In the field of precision manufacturing, the combination of metal inserts and plastic components has long been a core solution for enhancing product durability. This design not only addresses high-frequency usage scenarios involving repeated assembly/disassembly but also optimizes product frictional performance through the characteristics of metal materials. It is widely applied in industries such as home appliances, automobiles, and electronic devices. As the leading injection molding company, we have rich experience in insert molding. Now, we will delve into the core processes of insert assembly—ranging from the most commonly used molded-in plastic inserts to various press-fit inserts—clarifying design considerations, precautions, and performance differences.

- 1. Molded-In Inserts: Details Determine Success or Failure

- 2. Press-Fit Inserts: Flexible and Efficient Supplementary Solutions with Varied Process Focuses

- 2.1 Standard Cold Pressing: Low-Cost Basic Solution

- 2.2 Standard Heat Pressing: An Optimized Choice for Improving Adhesion

- 2.3 Self-Tapping Thread Inserts: Convenient Solution for Detachable Applications

- 2.4 Ultrasonic Inserts: High-Precision and Efficient Solution

- 2.5 Expansion Insert: The “Secret Weapon” of High-Strength Connections

- 3. Process Selection Guide: How to Choose Between Molded-In and Press-fit?

1. Molded-In Inserts: Details Determine Success or Failure

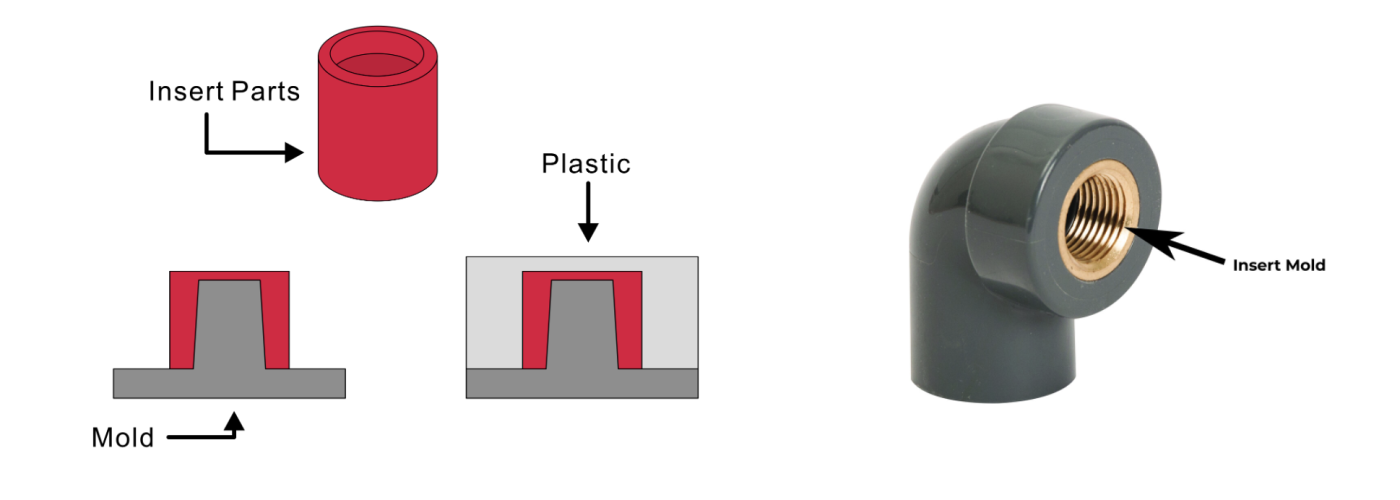

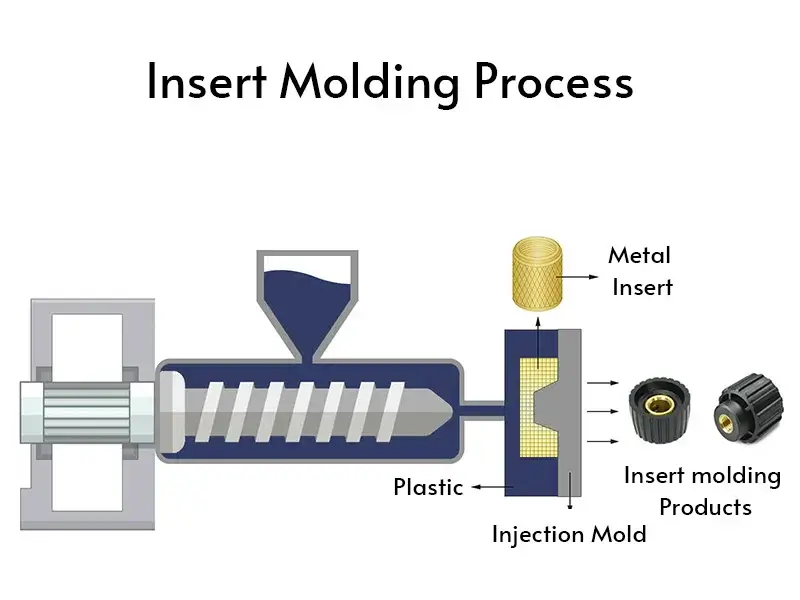

Molded-in inserts are currently the most widely used insert process, but their core logic is not complicated: metal inserts are pre fixed in designated positions on plastic molds, and then injected with plastic melt. After the melt cools and solidifies, the inserts are firmly locked in the plastic parts, forming an indivisible overall structure. The core value of this process lies in enhancing the structural strength and functional stability of the product through the complementary properties of metal and plastic.

1.1 Selection Guide for Molded-In Inserts: How to Choose Types and Materials?

The types of inserts need to be determined according to the product’s functional requirements, and common types include four categories:

(1) Threaded fasteners (such as nuts and studs), used to achieve detachable connections of the product;

(2) Strengthen the ribs and bearings to enhance the load-bearing performance and wear resistance of plastic parts;

(3) Conductive inserts provide stable conductive connection points for electronic devices;

(4) Special functional inserts, such as aluminum alloy scratch resistant strips on the panel, which balance protection and aesthetics. Among them, nuts and stud inserts are the most common in various products.

