When considering customizing branded hard coolers, have you ever been troubled by these questions: Is the mold cost expensive? Is the MOQ (minimum order quantity) intimidating? Is the production+delivery cycle long?

As a professional custom hard cooler manufacturer, we understand that many enterprises – especially start-ups, brands conducting promotional activities or corporates seeking employee gifting – hope to quickly obtain products with their own logos at a low minimum order quantity and cost. If you are looking for a solution that balances quality, cost and efficiency, then our “standard model + logo customization” service is exactly what you need.

Why Choose Standard Ice Box Models with Logo Customization?

Starting from scratch for customization can indeed achieve imaginative designs, but it also comes with high mold costs, long sample-making cycles, and daunting minimum order quantities. These barriers often put pressure on many enterprises, especially startups.

Our standard model with logo customization service is precisely designed for these purposes. The core advantage of this solution lies in: we use market-proven mature product models as the base, and you only need to focus on the presentation of your brand identity.

- No separate mold required: We utilize existing mature product models, so you don’t have to pay any mold fees.

- Low MOQ: Due to the elimination of mold building, our minimum order quantity can be as low as 100 pieces, and in some cases, we can even accept smaller trial orders.

- High cost-effectiveness: Significantly reduces initial investment, allowing enterprises with limited budgets to easily achieve product customization.

- Quick delivery: The production cycle is significantly shortened, and products are usually delivered within 2-4 weeks after placing an order.

This service is particularly suitable for enterprises that wish to quickly enter the market, test product responses, conduct small-scale promotional activities, or purchase gifts for employees. The flexibility behind this is supported by our rich experience in manufacturing and a mature supply chain.

Multiple Printing Techniques Meeting Different Customization Needs

When choosing the appropriate printing technique, we recommend considering multiple dimensions such as brand positioning, design complexity, and budget. Each technique has its unique advantages and applicable scenarios.

Screen printing, as one of the most classic techniques, is particularly suitable for logo designs with a single color or few colors. Its working principle is to precisely scrape ink onto the product surface through a silk screen. This technique performs exceptionally well on flat or slightly curved surfaces, presenting a rich and strong color coverage. You will notice a slight raised texture in the print, and this unique touch adds a sense of quality to the product.

