Plastic products have been deeply integrated into production and daily life, promoting the rapid development of the injection molding industry. However, traditional injection molding processes face pain points such as difficulty in balancing thick and thin walls, parts warpage, frequent sink marks, and difficulty in cost and precision control. Gas-assisted injection molding technology, a new process developed in the 1980s and put into practical use in the 1990s, uses high-pressure nitrogen as the core medium. Through hollow forming and gas pressure holding, it breaks through the bottleneck of traditional processes and has the advantages of material saving, time-saving, cost reduction, and quality improvement. It has been widely used in multiple industries and has become a key direction for upgrading the injection molding industry.

KingStar, as a leading injection molding company, has accumulated rich experience in gas-assisted injection molding technology. In this post, we will comprehensively analyze the core values and practical applications of gas-assisted injection molding technology.

1. What is Gas-Assisted Injection Molding (GAIM)? Principles & Advantages

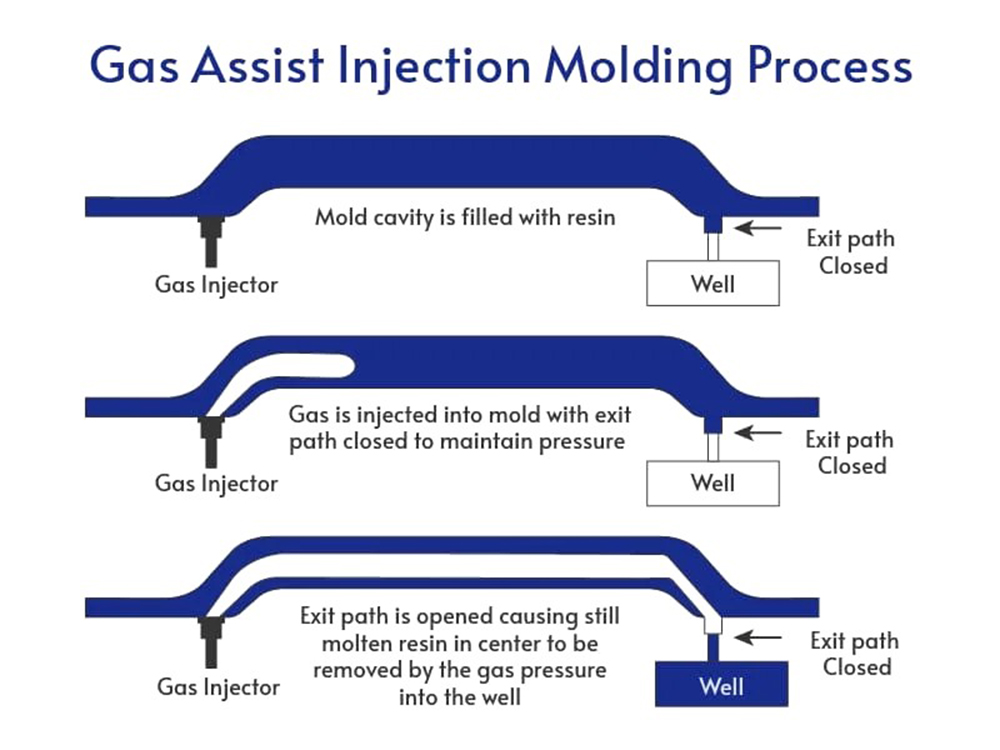

Gas-assisted injection molding is a novel plastic molding technology that introduces high-pressure gas into the thick walled part of the injection molded part. This forms a hollow section inside the injection molded part, completes the filling process, achieves gas pressure retention, and eliminates product sink marks. Traditional injection molding processes cannot balance thick and thin wall molding, resulting in high residual stress, warpage, and surface sink marks. However, gas-assisted technology successfully produces thick and deviated wall products by hollowing out the interior of the thick wall, with excellent appearance, low internal stress, lightweight and high strength.

