EDM Service At KingStar Mold

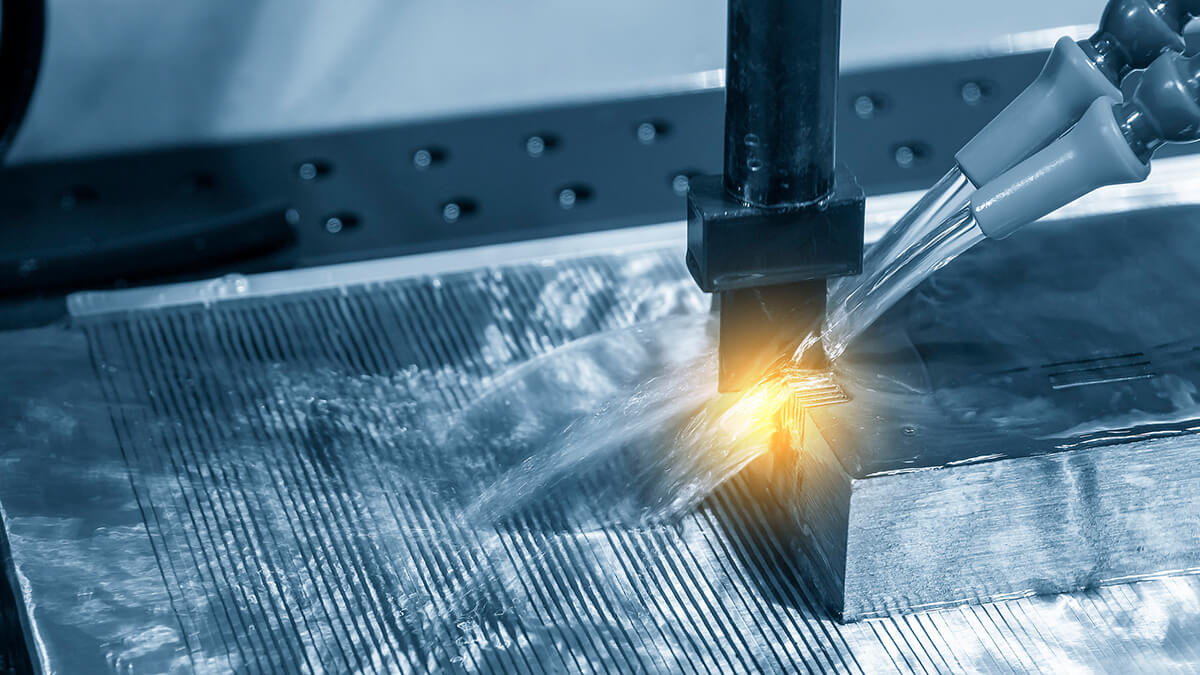

EDM (Electrical Discharge Machining) is a precision machining process that uses controlled electrical discharges to remove material from a workpiece. It is ideal for creating intricate shapes, tight tolerances, and fine details in hard materials like metals, which are difficult to machine with conventional methods. EDM is widely used in industries such as aerospace, automotive, and mold-making for producing complex parts and tools.

