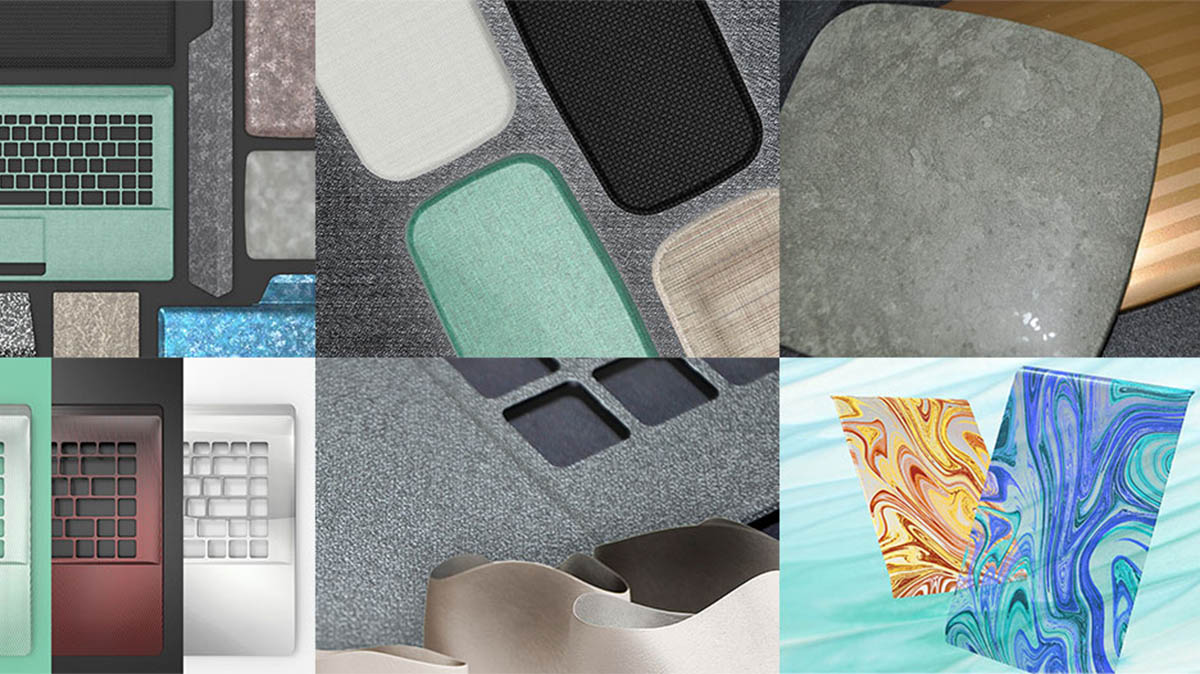

Nowadays, industries such as consumer electronics and home appliances are pursuing products that are “light, thin, and short”, and also value appearance, texture, and environmental friendliness. Traditional processes such as heat transfer printing and spray coating are no longer sufficient. The internationally popular IMD (In-Mold Decoration) technology stands out with the advantage of integrated molding, which can greatly enhance the product’s appearance and durability. KingStar, as a leading plastic injection molding company, today, we will provide a detailed introduction of the definition, classification, process, key parameters, and common solutions of IMD to help industry friends better utilize this efficient technology.

