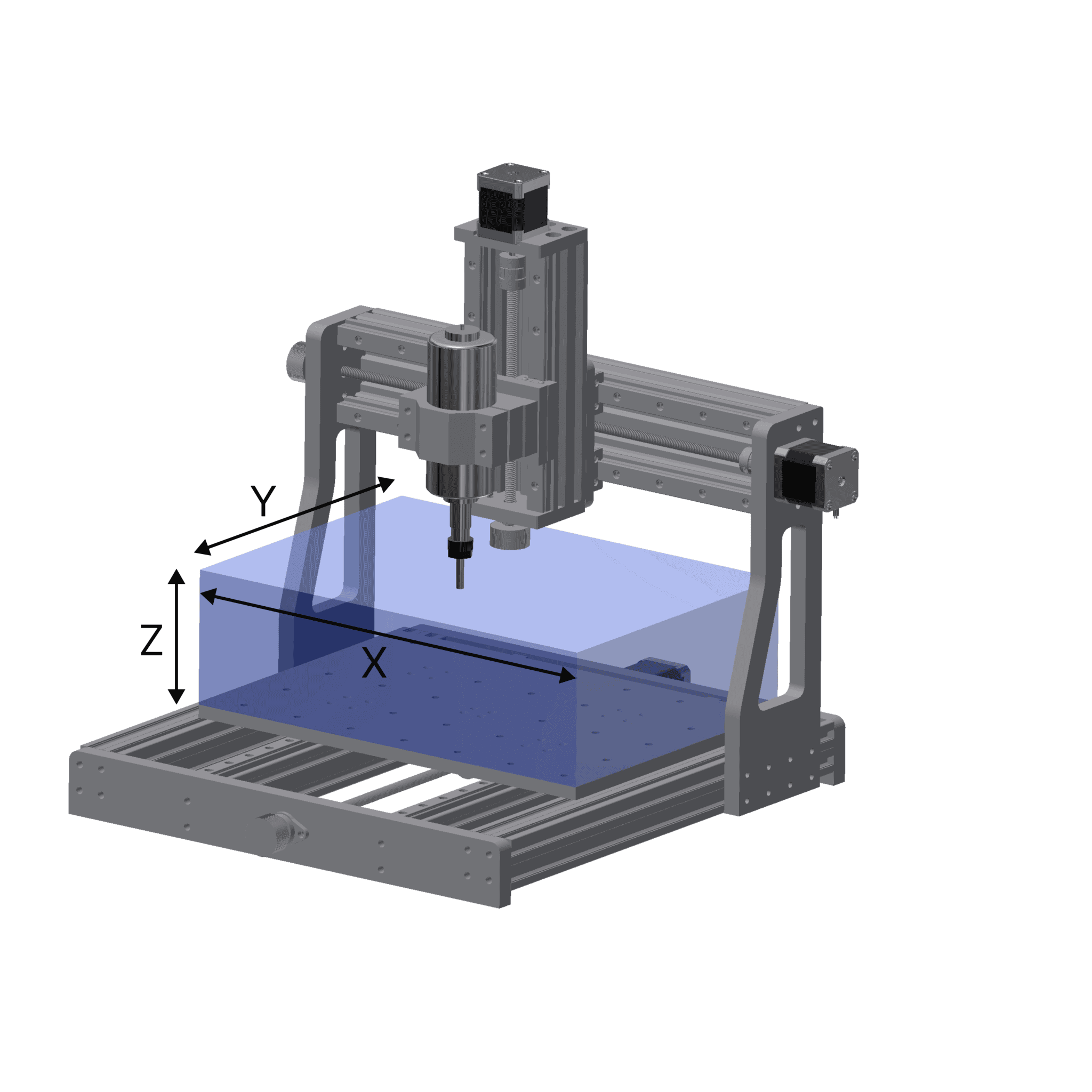

The reduced work envelope due to tooling size

