Compared with traditional glass and metal materials, plastic has demonstrated irreplaceable advantages in the medical field. It is cost-effective and particularly suitable for manufacturing disposable medical devices, effectively reducing medical expenses and eliminating the risk of cross-infection. The processing performance of plastic is excellent, allowing it to be conveniently molded into various complex-structured products, which is something that many metal materials cannot achieve through traditional processing methods. At the same time, plastic is tough and elastic, avoiding the fragility risk of glass and significantly enhancing the safety and convenience of use. These core advantages have made various types of plastics, including Polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), polycarbonate (PC), polystyrene (PS), ABS, polyurethane, polyamide, thermoplastic elastomer, polysulfone, polyetheretherketone, indispensable etc., suitable raw materials for modern medical equipment.

In practical applications, the most suitable type and specific grade of plastic need to be selected based on the specific structure, strength, and usage requirements of the medical device. This decision-making process must comprehensively consider factors such as the processing performance, mechanical strength, usage cost, assembly method, and sterilization ability of the material. This article will provide a detailed analysis of the processing and physical properties of the four most commonly used medical plastics: Vinyl chloride (PVC), polyethylene (PE), polypropylene (PP) and polycarbonate (PC).

1. PVC for Medical Purpose (Polyvinyl chloride)

Polyvinyl chloride (PVC) is one of the most widely produced plastic varieties globally and is widely used in the medical device industry. According to market estimates, approximately 25% of medical plastic products are made by PVC. This is mainly due to its low cost, easy processability, and excellent comprehensive physical properties.

Pure PVC resin is white or light yellow powder and belongs to random structure. It is hard and brittle by nature and is rarely used in practical applications. In actual production, by adding different types of additives, its physical and mechanical properties can be significantly changed. For example, by adjusting the dosage of plasticizers, both soft and hard, semi- or even fully-transparent products can be made: Hard PVC contains very little plasticizers and has a good combination of tensile, compressive, flexural, and impact strength, and can be used independently as a structural material; while soft PVC contains more plasticizers and performs better in terms of softness, elongation at break, and cold resistance, but its hardness and tensile strength will decrease accordingly. Pure PVC has a density of approximately 1.4 g/cm³, while PVC products with added plasticizers and fillers typically have a density ranging from 1.15 to 2.00 g/cm³.

In the medical field, the softness and elasticity of PVC make it an ideal material for manufacturing many key products, such as blood bags, hemodialysis tubing, infusion tubes, breathing masks, urinary drainage tubes, and artificial ears and noses. These characteristics largely result from the addition of di-(2-ethylhexyl) phthalate (DEHP) plasticizer. DEHP is currently one of the most economical, effective, and widely used plasticizers. It gives PVC products excellent softness and flexibility.

Initially, the use of plasticized PVC to manufacture medical products was to replace the commonly used natural rubber and glass at that time. Compared with these traditional materials, PVC has significant advantages: it’s easier to sterilize, possesses higher transparency, better chemical stability and economic performance. In addition, the medical products made from it are convenient to use, and their softness and elasticity can effectively avoid damage to sensitive tissues of patients and improve the comfort of use.

PVC Medical Grade Tubing

Processing conditions:

- Applicable process: Injection molding, extrusion, blow molding, and calendaring.

- Typically no drying treatment is required.

- Melting temperature: 170-200℃, mold temperature: 20-50℃

- Injection pressure: can be as high as 1500 bar, holding pressure: can be as high as 1000 bar.

- Injection speed: To avoid material degradation, a relatively low injection speed is typically required.

Main performance features:

- PVC is a non-crystalline material and can be dissolved in organic solvents such as cyclohexanone and tetrahydrofuran. Therefore, cyclohexanone is usually used to bond PVC components.

- PVC materials are often added with stabilizers, lubricants, dyes, etc. as additives in actual use.

- Lead-barium additives are the most effective heat stabilizers for PVC, but they are prohibited in medical applications. Calcium-zinc additives are often used as stabilizers for medical-grade PVC.

