Heat Treatment in 3D Printing

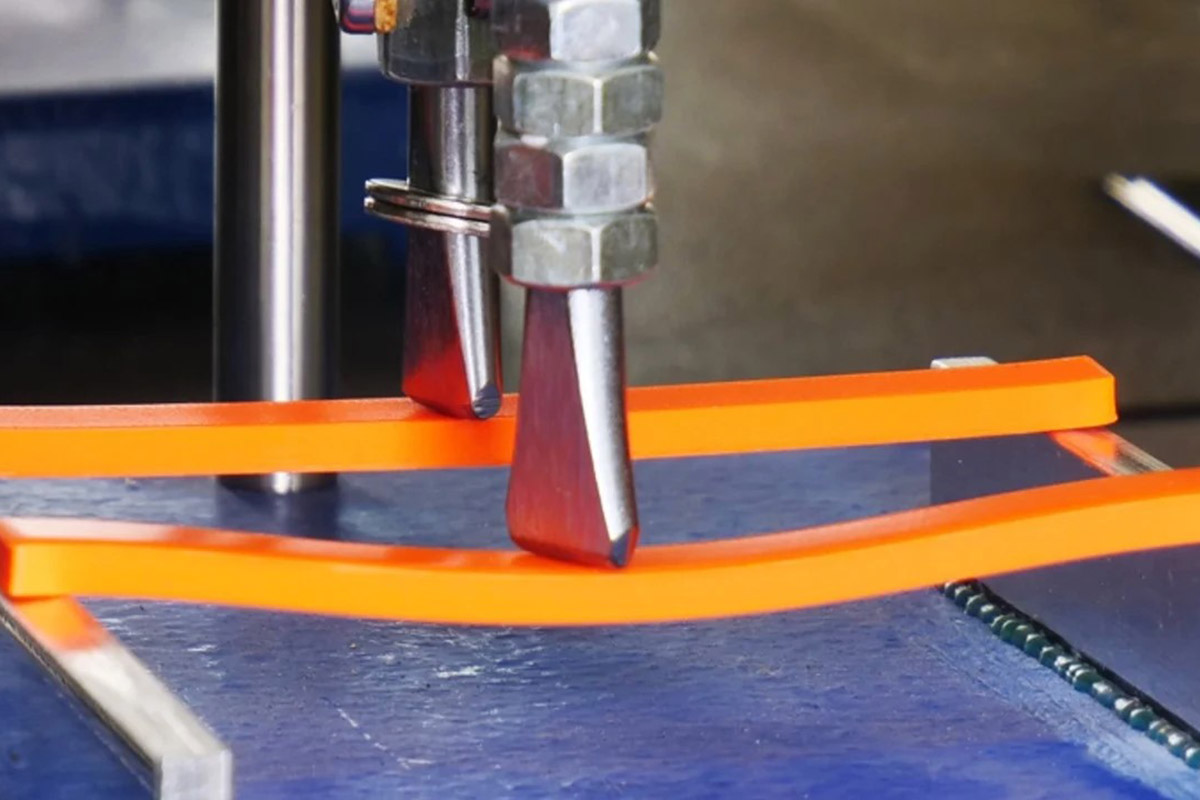

Heat treatment in 3D printing is a critical post-processing step that enhances the mechanical properties, dimensional stability, and performance of metal parts. By applying controlled thermal cycles, heat treatment relieves residual stresses, refines microstructure, and improves strength, hardness, and ductility. Common techniques include stress relief annealing, solution treatment and aging, and hot isostatic pressing (HIP), each tailored to specific material properties and application requirements. Proper heat treatment ensures that 3D-printed metal components meet industry standards for aerospace, automotive, medical, and energy applications, optimizing their durability and reliability in demanding environments.

