In today’s manufacturing environment that pursues exquisite product appearance, durability, and environmental protection, In-Mold Decoration technology has become a key innovation in the field of surface treatment. To help you fully understand this technology, At KingStar, a leading injection molding manufacturer, we hereby provide a detailed comprehensive explanation of IMD and IML injection molding processes. This document covers technical definitions, process flow, design points, comparative analysis, testing standards, and industry applications, aiming to provide practical technical references.

1. What is IMD?

IMD’s English name is In-Mold Decoration. IMD is a popular surface decoration technology internationally, which includes a surface-hardened transparent film, a middle printed pattern layer, a back-injection plastic layer, and an oil IN MOLDING LABEL ink middle. It can prevent scratches and wear on the surface of the product, and can maintain a bright color for a long time without fading easily.

IMD includes IML, IMF and IMR;

- IML: No stretch, small curved surface, used for 2D products.

- IMF: IN MOLDING FILMS, suitable for high stretch products, 3D products.

- IMR: IN MOLDING ROLLERS, the surface film on the product is removed, leaving only screen printing ink on the product surface.

The difference between IML, IMF, and IMR (whether a film layer is remains on the product surface).

Traditional plastic processing technology is gradually unable to meet the needs of the new era. With the rise of lightweight, thin, and compact consumer electronic products and environmental awareness, IMD technology has emerged on this basis. Due to the advantages of IMD, it is suitable for plastic products in 3C, home appliances, logo boards, and automotive parts, especially for popular mobile phone cases and various instrument panels. Advanced manufacturers around the world, such as Bayer from Germany and GE from the United States, are fully developing this process.

IMD (In Mold Decoration) is a relatively new automated production process that can reduce production steps and disassembly components compared to other processes. Therefore, it can quickly produce and save time and costs. At the same time, it also has the advantages of increasing image complexity, improving quality, and improving product durability. Applied to product appearance, IMD is currently the most effective method. It involves printing, high-pressure molding, die-cutting, and finally combining with plastic in-mold, eliminating secondary work procedures and human labor hours, especially in situations where backlighting, multi curved surfaces, metal imitation, hair line processing, logical light patterns, and rib interference are generally required. When the printing and painting process cannot handle it, it is even more appropriate to use the IMD process.

IMD (In Mold Decoration) can replace many traditional processes such as heat transfer printing, spray coating, printing, electroplating, and other appearance decoration methods. Especially when multiple color images, backlighting, and other related products are needed. The second meaning of IMD (sweet tones). It is in intermodulation distortion (using swept signals), unit is %, the smaller the better, the ideal value is 0.

