Mold Building Workflow

Customer Order

Process customer orders by reviewing their requirements and organizing the necessary documentation.

Working Schedule

Create a production schedule based on order specifications. The schedule is finalized after discussions and confirmation of details.

Mold Design

Our engineering team creates a 3D mold design based on the approved DFM report, incorporating all the necessary details for the injection mold.

Mold Design Approval

After the 3D mold design is completed, the design team will review it and send the drawing to the customer for approval.

Procurement of Mold Steel and Accessories

After the mold drawing is finalized, purchase the specified mold steel and accessories as outlined in the drawing.

Milling & Lathe

Milling machines and lathes are utilized in mold processing for tasks such as rough cutting, precision machining, drilling, boring, finishing, and threading.

CNC

CNC machines are utilized in mold processing for tasks such as precision cutting, drilling, milling, engraving, and shaping intricate contours in mold components.

EDM Operations

EDM machines are employed in mold processing to create intricate details, complex shapes, and fine surface finishes, particularly when working with hard materials.

Grinding & Polishing

Grinding and polishing in mold processing are essential for achieving precise dimensions, smooth finishes, and improving molds’ surface quality.

Fitting and Testing

Fitting and testing in mold processing ensure the accurate assembly, functionality verification, and proper alignment of mold components before the final production stage.

Quality Check

In mold processing, quality checks involve inspecting the dimensions, surface finish, and functionality to ensure they meet the design specifications.

Delivery

Export molds are packaged and shipped to customers, while production molds are delivered to the production department after acceptance.

Injection Molding Workflow

Customer Order

Process customer orders by reviewing their requirements and organizing the necessary documentation.

Working Schedule

Select the suitable injection molding production machine based on the order details, product production schedule, and other relevant factors.

Raw Material Purchasing

For injection molding mass production, raw materials such as polymers, additives, and colorants are purchased according to the production specifications and volume requirements.

Granular Plastic Processing

Granular plastic processing in injection molding includes drying, mixing, and, if necessary, compounding the granules before feeding them into the machine.

Machine Setup

During mass production, machine setup includes installing the molding machine, calibrating its parameters, and conducting initial test runs to ensure quality.

Data Setting

During mass production, injection machine data setting involves configuring parameters such as temperature, pressure, injection speed, and cycle time to ensure optimal performance.

Initial Production Review

The initial production review involves thorough quality checks, measurements, and performance evaluations of the first batch of products. This ensures they meet all required specifications and standards before proceeding to full-scale production.

Mass Production

Mass production in injection molding includes ongoing molding operations, quality monitoring, and adjustments to ensure both production efficiency and consistent product quality.

Quality Control

Quality control in mass production of injection molding involves regular inspections, defect analysis, and ensuring adherence to product specifications and standards.

Products Packing

Product packing in injection molding mass production involves sorting, quality control, labeling, and packaging for shipment and distribution.

Warehousing

In injection molding mass production, warehousing requires effective storage planning, inventory management, and logistics coordination for the finished goods.

Delivery

During injection molding mass production, product delivery involves packaging, labeling, logistics planning, and shipment to ensure timely delivery to customers.

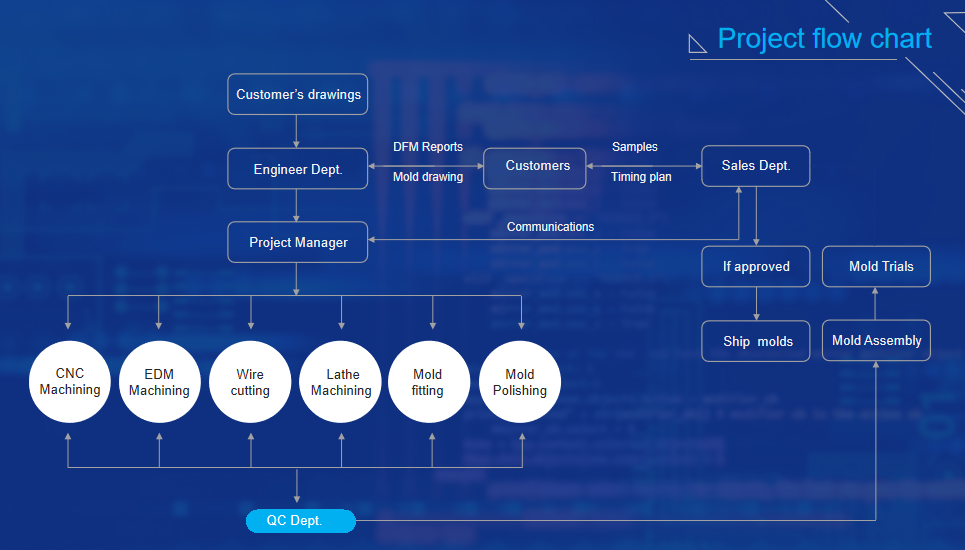

Other Projects‘ General Workflow

Yes, we provide you with a detailed design of the mold for approval before proceeding with production, ensuring it meets your requirements.

The timeline varies depending on the complexity of the design, but typically projects take 4 to 8 weeks, from initial consultation to final production.

You can start by contacting us with your project details, including design specifications and materials. Our team will then schedule a consultation to discuss the next steps.

Our workflow starts with understanding your needs, followed by design consultation, mold development, prototyping, testing, and finally, full-scale production. We guide you through each step for a seamless experience.

Yes, we provide regular updates on the progress of your project. Our team is always available to answer any questions or address concerns as the project moves forward.

We maintain strict quality control at each step of the process, from mold creation to final production, ensuring that the final product meets your specifications.

We encourage early feedback, but if changes are needed later, they can be accommodated depending on the stage of the project. Some adjustments may affect timelines or costs.

Once the mold is created and approved, we proceed with prototyping to ensure the design works as intended. After successful testing, we move to full-scale production.