Overview of Large Format 3D Printing

Maximum Part Sizes for Large Format 3D Printing

| Material | Build Size | |

|---|---|---|

| Plastic | PC-Like Translucent/Clear | 29 in. x 21 in. x 25 in. / 736mm x 533mm x 635mm |

| ABS-Like Gray | ||

| ABS-Like White | ||

| ABS-Like Translucent/Clear | ||

| PA 12 | 19 in. x 19 in. x 17 in. / 482mm x 482mm x 431mm | |

| Metal | Inconel 718 | 31.5 in. x 19.7 in. x 15.7 in. / 400mm x 500mm x 800mm |

| Aluminum (AlSi10Mg) |

Large Format 3D Printer

Metal 3D Printer

For large-scale metal additive manufacturing, we utilize the Sciaky EBAM 300 Series 3D printer. This electron beam additive manufacturing (EBAM) system offers an industry-leading build envelope of 19′ x 4′ x 4′ x 8′ (L x W x H x D), making it one of the largest metal 3D printing solutions available. The Sciaky EBAM process enables high deposition rates, rapid production, and exceptional material efficiency, making it ideal for aerospace, defense, and heavy industrial applications.

Plastic 3D Printer

Stereolithography (SLA)

For large, highly detailed SLA parts, we use the 3D Systems iPro 8000. This advanced SLA printer offers a build volume of 650 x 750 x 550 mm, ensuring high-resolution, smooth surface finishes ideal for prototypes, tooling, and master patterns.

Selective Laser Sintering (SLS)

For large, durable SLS parts, we utilize the sPro 140 system, capable of producing strong, functional parts in PA 12 and other high-performance polymers. With a build volume of 550 x 550 x 750 mm, this printer is well-suited for applications in aerospace, automotive, and medical industries.

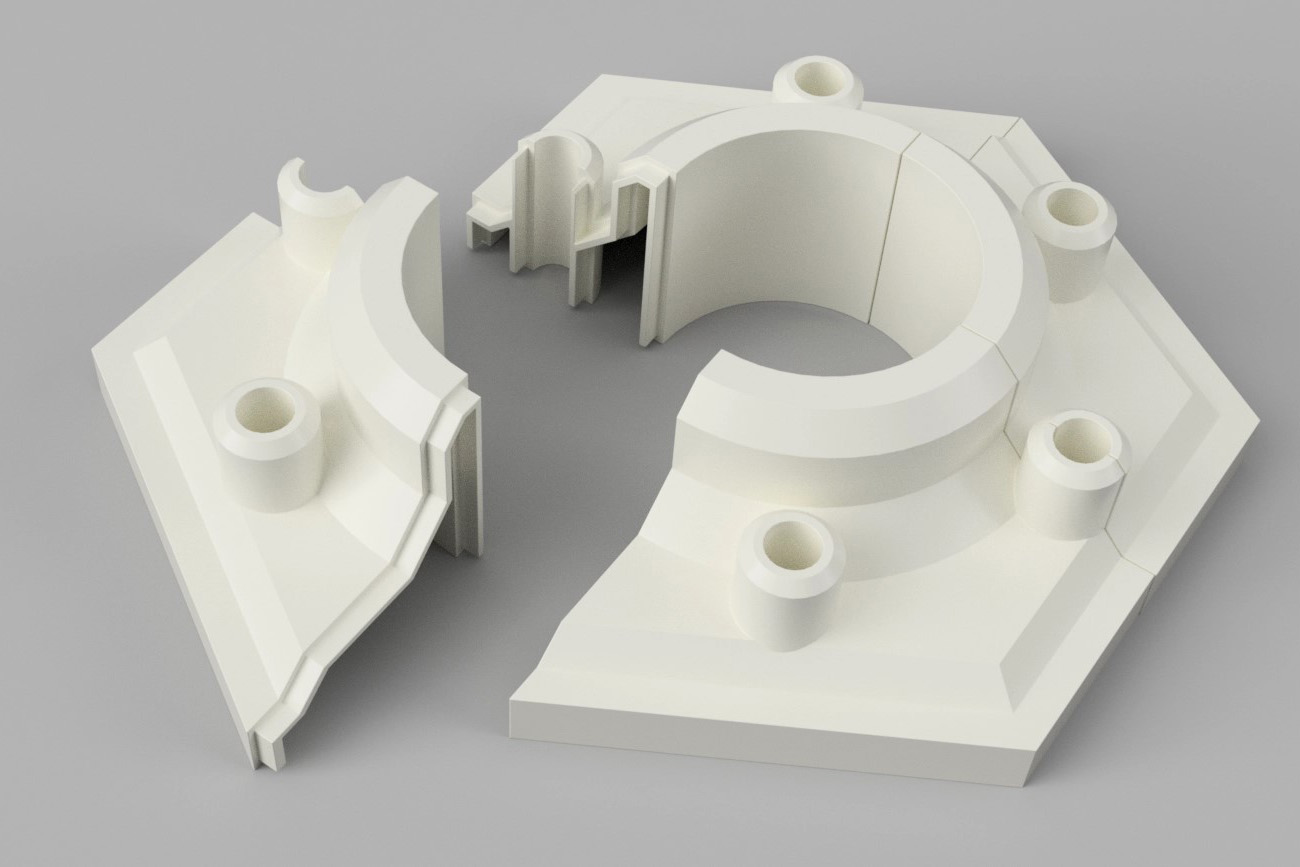

Bonding for Oversized Plastic Parts

If your design exceeds the maximum build volume of our 3D printing machines, we offer cutting and bonding solutions for SLA, SLS, and MJF parts. This process allows us to create even larger components while maintaining structural integrity.

To ensure a strong, precise cut, wall thickness must be sufficient. For large parts, we recommend a minimum wall thickness of 2.54mm (0.1″) to 3mm (0.12″), with thicker walls preferred to enhance stability and minimize warping. Robust walls not only improve the cutting process but also contribute to better overall durability.

Bonding results in visible seam lines where the sections are joined. While these seams may not be an issue for functional parts, they can be a concern for aesthetic applications. If a smooth, seamless appearance is required, we offer custom finishing services, including filling, priming, and painting. However, achieving a flawless finish on transparent parts can be particularly challenging.

Yes, large plastic parts can be cut and bonded to exceed the printer’s size limitations. Proper wall thickness and finishing techniques ensure strong and seamless joins.

Both metals and plastics can be used. Metal options include aluminum and titanium, while plastic options include PA12, ABS, and high-performance resins.

Build sizes vary by technology. For example, large-format metal printers can achieve up to 800 x 400 x 500 mm, while plastic printing depends on SLA and SLS machine capacities.

Large format 3D printing enables the production of oversized parts that exceed the capabilities of standard printers, using specialized machines for metals and plastics.

Post-processing options include sanding, machining, vapor smoothing (for plastics), and heat treatments (for metals) to achieve the desired finish.

It allows for more complex geometries and weight reduction strategies while maintaining structural integrity, making it ideal for high-performance applications.

While it is commonly used for prototyping, many industries use it for functional production parts, especially in low-volume manufacturing and tooling applications.

It enables the production of oversized components without assembly, reduces material waste compared to traditional machining, and allows for complex geometries in a single build.