Plastic Injection Molded Furniture Company

KingStar Mold’s Injection Molding Services

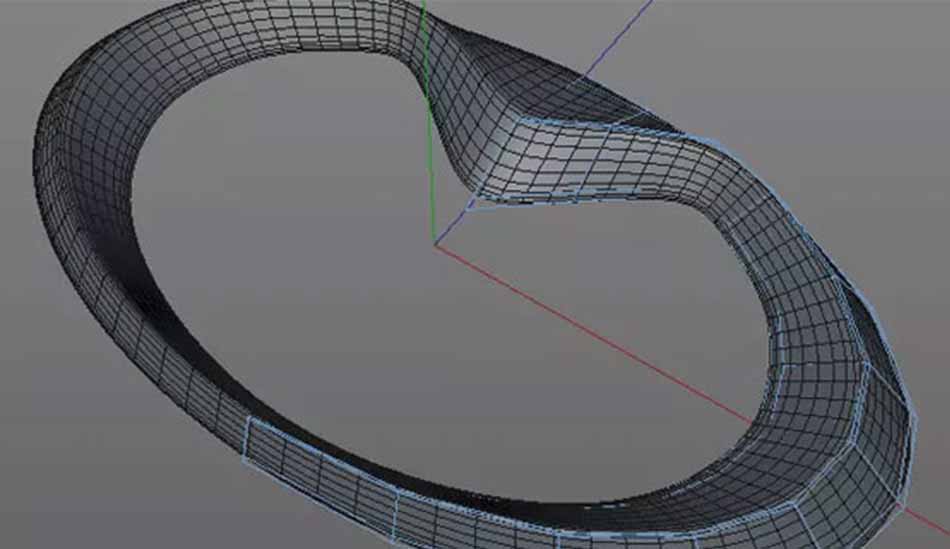

CAD Engineering

KingStar Mold offers advanced CAD engineering services to create precise 3D models and prototypes for plastic furniture parts. Our team utilizes cutting-edge CAD software to design and optimize components for enhanced performance and manufacturability.

Mold Flow Analysis

Our mold flow analysis service simulates the injection molding process to identify potential defects and optimize design efficiency. By using state-of-the-art mold flow analysis, we ensure the perfect distribution of materials and prevent issues like warping and air pockets.

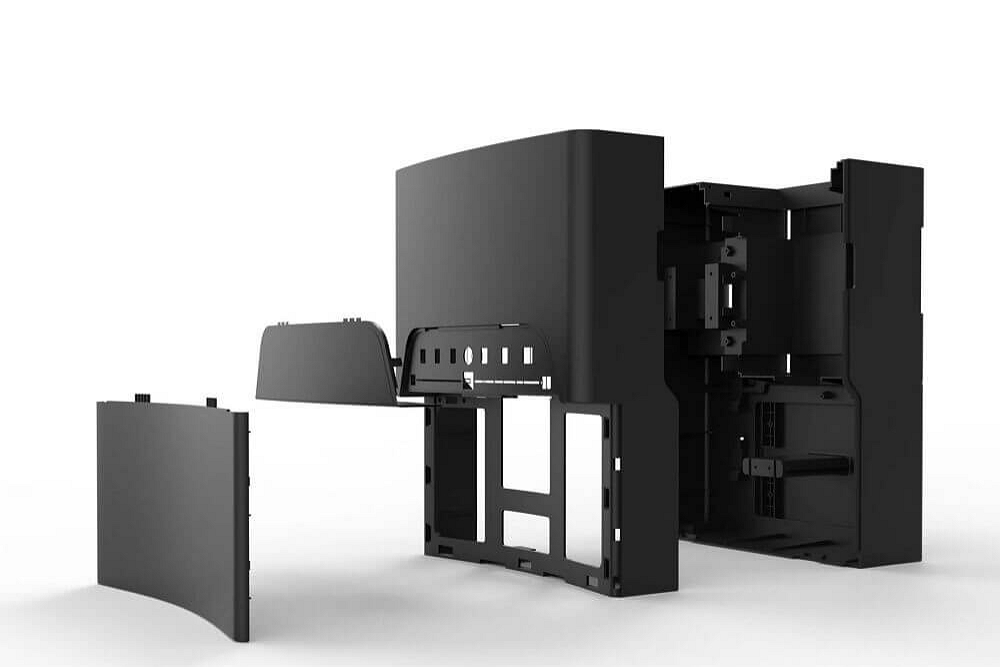

3D Printing

We use 3D printing technology to rapidly prototype and test furniture parts before full-scale production. 3D printing allows for high-precision, complex designs, accelerating the development of furniture components with reduced lead times.

CNC Machining

KingStar Mold provides CNC machining services that produce high-precision, unique-designed parts with tight tolerances. Our CNC machining capabilities ensure consistent quality and efficient production of metal and plastic components for the furniture industry.

Injection Molding

Our injection molding services allow for the mass production of high-quality furniture parts with complex shapes and fine details. We specialize in delivering fast and cost-effective solutions for producing durable, high-volume pieces of furniture.

Surface Finishing & Assembly

We offer a range of surface finishing services, including polishing, coating, and more, to enhance the performance of furniture parts. Our assembly services ensure that all components are accurately assembled and ready for integration into the final furniture design.

