What is Hot Stamping?

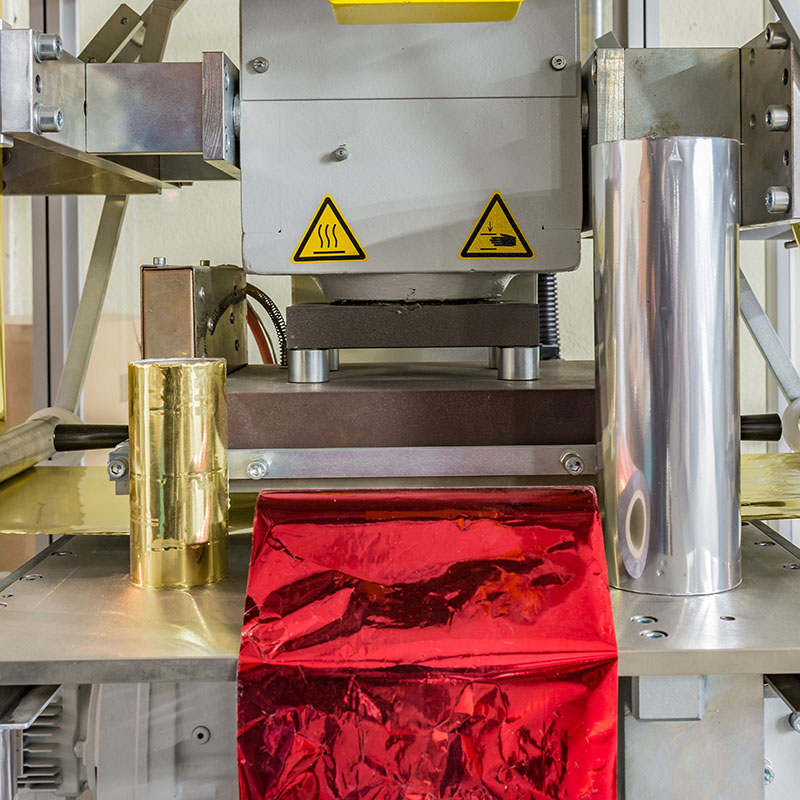

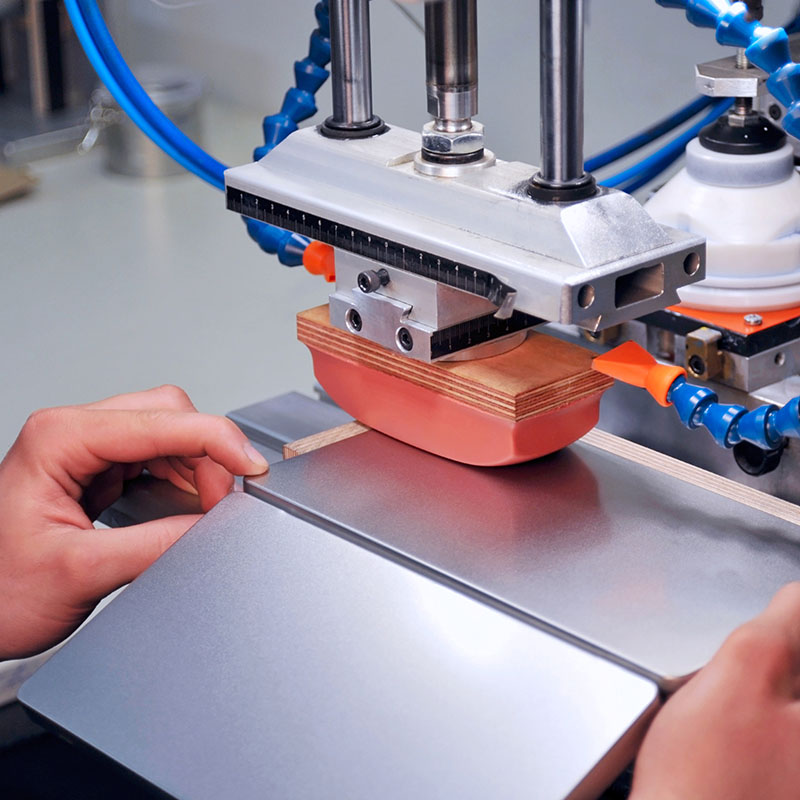

Hot stamping is a precise and versatile process that uses heat and pressure to apply metallic or pigmented foils onto various materials such as paper, plastic, metal, and leather. This method creates vibrant, durable designs that are often used for logos, text, and decorative elements, enhancing the visual appeal and quality of the product.