Heat Treatment Methods for Additive Manufacturing

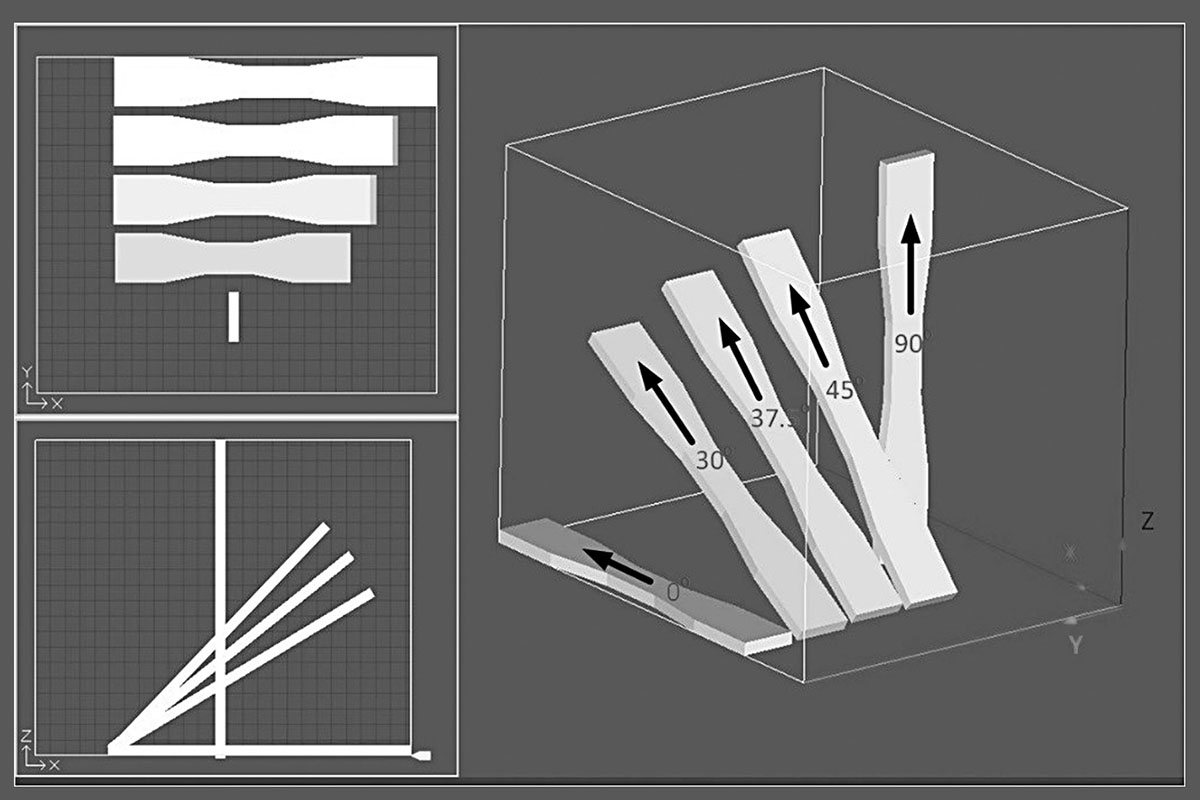

Various heat treatment techniques enhance the mechanical properties and reliability of 3D-printed parts. The ideal method depends on factors such as material type, part geometry, and final application.