1.1 The Essence of IMD Technology

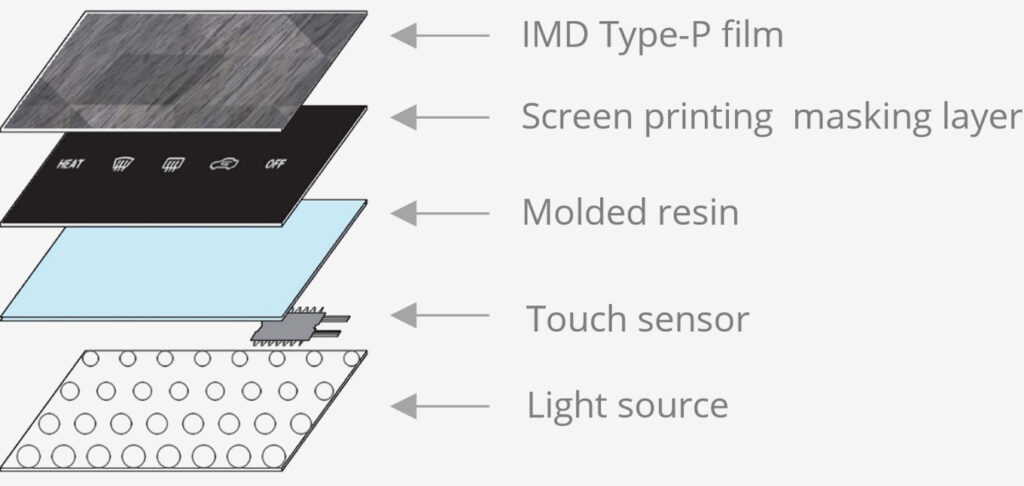

IMD is a molding method that involves placing pre printed film into a metal mold, injecting molding resin and bonding it with the film, and finally solidifying it to form an integrated product. Its structure consists of a surface hardened transparent film, a middle printed pattern layer, and a back injection molding layer. Ink is encapsulated in the middle layer, which can avoid surface scratches and abrasion, and maintain bright colors for a long time without fading, combining decoration and practicality.

1.2 Three Main Subtypes of IMD: Difference Between IML, IMF and IMR

- IML (In-Mold Label): No stretch, small curved surface, designed specifically for 2D products, suitable for flat or slightly curved decorative scenes.

- IMF (In-Mold Film): Suitable for high stretch requirements, can be used for 3D products, and can meet the decorative effects of complex surfaces.

- IMR (In-Mold Roller): After the product is formed, the surface film will be removed, leaving only the ink layer attached to the surface of the product, suitable for the demand for minimalist surface texture.

1.3 Core Advantages of IMD Process

- Excellent Surface Performance: Corrosion-resistant, wear-resistant, pattern does not peel off, and maintains bright colors for a long time.

- High Production Efficiency: Integrated molding simplifies production steps, reduces disassembly, and saves time and labor costs.

- Strong Design Flexibility: The color and pattern can be changed at any time, supporting decoration needs that are difficult to achieve with traditional techniques such as complex graphics and text, backlight effects, and imitation metal textures.

- Wide Application Range: Covering various products including mobile phones MP3, Home appliances, instruments and meters, automotive parts, LOGO nameplates etc.

2. Detailed Introduction of IMD Process Flow

The IMD process is a close coordination of the four major stages of printing, molding, die-cutting, and injection molding. Each step is independent and interrelated, and precise control of details is required to ensure product quality.

2.1 Pre-Production Process Design

- Workpiece Shape Design: Determine the basic form and surface complexity based on product usage and appearance requirements.

- Mold Design: Ensure that the mold cavity is consistent with the shape of the molding mold, and adapt to the bonding requirements of the film and resin.

- Gate Design: Clearly define the type, location, and quantity of injection ports, which directly affect the flow of resin and ink adhesion during injection molding.

2.2 Key Process Choices

Sheet Material and Ink Matching: Select sheet material type and thickness based on product requirements, paired with dedicated IMD inks (solvent-based or UV-curable):

Standard PC Sheets → Noriphan HTR series inks

Thin PC Sheets → Noriphan N2K series inks

PET Sheets → Noripet series inks

PMMA Sheets → Noricryl series inks (Bollhoff brand recommended for solvent-based)

Drying Method Selection: Choose corresponding drying equipment and processes based on the ink type (solvent-based or UV-curable).

2.3 Specific Implementation Steps

1. Film Output and Plate Making: According to the requirements of graphic design, select the appropriate screen, photoresist or film to prepare for printing.

2. Printing Operation: Mix the ink thoroughly and add diluent in proportion to adjust viscosity; Control parameters such as screen quality, scraper speed, and hardness to ensure even printing.

3. Drying Treatment (NORIPHAN® HTR N):

-Three-Stage Drying: First stage at 70 ℃, the second stage at 70-90 ℃, and the third stage at room temperature, with a conveyor belt speed of 3-7 meters per minute.

-Post-Drying: Place the printed sheet in a well ventilated oven and dry at 70-90 ℃ for 1-5 hours.