Ideal for applications in packaging, promotional items, and luxury goods, hot stamping provides both functional and aesthetic benefits. It is particularly valued for creating sharp, high-quality impressions with metallic effects, making it a popular choice for businesses looking to elevate their branding and product presentation.

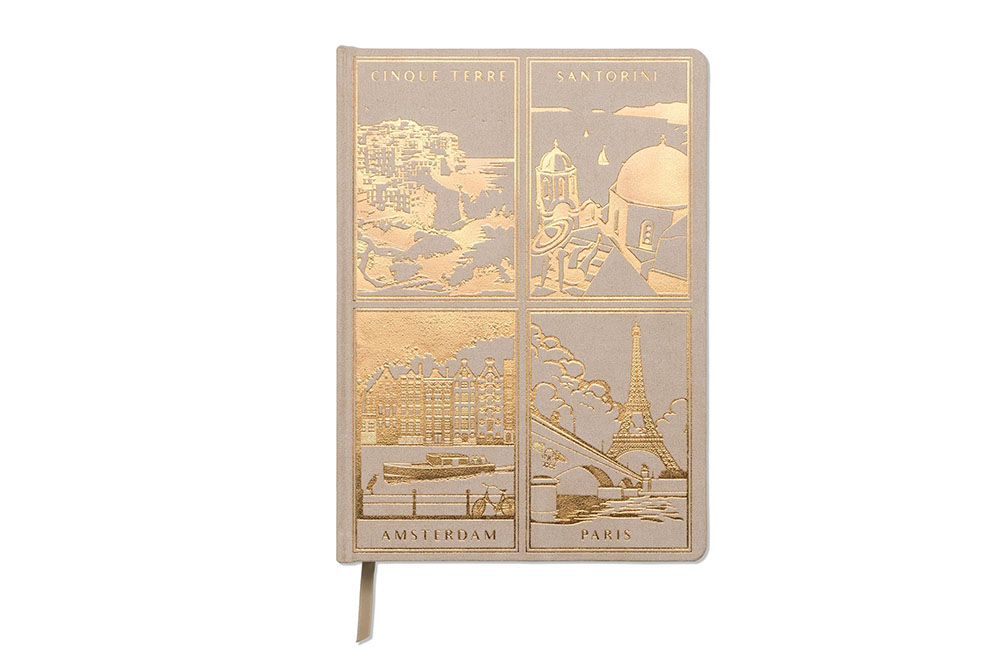

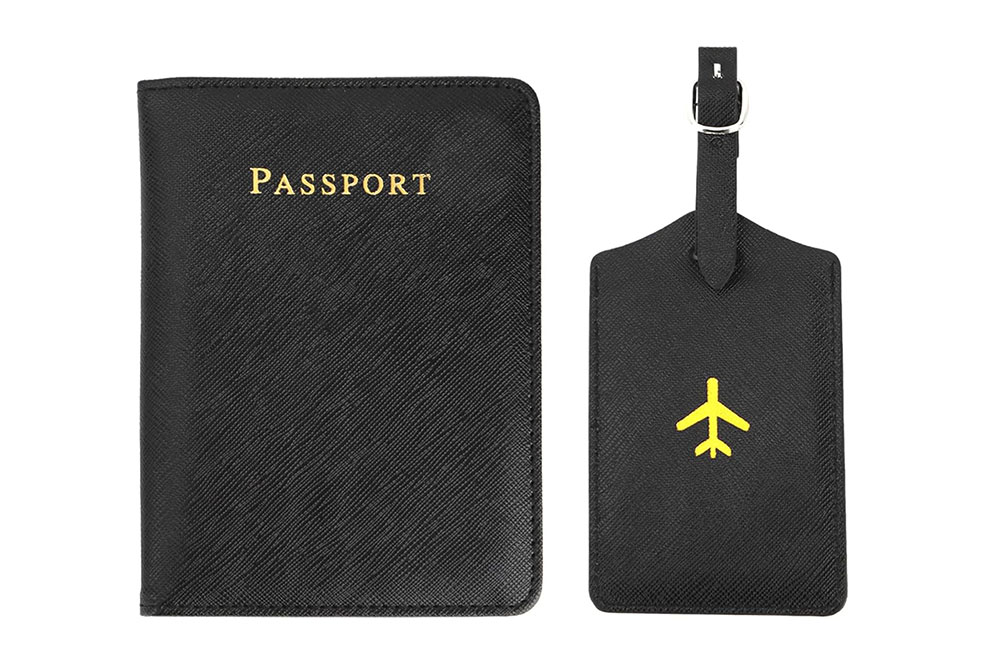

Showcase of Hot Stamped Products

Notebook

Passport Holder and Luggage Tag

Faux Leather Roll

Paper Packaging

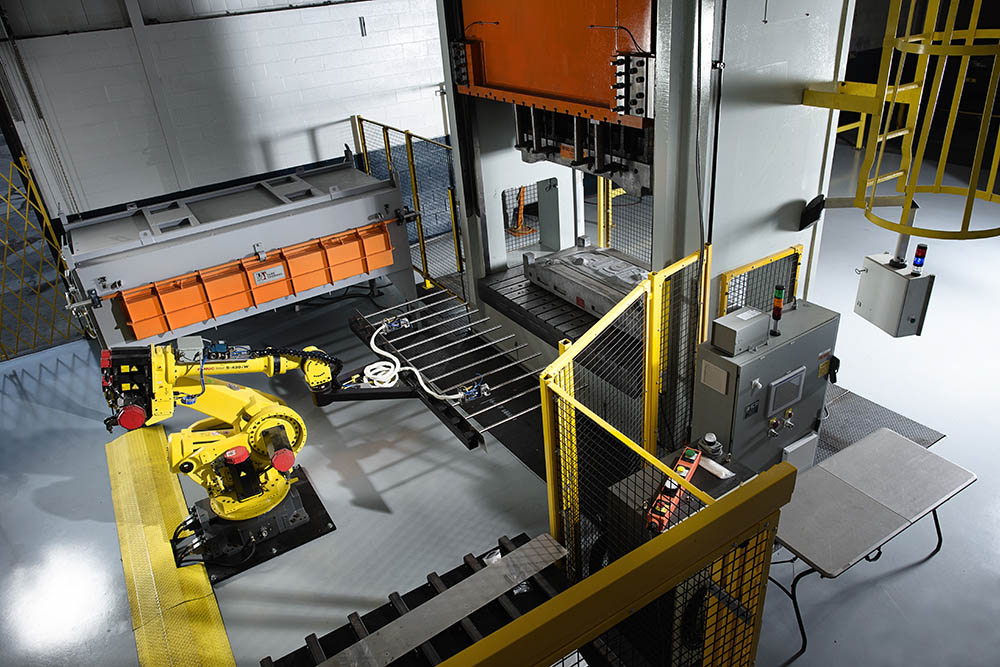

Advantages of Choosing Us to Hot Stamp Your Product

High-Quality Results

We use advanced hot stamping technology to deliver sharp, vibrant, and durable impressions that elevate the look and feel of your products.

Customizable Designs

Whether it’s logos, text, or intricate patterns, we offer fully customizable hot stamping solutions tailored to your brand’s unique needs.

Fast Turnaround Time

Comparison Between Different Types of Surface Treatment

| Surface Treatment | Description | Relevant Pre-Processing Services | Applicable Materials | Typical Applications | Relevant Standards | Cost | |

|---|---|---|---|---|---|---|---|

| Anodizing | Electrochemical process forming an oxide film (primarily for aluminum), enhancing corrosion resistance and wear resistance; available in natural, black, or colored finishes | CNC Machining, Extrusion Molding, Sheet Metal Fabrication | Aluminum & aluminum alloys (6061/2024/5052) | Automotive components (wheels, trim), electronic enclosures (phone middle frames), outdoor lighting housings | AMS 2471 (aerospace aluminum anodizing), ISO 7599 (aluminum anodizing), RoHS | $$ |