EDM Application

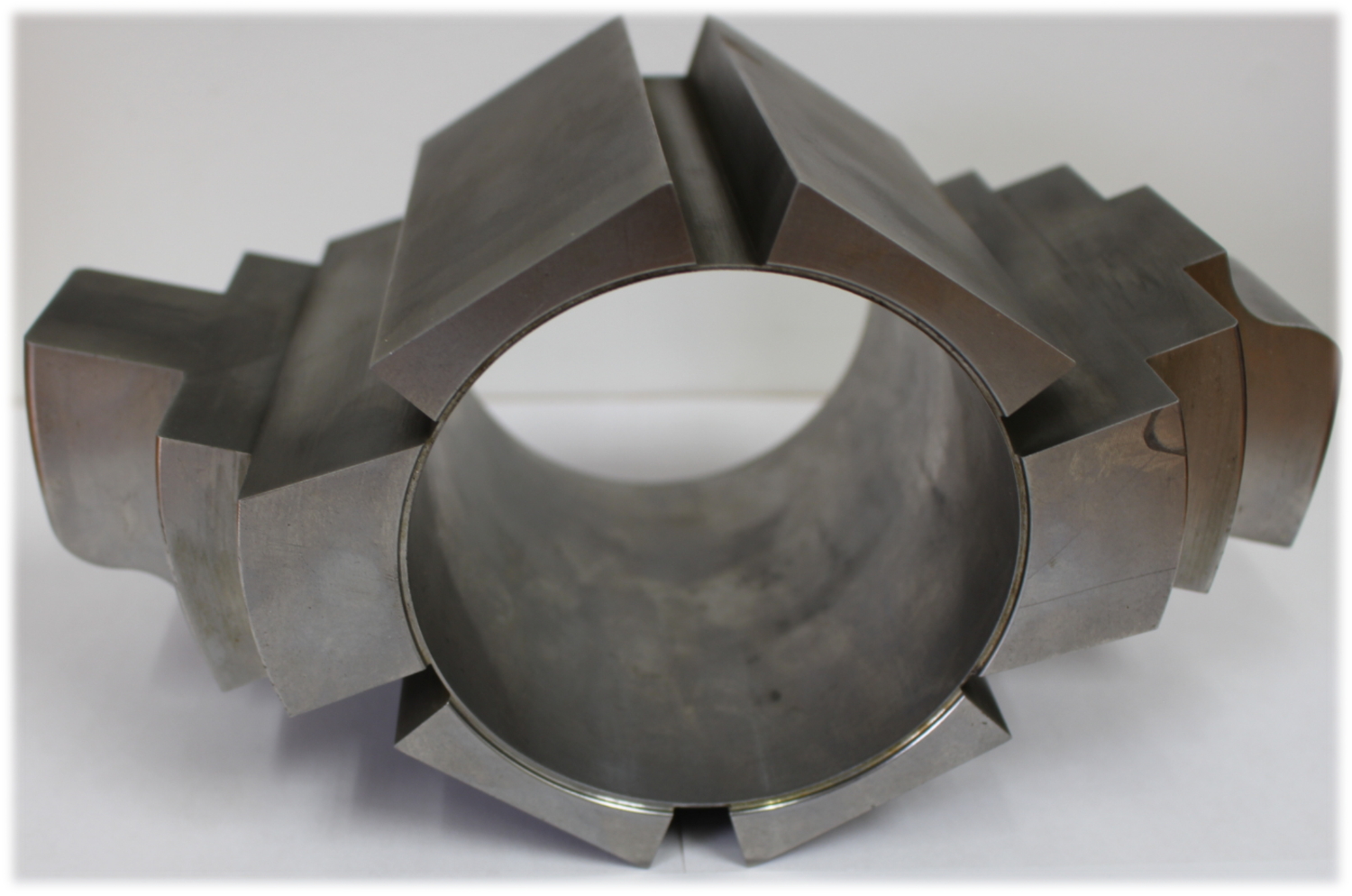

What We Can Produce Through EDM

Product Gallery

Why Choose Us

We Believe You Will Choose Us Again

Only companies with extensive market experience and a deep understanding of customer needs can offer the best service.

Skilled

High-precision production equipment, skilled production staff, and guaranteed delivery times.

Experienced

Over ten years of industry experience, with a mature quotation system and technical support.

Thoughtful

Customized processing options that save time and effort, with active support throughout pre-sales and post-sales.

Equipped

Engineers review designs to identify and resolve potential issues, backed by advanced testing equipment.

EDM offers high precision and can achieve tight tolerances, making it ideal for producing complex and detailed mold components.

EDM can be used with hard materials like tool steel, carbide, and other alloys, which are commonly used in mold-making.

Yes, EDM is highly effective for producing small, intricate mold parts that are difficult to machine with traditional methods.

EDM can produce various mold parts, such as cavity and core inserts, ejector pins, threaded inserts, and cooling channels, among others.

EDM uses controlled electrical discharges to remove material from a workpiece, allowing for the creation of complex shapes with tight tolerances.

EDM is used for creating precise and intricate mold parts, including cavities, cores, inserts, and cooling channels, which are essential for high-quality molds.

To get started, simply contact us with your design specifications, and our team will guide you through the process, from design to final production.

Yes, KingStar Mold provides EDM services for creating high-precision mold parts, including complex geometries and intricate designs.

EDM allows for high precision, the ability to machine complex shapes, and the use of hard materials that are difficult to process with conventional methods.

Yes, EDM is excellent for creating undercuts, as it can machine shapes that are difficult or impossible to achieve with traditional tools.

The time required depends on the complexity and size of the part, but EDM typically offers faster production of complex shapes compared to traditional machining methods.

Yes, EDM is suitable for both low-volume and high-volume mold production, depending on the complexity of the parts.