Classification of Materials in KingStar Mold’s Manufacturing

These carefully selected materials ensure that KingStar Mold delivers high-quality, durable, and precise components across all types of production, from mold buiding to injection molding, 3D printing, sheet metal fabrication and CNC machining.

Injection Molding Materials at KingStar Mold

Versatile, High-Quality Materials for Superior Molding

At KingStar Mold, we offer a wide range of injection molding materials to suit diverse production needs. Our selection includes thermoplastics, elastomers, and engineering plastics, each chosen for their specific advantages in strength, flexibility, and durability. Whether you’re producing components for consumer goods, automotive parts, or medical devices, we have the materials to meet your precise requirements. We prioritize quality and performance in every product we manufacture.

60+

Materials

From ABS and Nylon for robust and lightweight designs to advanced materials like PEEK and TPU for high-performance applications, our injection molding materials are tailored to deliver exceptional results. Our team ensures that the right material is selected to optimize both function and cost-efficiency for your project.

Mold Making Materials at KingStar Mold

Durable and Precision-Engineered Materials for Superior Molds

At KingStar Mold, we offer a variety of high-performance materials for mold making, including tool steels, aluminum alloys, and copper-based alloys. These materials are selected for their strength, heat resistance, and dimensional stability, ensuring molds that are durable, precise, and efficient for long-term production. Whether producing molds for complex designs or high-volume production, we choose the best materials for optimal results and durability.

30+

Materials

We use materials like P20 tool steel for its strength and long-lasting wear, and beryllium copper for its excellent heat dissipation properties. These selections help maximize mold life and improve production efficiency, ensuring that every mold performs at its best.

CNC Machining Materials at KingStar Mold

Precision Materials for High-Performance CNC Machining

At KingStar Mold, we offer a wide range of materials for CNC machining, ensuring precision, strength, and reliability for various applications. Our material selection includes metals like stainless steel, aluminum, titanium, and brass, as well as high-performance plastics such as POM and PEEK. These materials are chosen for their excellent machinability, durability, and ability to meet strict tolerances, allowing us to produce high-quality, intricate parts for industries ranging from aerospace to medical devices.

30+

Materials

We select materials like 6061 aluminum for its lightweight strength, stainless steel for corrosion resistance, and POM for its superior dimensional stability. These materials are carefully chosen to ensure optimal machining performance and the highest quality end products.

3D Printing Materials at KingStar Mold

Precision, Strength, and Versatility for Advanced Manufacturing

KingStar Mold provides a comprehensive selection of 3D printing materials, including high-performance plastics, durable metals, and flexible elastomers. Each material is carefully chosen for its unique properties, ensuring optimal strength, flexibility, and thermal resistance. Whether you need functional prototypes, aerospace components, or custom medical parts, we have the right materials to meet your exact specifications. Our commitment to quality and innovation guarantees superior results in every project.

30+

Materials

From PLA and Nylon for lightweight and cost-effective designs to advanced materials like Inconel and TPU for demanding applications, our 3D printing materials are engineered to enhance performance and efficiency. Our experts work closely with you to select the best material for your production needs, ensuring precision and reliability.