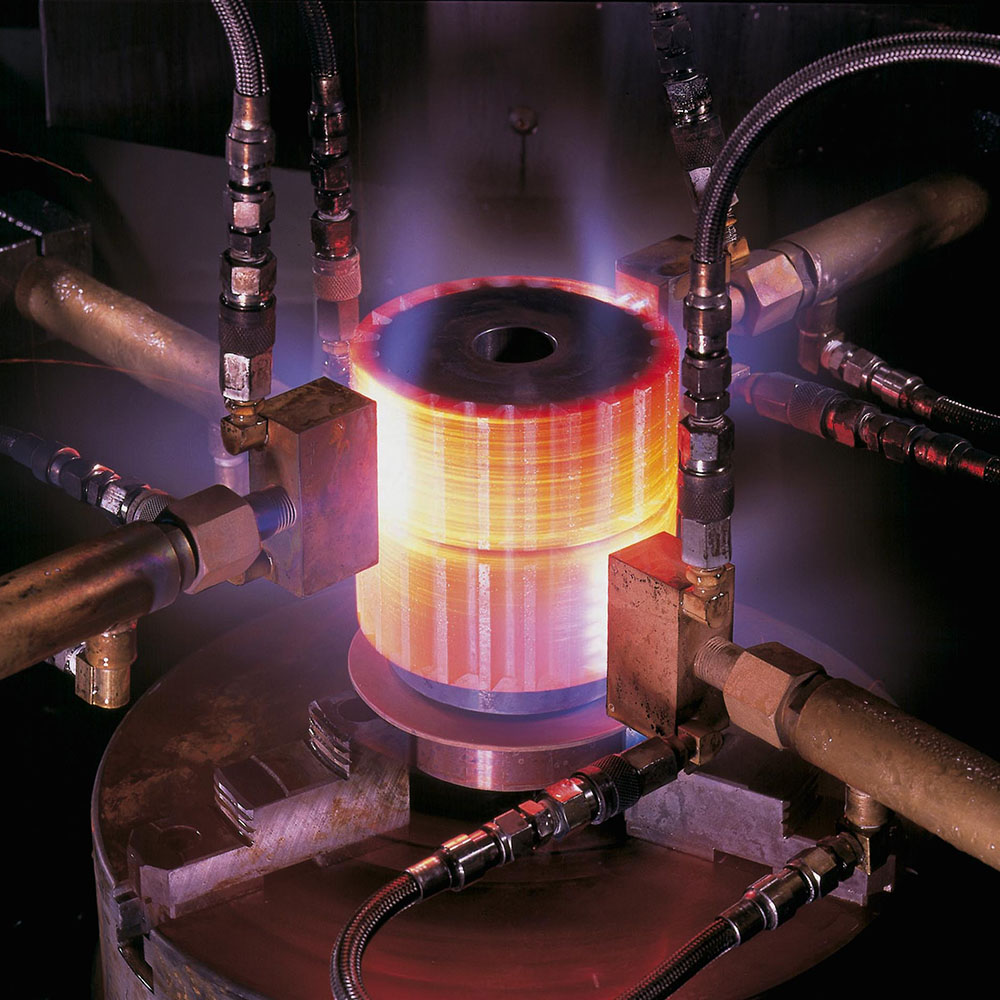

| Hot Stamping | High-temperature, high-pressure transfer of metal/pigment foils to surfaces, creating metallic or colored patterns with strong adhesion | Injection Molding, CNC Machining, 3D Printing | Plastic (ABS/PC), Metal (aluminum/stainless steel) | Appliance panels (refrigerator/washing machine logos), metal nameplates for gift boxes, automotive interior trim | REACH (chemical substance restrictions), FDA 21 CFR Part 175 (food-contact inks) | $$ |

