Digital Photopolymer Overview

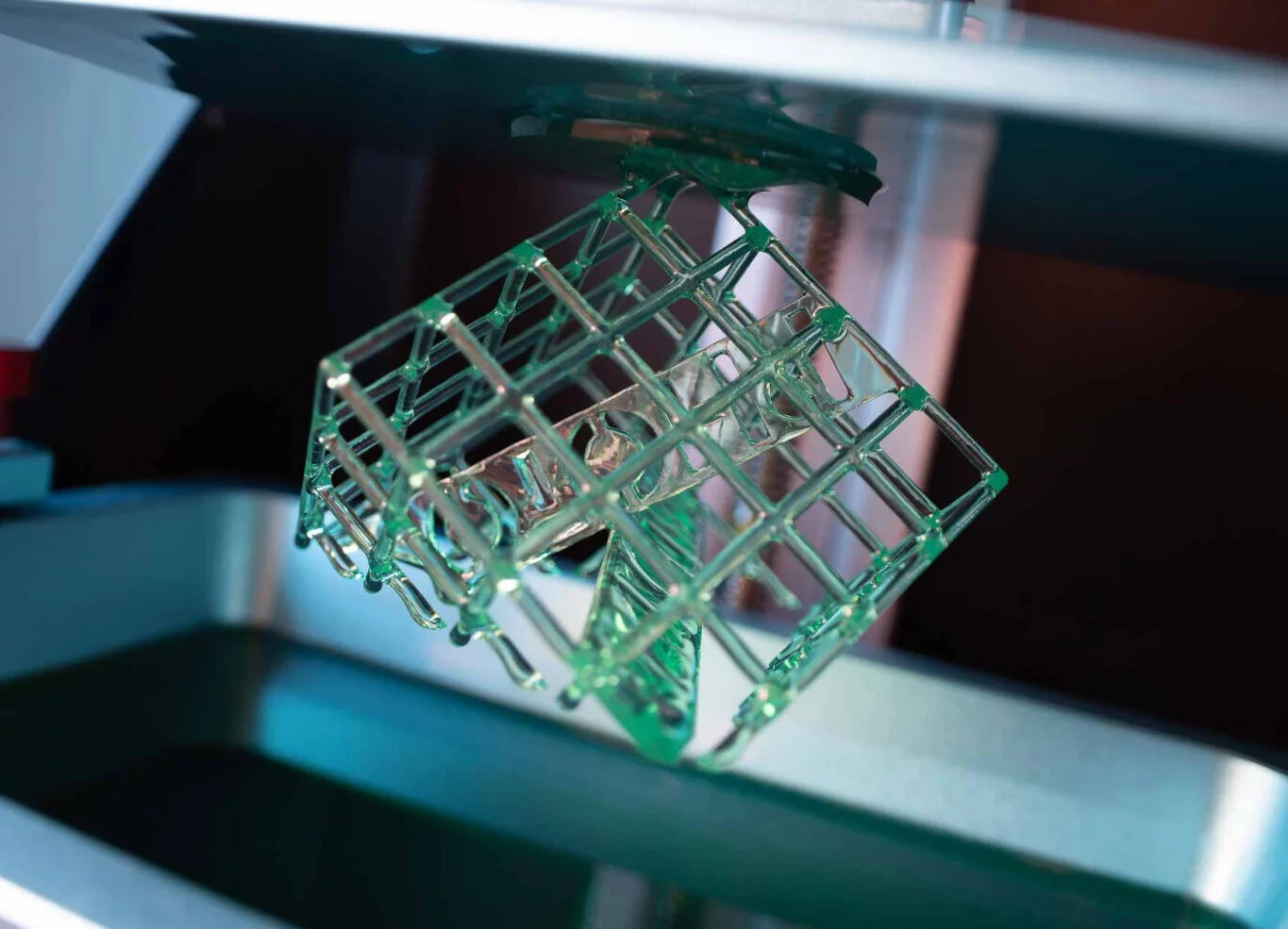

Digital photopolymer 3D printing is an advanced additive manufacturing process that harnesses digital light projection technologies, such as DLP (Digital Light Processing) and LCD (Liquid Crystal Display), to fabricate three-dimensional objects with remarkable precision. At its core, the printer takes a digital 3D model and slices it into numerous thin cross-sections. A specific wavelength of ultraviolet (UV) light, typically emitted by a UV light source in the printer, is then directed towards a vat of liquid photopolymer resin. This resin contains photoinitiators which, upon exposure to the UV light, trigger a polymerization reaction. As the light projects the shape of each layer onto the resin surface according to the sliced model data, the resin in the illuminated areas rapidly solidifies, forming a solid layer. The build platform then moves either up or down by the thickness of a single layer, and the process repeats. This layer-by-layer solidification and stacking continue until the entire 3D object is fully formed.

