Plastic products are everywhere in modern lifestyle, especially those with colorful appearance. When you see colorful bottles or ornaments, it’s likely that they’re made by two-shot injection molding technique. For those who seek for advises and help about this molding technique, this is the right passage for you.

We will go through 3 steps into this topic, starting from how these molding technique work, as well as the importance of one single type of raw material. Our team of experts with in-depth knowledge of injection molding have provided us with precautions for two shot injection molding, highlighting the importance of plastic bonding strength. Then we will go more practically, going over tips and experiences for bicolor molds, so that you will get a better understanding of how to improve your technique as well as your products’ quality and appearance, which are all guaranteed in KingStar’s production services.

1. Dual-color Injection Molding

Dual-color injection molding, also mentioned as 2K injection molding or two shot injection molding, is a plastic molding technique where two types of plastics with different colors are injected into the same mold. This technique is capable to bring dual colors to the molding products, even adds regular patterns or irregular cloud-shaped figure, enhancing both utility as well as aesthetics for the products.

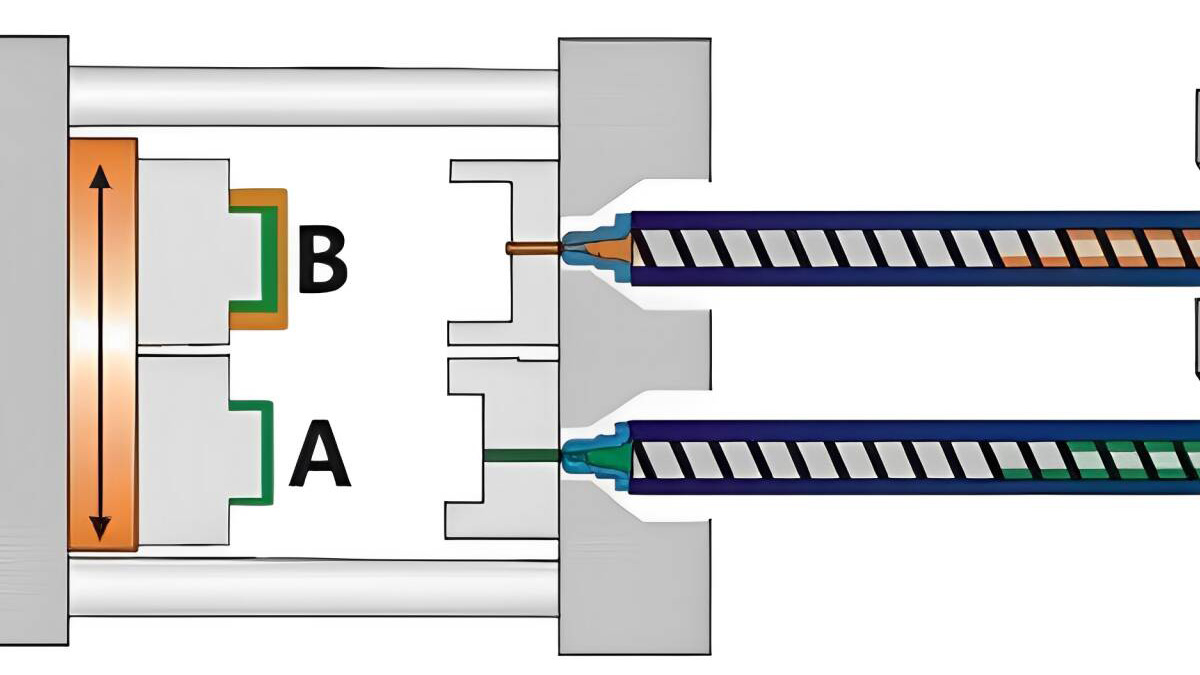

Figure 1 illustrates the core mechanism for dual-color injection molding. Two independent injection barrels operate parallelly, each functionally identical to standard injection barrels. Their melt channels connect with the nozzle assembly separately, where control valves (marked as 2 and 4) are installed. During the molding procedure, the melted plastic will flow into the nozzle after plasticizing, and inject into the mold cavity, with their flowing sequence and ratio regulated by control valves (marked as 2 and 4). When the molding process ends, plastic products with various colors blending patterns will be available.

