With the rapid development of technology, plastic parts have become widely used in various fields of daily life and industrial production due to their lightweight, low cost, and easy molding. From small tableware and kitchenware used in daily life to large precision mechanical components and electronic product casings, plastic parts are ubiquitous. Among them, electronics represented by mobile phones, computers, and smart wearable devices have extremely strict requirements for dimensional accuracy and surface smoothness.

In fact, precision control of precision plastic parts is a full process engineering, which requires laying a high-precision foundation from the mold design and manufacturing stages. So, what are the key factors affecting the accuracy of the injection molding stage? How can we optimize the process to improve the accuracy of thin-wall injection molded parts? As a leading plastic injection molding company, KingStar consistently focuses on the optimization and advancement of thin-wall injection molding technology, fully recognizing the decisive role of precision control in product quality. Today, we will introduce four core techniques for thin-wall injection molding for everyone.

1. How to Control Clamping Pressure for Precision Thin-Wall Molding?

The mold clamping pressure is the first line of defense for precision control in thin-wall injection molding, and its core principle is that the clamping pressure should be greater than the total pressure of the plastic injected into the mold, while taking the absence of flash as the core benchmark. For thin-walled parts, the sealing requirements of the mold cavity are higher. If the clamping pressure is insufficient, molten plastic is prone to overflow from the mold gaps during injection molding, forming flash that not only affect the appearance of the product but also lead to dimensional deviations; On the contrary, if the clamping pressure is too high, it will not only increase equipment energy consumption, but may also cause problems such as mold deformation and guide column wear, indirectly affecting machining accuracy.

Practical suggestion: According to the product dimensions, wall thickness, and raw material properties, gradually adjust the mold clamping pressure through trial molding. When testing the mold, a basic pressure can be set first to observe whether the product has flash, warping, and other problems, and then gradually adjust it to determine the optimal clamping pressure value that can ensure the mold seal without excessive pressure.

2. Optimizing Injection Pressure for Uniform Mold Filling

Injection pressure is the core driving force that drives molten plastic to fill the mold cavity, and its size directly determines the filling state of the plastic, thereby affecting product accuracy. Although the mechanism of action of injection pressure and injection speed mentioned later is different, the core purpose is the same – to ensure that molten raw materials can be uniformly, thoroughly, and appropriately filled into every corner of the mold.

Pressure regulation should avoid two extremes: If the pressure is too low, the flow momentum of molten plastic is insufficient, which can easily lead to defects such as short shots (incomplete cavity filling), shrinkage, etc., resulting in incomplete product dimensions; If the pressure is too high, it will cause excessive filling of the mold cavity with plastic, resulting in flash and overfilling, and may also cause mold sticking and burning problems. At the same time, it will increase the internal stress of the product, which is prone to cracking and deformation during subsequent use, and even accelerate mold wear, affecting the long-term accuracy and stability of the mold.

Practical suggestion: According to the product size, wall thickness, and raw material characteristics, gradually adjust the mold closing pressure through trial molding. When testing the mold, a basic pressure can be set first to observe whether the product has flash, warpage, and other problems, and then gradually adjust it to determine the optimal clamping pressure value that can ensure the mold seal without excessive pressure.

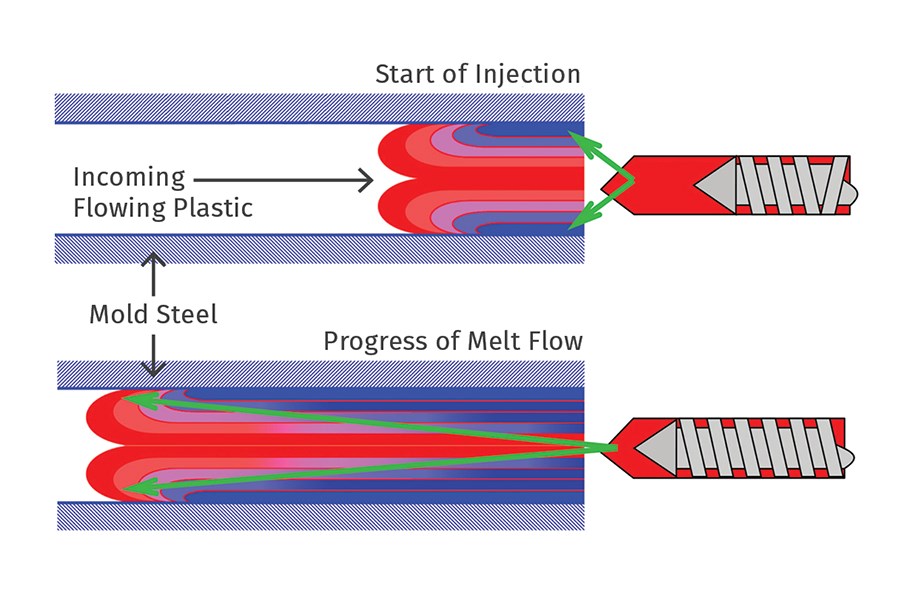

3. Setting Injection Speed to Optimize Plastic Flow in Thin Wall Injection Molding

Injection speed directly determines the flow state of molten plastic in the mold runner and cavity, and is one of the key parameters affecting the accuracy of thin-walled parts. For thin-wall injection molding, the cooling rate of plastic in the mold cavity is extremely fast. If the speed is not properly controlled, it is prone to molding defects.