The core advantages of this technology include:

- Material Saving & Weight Reduction: The highest raw material saving rate is 50%, and the weight of the product is significantly reduced;

- Efficient & Time-Saving: The molding cycle shortened by 30%, and the cooling time reduced by about 35%;

- Cost Optimization: Injection pressure is reduced by 60%, and large parts can be produced through small tonnage injection molding machines, extending mold life. Aluminum molds are widely applied in some scenarios to reduce equipment investment and power consumption;

- Quality Improvement: Eliminate surface sink marks, reduce internal stress and warpage, ensuring high-precision product dimensions;

- Design Flexibility: Supports stable structural designs such as thick ribs, simplifies complex processes, and reduces the need for side cores or secondary molding processing.

At present, mature core technologies have been developed, including gas-assisted product structure and mold design technology (including pouring system, gas injection method, and gas channel layout), gas-assisted injection molding process design technology, injection molding process computer simulation technology, product defect diagnosis and elimination technology, and gas-assisted process specialized material technology.

2. GAIM Applications and Material Selection

(1) Applicable Products and Industries

Gas-assisted injection molding technology is particularly suitable for pipe shaped products, thick walled products, deviated wall products (parts composed of different thickness cross-sections), and large flat structural parts. It is widely used in industries such as televisions, home appliances, automotive, furniture, daily necessities, office supplies, toys, computers, printers, health equipment, luggage, etc. Representative products include TV/audio enclosures, automotive plastic products, bathroom cabinets, refrigerator top covers, air conditioning fan panels, handles, hangers, etc, SONY, famous domestic and foreign companies such as Samsung and Haier have adopted it.

(2) Applicable Materials

Basically, all thermoplastic materials used for injection molding (reinforced or non reinforced), as well as general engineering plastics such as PPS, PES, PAI, are suitable for this technology.

3. Gas-Assisted Systems Equipment Composition and Investment Cost

(1) Core Equipment

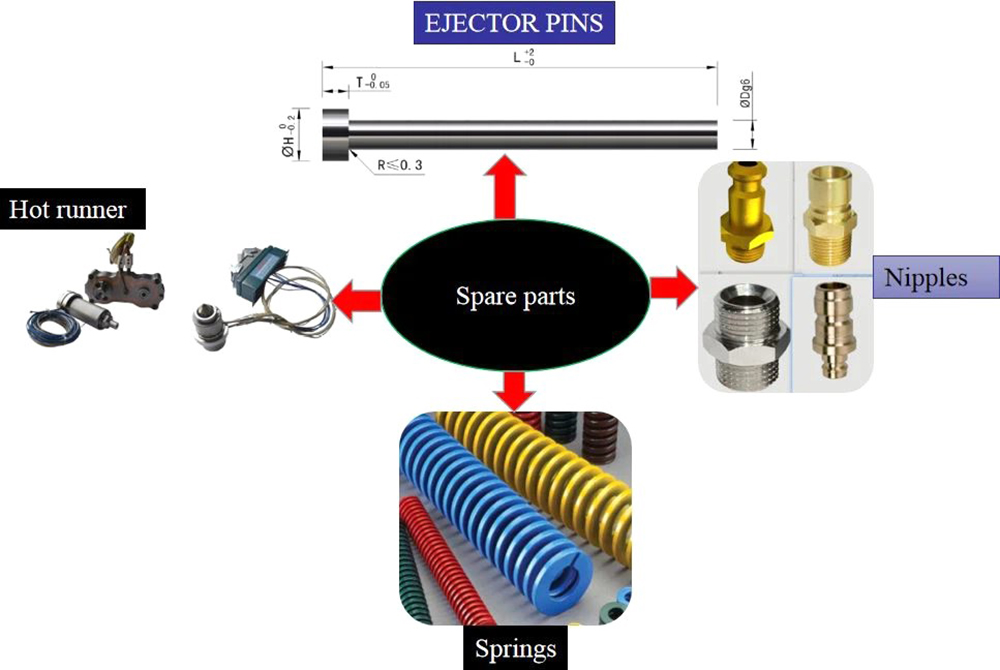

The gas-assisted device mainly includes a nitrogen generation and pressurization system, a pressure control unit, and gas injection components (gas pins). It can integrate with traditional injection molding machines. The two work together through an injection signal connection line.