Orders Workflow

Initial Consultation & Design Review

We begin by discussing your project’s goals and reviewing the design to ensure it’s optimized for the specific manufacturing process. At this stage, we suggest improvements or adjustments to enhance efficiency, functionality, and manufacturability.

Material Selection

Our experts assist in selecting the right materials for your product based on performance requirements and compatibility with the manufacturing process. The correct material choice ensures durability, cost-effectiveness, and the desired product functionality.

Design & Engineering

Using advanced CAD and simulation tools, we develop a custom design for your project. This step ensures precise details and identifies potential challenges early in the process, optimizing the design for efficient manufacturing.

Prototyping & Sample Testing

A prototype or sample is created to verify design accuracy, functionality, and performance. Rigorous testing is conducted to ensure the product meets your specifications before moving into full-scale production.

Production Setup & Initial Production

We set up the required machines, molds, or tools for the manufacturing process. The initial production run is performed to confirm the setup, assess quality, and fine-tune settings for optimal results.

Final Production & Quality Control

After final approval, we proceed with full-scale production, ensuring continuous quality checks. Comprehensive inspections at each stage ensure that every part meets the highest standards before delivery.

Why Choose Us

We Believe You Will Choose Us Again

Only companies with extensive market experience and a deep understanding of customer needs can offer the best service.

Skilled

High-precision production equipment, skilled production staff, and guaranteed delivery times.

Experienced

Over ten years of industry experience, with a mature quotation system and technical support.

Thoughtful

Customized processing options that save time and effort, with active support throughout pre-sales and post-sales.

Equipped

Engineers review designs to identify and resolve potential issues, backed by advanced testing equipment.

Why Choose Injection Molding For Plastic Furniture Manufacturing?

One key benefit of our injection molding technology is the rapid production of prototypes. By utilizing both 3D printers and CNC machines, we ensure your plastic furniture prototypes are created in the shortest time frame possible.

We take pride in being able to produce over 600 set molds in a year. This has garnered us a reputation for being able to fulfill any order, no matter how big it is. No matter how large the scale of the order, we are more than capable of fulfilling it.

KingStar Mold always adheres to a high standard of control. We follow the strictest quality control, and any plastic parts that we distribute, are tested by our specialized team of experts. Rest assured, any product you get from KingStar Mold is of the best quality possible.

By utilizing injection molding for your plastic furniture, you are assured that you will be saving money. Just one injection mold could be used to create a myriad of parts. This means that you will save on both material and production costs.

Over 10+ Experience as a Plastic Home Appliances

Manufacturer

KingStar Mold is a global leader in efficient and effective furniture molding. Below are some key applications we offer to the plastic furniture industry.

Our coffee tables are crafted from durable materials such as high-quality wood or plastic, designed to add both style and functionality to living spaces. We use precision molding and finishing techniques to create sleek, stable, and long-lasting designs.

Our kitchen trash cans are made from sturdy plastics like PP, ensuring durability and easy maintenance. Through high-precision injection molding, we create space-efficient, easy-to-clean, and odor-resistant products for everyday use.

Our nightstands are designed with both form and function in mind, using a combination of wood, plastic, or metal materials. Manufactured with attention to detail, we ensure smooth assembly, high durability, and aesthetic versatility for modern bedrooms.

Kitchen Trash Can

Nightstand

We produce lightweight, foldable outdoor chairs that are both comfortable and practical, made from weather-resistant plastic or metal. Our advanced manufacturing processes ensure these chairs are easy to store and durable for outdoor use.

Crafted from various plastics, our flower vases are lightweight, elegant, and designed to complement any decor. With precise molding techniques, we create durable, visually appealing vases that are ideal for holding flowers in homes or offices.

Designed with safety and comfort in mind, our children’s chairs are made from non-toxic, durable materials like PP and ABS. Using high-precision injection molding, we create sturdy, lightweight chairs that are easy to clean and perfectly sized for little ones.

Outdoor Folding Chair

Flower Vase

Chair For Children

Previous Injection Molded Furniture Projects

Yes, all our furniture products are made with non-toxic, safe materials that comply with international safety standards.

Lead time for custom furniture orders typically ranges from 2 to 4 weeks, depending on complexity and order size.

KingStar Mold employs strict quality control processes throughout the production cycle, from material selection to the final product inspection, ensuring each piece meets high standards.

We provide furniture manufacturing services for residential, commercial, and outdoor sectors, with high-quality products suitable for a range of applications.

Yes, we offer customization options for design, color, and size to meet the specific needs of our clients.

We use a range of durable materials including PP, ABS, PVC, PEEK, PLA and so on to ensure both aesthetic appeal and long-lasting performance.

KingStar Mold combines high-quality materials, advanced manufacturing techniques, and custom solutions to deliver furniture that meets your needs, with a focus on durability, design, and customer satisfaction.

Yes, we specialize in both small and large-scale production runs, ensuring that we can meet your needs whether you’re ordering a few pieces or bulk quantities.

Yes, we provide optional assembly services to ensure that your furniture is properly assembled and ready for use upon delivery.

Our furniture is designed for easy maintenance. Most pieces can be cleaned with a damp cloth or mild cleaning solution, depending on the material.

We manufacture a variety of furniture including coffee tables, nightstands, outdoor chairs, components needed for assembly, and so on, with customizable options available for each.

Yes, we offer eco-friendly furniture options made from sustainable materials, and we ensure that our manufacturing processes minimize environmental impact.