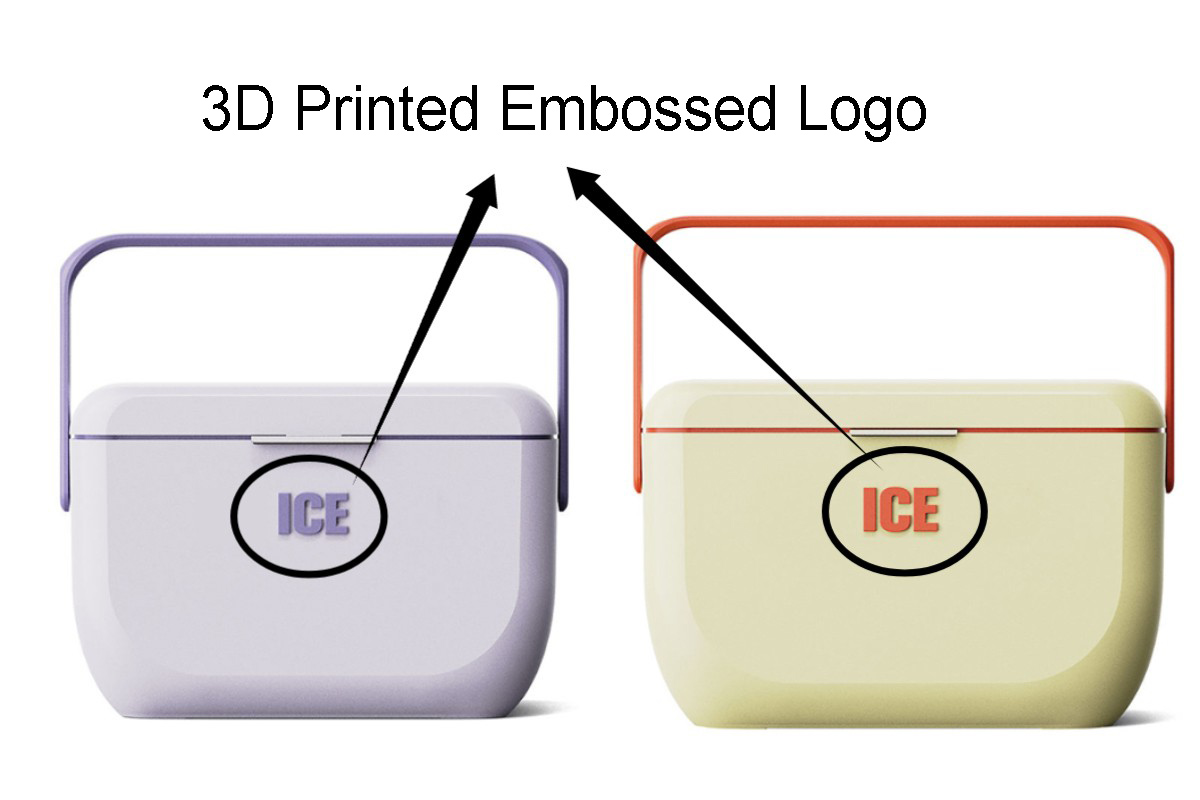

If you are looking for a more impactful brand presentation, 3D embossed printing might be a good choice. This technique creates a distinct raised and recessed three-dimensional effect through the layering of special inks. When consumers touch the raised logo, a unique tactile connection is established between the brand and the consumer. It is important to note that overly complex designs may not be perfectly presented with 3D effect. But our design team is always happy to provide professional advice.

For logo designs with complex color schemes and detailed patterns, UV digital printing technology can perfectly meet your needs. This technology reproduces photo-quality image effects through high-definition printing. The instant curing property of UV ultraviolet light not only ensures printing efficiency but also makes the patterns have excellent adhesion and durability. Whether your logo contains gradient colors or fine pattern details, they can be accurately reproduced.

In addition, heat transfer is a technique that is particularly suitable for handling complex patterns and transition color effects. First, the pattern is printed on a transfer film with special ink, and then precisely transferred to the surface of the product through heat and pressure. It can achieve a full-wrap design covering the entire curved surface, with the pattern seamlessly integrated with an outstanding visual effect. At the same time, it can also well present colored photos and complex gradient colored logos, making it suitable for customers who pursue complex and colorful design patterns with all-round brand display.

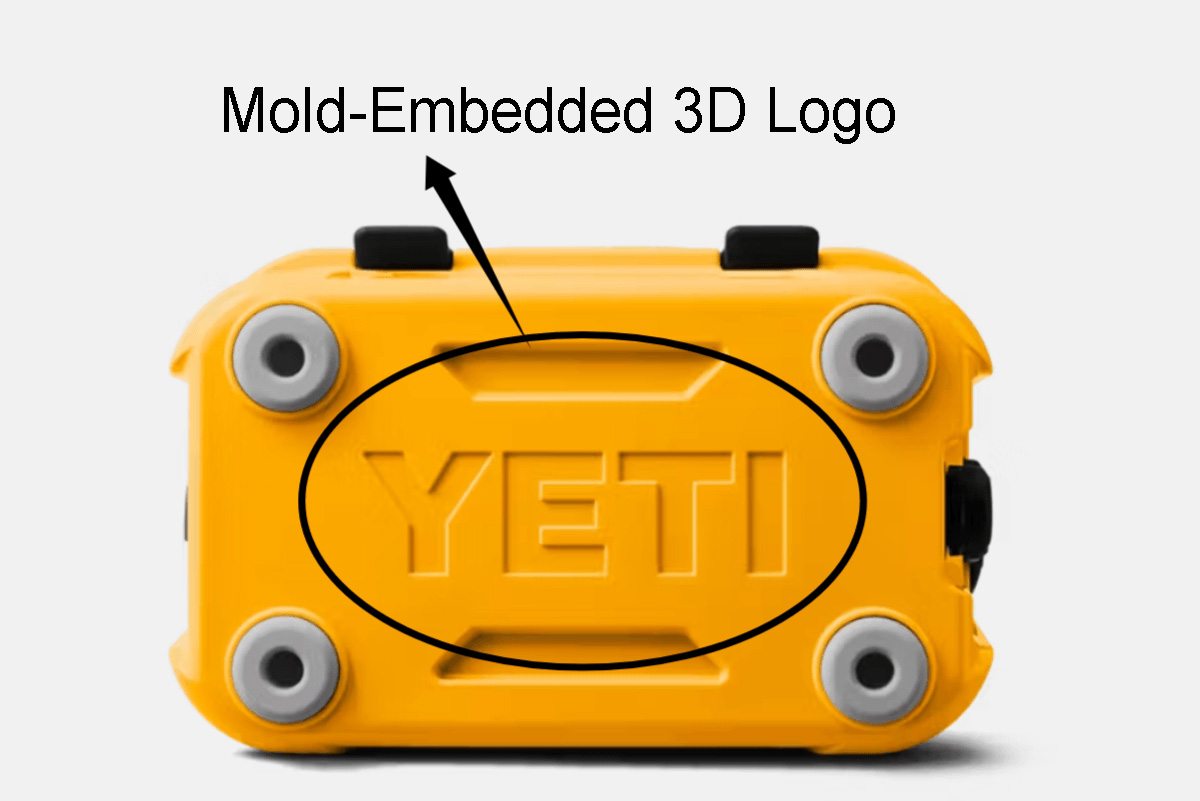

If your brand philosophy prioritizes seamless integration, structural integrity, and a minimalist aesthetic, then the In-Mold Logo process is its ultimate expression.

