Hot Runner Injection Mold Making

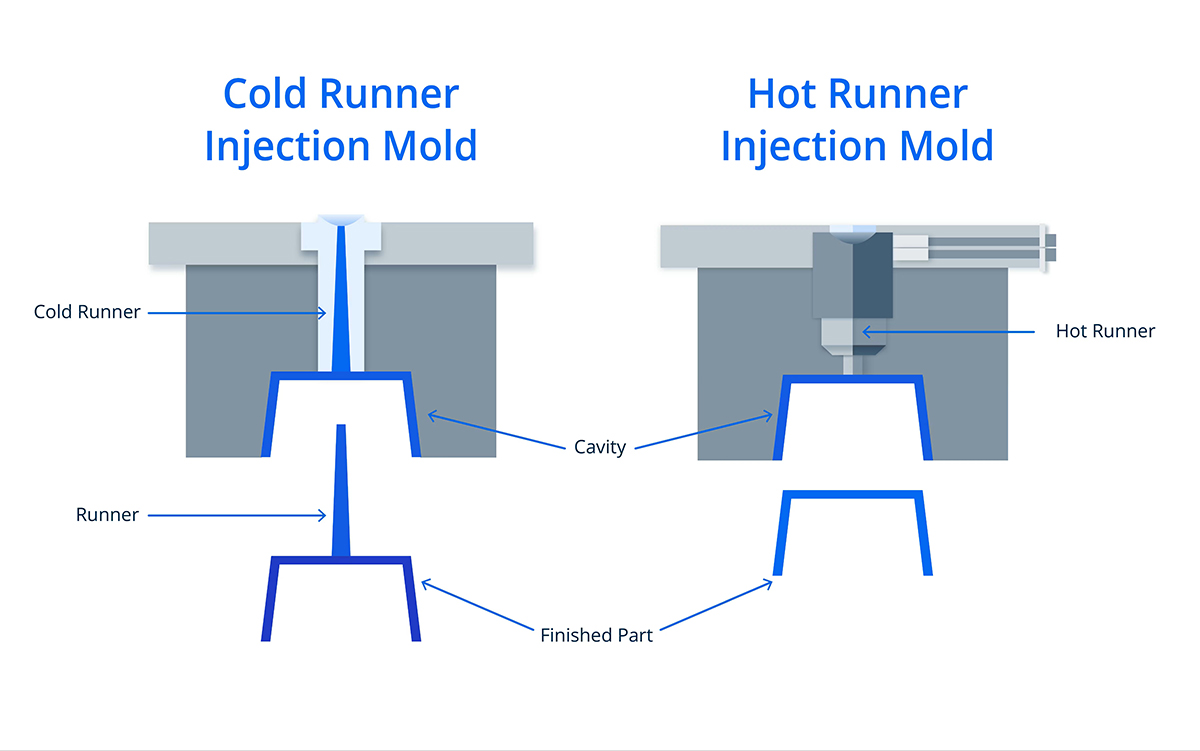

Hot Runner VS. Cold Runner System Injection Molds

The cold runner mold consists of unheated channels cut on the mold plate, which guide the molten plastic from the machine nozzle to the part cavity. Since these channels are not heated, the plastic within the channels cools together with the part and solidifies in the form of a “runner” before being ejected. This needs to be trimmed, and it frequently needs to be discarded or reground. The hot runner mold, on the other hand, keeps the plastic molten throughout the runner by using a heated manifold and nozzle system. This means that only the part solidifies and ejects, while the material in the runner does not undergo solidification and is ready for the next injection.

The two differ primarily in terms of production speed and economic efficiency: Although the cold runner system requires a longer cooling time for larger runners and produces a significant amount of material waste, it is easier to maintain and has a lower construction cost. The hot runner mold has substantial benefits in high-volume manufacturing, including a 30% reduction in injection cycle time, improved part consistency, and the elimination of ongoing material waste costs, but it also requires specialized maintenance and a larger initial capital investment.

Hot Runner System Injection Mold 101

- What Is Hot Runner Injection Molding?

- How Many Types of Hot Runner System Are There?

- What’s the Difference Between Hot Runner vs. Cold Runner Molds

- Why Choose Hot Runner System?

- When Not to Choose Hot Runner Molds?

- Design Principles and Selection Criteria for Custom Hot Runner Molds

- How to Maintain and Troubleshoot Hot Runner Molds?

What Is Hot Runner Injection Molding?

The hot runner injection mold is a complex injection molding system that keeps the plastic in a continuously molten state through a heated control manifold and nozzle assembly. Unlike traditional cold runner molds (in which the plastic solidifies in the channel and is expelled as waste), the hot runner system ensures that only the molded part itself solidifies.