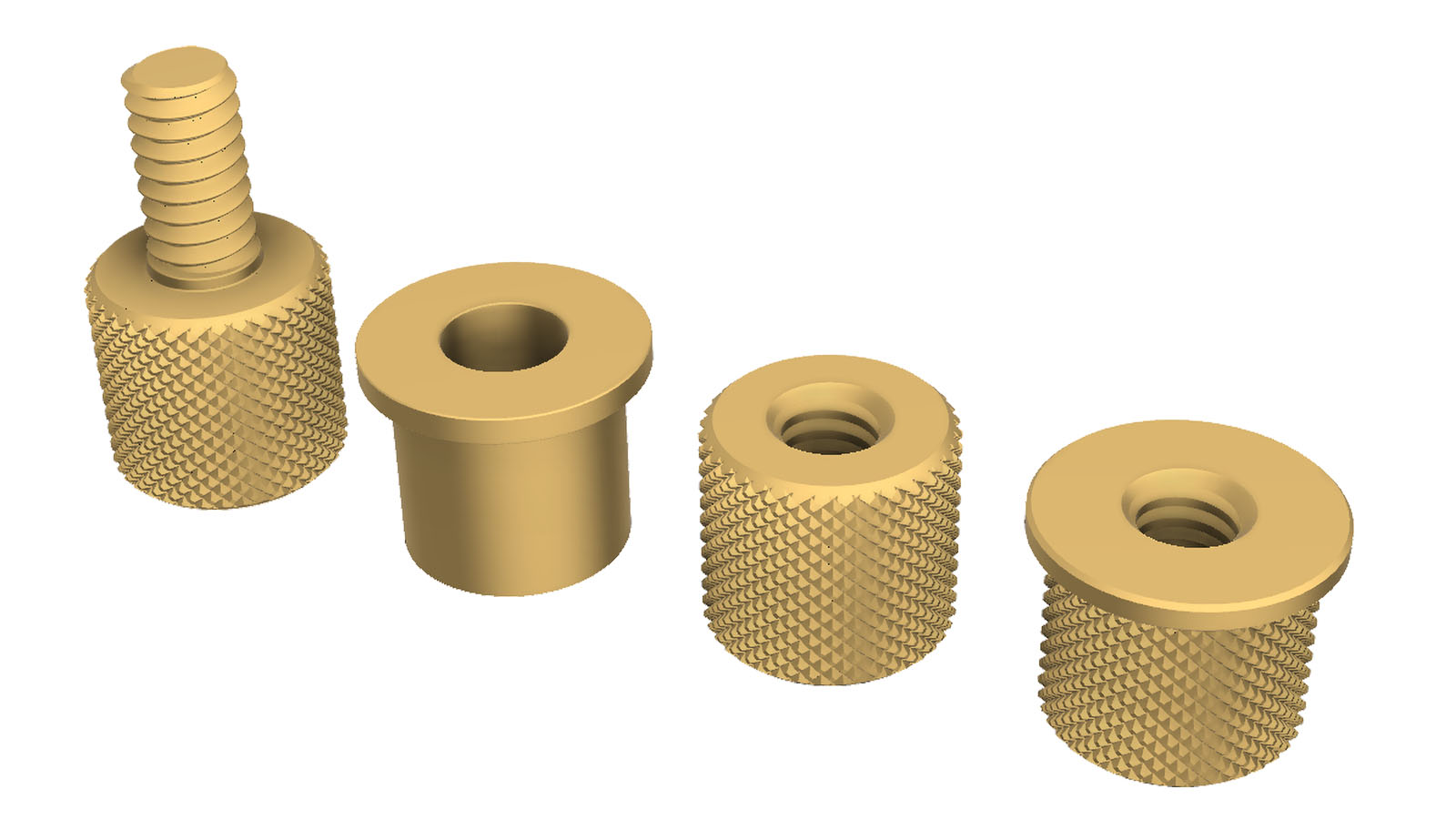

The material selection directly affects the service life and assembly stability of the inserts. From practical experience, it is preferred to use aluminum plated brass, stainless steel plated brass, or pure brass for machining inserts – brass not only has excellent corrosion resistance, but also has good machinability and can accurately match complex insert structures. From the perspective of materials engineering, the insert needs to have a certain degree of toughness in order to form a stable flow interception effect during the flow of plastic melt and avoid fracture of the insert due to excessive brittleness. When the shape of the insert is complex (such as irregular porous structure) and cannot be achieved through machining, powder metallurgy technology is a better choice, which can meet special structural requirements through mold pressing and molding.

It should be noted that molded-in inserts will significantly increase the material and processing costs of the product, so strict cost accounting is required. They should only be used when the function is necessary (such as improving connection strength) or when long-term costs are more economical (such as reducing later maintenance).

1.2 “Five Major Risk Points” That Cannot Be Ignored, Avoid Detours in Advance

Although molded-in inserts are widely used, there are many risk points in the process, and a slight lack of attention may lead to increased costs or product scrap. The core risks are concentrated in five aspects:

- Decreased Production Efficiency: Pre installation and positioning of inserts will prolong the cycle time of single molding, while frequent contact between inserts and molds will accelerate mold wear, resulting in a significant increase in mold maintenance costs. According to data from a certain household appliance company, the use of buried plastic inserts has increased the product molding cycle by 20% -30% compared to pure plastic parts.

- Risk of Scrapped Parts: During the injection molding process, issues such as missing or misplaced inserts, poor plastic filling, etc. can lead to the direct scrapping of the entire batch of parts, especially for manual pre assembly of small inserts, which has a relatively high error rate.