This technique involves precision-etching your logo directly into the tooling mold itself. During the injection molding process, molten material fills every contour of the mold, resulting in a product where the logo is formed as one continuous, monolithic piece with the cooler body. There is no added layer, no separate patch, and no applied label—just a crisp, clean impression that is intrinsically part of the product’s form.

The advantages are profound: the logo is virtually indestructible, immune to peeling, scratching, or wear because it is not an application but the very structure itself. It offers a smooth, uniform surface that is easy to clean and exceptionally tactile. This method embodies a philosophy of “inherent, enduring, and refined” branding. It is the preferred choice for brands in premium lifestyle, outdoor, and modern consumer goods sectors, where authenticity, durability, and understated design are paramount. The logo doesn’t sit on the product; it is of the product.

When standard printing techniques cannot meet your requirements for special textures, label application provides another option. We can fix pre-made metal, PVC, or ABS labels on the box through adhesive or riveting. This method is particularly suitable for presenting a metallic texture or special surface treatment effect, adding a touch of luxury to the product.

How to Choose the Best Technique of Customizing Logos for Your Ice Chests?

With so many options available, you might wonder: Which one is the most suitable for my products? Don’t worry. We can help you narrow down the best solution through the following key questions:

- Is your Logo in a single color or multiple colors? (Single-color: Silk screening or In-Mold; Full-color graphics or photographs: UV printing or heat transfer)

- Do you want the Logo to have a three-dimensional touch? (If so, consider 3D printing)

- Does your box have complex curved surfaces? (Heat transfer can perfectly wrap around the curved surfaces)

- What do you value more: ultimate durability or stunning visual effect? (For permanent integration that lasts the product’s lifetime: In-Mold; For the most vibrant, high-definition colors: UV or heat transfer printing)

Our expert team will provide the most professional process recommendations based on your specific design files, budget and expected results, ensuring your brand is presented in the best form.

| Process Name | Best Use Cases | Visual Effect | Tactile Feel | Relative Cost |

|---|---|---|---|---|

| Silk Screen Printing | Single/Few-color Logos | Color-rich & Vivid | Slightly Raised | $ |

| 3D Embossed Printing | Seeking Dimensional Feel | Strong 3D Effect | Noticeably Textured | $$ |

| UV Digital Printing | Full-color/Complex Graphics | Photorealistic & Vibrant | Smooth | $$ |

| Heat Transfer Printing | Full-wrap Surfaces/Complex Patterns | Seamless & Integrated | Smooth | $$$ |

| In-Mold | Permanent, integrated branding; premium minimalist aesthetic | Crisp, seamless, and monolithic | Smooth, with a subtle raised/depressed contour | $$$ |

| Labeling/Badging | Metallic/Special Finishes | Luxurious & High-end | Detached Badge | $$$ |

How to Start Custom Branding Your Hard Cooler?

- Select the basic model: Choose the shape, capacity, color and surface treatment (such as matte or glossy) that you like from our extensive standard ice chest/hard cooler inventory.

- Provide your logo design draft: Please provide a high-resolution vector file (such as .AI, .EPS, .JPEG, .PNG or other applicable format), which will ensure a clear and perfect printing effect.

- Confirm printing process and position: Communicate with our sales consultant to select the most suitable printing method based on your design draft and budget, and determine the specific position of the logo on the box.

- Confirm samples: Before mass production, we can provide a printed effect illustration or a physical sample to ensure everything meets your expectations.

- Start production and fast delivery: After confirmation, we will immediately arrange production and deliver your branded products to you as quickly as possible.

90L Waterproof Thermal Food Marine Medical 95.1QT Trolley Cooler Box with Wheels Unit Price: $45.60-51.11

55QT Customized Plastic Rotomolded Beverage Cooler 52L Ice Box for Outdoor Unit Price: $59.85-61.75

In an increasingly competitive market environment, a custom branded cooler box featuring your uniquely designed logo is more than a practical product, it is also a mobile brand promotion tool. Whether you are a start-up seeking a market entry point, a mature brand planning a marketing campaign or an enterprise just wanting to purchase gifts for your employees, we can provide the most suitable customized solution.

Want to create impressive coolers for your banding or business gifting? please feel free to contact us at sales@kingstarmold.com to obtain exclusive quotations and professional advice.