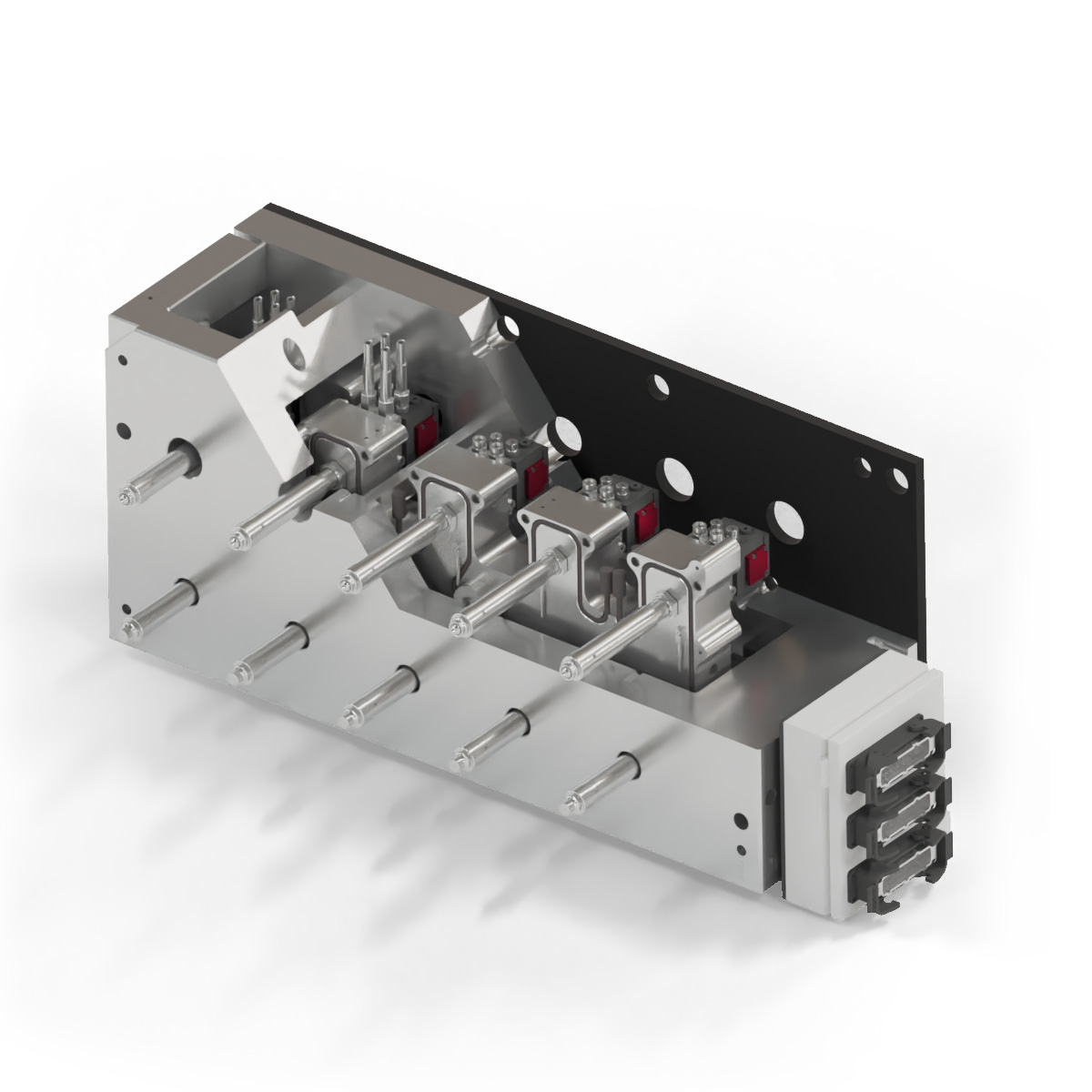

This system consists of two main components: the manifold and the heating nozzle. The manifold distributes the molten resin from the injection unit of the machine to each cavity, while the built-in heating elements maintain precise temperatures. Since the plastic in the runner never cools down, it is immediately ready for the next “injection” after the part is ejected.

How Many Types of Hot Runner System Are There?

Selecting the appropriate hot runner configuration is of vital importance for balancing production speed, part quality and mold cost. The hot runner system is mainly classified based on its gating method and manifold configuration:

What’s the Difference Between Hot Runner vs. Cold Runner Molds

The fundamental difference lies in thermal management. While both systems transport molten plastic to the mold cavity, the cold runner permits the delivery channel to solidify along with the part, while the hot runner keeps the material’s temperature constant.

Why Choose Hot Runner System?

When Not to Choose Hot Runner Molds?

| Use Cold Runner | Use Hot Runner | |

|---|---|---|

| Material | PVC, Heat-Sensitive, High-Fill | ABS, PP, PC, Stable Engineering Resins |

| Production Volume | Low (< 50k parts) | High (> 100k parts) |

| Color Changes | Daily / Frequent | Monthly / Infrequent |

| Tooling Budget | Limited / Entry-level | Strategic / High-performance |

Although the hot runner system is the optimal choice for achieving efficient manufacturing, it is not an all-applicable solution to all situations. In certain specific scenarios, the cold runner system or specialized processing methods may have technical advantages or be more cost-effective.

Design Principles and Selection Criteria for Custom Hot Runner Molds

How to Maintain and Troubleshoot Hot Runner Molds?

To ensure the longevity of your investment and maintain ≤0.05mm tolerances over millions of cycles, a proactive maintenance strategy is essential. Hot runner systems are precision thermal instruments; neglecting them leads to gate blockages, electrical failures, and costly downtime.