- Mold Damage Hazard: If the size of the insert exceeds the tolerance and the structural design is unreasonable (such as sharp edges), it may collide with the mold core during clamping, causing scratches or cracks on the mold, and the repair cost is extremely high.

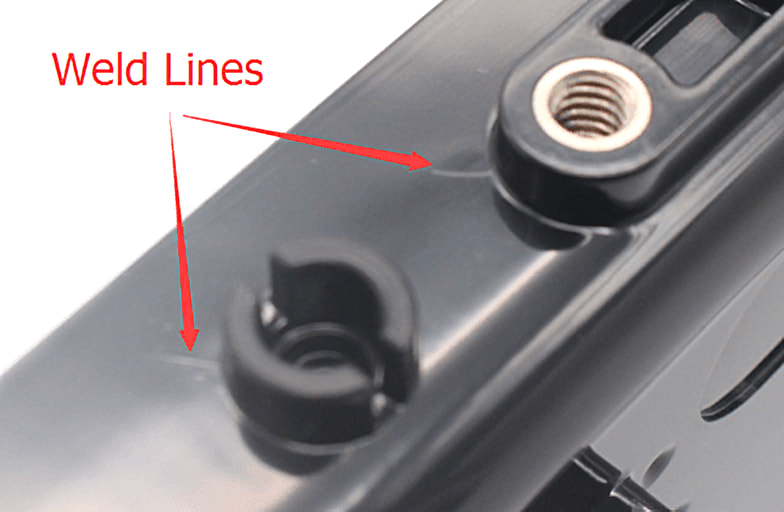

- Weld Line Issue: Plastic melt will form a shunt when flowing around the insert, and after cooling, it is easy to produce weld lines around the insert, affecting the appearance and structural strength of the product. At present, there is no absolutely effective solution, and it is necessary to rely on senior mold designers to optimize the gate position and melt flow path, in order to minimize the impact of the weld line as much as possible (detailed solutions for the weld line will be shared separately in the future, please stay tuned).

- Residual Stress Leads to Cracking: Plastic undergoes natural shrinkage after cooling, while metal inserts have almost no shrinkage. This shrinkage difference can cause residual stress at the interface between the insert and the plastic, which can lead to plastic cracking in severe cases. The key to solving this problem is to choose plastic materials with good elasticity, such as ABS, PC, etc; However, brittle materials such as PS and PMMA should be strictly avoided from use.

The design defects of molded-in inserts are often hidden in easily overlooked details, and the core needs to be related to the design specifications of the two main bodies of injection molded plastic parts and inserts.

- Plastic Part Design: The overall design difficulty is relatively low, and the core attention is to control the thickness of the plastic at the bottom of the insert – too thin thickness can lead to insufficient pressure during injection molding, resulting in defects such as short shot and sink marks; It is generally recommended that the thickness of this area be no less than 1.5mm, and it needs to be adjusted according to the flowability of the plastic material (such as thinning appropriately for PP with good flowability, and thickening for PC with poor flowability).

- Insert Design: Beyond material selection, the most crucial thing is to solve the “loosening problem” of the insert – that is, the looseness of the inserts in the axial (length direction) and radial (diameter direction) axes. The common solution in the industry is to design anti-rotation structures on the surface of the inserts, such as rolling patterns (diamond or straight), annular grooves, axial slits, etc. These structures can form mechanical interlocking with the plastic, greatly improving the stability of the connection. Taking M6 nut inserts as an example, adding a diamond pattern on the surface can increase the pulling force by more than 40%.

2. Press-Fit Inserts: Flexible and Efficient Supplementary Solutions with Varied Process Focuses

In addition to molded-in inserts, press-fit inserts are also frequently used in product design. Unlike the molding-in process, press-fit inserts are fixed by pressing the insert into a predetermined plastic hole position through external force after the plastic part is formed. This process does not require modification of the injection mold and has higher flexibility. According to the different pressure methods and insert structures, it can be divided into five categories:

2.1 Standard Cold Pressing: Low-Cost Basic Solution

The core principle is to use tools such as compression machines and pliers to forcefully press the insert into the plastic hole position, and form an interference fit with the insert through slight deformation of the plastic hole. The advantages are simple equipment and low cost; The disadvantage is that the compressive force is difficult to accurately control, which can easily lead to plastic hole cracking. It is suitable for low precision, non stress parts of insert assembly, such as connection inserts for small toys.