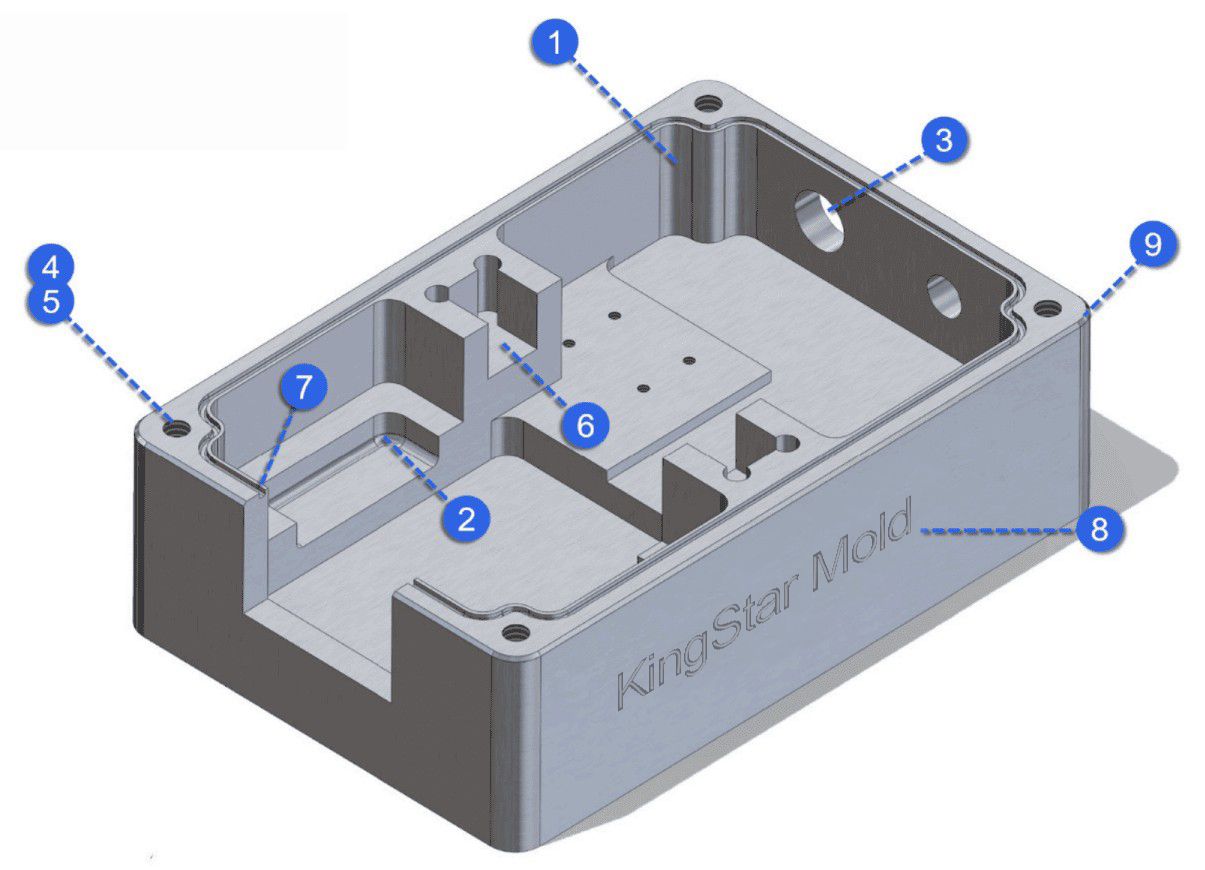

Why Are There Size Limitations for CNC Machining?

