Professionals in the 3C electronics, automotive interior, or smart home industries have most likely encountered this issue: in order to give the product a special texture (such as walnut texture), they need to integrate transparent and silk screen effects, but traditional injection molding or splicing processes either cannot achieve it at all, or the accuracy is poor and the appearance is rough. The IML (In-mold Label) process can solve these problems perfectly. From a practical application perspective, in this article, we will introduce of IML process from principle to practice.

- 1. Why Use IML (In-Mold Label) Process?

- 2. What Exactly is IML?

- 3. Complete In-Mold Label Process Flow

- 4. Advantages and Disadvantages of IML

- 5. Where Are In-Mold Label Actually Used?

- 6. What Should We Consider When Using IML?

- 7. Practical Experience Sharing, Don’t Step on These Pitfalls

- Conclusion:

- Get In Touch

1. Why Use IML (In-Mold Label) Process?

In fact, the core of choosing IML technology is to solve the problems that traditional technology cannot handle, mainly in two situations:

1) Some special effects cannot be simulated by pure injection molding. For example, the walnut wood veneer panel on a car can only produce a rough outline through injection molding, and the texture and realism are far from satisfactory. However, IML can accurately reproduce this texture.

2) Small precision parts need to integrate multiple effects. Just like the front triangle of the early MOTO V60, it requires electroplating texture, transparent area, and silk screen pattern, with particularly high precision requirements. If real electroplated parts and transparent sheets are separately injection molded and then spliced, it is not only difficult, but also prone to problems such as gaps and misalignment. IML can handle all of them in one molding process.

2. What Exactly is IML?

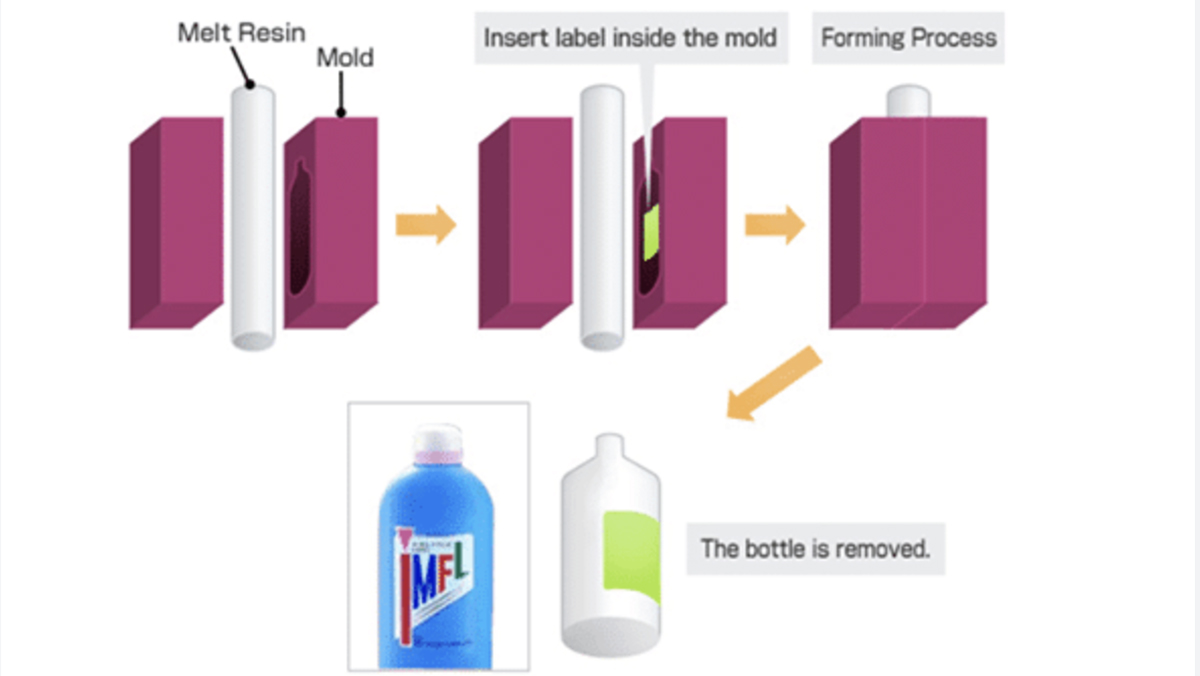

Traditional surface decoration involves first injection molding the parts and then screen printing patterns on the surface, which can easily cause scratches and color fading. And IML is exactly the opposite:

First, use specialized ink to screen print the pattern on the back of the transparent film, and then place the printed film into a plastic mold and inject molten plastic. In this way, the ink layer printed with the pattern is sandwiched between the injection molding material and the transparent film, forming a closed state – it can not only play a bonding role similar to glue, but also serve as a protective layer on the outer transparent film, so the wear resistance of IML products is particularly good.