2.2 Standard Heat Pressing: An Optimized Choice for Improving Adhesion

The difference from cold pressing is that the insert is preheated (usually heated to 80-120 ℃) before pressing. When the insert is pressed, the plastic in the contact area will soften locally. After cooling, the plastic shrinks and forms a tighter bond with the insert. This process can reduce plastic stress during the compression process, lower the risk of cracking, and is suitable for medium-to-high strength plastic materials such as PC and ABS. It is commonly used in threaded insert assembly of home appliance control panels.

2.3 Self-Tapping Thread Inserts: Convenient Solution for Detachable Applications

The external surface of the insert is designed as a self-tapping thread structure, and there is no need to pre-machineed precise hole positions during assembly. Simply “screw” the insert into a pre-formed plastic hole like a screw, and the thread will automatically cut the plastic to form a fit. The advantage is that it is easy to assemble and can be disassembled repeatedly, but the disadvantage is that it requires high plastic strength (ABS, POM and other materials need to be selected), otherwise it is prone to thread slippage. Widely used in lightweight products such as phone stands and laptop cases.

2.4 Ultrasonic Inserts: High-Precision and Efficient Solution

The high-frequency vibration (20-40kHz) generated by ultrasonic equipment is used to rapidly heat up the contact area between the insert and the plastic. After the plastic softens, the insert can be inserted under slight pressure. After the vibration stops, the plastic quickly cools and solidifies. The advantage of this process lies in its short pressing time (usually only 2-5 seconds), precise positioning, and no significant plastic stress. It is suitable for the insert assembly of precision electronic components (such as connectors and sensors) and can effectively protect sensitive structures inside the product.

2.5 Expansion Insert: The “Secret Weapon” of High-Strength Connections

The structural principle is similar to that of expansion screws. The insert is equipped with an elastic expansion mechanism inside. After being pressed into the plastic hole, the expansion structure is triggered by a tool, which increases the outer diameter of the embedded part and forms a strong mechanical lock with the plastic hole. The tensile and torsional strength of this type of insert far exceeds that of ordinary press-fit inserts, making it suitable for scenarios with high stress, such as fixed brackets for automotive interiors and installation bases for industrial equipment.

3. Process Selection Guide: How to Choose Between Molded-In and Press-fit?

There is no absolute superiority or inferiority between the two embedding processes, and a comprehensive judgment should be made based on product requirements. The core reference dimensions are as follows:

| Evaluation Aspects | Molded-In Inserts | Press-Fit Inserts |

|---|---|---|

| Connection Strength | High (plastic and insert fuse integrally) | Medium to High (relies on interference fit or mechanical locking) |

| Production Efficiency | Low (requires pre-placement, extends molding cycle) | High (enables batch, rapid pressing) |

| Mold Cost | High (mold modification needed for insert positioning) | Low (no modifications to plastic mold required) |

| Applicable Scenarios | High strength, high precision, high-volume production | Low-volume, multiple specifications, detachable connections |

The essence of insert assembly design is to achieve performance matching between metal and plastic, and match the process with the required scenarios. Whether it is the optimization of molds and material selection for molded-in inserts, or the process selection and structural design for press-fit inserts, they all need to revolve around the core goals of “firm connection, controllable cost, and efficient production”.

The art of insert assembly lies in precisely balancing structural integrity, manufacturing efficiency, and total cost. At KingStar, we don’t just supply parts; we are your dedicated manufacturing partner, leveraging this expertise to ensure your product’s success. Reach out to our team at sales@kingstarmold.com to begin the conversation.