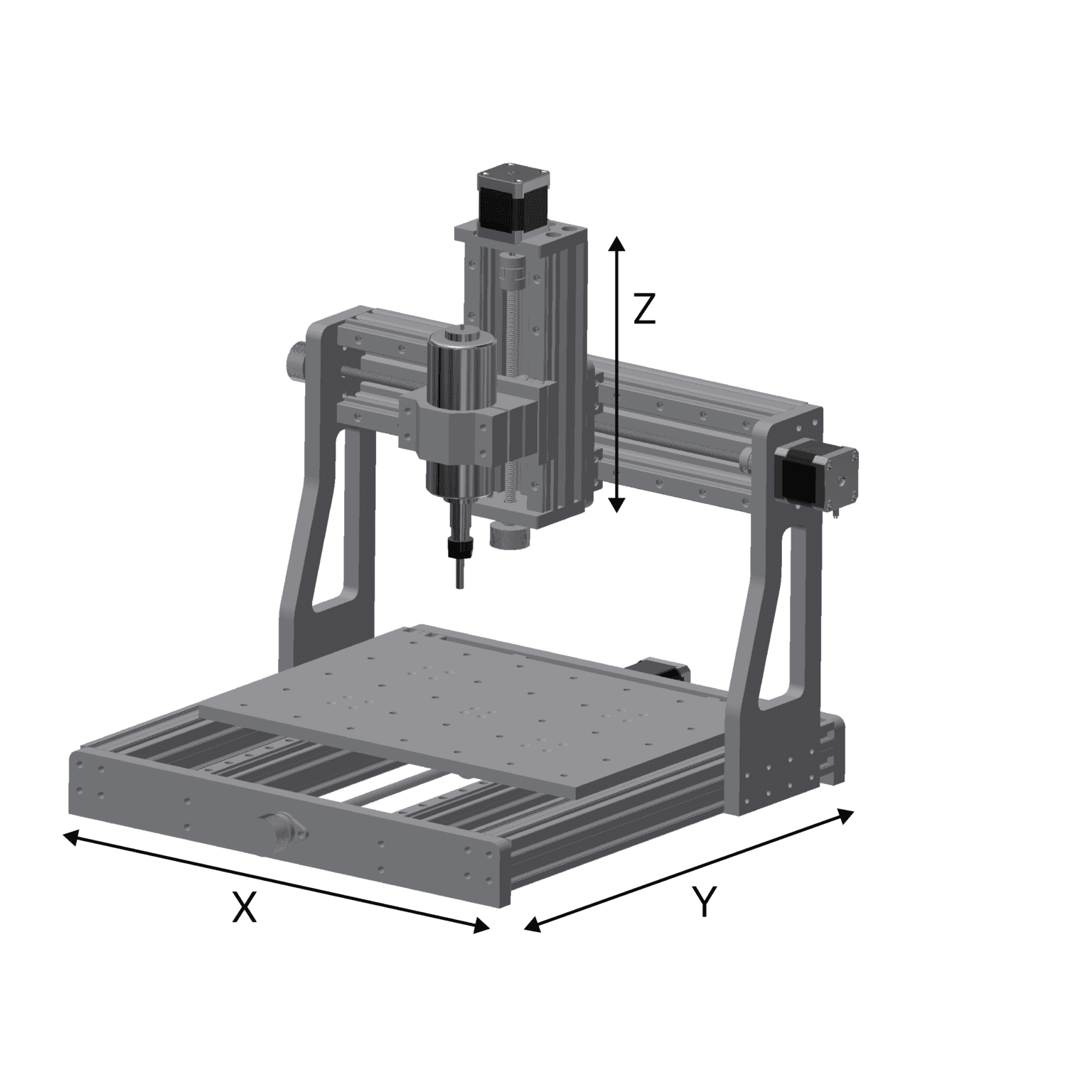

The core factor that limits CNC machining size is axis travel—how far the cutting tool can move along the X, Y, and Z directions. In a typical 3-axis CNC milling machine, this travel determines the boundaries of the work envelope. Larger machines have longer rails and a wider range of motion, enabling them to handle bigger parts.

However, the usable space can be slightly reduced by the length of the cutting tool, especially in the Z-axis. Designers should account for tool length when estimating maximum part size.

While 3-axis machines are standard, adding rotational axes greatly expands both part complexity and practical size limits.

-

4-axis machines allow rotation around one axis, useful for machining cylindrical or angled parts without repositioning.

-

5-axis machines add a second rotation, enabling the tool to reach almost any surface in a single setup.

These added axes increase flexibility, especially for large or irregularly shaped components. More complex machines make it possible to process intricate geometries within a compact footprint, effectively maximizing usable volume.

