What is Electroplating?

Showcase of Anodizing Finished Products

Caster Wheel

Iron Pipe

Fidget Spinner

Glossy Vase

Pendant Light

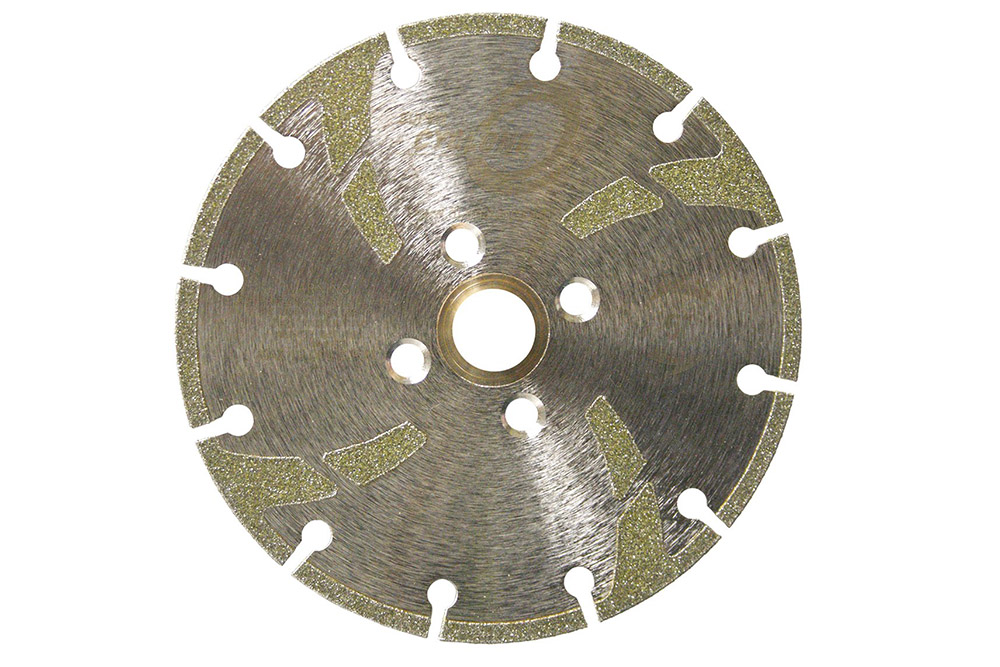

Marble Blade

Metal Money Clip

motorcycle chain

Advantages of Anodizing Your Product

Enhanced Durability

Electroplating improves the wear resistance and longevity of products, protecting them from corrosion, scratches, and damage over time.

Aesthetic Appeal

With electroplating, you can achieve a smooth, shiny finish that enhances the visual appearance of products, ideal for decorative and high-end applications.

Cost-Effective Protection

Various Options for Electroplating

| Electroplating Type | Applications | Cost Range |

|---|---|---|

| Gold Plating | Jewelry, electronics, connectors, decorative finishes | High ($$$) |

| Nickel Plating | Automotive parts, machinery, electronics, corrosion protection | Medium ($$) |

| Silver Plating | Electrical components, jewelry, medical devices, decorative items | Medium ($$) |

| Chrome Plating | Automotive parts, household items, tools, decorative finishes | Medium to High ($$-$$$) |

| Copper Plating | Electrical conductors, printed circuit boards (PCBs), machinery | Low to Medium ($-$$) |

| Zinc Plating | Fasteners, hardware, automotive parts, corrosion resistance | Low ($) |

| Palladium Plating | Jewelry, electronics, high-end connectors | High ($$$) |

| Rhodium Plating | Jewelry, watches, decorative finishes, corrosion resistance | High ($$$) |

Nickel plating provides excellent corrosion resistance, enhances durability, and improves the appearance of the surface, making it ideal for automotive, machinery, and electronics.

Yes, KingStar Mold offers customized electroplating services to meet your specific needs, whether you require a particular metal coating or a custom finish.

The durability of an electroplated surface depends on factors like the type of metal, the thickness of the coating, and environmental conditions, but it can last several years with proper maintenance.

Common metals used for electroplating include gold, silver, nickel, chrome, copper, and palladium, each offering different properties based on the application.

Electroplating offers superior protection, improves the aesthetic appearance, and enhances the performance of your products at a cost-effective price.

Electroplating is a process that uses electrical current to deposit a thin layer of metal onto a surface, enhancing its durability, appearance, and resistance to corrosion.

To maintain electroplated surfaces, clean them regularly to avoid buildup of dirt or chemicals, and avoid harsh abrasives or chemicals that can damage the plated layer, ensuring its longevity.

Electroplating is most commonly applied to metals, especially those that are conductive, such as aluminum, steel, and copper, though some non-metal materials can be treated with special processes.

To get started, simply reach out to KingStar Mold with your project details, and our team will guide you through the process, providing a tailored solution and quote.

KingStar Mold ensures high-quality, precise electroplating by using advanced equipment and techniques to provide reliable, consistent results that meet your product specifications.

Electroplating is widely used in automotive, electronics, jewelry, aerospace, and medical industries, offering both functional and decorative benefits for various components.

The electroplating process involves cleaning the base material, immersing it in a metal salt solution, and using an electrical current to deposit the metal layer onto the substrate.

Electroplating enhances your product’s surface by improving its hardness, reducing friction, preventing corrosion, and providing a sleek finish, which ultimately boosts its performance.