- Di(2-ethylhexyl) phthalate (DEHP) was historically widely used as a plasticizer for medical-grade PVC. However, DEHP can migrate out of medical devices, particularly when in contact with fatty liquids, and its potential reproductive toxicity risks have drawn significant concern. Consequently, regions such as the European Union and the United States have imposed strict restrictions on its use in medical devices. Regulatory authorities in China have also strengthened lifecycle management by including DEHP in the “Priority Control Chemicals List,” among other measures.

- PVC has poor thermal stability and will decompose when heated for a long time, releasing hydrogen chloride gas and causing PVC to change color.

- The application temperature range is narrow, generally between -15-5℃.

- PVC has a low shrinkage rate, usually 0.2-0.6%.

- PVC is a polar material and is prone to adsorption with some polar drugs.

- Soft PVC films can be processed into bags using high-frequency welding, such as bag-type infusion devices and urine bags.

2. Medical Grade PE (Polyethylene)

Polyethylene (PE) is the most produced type in the plastic industry, presenting as a milky white, odorless, and tasteless waxy granule. It has the characteristics of low cost and excellent comprehensive performance, and is widely used in industrial engineering, agriculture, packaging, and daily products.

In the medical field, polyethylene demonstrates outstanding application value. It is formed from ethylene and not only has good chemical stability, cold resistance, electrical insulation, and processing properties, but also possesses excellent biocompatibility – being non-toxic and odorless, and will not cause harmful effects when implanted in the body. Therefore, medical PE is highly suitable for use as packaging materials for food and drugs, and is used to manufacture tableware and various medical devices. Common applications include medicine bottles, cap lids, injection rod pushers, infusion regulators, infusion bags, and injection bag packaging, etc.

Medical polyethylene mainly includes the following important varieties:

- Low-density polyethylene (LDPE): Its molecular chain contains many branches, resulting in relatively lower relative molecular mass, crystallinity, and density. This structure gives it better flexibility, impact resistance, and transparency, and thus is often used for blow-molding films, being an important substitute for PVC in the soft packaging field at present.

- High-density polyethylene (HDPE): Its macromolecular chain has fewer branches, thus having higher relative molecular mass, crystallinity, and density, showing greater hardness and strength, and a higher melting point, and is often used for injection molding.

- Ultra-high molecular weight polyethylene (UHMWPE): As a special engineering plastic, it combines high impact resistance, excellent wear resistance (referred to as “the king of plastics”), low friction coefficient, and biological inertness. Its chemical stability can be comparable to polytetrafluoroethylene (PTFE). These characteristics make it an ideal material for manufacturing artificial hips, artificial joints (such as wrist joints, knee joints, and hip sockets), successfully solving the friction and wear problems of artificial joints and significantly extending their service life. Additionally, its excellent biocompatibility and mechanical strength also show promising application prospects in the field of biological scaffolds.

In actual production, HDPE and LDPE are often mixed to obtain the desired material properties according to performance requirements.

PE Syringes

Processing conditions:

- Drying: Low water absorption, usually no drying required. Melting temperature: 170-260℃. Mold temperature: 20-40℃.

- Injection pressure: can reach 1500 bar at maximum. Holding pressure: Can reach 750 bar at maximum. Injection speed: A fast injection speed is recommended.

- Channels and gate: Various types of channels and gates can be used. LDPE is particularly suitable for using hot runner molds.

Main performance characteristics:

- The most significant feature of PE parts is the large molding shrinkage rate, which is prone to shrinkage and deformation.

- The processing temperature range of PE is wide, and it is not prone to decomposition (decomposition temperature is approximately 300℃). The processing temperature is preferably 180-220℃. If the injection pressure is high, the product density will be higher and the shrinkage rate will be smaller.

- PE has medium flowability, requiring a relatively long packing time and maintaining a constant mold temperature (40-70°C). The crystallinity of PE is influenced by the molding process conditions. It has a relatively high solidification temperature, and lower mold temperatures result in lower crystallinity.

- During the molding process, it is advisable to have a higher material temperature and mold temperature. The injection pressure should be as low as possible while ensuring the quality of the molded part.

- Like PP, PE is a non-polar material, not easy to bond, has a small drug adsorption capacity, and cannot be processed into bags by high-frequency welding. It should be welded using the heat sealing process.