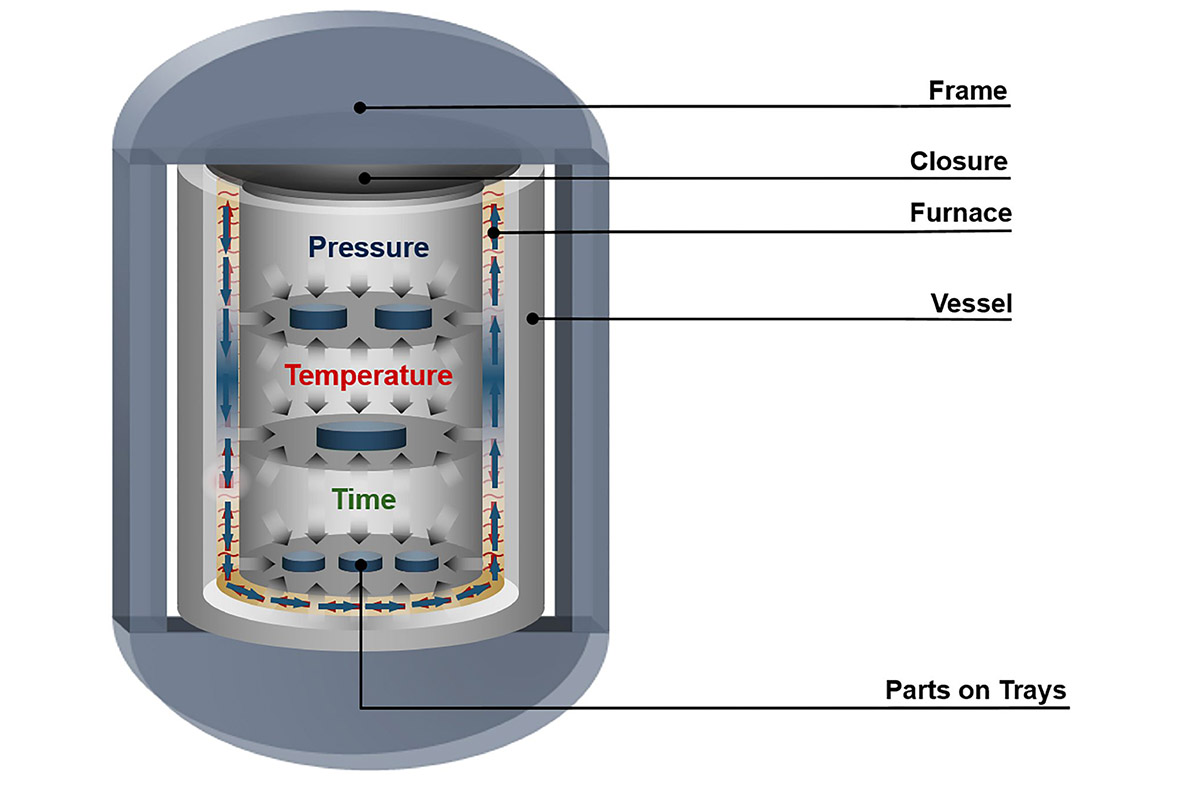

Hot Isostatic Pressing (HIP)

HIP utilizes a combination of high temperature and isostatic pressure to eliminate internal microporosity and residual stress. Even metals printed using DMLS, which already achieve near-full density, benefit from this process for additional structural integrity. HIP is commonly applied to Inconel and 17-4 PH stainless steel, as well as FDM parts requiring improved density.