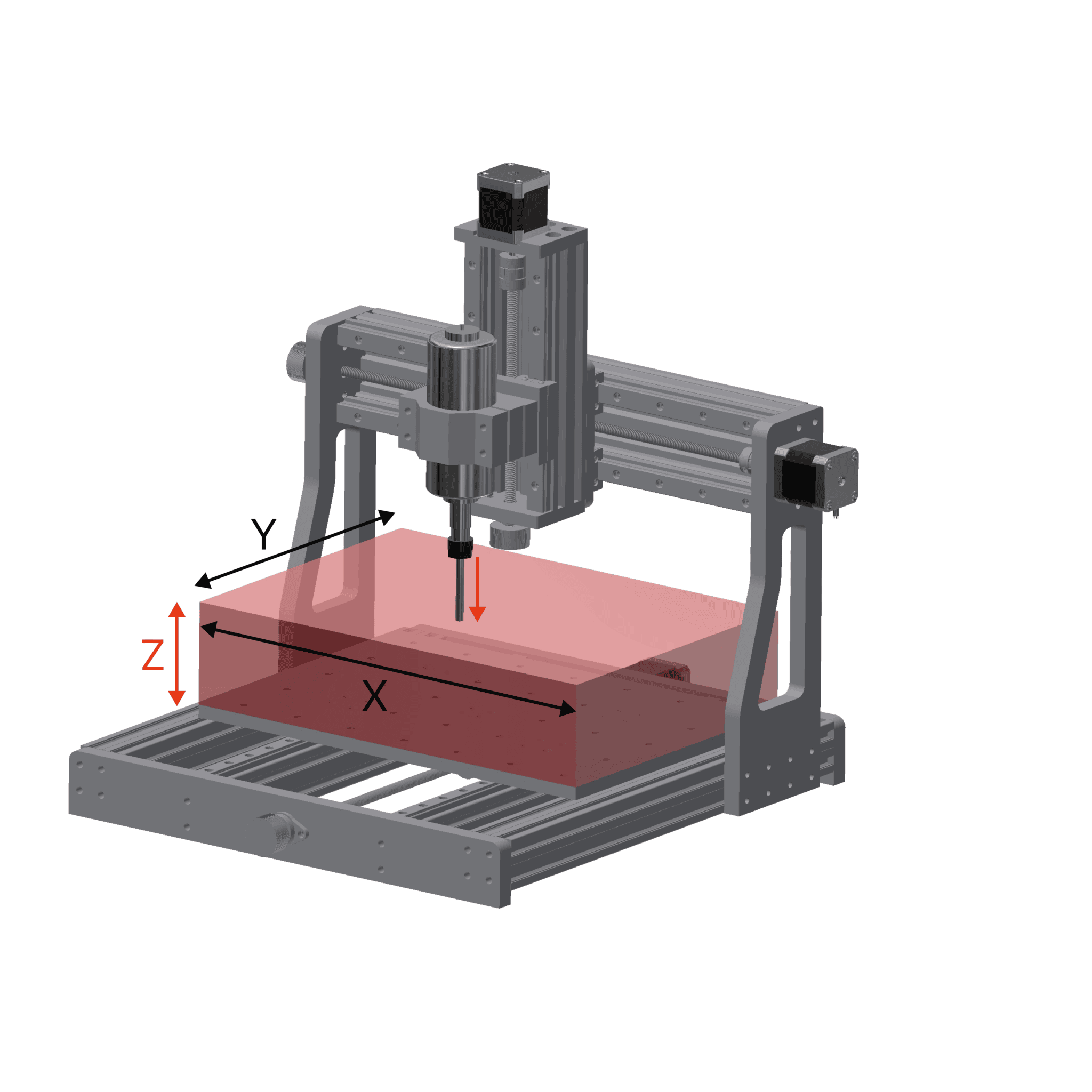

General Size Limitations of CNC Machining

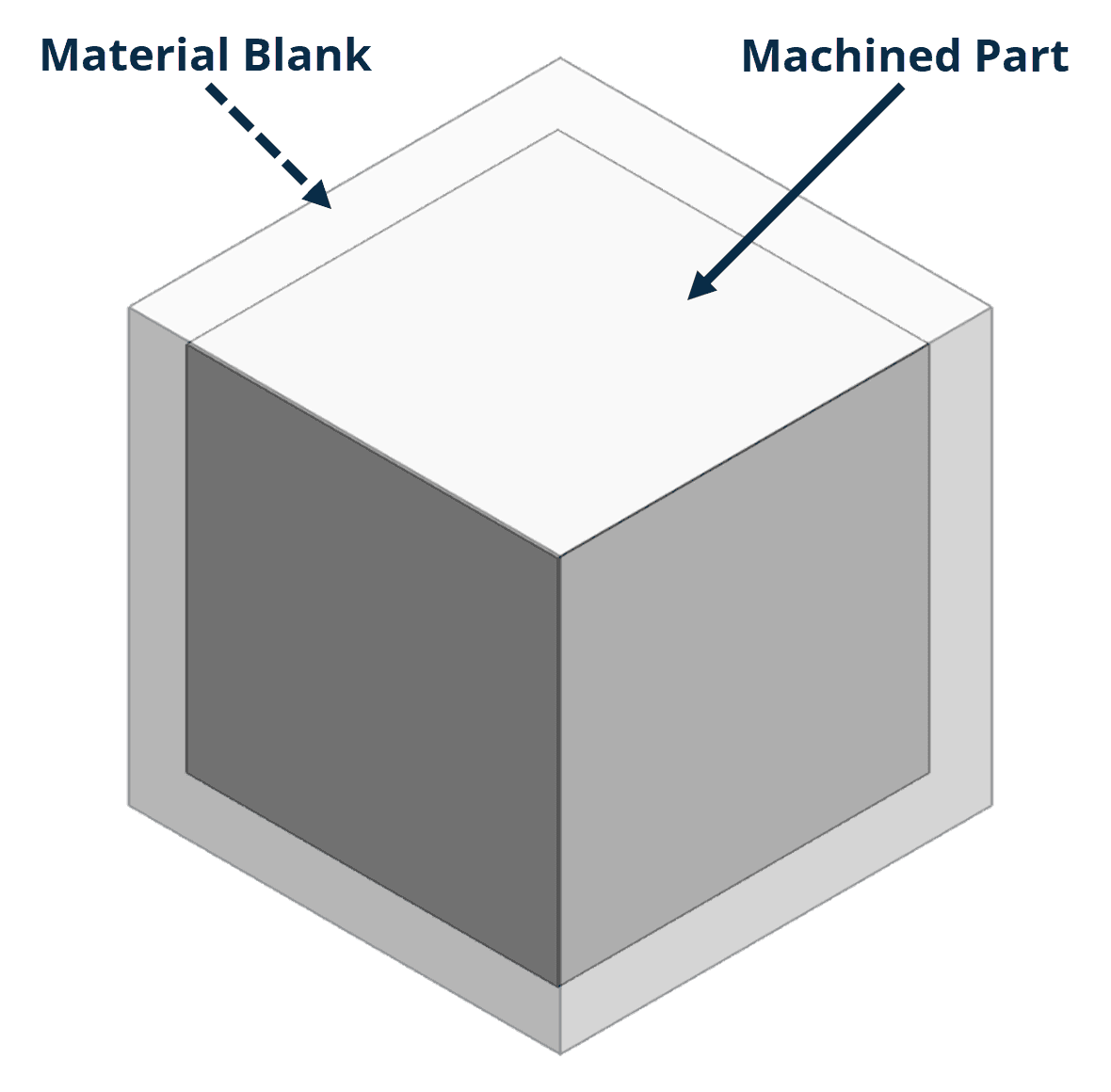

Material Blank Size

When you’re planning a part, remember that your starting block of material—often called the “blank”—needs to be a bit bigger than the final shape. Think of it like carving a sculpture: you always start with extra material so you can shave off the rough edges and fine-tune the details.