Its “digital-driven” design, featuring technologies like DLP’s micromirror arrays, enables pixel-level light control—cutting layer curing time to 1–10 seconds and achieving ±0.01mm precision, making it ideal for intricate details. Traditional SLA, with its laser point-scanning, offers its own strengths in certain applications, and you can explore our SLA or other 3D printing services via the navigation below for options that may suit your needs.

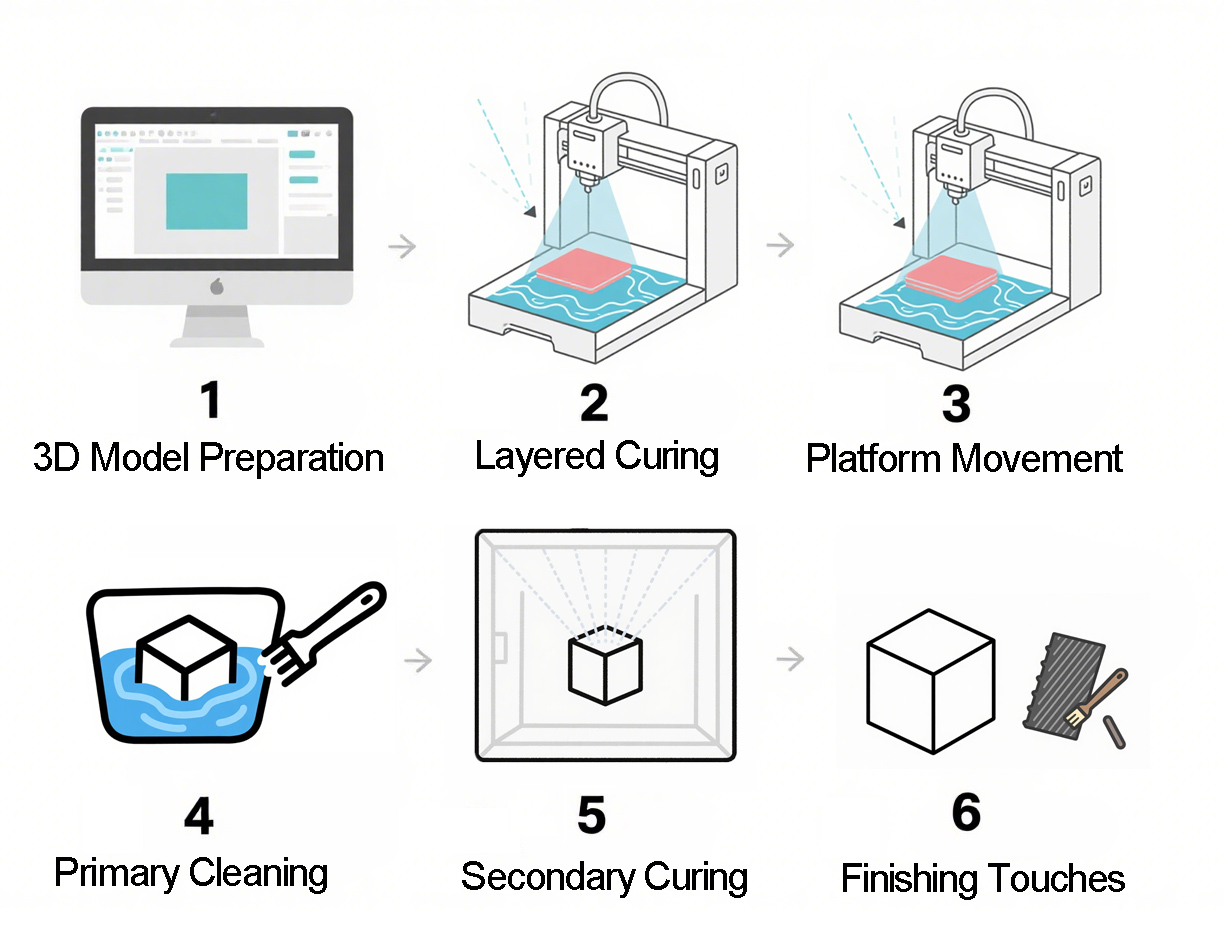

Digital Preparation: A 3D model is sliced into ultra-thin cross-sections (typically 5–100μm thick) using specialized software, generating layer-by-layer digital blueprints with precise dimensions.