3. PP for Medical Usage (Polypropylene)

Polypropylene is a colorless, odorless, and non-toxic general-purpose thermoplastic. Its appearance is similar to polyethylene, but it is lighter and more transparent. It has excellent properties such as low density (about 0.9 g/cm³), easy processability, impact resistance, and flexibility. It is widely used in daily life.

In the medical field, polypropylene demonstrates its irreplaceable value. It exhibits excellent chemical stability and fatigue resistance, particularly outstanding heat resistance, enabling it to withstand sterilization at temperatures exceeding 100°C. At the same time, medical PP also has high transparency, good barrier properties, and radiation resistance, without being prone to environmental stress cracking. These characteristics make it an ideal material for manufacturing medical equipment and packaging, and it is an important choice to replace PVC in the “Non-PVC” material system.

Based on these properties, polypropylene is applied in multiple aspects of medical care: disposable medical devices, such as disposable syringes, infusion bags, connectors, transparent bands for drip, etc., which are its most well-known uses; PP fiber materials and PP non-woven fabric products, including blood filtration nets, surgical repair sheets, sutures, etc.; thanks to its good chemical stability, mechanical properties, and biocompatibility, PP can also be made into hard instruments and implants, such as the clamp for the flat artificial kidney, and after special surface treatment, polypropylene can even be used to manufacture advanced medical devices like artificial lungs.

PP Medical Grade Test Tubes

Processing conditions:

- Applicable process: Injection molding, extrusion, blow molding, and film production.

- Drying Treatment: Medical-grade PP has low hygroscopicity and typically does not require drying. If necessary, pre-drying can be performed at 80-100°C for 1-2 hours to ensure optimal results in moisture-sensitive applications.

- Melting temperature: 220-270°C, note not to exceed 275°C.

- Mold temperature: 40-80 °C, 50 °C is recommended.

- Injection pressure: can be as high as 1800 bar. Injection speed: using high-speed injection can reduce internal pressure to the minimum. If defects appear on the surface of the product, then use low-speed injection at a lower temperature.

- Flow channels and gate: for cold flow channels, the typical flow channel diameter range is 4-7 mm. It is recommended to use a circular inlet and flow channel throughout. All types of gates can be used. The typical gate diameter range is 1-1.5 mm, but a gate as small as 0.7 mm can also be used. For edge gates, the minimum gate depth should be half of the wall thickness; the minimum gate width should be at least twice the wall thickness. Hot flow channel systems are applicable.

Main performance characteristics:

- PP is a semi-crystalline material with a high melting point, good heat resistance, and can be sterilized and disinfected at temperatures above 100°C.

- Yield strength, tensile strength, compressive strength, hardness, and elastic modulus are higher than those of polyethylene (PE).

- Homopolymer PP has greater brittleness, and the irregular copolymer PP of ethylene has better toughness and stronger impact resistance. Generally, products used under low-temperature conditions should preferably choose copolymer PP or modify PP by adding thermoplastic rubber to increase its flexibility and low-temperature impact resistance. The large non-PVC infusion bag is made by blending copolymer PP and elastomer.

- It is easily degradable and aged under the action of oxygen, heat, and light, so anti-aging agents must be added.

- PP products are not easy to bond. Before bonding, they need to be treated and use special adhesives.

- Poor coloring, large shrinkage rate (generally 1.6-2.5%), poor flame resistance, and prone to ignition.

- As a non-polar material, PP exhibits minimal adsorption of pharmaceutical substances, making it suitable for pharmaceutical packaging and medical devices.

4. PC for Medical Devices (Polyacrylonitrile/Polycarbonate)

Polycarbonate is a thermoplastic resin with the structural unit —[O-R-O-CO]— in its main chain. The most practical type is the aromatic polycarbonate represented by bisphenol A.

The typical characteristics of PC lie in its excellent mechanical properties and high transparency: it has high strength, high toughness, high rigidity, and can withstand strict disinfection conditions such as steam. These features make it the preferred choice for manufacturing key equipment components in the medical field.

Based on these properties, the main applications of PC in the medical field include:

- High-risk surgical and treatment equipment: widely used in blood dialysis (filtration) filters, artificial lungs (blood oxygen supply equipment) shells, perfusion instruments, etc. in cardiac surgery.