So, if your finished piece needs to measure 50 × 50 × 50 mm, grab a blank that’s around 53 × 53 × 53 mm. That little bit of extra room in X, Y, and Z gives you the freedom to machine away imperfections and still hit your exact dimensions. Always factor those extra millimeters into your design before you check it against your machine’s size limits.

Size Limitations for CNC Milling

CNC milling machines offer exceptional precision and versatility, but they aren’t without physical limits—especially when it comes to part size. Two major factors come into play here: the machine’s work envelope and the cutting tool’s reach.

The CNC work envelope defines the maximum space the machine can operate in, usually measured by the movement range along the X, Y, and Z axes. This is determined by the size of the machine bed and how far the tool can travel vertically and horizontally. However, the full envelope isn’t always usable. Large fixtures, part overhangs, or bulky setups can all chip away at that usable space.

Then there’s the tool reach, which is often the more hidden constraint. Even if your machine’s Z-axis can travel deep, your actual cutting tool needs to be long enough—and rigid enough—to get there without deflecting or crashing. For example, if you’re trying to machine a part with narrow, deep grooves, you may hit a wall if your tool simply isn’t long enough to reach without the holder interfering.

While high-end milling machines like those from Kern Microtechnik can hit extreme precision tolerances down to ±2 microns, even the best machines are limited by physics. Tool rigidity, machine size, and workholding setups will always define the maximum part size and geometry you can mill effectively.

Different (Milling) Max. Diameters of Different Materials

| Material | Max. Depth (US Units) | Max. Depth (Metric Units) |

|---|---|---|

| Aluminum 6061-T651 | 3.75 in. | 95.25 mm |

| Aluminum 7075-T651 | 3.75 in. | 95.25 mm |

| Brass 260 | 1.75 in. | 44.45 mm |

| Copper C101 | 2.75 in. | 69.85 mm |

| Low Carbon Steel CR 1018 | 1.25 in. | 31.75 mm |

| Steel Alloy 4140 | 1.75 in. | 44.45 mm |

| Titanium Ti 6-4 | 1.75 in. | 44.45 mm |

| Stainless Steel 17-4 PH | 1.75 in. | 44.45 mm |

| Stainless Steel 304/304L | 1.75 in. | 44.45 mm |

| Stainless Steel 316/316L | 1.75 in. | 44.45 mm |

| ABS | 3.75 in. | 95.25 mm |

| ABS Flame Retardant | 1.75 in. | 44.45 mm |

| HDPE | 3.75 in. | 95.25 mm |

| LDPE | 0.75 in. | 19 mm |

| PP (Polypropylene Copolymer) | 3.75 in. | 95.25 mm |

| PP (Polypropylene Homopolymer) | 2.75 in. | 69.85 mm |

| PEEK | 1.75 in. | 44.45 mm |

| PEI Ultem 1000 | 2.75 in. | 69.85 mm |

| PEI Ultem 2300 (30% glass-filled) | 1.75 in. | 44.45 mm |

| PMMA (Acrylic) | 2.75 in. | 69.85 mm |

| Polycarbonate (Black) | 1.75 in. | 44.45 mm |

| Polycarbonate (Clear) | 1.75 in. | 44.45 mm |

| Polycarbonate (Translucent) | 3.75 in. | 95.25 mm |

| Polycarbonate (20% GF) | 1.75 in. | 44.45 mm |

| POM Acetal Homopolymer (Delrin 150) | 3.75 in. | 95.25 mm |

| POM Acetal Static Dissipative (Tecaform SD) | 2.75 in. | 69.85 mm |

| POM Acetal 20% Glass filled (Delrin 570) | 1.75 in. | 44.45 mm |

| POM Acetal Copolymer | 3.75 in. | 95.25 mm |

| PPE/PS (Noryl 265) | 1.75 in. | 44.45 mm |

| PPSU (Radel R 5500) | 1.75 in. | 44.45 mm |

| Polystyrene (PS) | 1.75 in. | 44.45 mm |

| Polysulfone (PSU) | 1.75 in. | 44.45 mm |

| PTFE (Teflon) | 2.75 in. | 69.85 mm |

| PVC | 3.75 in. | 95.25 mm |

| UHMW | 3.75 in. | 95.25 mm |

| PA Nylon 6 | 2.75 in. | 69.85 mm |

| PA Nylon 6/6 | 0.75 in. | 19 mm |

| PA Nylon 6/6 (30% GF) | 1.75 in. | 44.45 mm |

Size Limitations for CNC Turning

CNC turning comes with its own set of size limitations, mainly dictated by the design of the lathe. Since the process involves spinning the workpiece while a stationary tool cuts it, several key dimensions control what you can actually machine.