4. Film Forming: Printed sheet is processed into a shape that fits the mold using methods such as metal mold forming, vacuum forming, or high-pressure forming.

5. Precise Die-Cutting: According to the size of the molding mold and injection mold, the formed film is punched and cut to ensure perfect matching with the mold.

6. Back Injection Molding: Select the appropriate injection molding resin, set the injection molding temperature according to the characteristics of the injection molding material, inject the resin into the mold, and integrate it with the film for molding.

3. Key IMD Process Parameters and Injection Molding Precautions

3.1 Core Influencing Parameters (Over 50 types, focus on the following 12 items)

- Workpiece design, sheet selection, diluent/hardener dosage.

- Drying degree of ink, residence time between printing and injection molding.

- Injection port design, injection temperature, and selection of thermoplastic materials.

- The leveling properties, injection pressure, cycle time, and mechanical tool temperature of thermoplastic materials.

3.2 Core Precautions for Injection Molding

- The high-temperature resistance limit of ink is 250-260 ℃, and it is necessary to optimize the injection pressure, injection time, and gate design:

1) Try to shorten the pouring channel as much as possible and prioritize using hot pouring channels;

2) Increase the gate area or use multi-point gates;

3) Choose high fluidity injection molding material to reduce injection temperature and pressure. - The structure of the injection mold needs to ensure that the cavity is consistent with the shape of the molding mold, and anti impact ink can be added to the gate position (provided by PROELL).

- Avoid selecting the highest stretching position for the injection intersection point (such as the four corners, which are prone to wrinkling due to thermal expansion and contraction).

- When the first mock examination has multiple holes, the consistency of injection, pressure holding time and temperature shall be strictly controlled.

- It is recommended to use a semi clamp or fully clamp injection molding machine, combined with a mold temperature machine to control the mold temperature and avoid deformation of the film due to thermal expansion and contraction.

- Thicker parts of the product are prone to shrinkage and need to be solved through material reduction and hollowing. Traditional pressure holding and overpressure methods should not be used.

4. Common Problems and Solutions

4.1 Pattern/Ink Being Washed Away During Injection

- Main Causes: Ink drying is not transparent, residual solvents; Insufficient drying time for silver ink; The sheet is too thick; Unreasonable design of injection molding port; Improper temperature of plastic injection; The ink layer is too thin and not resistant to high temperatures; The plastic injection has not been dehumidified; Inappropriate adjustment of ink viscosity.

- Solution Directions: Extend drying time (especially for silver ink); Optimize sheet thickness and injection port design; Match high-temperature resistant ink and control printing thickness; Remove moisture from the injected plastic before injection molding; Accurately adjust ink viscosity.

4.2 Easy Separation Between Sheet and Resin

- Main Causes: residual solvents in ink; Improper control of injection molding temperature, pressure, and cooling system; The content of silver ink pigment is too high or does not match the process; Poor adhesion between ink and substrate; Unprinted water-based adhesive; Mirror ink is too close to the curved edge; Plastic contains moisture; The temperature of HTR ink does not match that of injection resin.

- Solution Directions: Ensure that the ink is completely dry; Optimize injection molding process parameters; Select ink suitable for the substrate; Add water-based adhesive; Adjust the printing position of mirror ink; dehumidify molding resin.

5. IMD Industry Applications and Development Trends

IMD technology, with its irreplaceable advantages, has been widely used by internationally renowned manufacturers such as Bayer in Germany and GE in the United States in the fields of 3C products (phone cases, instrument panels), home appliances, automotive parts, etc. With the upgrading of consumer market demand for personalized product appearance and high-end quality, IMD technology will further develop towards refinement, efficiency, and environmental protection. In the future, it has enormous potential for application in more emerging fields such as smart wearables and smart homes.

Mastering the core logic and detail control of IMD technology can help companies seize the opportunity in product appearance competition. Whether upgrading traditional manufacturing or developing emerging products, IMD technology will become an important choice for enhancing product added value.

If you encounter any other technical issue in IMD molding production, or you are sourcing a reliable custom manufacturing company, please feel free to communicate with KingStar at sales@kingstarmold.com or leave an online message at any time. We will reply to you within 24 hours.