From the outside to the inside, the material structure of IML products is very clear:

- Outer layer: PC or PET film (thickness 0.125-0.75mm), mainly used for protection and light transmission;

- Middle layer: solvent based or UV curable specialized ink, which is the pattern we see;

- Inner layer: PC, ABS, PC/ABS, PMMA, PS and other resin injection plastics, forming the main structure of the product.

3. Complete In-Mold Label Process Flow

The core advantage of IML is “one-step molding”, which integrates printing, molding, and decoration, and the steps are actually not complicated:

1) Transparent film back screen printing: The pattern is printed on the back, which can avoid wear and tear and make the visual effect more transparent;

2) Ink drying: UV ink or solvent based ink is used, and it must be thoroughly dried after printing, otherwise there will be problems during injection molding;

3) Film coating or adhesive application: Either cover with a layer of PC film for protection, or screen print with water-based adhesive to enhance the adhesion of subsequent plastic injection molding;

4) Mold forming: Press the printed film into a shape that fits the mold, preparing for injection molding;

5) Trimming: Cut off excess waste after molding to ensure a perfect match between the film and the mold;

6) Injection molding: First, dry and preheat the injection molding material, then inject it into the mold and fuse it with the film material into one;

7) Post-processing: With a simple adjustment, the product is formed.

4. Advantages and Disadvantages of IML

First, let’s talk about the advantages:

1) The molding and coating are done in one step, without the need for traditional injection molding and processing, which saves a lot of processes;

2) High flexibility, able to adjust according to needs to meet different decorative effects;

3) Strong durability: scratch resistant, chemical resistant, not easily damaged during daily use;

4) High pattern accuracy: able to achieve continuous graphic transfer, with a positional tolerance controlled below 2mm, particularly precise;

5) Large design space: can adapt to multiple materials, with rich colors, and can achieve almost all desired effects;

6) High cost-effectiveness: High quality surface effects can be achieved at a lower cost, making mass production very cost-effective;

7) Environmental Protection: The entire process does not contain harmful chemicals such as VOC solvents, which meets environmental protection requirements;

8) No need for additional auxiliary processes, the coating process can be completed in one step, saving time and manpower.

Speaking of disadvantages, not all situations are applicable:

IML can produce A-level surfaces without the flow marks of in mold coloring, but if there are many holes on the molded parts that need to be modified, its economy will be greatly reduced – the cost of subsequent hole processing is too high, so it is better to choose other processes.

5. Where Are In-Mold Label Actually Used?

- In the field of mobile phones, IML technology can simultaneously enhance the appearance and durability of mobile phones. Some people are still trying to use it on elastic materials and comfortable touch films. If successful, the feel and appearance of mobile phones can be taken to the next level;

- Automotive interior field: This is an important application scenario for IML. For example, GE Plastics’ Legacy film series uses Lexan PC and Ultem PEI as substrates, which can create velvet and suede like textures, as well as high gloss and low gloss components. It is commonly used for PRNDL (shift lever panel), HVAC (air conditioning control panel), and dashboard components. In addition, the Lextra II polycarbonate, jointly launched by GE and Fiberloc, has a fabric like appearance and soft feel. It can not only be used for mobile phones, but may also replace fabrics in car interior parts such as doors, seat armrests, and steering wheels.

6. What Should We Consider When Using IML?

Not all products are suitable for IML. Before making a decision, please think carefully about these points:

1. Injection parameters need to be matched: the ideal state is a slower injection speed and lower melt temperature, because the ink used in IML cannot withstand high shear stress under high temperature and pressure;

2. The product type should be suitable: especially suitable for small components produced in large quantities; If it is a larger component and only a small portion of the surface needs to be coated, then using IML does not have much advantage;

3. The cost of molds should be calculated clearly: molds specifically designed for IML technology have much lower costs than modifying existing molds, and a budget should be prepared in the early stages.

7. Practical Experience Sharing, Don’t Step on These Pitfalls

After making several IML products, We have summarized several practical experiences for everyone’s reference:

1) When designing a product, try to make changes to the surface as much as possible, so that the overall visual experience of the lens will be more diverse; If only the silk screen pattern changes, the finished product will appear flat and lack texture;

2) Due to the thick film covering the surface of the product, the actual product produced will have a larger arc shape than the one on the design drawing. This error should be reserved in the early design stage;

3) If you want the lens to produce a three-dimensional effect through front and back screen printing, you must communicate clearly with the manufacturer in the first place and clarify the requirements, otherwise you may need to change the mold later, which will be time-consuming and costly.

Conclusion:

IML is not actually a new technology, it has gradually become popular in personal electronic products such as mobile phones in recent years. Compared with traditional coating processes, its core advantage is cost-effectiveness – it does not require spending hundreds of millions of dollars to build a coating production line, and can achieve equivalent or even better results with IMD film. The produced components are scratch resistant and collision resistant, and do not require subsequent precision machining, saving equipment and manpower.

If you are facing any technical challenges in IML molding production, or you are looking for a reliable custom manufacturing company, please feel contact KingStar at sales@kingstarmold.com or leave online message at any time. We will get back to you within 24 hours.