If the injection speed is too fast, the molten plastic will rush into the mold cavity at a high flow rate, which not only easily leads to flash and overfilling, but also may cause the plastic to burn due to excessive local shear force. At the same time, the rapidly flowing plastic will carry air into the mold cavity, forming defects such as bubbles and air streaks; If the injection molding speed is too slow, the molten plastic will quickly cool and solidify during the flow process, resulting in incomplete filling of the mold, short shots, sink marks, and poor fusion effect of the plastic at the joint, which can easily produce weld lines, reduce the structural strength of the product, and even lead to product fracture.

Practical suggestion: Combining mold gate design with product structure, adopt the “variable speed injection molding” mode. For the area near the gate, a slower speed can be used to avoid local defects caused by plastic impact on the gate; For thin-walled and complex areas, increase the speed appropriately to ensure that the plastic is filled before cooling; When approaching the completion of mold filling, reduce the speed again to minimize the risk of overfilling.

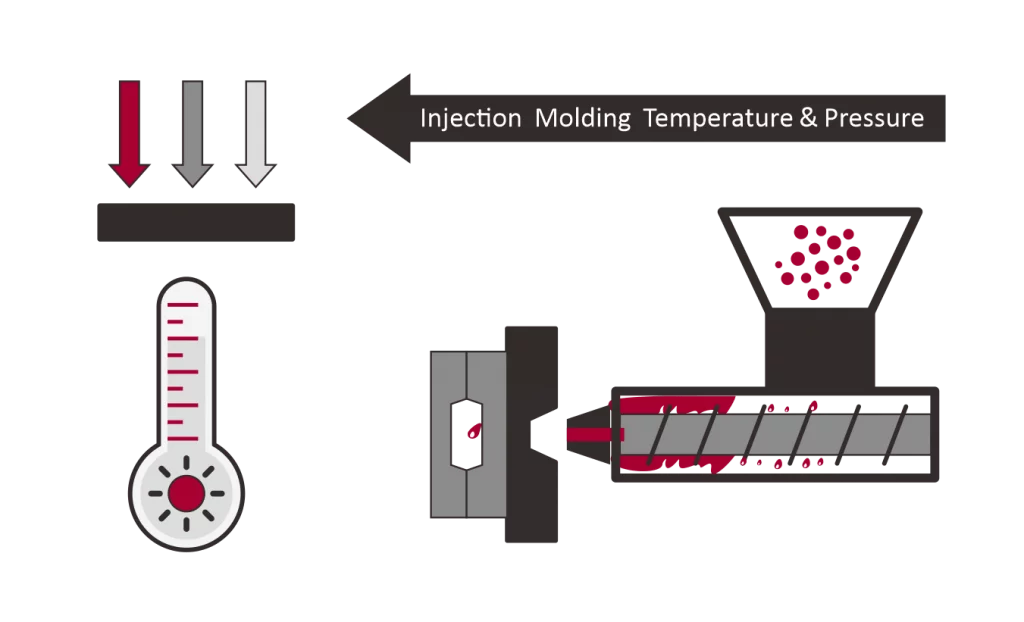

4. Temperature Control Strategies for Stable Plastic Injection Molding

Temperature parameters include barrel temperature, nozzle temperature, and mold temperature. The high temperature resistance characteristics of different plastic raw materials vary greatly, and targeted settings are needed. Even slight deviations in temperature can directly affect the flowability and formability of the molten plastic, thereby affecting product accuracy.

If the temperature is too low, the plasticization of the molten plastic is not sufficient, and the flowability is poor, it will not only cause uneven color, but also significantly increase the internal stress of the product, which is prone to warping and cracking in the future; At the same time, the molding resistance of low-temperature plastics increases, which may need to be compensated for by increasing the injection pressure, and excessive pressure can increase the risk of screw fracture. If the temperature is too high, the plastic will undergo excessive plasticization, with excessive flowability, resulting in flash on the product; Moreover, the temperature difference between the high-temperature plastic and the mold during cooling is too large, which can cause uneven shrinkage and result in product size deviation; More seriously, excessively high temperatures can cause plastic to decompose, turn yellow, and discolor, reducing product performance. At the same time, it can prolong cooling time, affect production efficiency, and may also cause trapped gas in the plastic in time, resulting in bubble defects.

Practical suggestion: Firstly, check the optimal plasticizing temperature range based on the raw material model (such as PP, ABS, PC, etc.), and set the basic temperature. Then observe the product condition through trial molding. If there are problems such as uneven color and high internal stress, increase the temperature of the material barrel appropriately; If there are issues such as flash or discoloration during decomposition, lower the temperature. At the same time, it is necessary to optimize the mold temperature synchronously to ensure uniform cooling of the plastic and reduce shrinkage deviation.

Summary:

Improving the precision of thin-wall injection molding is not achieved by optimizing a single parameter, but by coordinating the four core parameters of clamping force, injection pressure, injection speed, and temperature. At the same time, comprehensive optimization should be carried out in combination with mold precision, raw material characteristics, and product structure. In actual production, it is recommended to accumulate data through system trial molding, establish a process parameter database for different products, and strengthen parameter monitoring during the production process to timely respond to factors such as raw material fluctuations and equipment condition changes.

With the continuous development of the precision manufacturing industry, the precision requirements for thin-wall injection molding will continue to increase. Mastering scientific process control techniques can not only effectively improve product qualification rates, but also enhance the market competitiveness of enterprises. If you encounter any other challenges in thin-wall injection molding production, feel free to communicate and discuss with KingStar at sales@kingstarmold.com or leave online message at any time. We will provide you with solutions by leveraging our professional technical team!