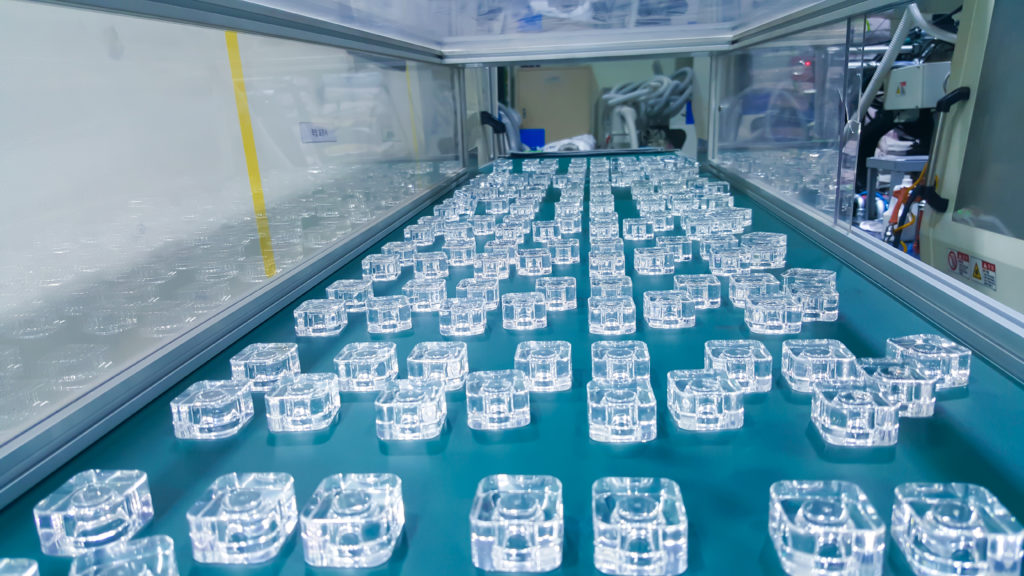

Mass Production Capacity of Molds

Advanced Solutions for Plastic and Metal Molds

At KingStar Mold, we specialize in high-volume production of both plastic and metal molds. Our cutting-edge technology and skilled workforce allow us to efficiently handle large-scale production runs while maintaining precision and quality. Whether you require intricate plastic parts or durable metal components, we offer scalable and cost-effective solutions. We ensure consistency across all production stages, serving industries such as automotive, electronics, and consumer goods with dependable and high-quality molds.

Mass Production Showcase

Exploring Our Capabilities Across Various Industries

Quality Management at KingStar Mold

At KingStar Mold, quality is the cornerstone of everything we do. Our robust quality management system ensures that every product meets the highest industry standards, from initial design to final delivery. We implement comprehensive inspection and testing protocols to guarantee precision, consistency, and reliability across all our services. With advanced technologies and strict quality controls in place, we aim to exceed our clients’ expectations on every project.

Surface Finishing

We offer a variety of surface treatments, including polishing, coating, and anodizing, to ensure products meet aesthetic and functional requirements.

Dimensional Accuracy

Strict measurements and advanced inspection tools ensure that every part is produced with precise dimensions and tolerances.

Material Testing

We conduct thorough testing of materials to verify their strength, durability, and suitability for the intended application.

Environmental Testing

Parts undergo tests to assess their performance in different environmental conditions, such as temperature extremes, humidity, and exposure to chemicals.

Durability & Performance Testing

We simulate real-world conditions to evaluate the longevity and functionality of parts, ensuring they perform reliably over time.

Visual Inspection & Quality Audits

Every product is visually inspected for defects, and our processes are subject to regular quality audits to maintain high standards.

We maintain rigorous quality control through automated inspections, continuous testing, and detailed process monitoring to ensure every product meets our high standards, even in large production volumes.

Mass production offers several benefits, including lower production costs, faster production times, and consistent product quality. It also helps businesses meet high market demand efficiently.

Yes, we can customize designs for high-volume production. Our team works closely with clients to ensure that specific design and functionality requirements are met while maintaining cost-effectiveness.

We provide mass production services across multiple industries, including automotive, medical devices, electronics, consumer goods, and industrial applications, among others.

At KingStar Mold, we have advanced manufacturing capabilities that allow us to handle large-scale production runs efficiently. We use automated systems, skilled labor, and strict quality controls to meet the demands of high-volume orders.

Mass production is the process of producing large quantities of standardized products, typically through automated methods, to achieve economies of scale and cost efficiency.

Absolutely! KingStar Mold specializes in custom CNC machining projects, offering tailored solutions to meet specific design requirements with high precision and quality.

We work with a broad range of materials, including plastics (such as ABS, PBT, PA) and metals (such as aluminum, steel, and stainless steel), tailored to meet the specific needs of the product and industry.

Yes, we offer prototyping services to test designs and make any necessary adjustments before committing to large-scale production.

We scale our production processes to meet demand, utilizing flexible manufacturing systems and automation to increase production output as needed.

While we are capable of mass-producing a wide variety of products, there may be specific material or design constraints depending on the complexity of the part. Our team can assess feasibility for any product.

We use advanced scheduling tools, streamlined production processes, and close coordination with our logistics team to ensure timely delivery of all mass-produced items.

We can accommodate both low and high-volume orders, with flexible minimum order quantities depending on the project’s requirements.