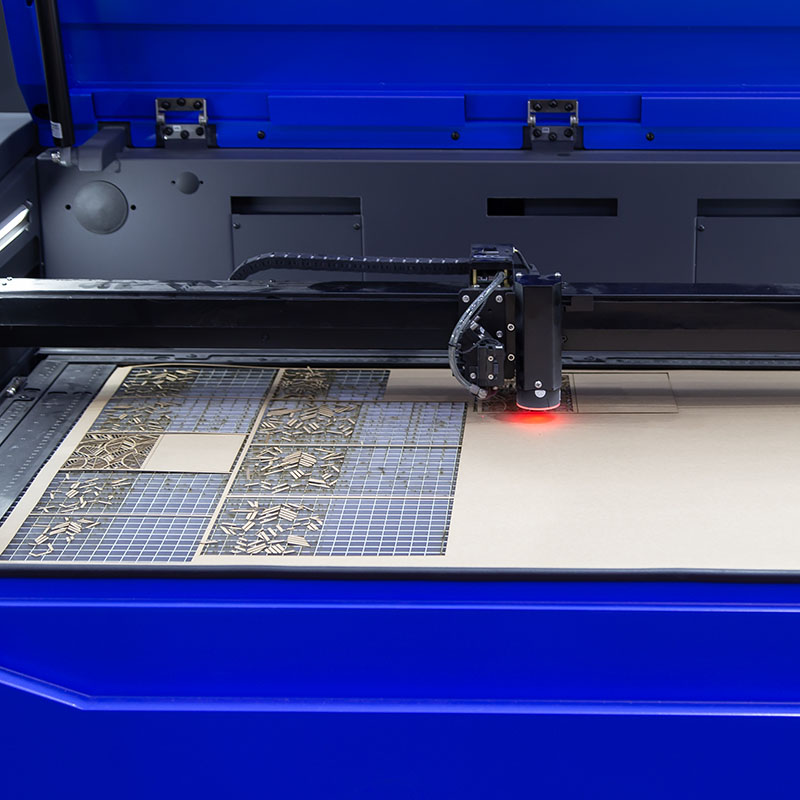

| Laser Engraving | High-energy laser etching patterns/text on surfaces with high precision (0.01mm); no residual consumables, permanent texture | CNC Machining, 3D Printing, Sheet Metal Cutting (sheet cutting) | Metal (all types), Plastic | Medical device serial numbers, electronic component markings, tool handle scales, custom metal signs | ISO 13007 (laser processing quality), FDA 21 CFR Part 820 (medical device labeling) | $$$ |

| Pad Printing | Ink transfer to irregular surfaces (curves/recesses) via silicone pads; ideal for small-area patterns with flexible color options | Injection Molding, CNC Turning, Rubber Molding (rubber part molding) | Plastic (PP/PE/ABS), Metal (small parts), Rubber | Toy surface patterns, electronic key characters, small hardware logos, medical device knob markings | REACH (ink chemical restrictions), ASTM D3359 (adhesion testing) | $$ |

| Sand Blasting | High-pressure abrasive (quartz sand/alumina) spray to create a matte, rough surface; removes oxide layers/burrs and improves coating adhesion | CNC Machining (casting deburring), Forging, Sheet Metal Fabrication (sheet rust removal) | Stainless steel, Aluminum, Carbon steel, Copper | Industrial equipment enclosures (slip-resistant), architectural decorative panels (matte finish), automotive chassis components (pre-treatment), mold surface roughening | ISO 8501-1 (surface cleanliness), ASTM B215 (metal sandblasting standard) | $$ |

| Electroplating | Electrochemical deposition of metal layers (chrome/nickel/zinc/gold) to enhance gloss, corrosion resistance, and wear resistance; available in mirror or matte finishes | CNC Machining (pre-polishing), Injection Molding, Stamping | Stainless steel, Carbon steel, Copper, Brass | Bathroom hardware (chrome-plated faucets), electronic connectors (gold/nickel plating), automotive wheels (chrome plating), jewelry components (silver plating) | RoHS (lead/cadmium-free), ASTM B456 (chrome plating standard), FDA 21 CFR Part 175.300 (food-contact plating) | $$$$ |

| Spraying | High-pressure spray gun applying liquid coatings (paint/resin) for uniform coverage; wide color range with customizable matte/glossy finishes | CNC Machining, Injection Molding | Metal (all types), Plastic | Furniture frames, automotive bumpers, outdoor billboards, industrial control cabinet enclosures | REACH (coating chemical restrictions), ASTM D1653 (coating corrosion resistance), ISO 12944 (corrosion protection coatings) | $$$ |