One of the biggest factors is the distance between centers—the space between the headstock and tailstock. This defines the maximum length of the part you can turn. If your part is longer than this, it simply won’t fit on the machine.

Then there’s the swing capacity, which limits how wide your part can be. “Swing Over Bed” tells you the largest diameter that can physically rotate over the lathe bed. But it doesn’t stop there. The Swing Over Cross Slide is even more restrictive, as it accounts for the clearance over the tool carriage. If your part’s diameter exceeds this, the cutting tool can’t reach it without crashing into the part. Some lathes also feature a Swing Over Gap, where a portion of the bed is removable to allow extra diameter—but this usually restricts usable length and cutting angles.

In short, CNC turning is ideal for long, round components—but be sure your part fits within both the length and diameter limits of your machine before you start turning.

Different (Turning) Max. Diameters of Different Materials

| Material | Max. Diameter (US Units) | Max. Diameter (Metric Units) |

|---|---|---|

| Aluminum 6061-T651 | 3.95 in. | 100 mm |

| Aluminum 7075-T651 | 3.95 in. | 100 mm |

| Brass C360 | 3.95 in. | 100 mm |

| Low Carbon Steel CR 1018 | 2.95 in. | 75 mm |

| Steel Alloy 4140 | 2.95 in. | 75 mm |

| Titanium Ti 6-4 | 2.95 in. | 75 mm |

| Stainless Steel 17-4 PH | 2.95 in. | 75 mm |

| Stainless Steel 304/304L | 2.95 in. | 75 mm |

| Stainless Steel 316/316L | 2.95 in. | 75 mm |

Frequently Asked Questions

Absolutely. At KingStar Mold, we routinely handle parts that push beyond standard machining limits through customized setups and tooling strategies.

For example, a recent client needed a large plastic mold base with deep core cavities and a parting line spanning over 1,100 mm—exceeding the Z-axis and travel limits of most conventional CNC machines. Our engineering team designed a two-step milling strategy using custom long-reach tools and modular fixturing. The base was rotated and repositioned with precision reference points to ensure perfect alignment between operations.

This solution not only allowed us to machine the oversized part with tight tolerances but also avoided the need for expensive outsourcing or part redesign. If you have a challenging or oversized project, simply send us your drawings—KingStar Mold will find the most efficient way to make it work.

Yes, but with caution. In CNC turning, machining long and slender parts introduces challenges like deflection, vibration, and chatter due to the workpiece’s lack of rigidity. These issues can lead to poor surface finish, dimensional inaccuracy, or even tool breakage. To counter this, machinists typically use tailstocks, steady rests, or support fixtures to stabilize the part during rotation.

In CNC milling, long parts must fit within the machine’s X-axis travel and be clamped securely to the bed. Even when the length is within the machine’s limit, thin cross-sections or extended overhangs can still flex under cutting forces. In such cases, proper fixturing, minimal tool engagement, and reduced cutting speeds are crucial to avoid vibration and ensure precision. If long parts exceed the machine’s travel, they may need to be machined in multiple setups, which adds complexity but is often manageable with careful planning.

Material blanks should be slightly oversized—usually by 2–5 mm in each dimension—to allow room for rough cuts and machining tolerances. Be sure to factor in this excess when checking against your machine’s max size limits.

Tool reach limits how deep into a part the cutter can go. Even if the machine’s Z-axis has enough travel, the cutting tool must be long enough to reach without interference. This is especially important for deep pockets, narrow grooves, or tall part features.