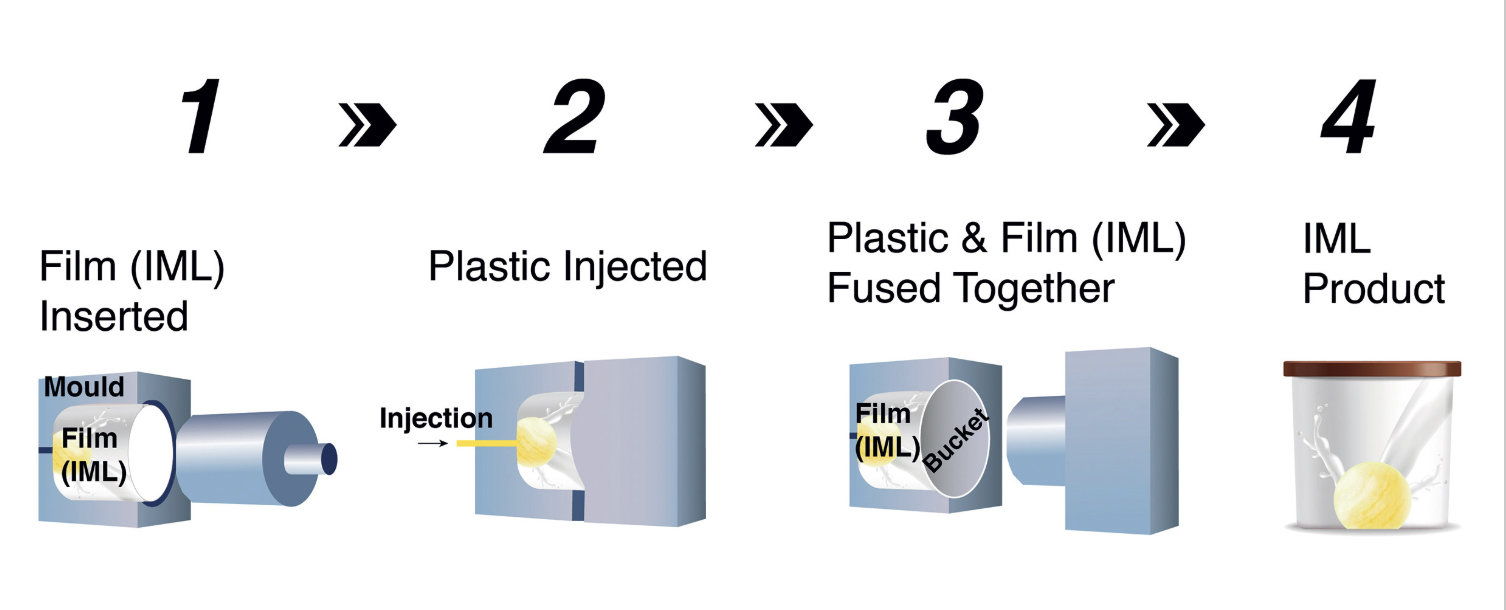

2. What is the Process of IML?

This article mainly introduces the principle and process of IML molding, and compares and analyzes IML and IMD processes, summarizing the advantages and disadvantages of IML process. The information is collected and organized online for your reference.

2.1 The Concept of In-Mold Labeling

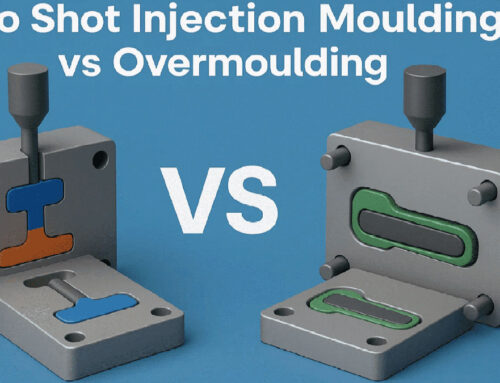

IMD (In Mold Decoration) is a new technology that places a film inside the injection molds to decorate the surface of plastic. Currently, there are two manufacturing methods for IMD. One is to make the printed Film into a circulating roller shaped belt, which is installed in the injection molding machine and mold, and the label is attached to the front mold surface for fully automatic circulating belt mobile production; It is known as IMD (In Mold Transfer Injection Molding).

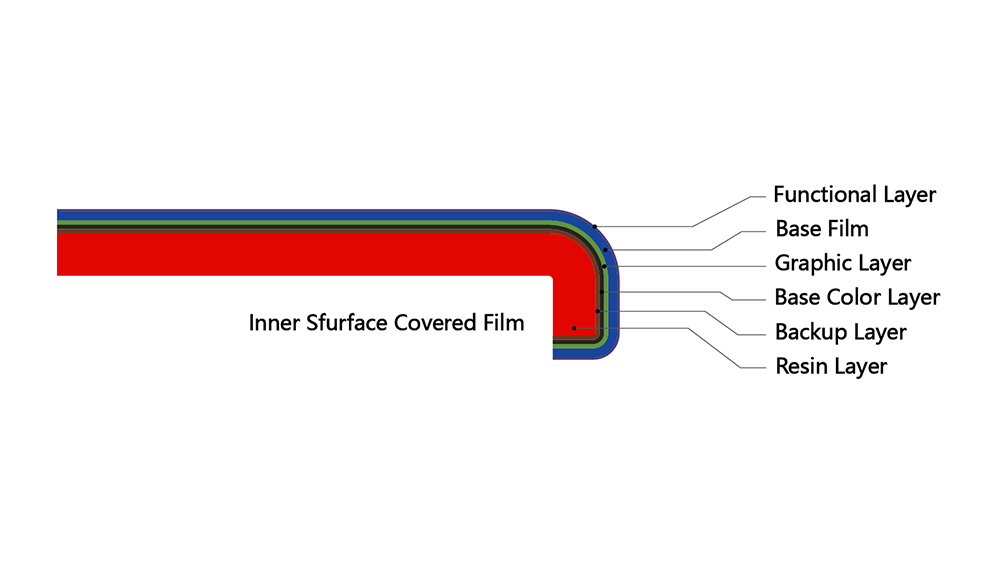

The other is to print the film and form it using a molding machine, then cut it and place it in an injection mold to produce it. It is called IML (film injection molding inside the mold). This film can generally be divided into three layers: ink layer (INK), substrate (usually PET), and bonding material (usually a special type of adhesive).