(2) Equipment Parameters and Investment

- Gas Requirements: Inert gas (usually nitrogen) should be used, with a maximum pressure of 35MPa (70MPa in special cases) and a purity of ≥98%;

- Control Unit: Equipped with multiple gas channel designs, capable of controlling multiple injection molding machines simultaneously, with gas recovery function. Core control parameters are injection time (seconds) and injection pressure (MPa);

- Injection Machines Adaptation Conditions: It is required to be equipped with a slingshot nozzle (to prevent high-pressure gas from entering the screw), a screw stroke electronic ruler stroke switch (to trigger the injection signal), and be compatible with injection molding machines of different brands worldwide;

- Investment Cost: About 57640 to 288200 dollars (depending on the scale and equipment level), usually the cost of new equipment can be recovered within 6-18 months (specific economic benefits vary depending on the condition of the parts).

4. GAIM Process Control

(1) Key Parameter Control

- Injection Volume: Using the “short shot”method, inject 70%-95% of the full injection volume of the melt before injecting gas. The larger the airway section and the more consistent it is with the flow direction, the more suitable it is to use a larger short injection rate to avoid sink marks caused by too much material or blow through caused by too little material;

- Injection Speed and Holding Pressure: On the premise of ensuring that the surface of the product is defect free, try to use a higher injection speed. Gas holding pressure can replace traditional injection holding pressure. Some products require a small amount of holding pressure, but the pressure should not be too high (to avoid gas pin sealing or hindering gas penetration);

- Gas Pressure and Injection Speed: Materials with good fluidity (such as PP) should use lower injection pressure (8-10MPa), HIPS recommends 15-20MPa, ABS recommends 20-25MPa. The injection speed needs to match the mold situation. If it is too fast, it is easy to blow through or produce flow marks, while too slow leads to incomplete filling;

- Delay Time: Refers to the time period from the start of glue injection to gas injection, which needs to be reasonably controlled. If it is too short, it may cause gas divergence, while if it is too long, it is not conducive to gas penetration

(2) Computer-Aided Simulation Analysis

Through computer-aided simulation analysis, it is possible to prevent trapped gas and ensure uniform gas filling; Avoid gas damage to the surface of the finished product; Accurately predict the distribution of plastics and the filling effect of molds, and optimize the performance during the pressure holding stage.

Collapsible Storage Bins With Lids Doors and Wheels Unit Price: $4.05-5.99

Colorful Multipurpose Plastic Large Storage Bin Unit Price: $2,84-2.98

5. Gas-Assisted Mold Design

The difference between gas-assisted molds and traditional injection molds is not significant, and the core new designs include:

- Gas Channel Design: As a gas channel, it is a part of the product or a plastic position specifically designed to guide the airflow. When designing, the gas flow should be kept as consistent as possible with the flow direction to improve gas penetration and emptying rate;

- Gas Injection Component (Gas Pin): A key component, the core of which is a cylindrical body with small gaps. The size of the gaps affects the air output-if the gap is too large, it is easy to be blocked by adhesive glue, and if it is too small, the air output will be insufficient, requiring precise matching with process requirements.

6. GAIM Industry Case Studies

- TV Front Frame: Used by major home appliance manufacturers for production, saving 10% -20% of raw materials and significantly reducing mold clamping force;

- Refrigerator Top Cover: The traditional injection molding arch warpage is 1.7-2mm. With GAIM, it is controlled below 0.5mm to meet assembly requirements;

- Air Conditioner Horizontal Fan Panel: The warpage of traditional injection molding is 3-4mm, and it is reduced to within 1mm after gas assistance to avoid affecting the operation of the wind direction motor;

- Handle Products: GAIM achieves “integration into one”, omitting a set of molds and assembly processes, improving strength and aesthetics.

Gas-assisted injection molding is a new technology that has emerged in recent years and has been widely used abroad. However, it is still in its initial stage in China. Currently, large home appliance factories have started to apply this new technology. We believe that with the deepening of understanding of gas assisted technology among manufacturers, GAIM will become increasingly common. GAIM, with its core advantages of material savings, quality improvement, and cost reduction, is leading the upgrade of the injection molding industry.

If you encounter any technical issues related to gas-assisted injection molding or would like to seek a custom injection molding manufacturer / mold maker, please feel free to contact us at sales@kingstarmold.com or leave online message at any time. We have the full chain support capability for GAIM and sincerely invite partners to join hands, explore new opportunities for cooperation, and create value together.