Design Guidelines for Heat Treated 3D-Printed Parts

Consider the Effect of Heat Treatment on Material Properties

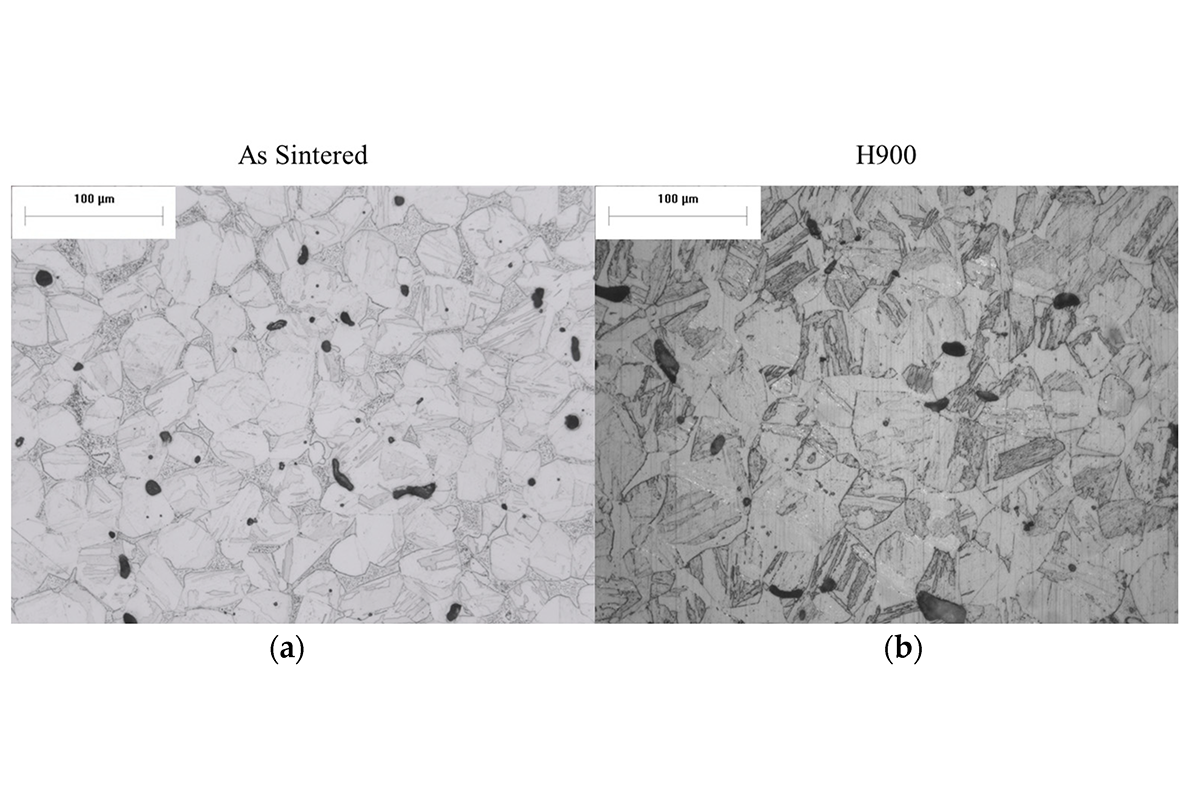

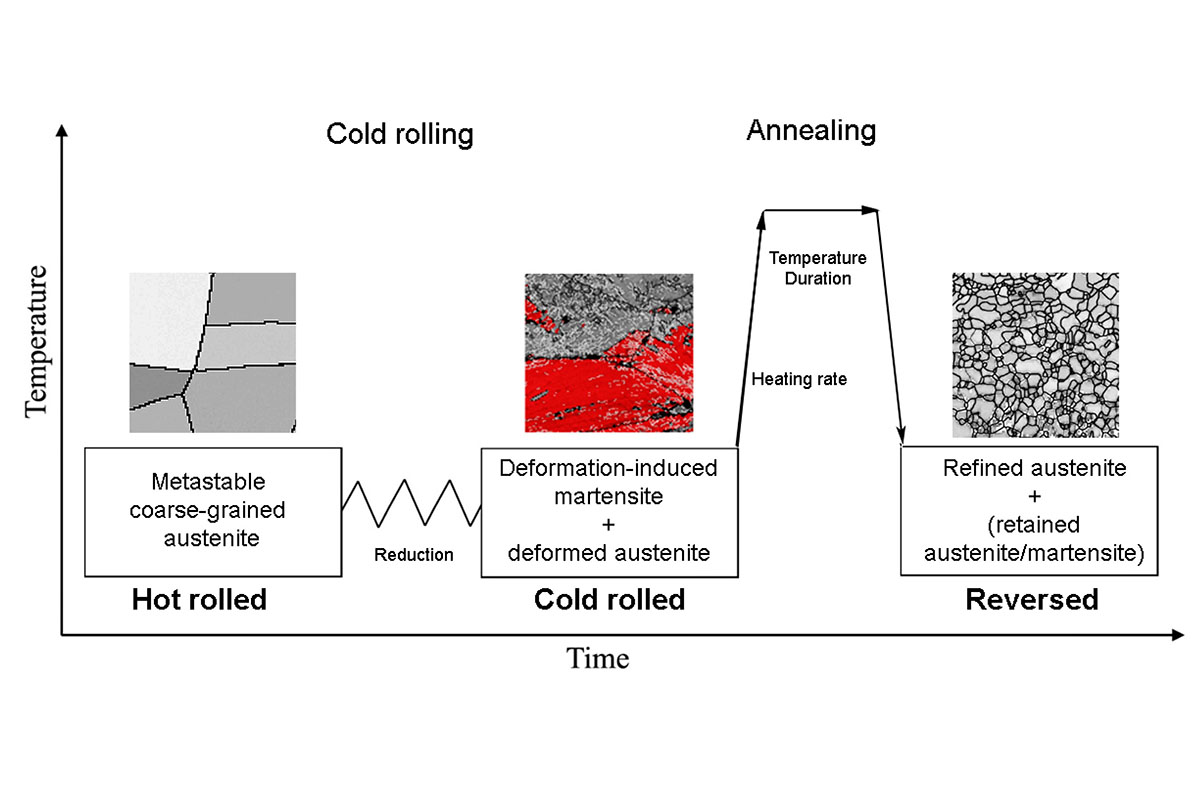

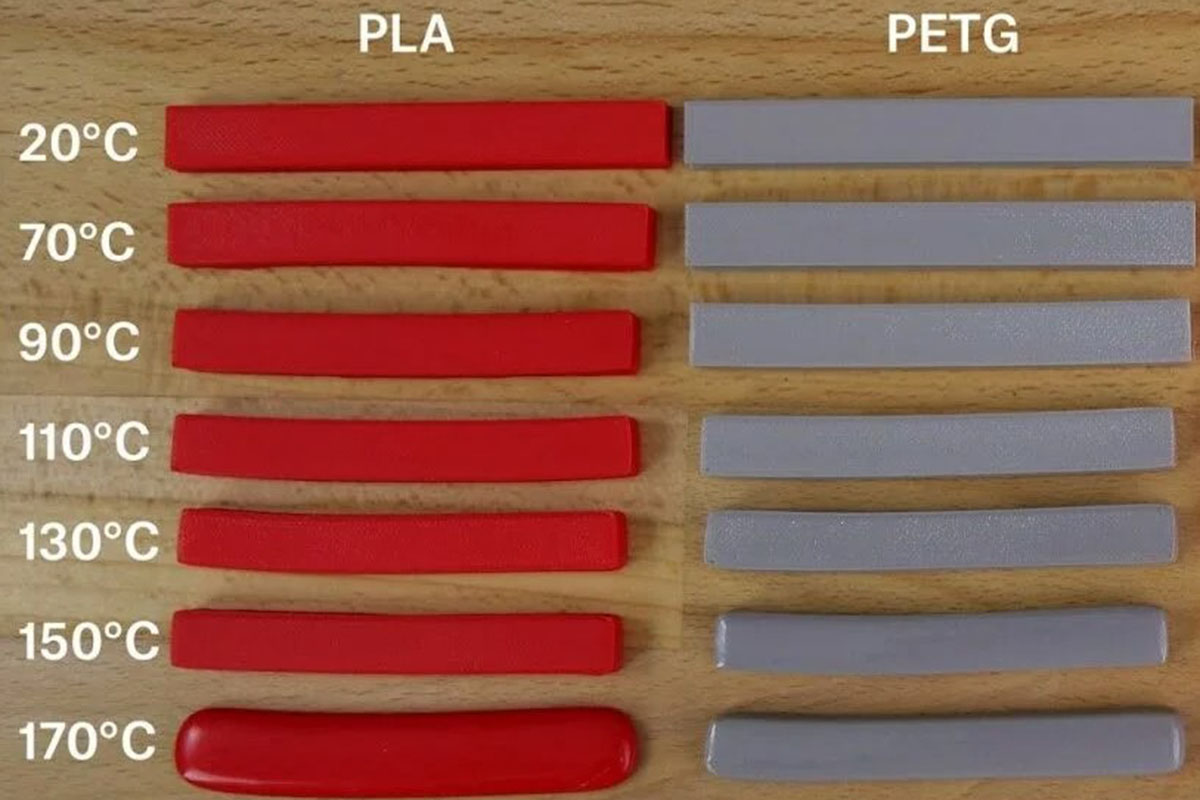

Heat treatment alters the grain structure of materials, affecting mechanical properties. When designing, it is important to understand how the chosen material behaves after heat treatment to ensure the final part meets performance requirements.

Consider the Effect of Heat Treatment on Material Properties

Heat treatment alters the grain structure of materials, affecting mechanical properties. When designing, it is important to understand how the chosen material behaves after heat treatment to ensure the final part meets performance requirements.

Yes, KingStar Mold offers heat treatment services tailored to various metal 3D printing materials, ensuring optimal mechanical properties and dimensional stability.

It reduces internal stresses, increases strength, enhances fatigue resistance, and minimizes the risk of deformation or cracking under mechanical loads.

Common processes include stress relief, hot isostatic pressing (HIP), solution annealing, and aging, each serving different purposes based on material and application needs.

Heat treatment is a thermal process that enhances the mechanical properties of 3D-printed metal parts by relieving residual stress, improving hardness, and refining microstructure.

Aerospace, medical, automotive, and energy industries frequently use heat-treated parts for enhanced strength, wear resistance, and long-term reliability.

Yes, we tailor heat treatment parameters to match the specific mechanical and thermal needs of each 3D-printed part, ensuring the best results.