Figure 1: Principle For Dual-color Injection Molding Technique

1—Nozzle Assembly 2—Control Valve 3—Injection Barrel 4—Control Valve 5—Injection Barrel

2. Dual-pattern Injection Molding

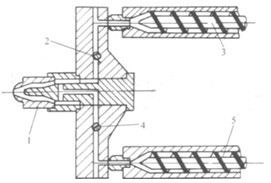

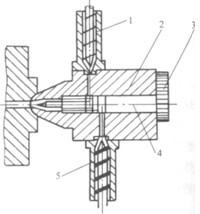

As illustrated in Figure 2, it also features two injection barrels, marked as 1 and 5. What’s special about this technique lies in the nozzle assembly. Besides its basic function as a nozzle, it can be rotated by a gear marked as 3 installed at the back.

During molding procedure, barrel marked as 1 and 5 will contain and plasticize melted plastic of different colors separately, meanwhile gear 3 will drive the rotating shaft 4 to rotate, injecting melted plastics of different colors alternately into the mold cavity. This result will result in plastic products with various colors and patterns radiating outwards from the center.

Figure 2: Principle For Dual-pattern Injection Molding Technique

1—Injection Barrel 2—Nozzle Assembly 3—Gear 4—Rotating Shaft 5—Injection Barrel

3. Cautions For Dual-color Injection Molding

It’s recommended to use the same plastic material with different colors. Given the fact that dual-color injection molding involves melted plastics from two barrels, their bonding strength must be guaranteed, otherwise mixing plastics with unqualified bonding strength could cause defections like cracks on the products. If you insist on utilizing different types of plastic material for dual-color injection molding, make sure you have tested their bond strength performance for qualification.

4. Bicolor Injection Mold

Bicolor injection mold is designed for dual-color injection molding technique, where two distinct plastic material are involved in the same molding process. It takes a two-step molding operation ,but only undergoes one demolding process.

As we mentioned above, this technique, also referred as 2K injection or two shot injection, is typically executed within a single set of molds, and necessitates the use of a dedicated dual – color injection molding machine.

Bicolor injection mold is gaining popularity increasingly in the market, given that this dual injection molding technique could improve products’ appearance and change colors without painting. However, it costs a lot and demands advanced technical expertise.

5. Tips And Cautions For Bicolor Injection Mold

1. The cavity comes in two different shapes, both are designed for one product separately, however they’re identical when it comes to the core.

2. The cavity and core must fit perfectly after a 180’ rotation around the center. This alignment check is essential during the design phase and requires high precision in the positioning and machining of the mold base.

3. The combined thickness of the cavity faceplate and the A-plate should not be less than 170mm. Carefully review other reference data of this type of injection molding machine, such as the maximum and minimum mold thicknesses and the KO holes distance.

4. An automatic demolding feature is recommended for the three plate mold’s gate. Pay extra attention to the reliability of the soft plastic gate’s demolding process.

5. When designing the cavity for a second injection, some mold clearance space can be allocated to prevent the cavity mold from scratching or damaging the molded part of the product in the first injection. However, it’s highly recommended to keep an eye on the strength of each sealing. Because there’s a potential threat that defection of excessive flash may emerge during the second injection, due to high pressure that causes the plastic to deform during the injection process.

6. During the first injection, the size of the molded product can be slightly larger so that it can fit better with the other core in the second injection, achieving a better sealing effect.

7. Be aware that during the second injection, the flow of melted plastic may displace the molded product in the first injection, causing deformation of its plastic part. If this is possible, measures must be taken to improve the situation.

8. There’s a possibility that the cavity which has a angular lifter or a slide design may reset prematurely and damage the product before the A and B plates are sealed. If so, solutions must be made to ensure that the A and B plates seal before the cavity resets.

9. The cooling water lines in both the cavity and the core should be designed to be as adequate as possible, meanwhile remain balanced and consistent.

10. In 99% of cases, the hard plastic part of the product is injected first, followed by the soft plastic part, as soft plastic is more prone to deformation.

Now you have learnt more about dual-color injection molding technique and its differences between dual-pattern injection molding, along with several expertise experience about the molding progress to improve efficiency and avoid defection. If you intend to develop further into this industry, but lacking relative experience, like designing both cost-efficient and accurate molds, KingStar, the leading custom manufacturing company, stands out as a capable partner. With advanced technology and professional expertise, we can handle all aspects of injection molding. We ensure the best quality material, precise mold design, and excellent product appearance.

Ready to turn your dual-color design ideas into reality? Let’s discuss—we’re here to make the process smooth. Please contact us at sales@kingstarmold.com.