After injection molding is completed, the film and plastic are tightly bonded and integrated through the adhesive. Due to the fact that the PET coated with wear-resistant protective film on its front surface is on the outermost layer, it has wear-resistant and scratch resistant properties, and its surface hardness could reach 3H, and it will become brighter with touch. Injection molding materials are mainly PC, PBT, PMMA, etc.

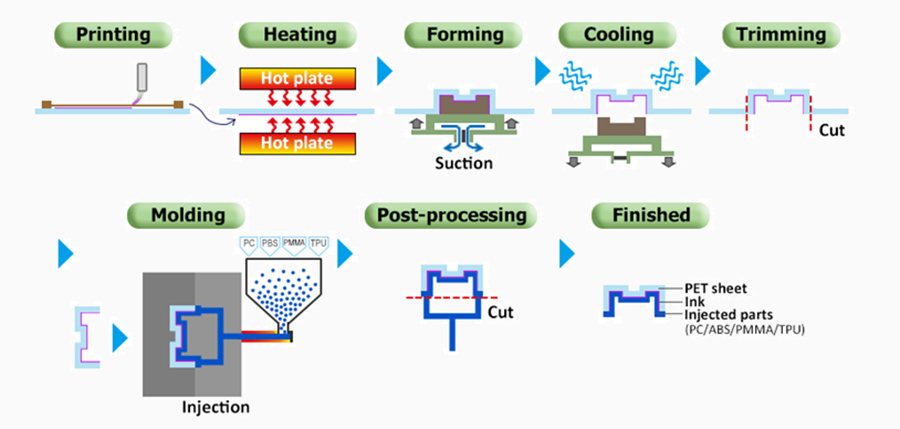

2.2 IML Process Procedures

Material Cutting – Flat printing – Ink drying and fixation – Applying protective film – Positioning Punching holes – Thermoforming – Cutting peripheral shape – Material injection molding

Specific instructions are as follows:

1) Material Cutting: Cut the roll shaped film into square pieces of the designed size for printing and molding processes.

2) Flat printing: Produce a film mesh according to the required icons and text, and print the icons and text on the cut square blocks of the film.

3) Ink drying and fixation: Place the printed film square in a high-temperature oven to dry, with the aim of fixing the IML ink.

4) Applying protective film: To avoid scratching the surface of the already printed film during the punching and positioning process, it is sometimes necessary to apply a single or double layer protective film.

5) Positioning Punching holes: Thermoforming positioning holes should be punched precisely. Positioning holes for the cutting process shall be punched in advance.

6) Thermoforming (high-pressure or copper mold): After heating the printed film, it is formed using a high-pressure machine or copper mold in a preheated state.

7) Cutting peripheral shape: Cutting off the waste of the formed 3D film.

8) Material injection: Put the film with the same solid shape as the front mold after molding on the front mold to inject the IML finished product.

2.3 Advantages and Disadvantages of IML Process

Advantages:

1) Short film production cycle, capable of displaying multiple colors;

2) The pattern and color can be changed at any time during production;

3) The outermost layer of IML is FILM, with screen printing ink printed on the middle layer. The surface is smooth and beautiful, and the more you touch it, the brighter it becomes. It has excellent scratch resistance;

4) IML production batch quantity is very flexible, suitable for small-scale production of multiple varieties

Disadvantages:

1) Long lead time in the initial phase.

2) Easy to cause film detachment, warping and deformation;

3) The product defect rate is high.

2.4 In-Mold Labeling Design Considerations

1) Injection Wall thickness: It is recommended that the average wall thickness be no less than 1.2 mm (excluding film, which is 1.0 mm).

2) Film thickness specifications are: 0.1 mm, 0.125 mm, 0.175 mm.

3) Film single sheet printing, more suitable for small and diverse design occasions.

4) Colors with a metallic appearance such as bright silver or electroplated silver are not suitable for this method, as they can easily cause the film to peel off due to high and low temperatures.

5) The dimension of the outer edge of the film is absolutely related to the dimension of the mold cavity. If it is too small or too large, it will cause the mold cavity to shoot and stretch, resulting in edge leakage.

6) The minimum diameter of the round hole on the Lens is Φ 1.0 mm.

7) The position of Lens Parting Line (P.L.) is generally at the bottom of the Lens. If there is a problem with the draft angle, it can be located 0.2 mm below the edge of the Film coating.