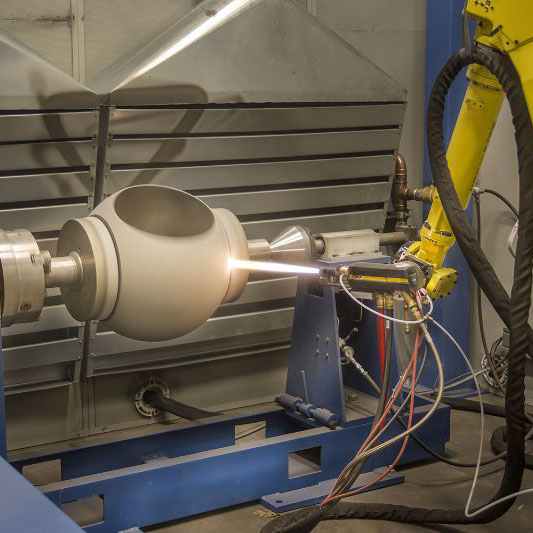

| PVD | Vacuum deposition of metal compound films (TiN/Chrome/Ceramic); thin film (1-5μm) with high hardness and wear resistance | CNC Machining, Titanium Forging | Stainless steel, Titanium, Aluminum, High-carbon steel | Luxury hardware (watch cases), aerospace components, medical surgical instruments, high-end kitchen panels | AMS 2486 (aerospace PVD coatings), ISO 14713 (PVD coating standard), FDA 21 CFR Part 820 (medical applications) | $$$$$ |

| Silk Screening | Screen stencil-based ink printing on flat/simple curved surfaces; cost-effective, high-efficiency for large-area single/multi-color patterns | Injection Molding, Sheet Metal Fabrication (flat metal processing) | Metal (flat sheets), Plastic | Electronic enclosures (laptop A-side), architectural decorative paintings, appliance control panels, advertising signs | REACH (ink restrictions), ASTM D3359 (adhesion testing), FDA 21 CFR Part 177 (food-contact materials) | $$ |

| Powder Coating | Electrostatic adsorption of powder coatings followed by high-temperature curing; thick film (50-150μm) with impact/corrosion resistance; solvent-free and eco-friendly | CNC Bending, Welding | Steel (carbon/stainless), Aluminum | Automotive wheels, outdoor furniture, fitness equipment, industrial racks, electrical distribution box enclosures | AMS 2485 (aerospace powder coatings), ASTM D7091 (powder coating performance), RoHS | $$$ |

