Comprehensive Manufacturing Solutions for Diverse Industries

“Manufacturing is the engine of innovation, turning ideas into reality, creating jobs, and driving economic growth. It’s about precision, craftsmanship, and the continuous pursuit of excellence.”

Henry Ford

Industries We Serve

We use non-toxic, child-safe materials and conduct thorough testing to meet safety regulations. KingStar Mold is committed to producing safe, durable, and reliable baby products such as bottles, pacifiers, and high chairs.

Absolutely. KingStar Mold specializes in low-volume production runs, allowing businesses to test new products or enter new markets without committing to large production quantities upfront.

We manufacture mounting brackets, junction boxes, wiring clips, frame components, electrical connectors, glass holders, cable trays, protective covers, enclosures, and support structures for solar panels.

We offer rapid prototyping services that allow companies to test designs and functionalities quickly. This helps reduce lead times and provides valuable feedback before moving to full-scale production.

Yes, we work closely with clients to create custom furniture components such as chair frames, table legs, drawer slides, cabinet handles, and more, tailored to their specific design and functional requirements.

We use high-quality, food-safe plastic materials such as polypropylene (PP), polystyrene (PS), and polyethylene (PE) to manufacture forks, knives, spoons, plates, and other plastic cutlery products.

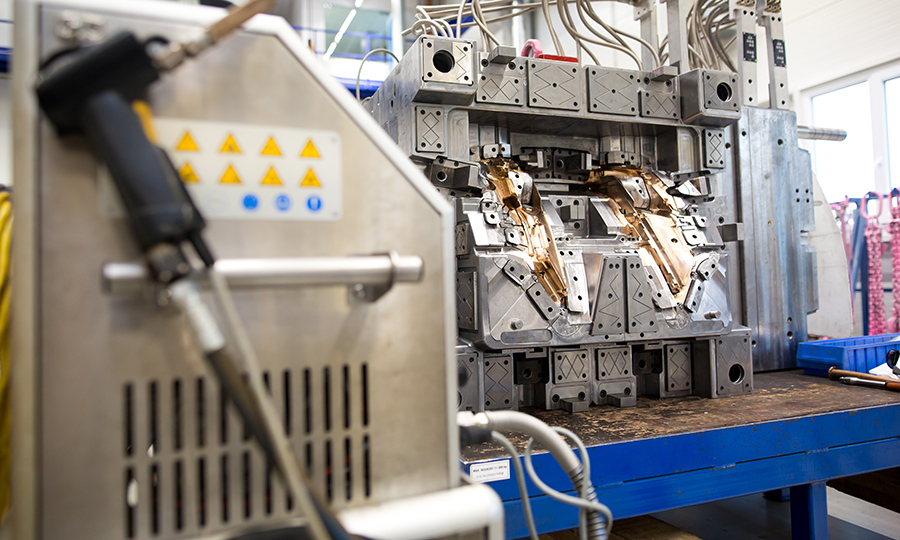

KingStar Mold uses state-of-the-art equipment, strict quality control procedures, and a skilled workforce to ensure that every part meets the highest standards of precision and durability.

We manufacture dashboard components, interior trim pieces, engine covers, grilles, bumpers, door panels, air vents, wheel covers, mirror housings, and plastic clips and fasteners.

At KingStar Mold, we provide precision manufacturing services across a wide range of industries, including automotive, furniture, household goods, solar panels, pet products, plastic cutlery, plastic baskets, plastic POS displays, baby products, and more.

Yes, we offer customization options for solar panel components like mounting brackets, junction boxes, and enclosures. Whether it’s specific dimensions, finishes, or features, we can tailor the designs to meet the unique requirements of your solar panel system.

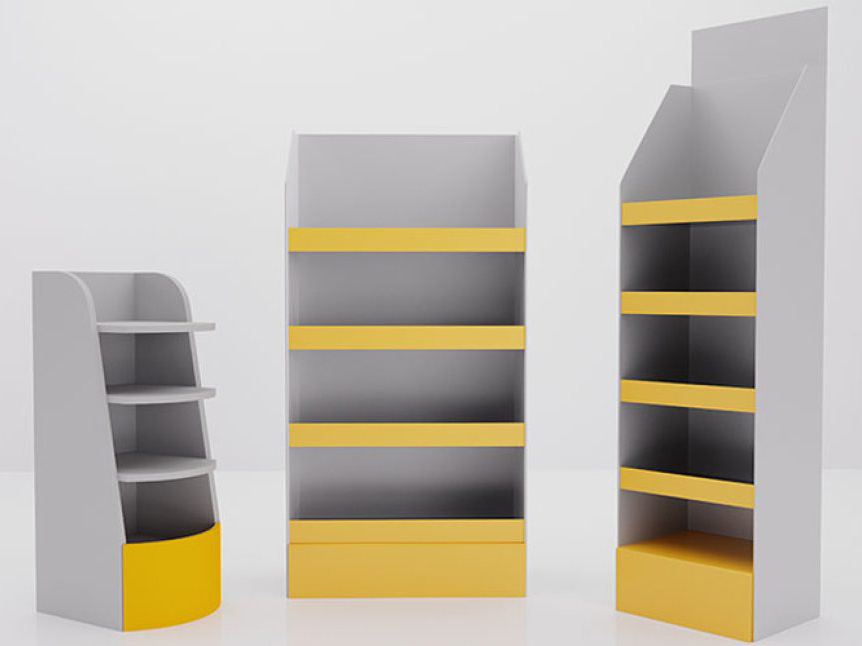

We use stringent quality control procedures for all plastic POS displays. This includes visual inspections, dimensional checks, and functional testing to ensure that each product meets the required standards for durability and functionality.

KingStar Mold uses high-quality, durable plastics designed for longevity, whether it’s for pet toys, carriers, or grooming tools. We test each product rigorously to ensure it can withstand wear and tear from everyday use.

Yes, KingStar Mold specializes in creating precision tooling for furniture components. Our advanced equipment and expertise allow us to produce complex molds for parts like chair frames, recliner mechanisms, and adjustable brackets with high precision.

Lead times vary depending on the complexity of the parts and order volume. Typically, our lead times for automotive parts range from a few weeks for prototyping to several months for large-scale production, with expedited options available for urgent needs.

Yes, KingStar Mold offers design assistance, including prototyping and CAD services, to help customers refine their product concepts before manufacturing. We collaborate closely to ensure the final product meets both functional and aesthetic requirements.

We prioritize the use of recyclable materials and work towards minimizing waste during production. KingStar Mold is also exploring eco-friendly alternatives to conventional plastics in order to reduce environmental impact.

KingStar Mold is distinguished by our commitment to precision, quality, and customer collaboration. Our ability to work across various industries and our expertise in handling complex manufacturing challenges set us apart in the marketplace.

We manufacture various types of plastic baskets, including storage baskets, laundry baskets, fruit baskets, collapsible baskets, hanging baskets, and more for diverse consumer and industrial uses.