8) The draft angle of Lens is generally 3°.

9) For the situation where there is a height difference in the appearance of the Lens, the Film must form the appearance in advance.

10) Fillet design: The appearance of IML forming cannot create a sharp shape, and the contour of the appearance should avoid sharp angles. Therefore, sharp angles are not allowed in the design, and there must be a fillet (at least 0.3R) at the corner of the product.

11) Edge wrapping issue: Edge wrapping refers to the area where the film is bonded to the plastic at the edge. This edge cannot be very neat after injection molding, so when designing products by using IML, we could use plastic parts to block the edge wrapping.

12) Surface erosion resistance hardness: It should be above 3H.

2.5 Comparison of Characteristics Between IML and IMD

(1) IMD is suitable for large batches (100k units or more); IML production batch size is very flexible.

(2) IMD pattern 3D forming height not exceeding 1.5mm; IML can process various complex 3D productions, such as flat, curved, and edge wrapped products, with a 3D pattern forming height of up to 40MM.

(3) IMD products have screen printing ink printed on the surface, so the font is not easily touched off; IML ink is printed on the middle layer, so the appearance is smooth and beautiful, and the more you touch it, the brighter it becomes. It has excellent scratch resistance and can change the pattern and color at any time during production.

(4) IMD can only use a screen printing process similar to hot stamping foil, and its screen color cannot be changed; The ink color of IML has no limit, and the screen printing color can be freely changed in the same batch of production.

IML’s sheet materials are divided into PET, PC, and PMMA, and the materials can be divided into:

A. Transparent: sandblasted surface, silver dots, color, etc.

B. Electroplating.

C. Artificial leather, fur.

(5) IMD 5 is unable to make press buttons; IML can be produce products with buttons;

(6) IML has a short overall development time (while developing injection molds, it can also develop molds for molding, punching, and other auxiliary processes); Several parts can be produced together, so the cost is relatively reduced; Due to the absence of a check mark, products with relatively thin thickness can be produced.

2.6 IML Application Fields

At present, IML has a wide range of applications, currently used in the mobile phones and white goods industries, and will develop into anti-counterfeiting labels and the automotive industry in the future. Its products have good sun resistance and can be used for signs on cars, etc; Hardness can reach 2H~3H, suitable for use in mobile phone lenses, etc; The lifespan of the buttons can reach more than 5 million times and can be used for rice cookers, etc.

2.7 IML Product Testing and Inspection

IML products have passed the following tests and meet the requirements.

1. Hardness test: Use a ground 2H~3H pencil with a force of 500g and push it flat towards the surface of the product at a 45 degree angle. If there are no obvious scratches or marks on the surface, it is considered qualified.

2. Temperature test: Place the product in a furnace with a relative humidity of 95%~100% and a temperature of 57 ± 3 ℃ for 48 hours. If there are no phenomena such as cracking, discoloration, deformation, color fading, or loss of function qualities, it is considered qualified.

3. Wear resistance test: Align the rubber with the surface of the product and attach a weight of 500g. Rub back and forth 300 times (one back and forth is considered one cycle) at the same position for a length of 2 inches. If there is no obvious bottom visible on the surface, it is considered qualified.

4. Sand Erosion test: The fixed test coating is placed at a 45 degree angle on the abrasion instrument, and the coating surface is flushed with the specified sand amount and flow rate (2 liters/21-23.5 seconds) according to the product reliability specifications. The material under the paint can be seen as severe after flushing to 500ml of sand particles, and slight after flushing to 100ml of sand particles; Minor defects exceeding 20% of the total number of samples are considered unqualified, while major defects exceeding the total number of samples are considered unqualified.

3. IMD/IML Process for Mobile Phone Case Lenses

3.1 Characteristics of IML Process

IMD/IML products are widely used in 3D shaped appearance products such as mobile phone lenses and casings due to their high clarity, good stereoscopic effect, scratch resistance on the surface, the ability to freely change design patterns, enhanced product aesthetics, and the ability to reflect perfect shaped structures. Solve the problem of irregular effects and multiple colors that acrylic sheets cannot achieve in the past.