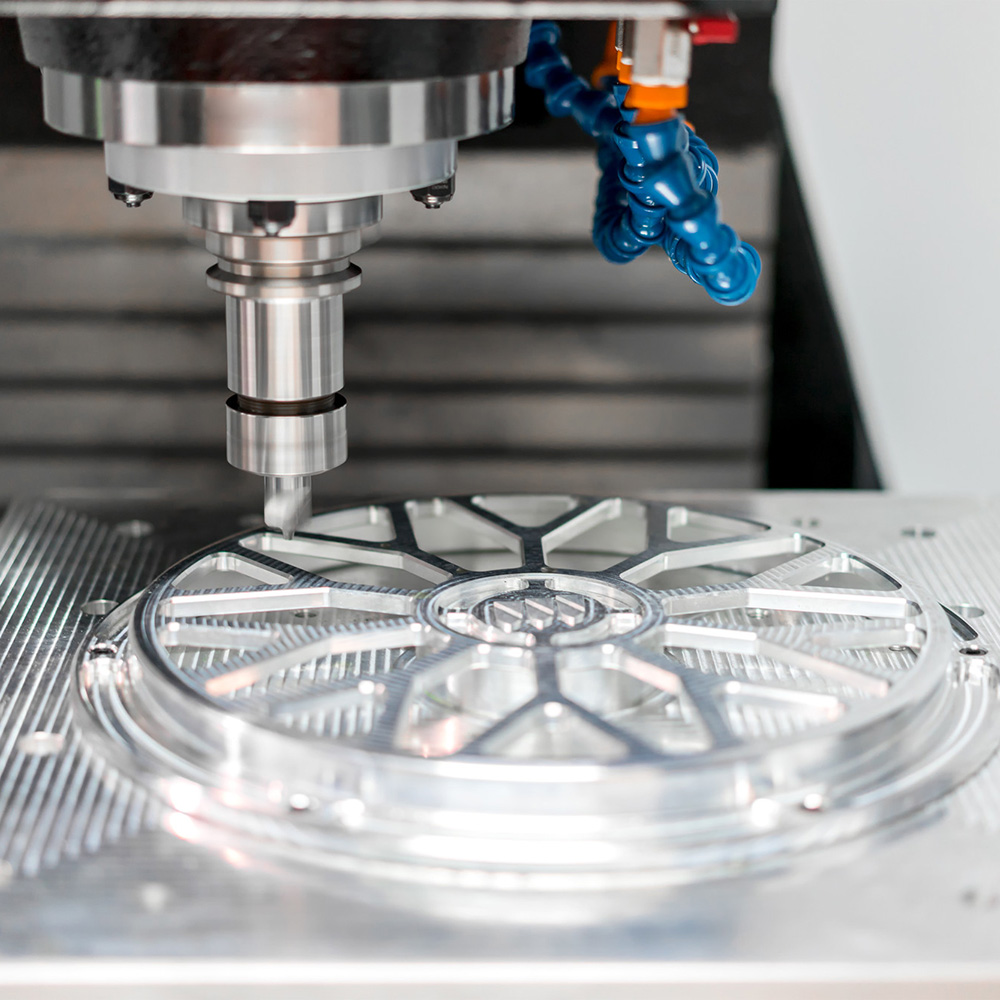

| CNC Milling (As Machined) | Retains original surface after CNC machining (no additional treatment); showcases natural metal texture with precision dependent on machining parameters (Ra 1.6-6.3μm) | CNC Milling, CNC Turning, 5-Axis Machining | All metals (aluminum/steel/titanium), Plastic | Mechanical parts (gears/bearing housings), automation equipment components, prototypes, industrial jigs | ISO 8685 (CNC machining surface quality), ASTM B468 (metal machining precision) | $$ |

| Electropolishing | Electrochemical removal of micro-protrusions to create mirror or ultra-smooth surfaces (Ra 0.025-0.1μm); enhances corrosion resistance | CNC Machining | Stainless steel (304/316), Titanium, Copper | Medical devices (surgical instruments/cavity components), food machinery (conveyor tubes), semiconductor parts, laboratory equipment | FDA 3-A (hygiene standard), ASTM B912 (stainless steel electropolishing), ISO 10993 (medical biocompatibility) | $$$$ |

| Vibratory Tumbling | Abrasive-workpiece friction via vibration to remove burrs/sharp edges; creates matte or lightly polished finish ideal for high-volume small parts | CNC Turning, Stamping, Injection Molding | Aluminum, Stainless steel, Brass, Zinc alloy | Small hardware (screws/nuts), electronic component pins, automotive small parts (clips), jewelry blanks | ASTM B611 (metal deburring standard), ISO 8503-3 (surface roughness testing) | $ |

| Heat Treatment | Altering metal internal structure via heating/cooling (not a surface coating) to enhance hardness/toughness (e.g., quenching, annealing, tempering) | CNC Machining (tool roughing), Forging | Carbon steel, Alloy steel, Tool steel, Titanium | Tools (wrench/screwdriver blade quenching), automotive transmission components (gear tempering), mechanical shafts (quenching-tempering), mold steel (hardening) | AMS 2750 (heat treatment temperature uniformity), ASTM A959 (steel heat treatment standard), ISO 9001 (quality management system) | $$$ |

| Alodine Finish | Chemical conversion coating (aluminum-only) forming a colorless/light yellow protective film; enhances corrosion resistance, ideal as a coating base | CNC Machining, Extrusion Molding | Aluminum & aluminum alloys (6061/2024) | Aerospace components (lightweight aluminum parts), automotive aluminum brackets, electronic heat sinks, outdoor aluminum structures | AMS 2473 (aerospace aluminum Alodine treatment), ISO 17892 (aluminum chemical conversion coatings), RoHS | $$ |

| Teflon Coating | Polytetrafluoroethylene (PTFE) spraying for high-temperature resistance (-200℃ to 260℃), non-stick properties, and chemical corrosion resistance | CNC Machining, Injection Molding | Metal (screws/bolts), Aluminum, Steel, Titanium | Kitchenware (non-stick pan coatings), industrial fasteners (corrosion protection), medical devices (sterilization resistance), high-temperature valve components | FDA 21 CFR Part 177.1550 (food-contact PTFE), ASTM D3300 (PTFE coating performance) | $$$$ |