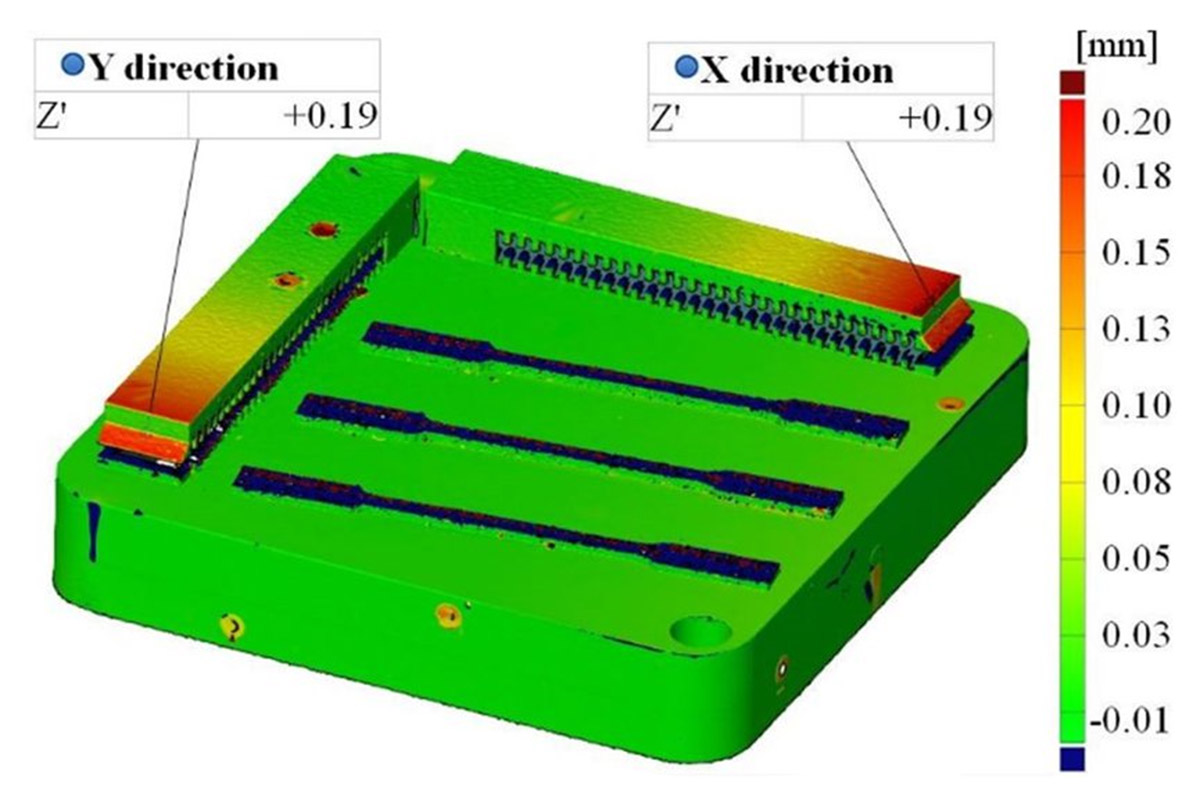

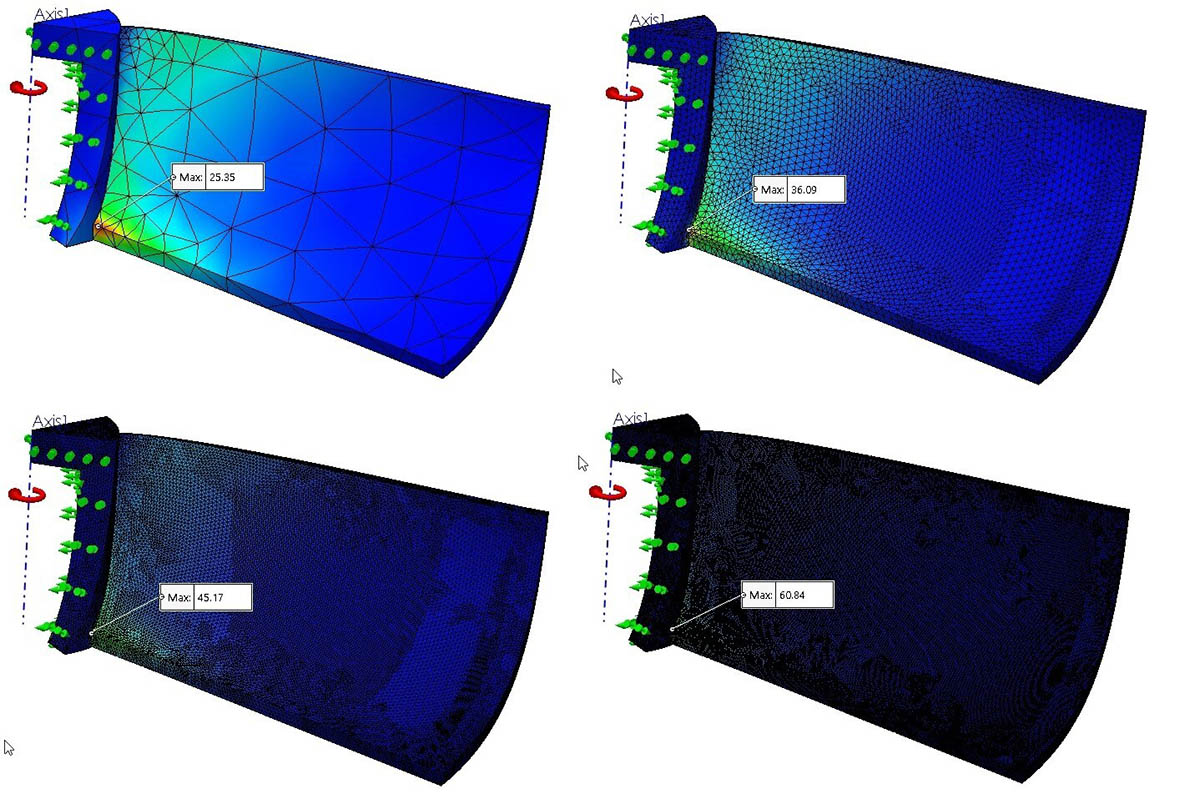

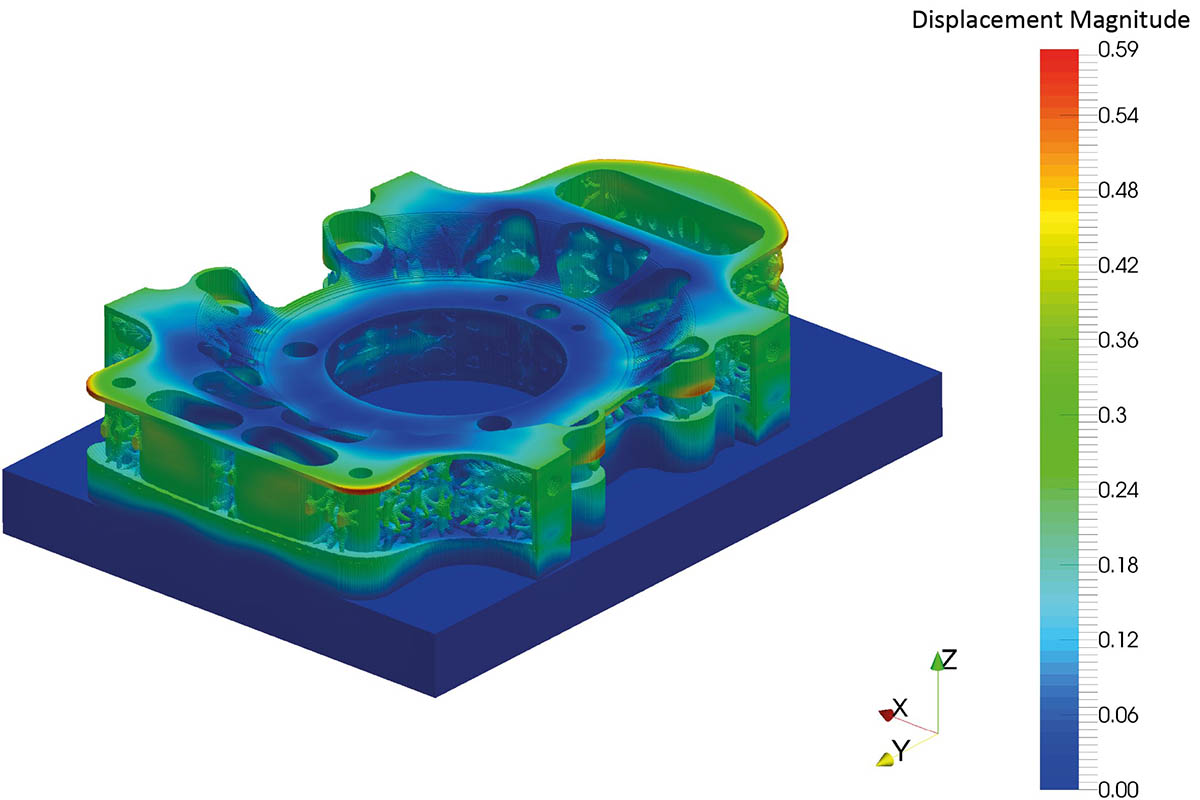

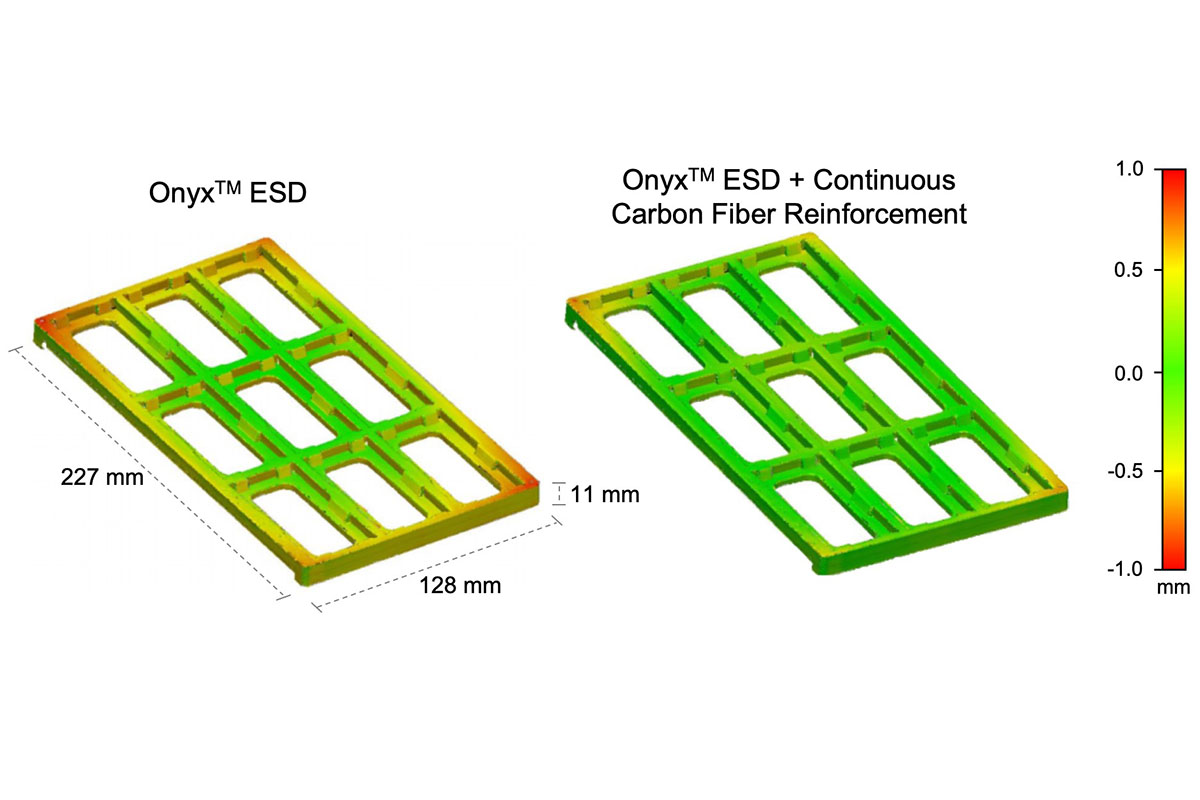

Heat treatment can cause minor shrinkage or expansion, so compensations are applied during design and post-processing to maintain tight tolerances.

We provide heat treatment for Inconel, titanium, cobalt chrome, stainless steel, and other high-performance alloys used in additive manufacturing.