3.2 IMD/IML Technology

It is a new type in-mold decoration technology that combines molding, screen printing, and injection molding. In decorating a product, IMD/IML is the one of the most cost-effective method, widely applied in communication products (e.g., mobile phone/PHS lenses, decorative parts, casings, etc.), home appliances (window panels, decorative panels, button panels, etc.), medical equipment (window lenses, decorative parts, casings, etc.), and automotive dashboards. Diversified applications have made IMD/IML an ideal replacement for many traditional processes, such as heat transfer printing, surface direct printing, direct electroplating, surface spraying, two-color injection molding, and other traditional decoration methods. It is most suitable for 3D products, especially those that require consistent color matching patterns, backlighting, multiple colors, and should be reflected on various surfaces, curves, and slopes.

3.3 Advantages of IMD/IML Products

1. Scratch-resistant, corrosion-resistant, and have a long service life.

2. Good sense of three-dimensionality.

3. Strong ability to prevent dust, moisture, and deformation.

4. Colors and patterns can be changed freely.

3.4 Key Features

1. The entire manufacturing process, from sheet printing and forming, mold design and production to injection molding and replication, is completed internally by our company;

2. Minimize research and development time to ensure on-time supply;

3. Flexible design to quickly achieve product diversification at a lower cost;

4. No need for panel pasting, does not contain any adhesive, meets environmental protection requirements;

5. The button can achieve protrusion during in mold injection molding, and the button life can be pressed 1 million cycles; Realize high-precision decoration of 3D surfaces, with hidden decorative patterns that never wear out (unless damaged);

6. Higher scratch resistance and transparency, easily achieving permanent clear display;

7. Highly integrated, saving subsequent assembly processes, fast assembly, and improving qualification rates;

8. 3D molding enables complex components to achieve high-level decoration;

9. Provide end-users with more beauty, lightness, solidity, choices, and safety. Application areas: Widely used in various products, such as home appliances, computers and peripheral products, mobile communication terminal products, automotive industry, etc.

3.5 Advantages of In-Mold Labeling

1. Product stability: Ensure consistency and standardization of correct color matching for the product.

2. Product durability: With the protection of specially treated COATING film, the product can provide better surface wear resistance and chemical resistance.

3. 3D Complex Shape Design: By utilizing the excellent stretchability of thin films, the required product complexity can be smoothly achieved through external design requirements.