Layered Curing: The printer projects UV light onto a vat of liquid photopolymer resin, matching the exact shape of the first sliced layer. The resin’s photoinitiators react instantly to the light, triggering polymerization—solidifying only the illuminated area into a firm, precise layer.

Platform Movement: The build platform shifts upward (or the resin vat lowers) by the exact thickness of one layer, exposing a fresh film of liquid resin for the next cross-section.

Primary Cleaning: Once printing finishes, the part is removed from the build platform and submerged in isopropyl alcohol (IPA) or a specialized cleaning solution for 5–10 minutes to dissolve uncured resin clinging to surfaces, ensuring no sticky residue remains.

Secondary Curing: The cleaned part is placed in a UV curing chamber (with controlled intensity and wavelength) for 10–30 minutes. This step fully activates the resin’s cross-linking, boosting mechanical strength (e.g., tensile strength or flexibility) by up to 40% compared to the initial printed state.

Finishing Touches (Optional): For higher precision, fine sanding with micro-grit sandpaper (400–1000 grit) smooths layer lines; some parts may also undergo painting, coating, or assembly depending on end-use needs.

SLA/PolyJet Printing Capabilities & Material Properties

SLA

| Parameter | Specs |

|---|---|

| Printing Accuracy | ±0.05-0.2mm (higher accuracy for small parts, e.g., dental models up to ±0.01mm; ±0.1%×L for large parts >100mm) |

| Layer Thickness Range | 25-100μm (standard 50μm; 16μm in high-precision industrial machines) |

| Surface Roughness | Ra 1.6-3.2μm (requires post-polishing for higher smoothness; specialized resins can reach Ra 0.8μm for dental use) |

| Printing Speed | 5-20mm/h (vertical direction; slower for complex geometries; high-speed models like ProX 950 offer 10x efficiency) |

| Maximum Build Size | Up to 1000×800×500mm (industrial machines; desktop models typically 200×200×200mm) |

PolyJet

| Parameter | Specs |

|---|---|

| Printing Accuracy | ±0.02-0.1mm (up to ±0.01mm for small parts; supports microchannels <0.5mm and complex hollow structures) |

| Layer Thickness Range | 16-30μm (14μm in high-precision models like J850 Prime) |

| Surface Roughness | Ra 0.8-1.6μm (injection-mold-like finish; no post-polishing needed for most applications) |

| Printing Speed | 10-30mm/h (vertical direction; faster with multi-nozzle jetting; 30% speed boost for clear aligners in high-speed mode) |

| Maximum Build Size | Up to 500×400×300mm (industrial models like J850 Prime; dental-specific DentaJet XL for mass production) |

| Shore A | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| ASTM Standard | 30 | 40 | 50 | 60 | 70 | 85 | 95 | Rigid | |

| Tensile Strength | D-412 | 2.4-3.1 MPa | 3.0-4.0 MPa | 3.0-4.0 MPa | 3.5-4.5 MPa | 4.0-6.0 MPa | 6.0-10.0 MPa | 10.0-14.0 MPa | 50-65 MPa |

| Elongation at Break | D-412 | 220-270% | 190-210% | 170-210% | 150-170% | 120-140% | 70-90% | 50-70% | 10.0-25.0% |

| Tensile Tear Strength | D-624 | 5.0-7.0 Kg/cm | 6.0-8.0 Kg/cm | 7.0-9.0 Kg/cm | 7.0-10.0 Kg/cm | 12.0-14.0 Kg/cm | 22.0-26.0 Kg/cm | 26.0-30.0 Kg/cm | - |

| Shore Hardness | D-2240 | 30-35 (Scale A) | 40-50 (Scale A) | 50-55 (Scale A) | 55-60 (Scale A) | 60-70 (Scale A) | 80-85 (Scale A) | 85-90 (Scale A) | 83-86 (D) (Scale A) |

*Note: All data provided are typical ranges for reference only. Actual values may vary slightly depending on factors such as specific printer models, resin formulations, part geometries, and operational settings. As a result, the information is not legally binding or certified.

Why Choose Digital Photopolymer 3D Printing