- Reusable surgical instruments: due to its excellent rigidity and disinfection resistance, it is often used to make handles of surgical tools, blood centrifuge bowls and pistons.

- Disposable medical consumables: used for catheters and clamps of venous connectors, needleless injection systems, cannulas, and traction devices required for endoscopy examinations.

In addition to the mainstream aromatic polycarbonate, aliphatic polycarbonate, as another important branch, shows great potential in the biomedical field. It has excellent biodegradability and biocompatibility, especially suitable for temporary implantation occasions such as drug-controlled release systems, tissue engineering scaffolds, surgical sutures, etc. It has developed rapidly in recent years.

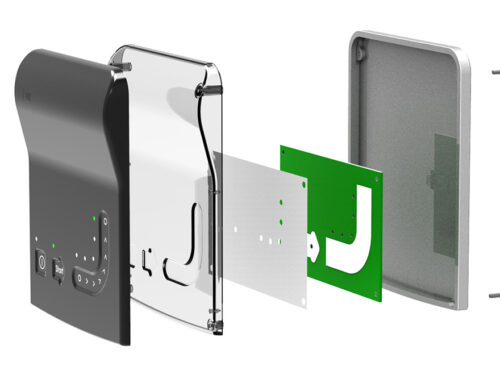

PC Medical Device Housings

Processing conditions:

- In the medical field, PC is mostly processed by injection molding, rarely by extrusion tube or blow molding.

- Drying treatment: PC materials have hygroscopicity, so drying before processing is very important. It is recommended to dry at 100°C to 160°C for 3-4 hours. The humidity before processing must be less than 0.02%. Melting temperature: 260-340°C Mold temperature: 70-120°C.

- Injection pressure: A high injection pressure is recommended.

- Injection speed: Use low speed injection for small gates, and high speed injection for other types of gates.

Main performance characteristics:

- PC is a non-crystalline engineering material, with particularly good impact strength, thermal stability, transparency, glossiness, antibacterial properties, flame retardancy, and anti-pollution properties.

- The impact strength of PC is very high, and the shrinkage rate is low, generally 0.4%-0.8%, with good dimensional stability.

- PC has excellent mechanical properties and high-temperature resistance. It is resistant to creep, wear, heat, cold, with a brittle point below -100℃, and a long-term working temperature up to 120℃.

- The molded parts can achieve good dimensional accuracy and maintain their dimensional stability over a wide temperature range.

- However, its fluidity is poor, and the processing temperature requirement is high (above 300℃), making the injection process more difficult.

- The cost is high, with prices 2-3 times more than PE and PP materials.

- It exhibits good weatherability and resistance to water, dilute acids, oxidizing agents, reducing agents, salts, oils, and aliphatic hydrocarbons at room temperature. However, it is not resistant to alkalis, amines, ketones, esters, or aromatic hydrocarbons.

- Its biggest drawback is that the plastic products made by PC are prone to cracking and have poor fatigue strength.

In conclusion, the successful application of medical plastics ultimately stems from their fulfillment of two core requirements: outstanding chemical stability and absolute biological safety. Since these materials need to come into direct or indirect contact with human tissues and medicinal fluids, it is essential to ensure that their components are non-toxic and harmless, and do not leach out and cause any toxic side effects to the human body. Therefore, all compliant medical plastics must undergo rigorous certification and testing by authoritative medical regulatory bodies and be clearly marked as “medical-grade” designations to ensure user safety.

From the flexible PVC infusion bags to the heat-resistant PP syringes, and to the high-strength PC surgical instruments, the choice of each material is a precise balance of its performance and cost. It can be foreseen that with the advancement of material technology, these various-performance and specialized-purpose medical plastics will play an increasingly important role in the cause of safeguarding human health. Through our professional material selection guidance, validated manufacturing processes, and strict quality control system, we transform various high-performance, specialized medical plastics into trusted guardians of patient health. If you wish to learn more about the professional knowledge related to injection molding materials, or if you need quotations for your medical device component manufacturing project, please contact us at sales@kingstarmold.com.