| Black Oxide Finish | Chemical treatment forming a black oxide film (e.g., Fe₃O₄) on metal surfaces; low cost, improves rust resistance, matte black appearance | CNC Turning, Stamping, Tool Machining | Carbon steel, Alloy steel, Cast iron | Tools (wrenches/screwdrivers), automotive chassis parts, springs, firearm components, industrial fasteners | ASTM D1653 (coating corrosion resistance), ISO 10546 (black oxide film standard), RoHS | $ |

| Electroless Nickel Plating | Electroless nickel-phosphorus alloy deposition (no power source); uniform film (ideal for complex shapes) with corrosion/wear resistance and adjustable hardness | CNC Machining | Stainless steel, Carbon steel, Copper, Aluminum | Oil machinery components (oil corrosion resistance), medical devices (surgical instruments), electronic connectors, mold surfaces | ASTM B733 (electroless nickel plating standard), FDA 21 CFR Part 820 (medical applications), RoHS | $$$$ |

| Passivation Finish | Chemical treatment forming a passive film (e.g., Cr₂O₃ on stainless steel) on metal surfaces; enhances corrosion resistance with no thickness increase or appearance change | CNC Machining | Stainless steel (304/316), Titanium, Copper | Food equipment (stainless steel sinks), medical devices, marine components (saltwater corrosion resistance), chemical pipelines | FDA 3-A (hygiene standard), ASTM A967 (stainless steel passivation), ISO 8442 (metal passivation standard) | $$ |

| Brushed Finish | Controlled mechanical process with precision tools for uniform parallel/custom textures. It adjusts abrasion by material, delivers soft matte with subtle linear highlights, only changing surface roughness/texture (no color/coating shift). | CNC Machining, Sheet Metal Fabrication | Stainless steel (304/316/430), aluminum & alloys (6061/2024/5052), copper & brass, titanium, rigid plastics (ABS/PC/acrylic) | Luxury hardware, smartphone/laptop casings, food-grade equipment (stainless steel sinks/pipes), medical device panels, aerospace aluminum brackets, public building metal walls, vintage decorative art | NSF (food contact), FDA 3-A (medical/food), ASTM B117 (salt spray for post-treatment), Ra roughness specs (e.g., 18-31μin for hairline) | $ |

| SPI Surface Finish | SPI-standard plastic surface finish (Society of the Plastics Industry). Achieved via precision mold polishing/texturing (no post-coating; finish from mold), enhancing aesthetics, hiding fingerprints/scratches, and improving grip. | Injection Molding, CNC Machining | Thermoplastics (ABS, PC, PP, PMMA, POM, PET), thermosets (epoxy, polyester) – primarily injection-molded plastics | Consumer electronics (cases and shells), medical device plastic housings, automotive interiors (dashboard trims, door panels), home appliances, cosmetic packaging (lipstick tubes, lotion bottles) | SPI Mold Finish Standards, ASTM D2240, ISO 8256 (plastic surface gloss measurement) | $$ |

KingStar Mold offers high-quality hot stamping services with precision, fast turnaround times, and fully customizable options tailored to your product needs.

The cost of hot stamping depends on factors such as design complexity, material type, and quantity. We offer competitive pricing and can provide a quote based on your needs.

Turnaround time varies depending on the complexity and quantity of the order, but we strive for quick, efficient production without sacrificing quality.

Yes, we offer sample runs so you can see the finished product before committing to a full production order.

You can send your design file to us directly, and we will work with you to ensure it’s properly prepared for the hot stamping process.

Yes, hot stamping is an eco-friendly process as it uses no harmful chemicals and minimizes waste, especially when compared to other finishing methods.

Hot stamping offers a premium look with sharp details, long-lasting impressions, and the ability to create metallic effects that enhance product appearance.

Industries such as packaging, branding, luxury goods, and promotional products commonly use hot stamping for high-quality finishing.

Hot stamping creates permanent, durable designs that resist fading, wear, and tear over time.

We can hot stamp logos, text, intricate patterns, and decorative elements in a variety of metallic and matte finishes.

Hot stamping can be applied to a variety of materials, including paper, plastic, metal, leather, and textiles.

Hot stamping is a process where heat and pressure are applied to transfer metallic or pigmented foil onto a surface, creating vibrant and durable designs.