4. Diversified styles: Create metal plating or natural material special styles according to customer needs.

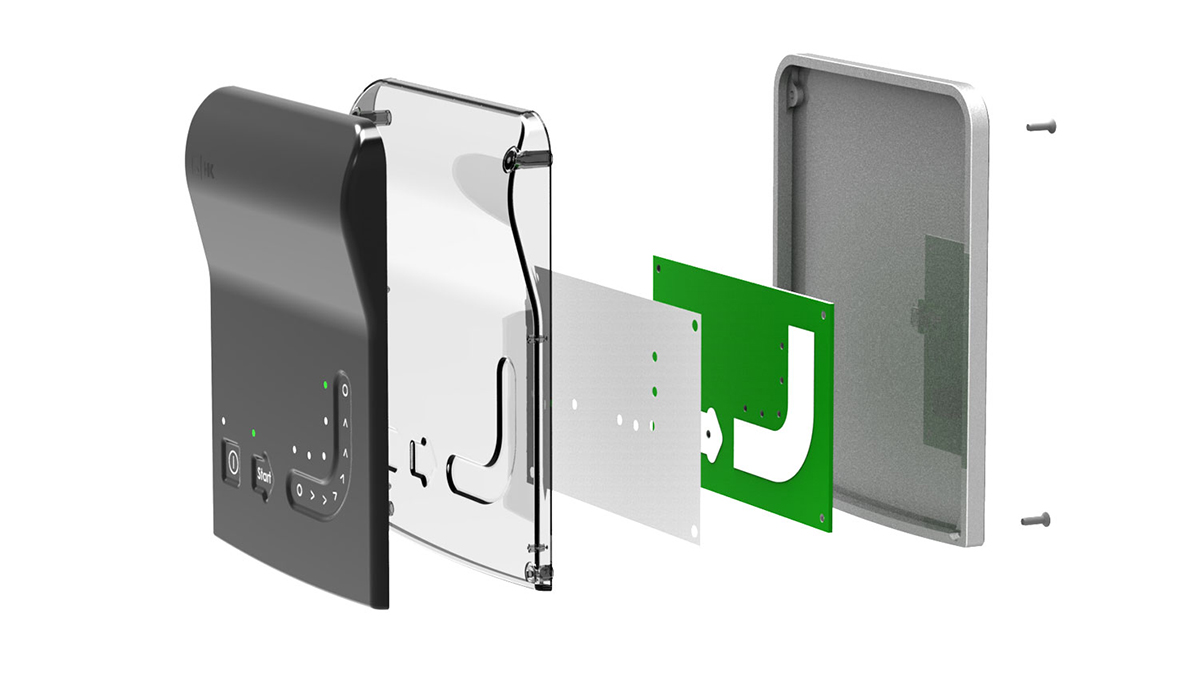

3.6 The Layer Structure of IML Process Products

PET/PC+Ink layer+plastic layer. Therefore, it is destined that the deformation direction of the product will be; And it requires the injection pressure to be higher than that of ordinary plastic parts. To prevent deformation of the parts, the adhesive thickness needs to meet certain conditions, and the design should meet other process and molding conditions:

A: Plastic Thickness (material thickness): Cannot be discussed without considering the size of the mirror surface area of the product; Smaller sizes below 20mm can be designed according to 1.1mm, while larger sizes require a glue thickness of 1.2mm or more. Local areas can be thinner and should be combined with surface shape. The adhesive thickness should be as thick as possible when the space is sufficient. Too thin thickness of the adhesive can cause difficulties in injection molding and result in color changes at the thinner area, making it unable to withstand cold impact and drop tests.

B: Shape and Thickness: Surfaces with convex and concave surfaces can be relatively thin, while windows with concave or raised edges can be locally thin to 1.05mm. Single plat and curved surfaces are easily deformed, and special attention should be paid to the conditions of high and low temperature tests. The higher the surface, the higher the requirements. It is better to have convex and concave surfaces in the shape as much as possible, and circular grooves can also be designed on the surface to overcome stress deformation But when the convexity and concavity exceed 0.25mm, they must transition with a draft angle and the angle should be greater than 45 degrees as much as possible.

C. Edge Treatment: The upper surface and side surfaces need at least R0.2 fillet; At least R0.3 fillet should be applied to the side and side surfaces. For both types of fillets, the higher the side surface, the larger the fillet and the greater the draft angle required. Excessive or sharp stretching of the surface coating can cause wrinkling of the film surface and detachment of printed ink, which can affect adhesion; In short, it is to ensure smooth film coverage and appearance quality.

D. Assembly Relationship: Considering the requirements of lens deformation and drop testing, it is recommended to consider increasing the adhesive area or adding melted columns or fasteners at the bottom of the deformation area during design.

4. Controlling Defect Rate of Mobile Phone Casings and Lenses in IMD/IML Process

IMD (In-Mold Injection Molding) technology is a whirlwind that has been blowing towards China’s plastic surface technology industry in recent years. It is a challenge to most traditional plastic surface treatment technologies such as coating, and a serious test for small and medium-sized enterprises that are processing abroad. How to face it is to wait and see; Or go with the flow? We hope that you will determine your choice based on your own situation. The IMD industry is a high cost, high profit industry, and how to succeed in this industry depends on whether you have control over costs? How to choose raw materials? How to improve skills? How to reduce the process defect rate? How to obtain a reasonable quotation, etc.

The control of the defect rate of IMD/IML/IMF mainly lies in the printing and injection parts. The selection of film forming equipment also determines the stability of film forming, which is an important factor in yield. Currently, the film forming equipment on the market mainly includes hot press machines, vacuum forming machines, and high-pressure gas forming machines, with prices ranging from a few thousand yuan for hot press machines to tens of thousands of RMB for vacuum machines. The price of high-pressure gas forming machines depends on their functional size, ranging from tens of thousands to hundreds of thousands of yuan. In recent years, IMD/IMF/IML equipment has developed from the United States and Germany to Taiwan, with equipment in the United States costing over 2 million RMB, equipment in Germany costing over 3 million RMB, and equipment in Taiwan costing around 1 million RMB. Manufacturers need to meet different product requirements. Consider the selection of equipment based on the stretching and positioning of the product, as well as the use of different sheets and printed graphics and text.

The control of IMD yield also includes the influence of the environment. We require that the entire process of IMD be carried out in a clean room, not to mention in the printing part, and also in the high-pressure forming and injection parts. This is because the heating of the sheet makes it easy for particles to stick to the sheet.

We hope that this detailed guide can assist you in better understanding and applying IMD/IML technology in product development and manufacturing, thereby enhancing product added value and market competitiveness. If you need further technical consultation, sample support, or business cooperation, KingStar is always ready to serve you. Please contact us at sales@kingstarmold.com to begin the conversation.