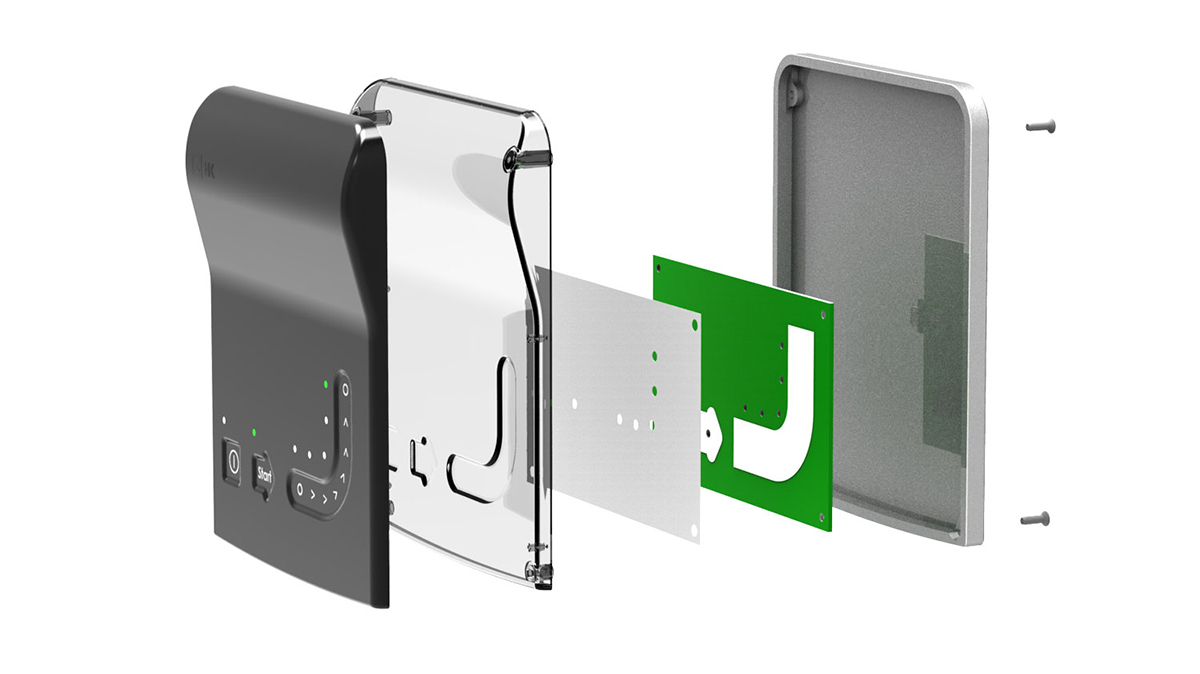

Sheet Metal Fabrication Materials at KingStar Mold

Durable, High-Precision Materials for Custom Metal Fabrication

KingStar Mold offers a wide range of sheet metal materials, ensuring strength, precision, and reliability for various applications. Our selection includes aluminum, stainless steel, and other high-performance metals, each chosen for its durability, corrosion resistance, and machinability. Whether you need enclosures, brackets, or structural components, we provide the right materials to meet your exact specifications. Our focus on quality guarantees consistent and precise fabrication results.

20+

Materials

From aluminum and mild steel for lightweight yet sturdy structures to stainless steel and titanium for high-strength applications, our sheet metal materials deliver exceptional performance. Our team works closely with you to ensure the best material choice for durability, functionality, and cost-effectiveness.

KingStar Mold serves a broad range of industries, including automotive, medical, electronics, consumer goods, and more. We offer tailored material solutions to meet the specific needs of each sector.

The best material for mold making depends on the application. Common choices include P20 tool steel for its strength, aluminum alloys for lightweight designs, and beryllium copper for excellent heat dissipation.

Yes, we offer FDA-approved materials for food-grade applications, ensuring your products meet safety and regulatory standards.

Yes, KingStar Mold is equipped to handle both small-batch and large-scale production runs. Whether you need prototypes or high-volume production, we have the capabilities to meet your needs.

We choose CNC materials based on the project’s requirements, including the strength, durability, and machinability of materials like stainless steel, aluminum, brass, and advanced engineering plastics.

Yes, our experienced team will collaborate with you to recommend the best materials based on your specific project needs, ensuring the ideal balance between performance and cost-effectiveness.

We work with stainless steel, aluminum, brass, titanium, and POM, each carefully chosen for its machinability and durability in precision machining.

KingStar Mold uses advanced CNC machining technologies and materials like stainless steel, aluminum, and titanium. We follow strict quality control measures to guarantee precision and superior performance in every part we produce.

We offer a variety of materials, including ABS, PA (Nylon), PBT, PC, PP, PS, and PMMA, each suited for different production needs such as strength, flexibility, and durability.

KingStar Mold offers a wide range of high-quality materials, cutting-edge technology, and exceptional expertise to deliver durable, precise, and cost-effective injection molding solutions tailored to your specific needs.

Yes, we use high-performance materials such as titanium and stainless steel, which are commonly used in aerospace applications due to their strength, durability, and resistance to extreme conditions.

Yes, we perform material testing to verify properties such as strength, heat resistance, and durability, ensuring our materials meet the specifications required for your molds.

We ensure high-quality mold making by selecting durable materials with excellent dimensional stability, strength, and heat resistance, and by conducting thorough testing at each stage of production.

Yes, KingStar Mold can accommodate custom material requests based on your project’s specific needs. Our team will help guide you in selecting the right material for optimal results.

Lead time for CNC machining depends on part complexity, material selection, and production volume. We provide clear timelines once we evaluate your project.

Molds made with materials like P20 tool steel and aluminum alloys are designed to last for many production cycles. Their longevity depends on production volume and maintenance.

We use tool steels, aluminum alloys, and copper-based alloys, selected for their strength, heat resistance, and dimensional stability, ensuring precise and durable molds.