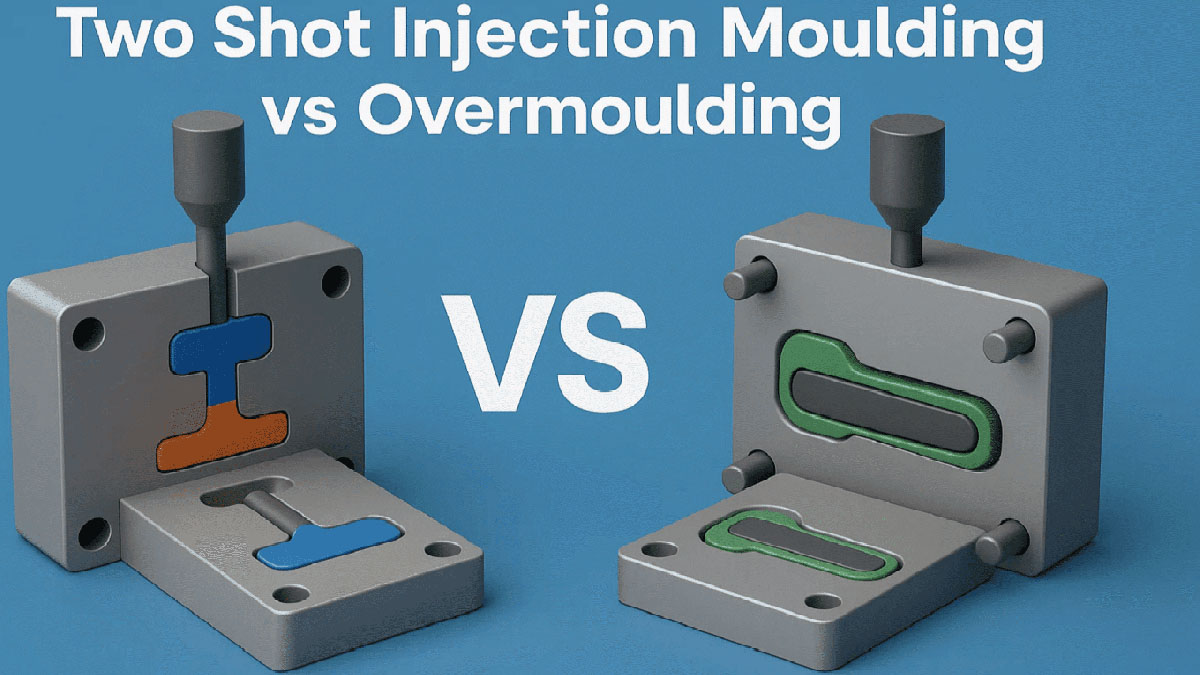

In the field of plastic product manufacturing, two-shot injection molding and overmolding are two mainstream multi-material molding processes. With their unique technical characteristics and application advantages, they serve diverse product manufacturing in different scenarios.

As a leading injection molding company, we receive inquiries every week about the difference between two-shot injection molding and over molding. In this post, we will comprehensively introduce the differences from multiple dimensions such as core advantages, molding principles, process characteristics, mold structure, and new technology applications, providing practical references for industry practitioners.

1.1 Core advantages of Two-shot Injection Molding

The core value of two-shot injection molding lies in achieving the integrated molding of two resins with different properties and colors, directly producing a single two-color product. This feature reduces the assembly process and post-processing steps of molded products from the source, not only saving additional costs such as bonding and printing, but also enhancing the visual aesthetics of products through color layering and material complementarity, significantly enhancing product grade and market added value. In terms of practical performance, the integration of flexible resin provides anti-slip and friction increasing functions, which are more in line with ergonomic design and have a comfortable and delicate feel. On the production level, two-shot molded products offer excellent stability, short molding cycle, easy control of products deformation, and large output. Compared with overmolding, losses can be reduced by 7% -10%, and manufacturing costs can be saved by 20% -30%, combining quality and cost-effectiveness advantages.

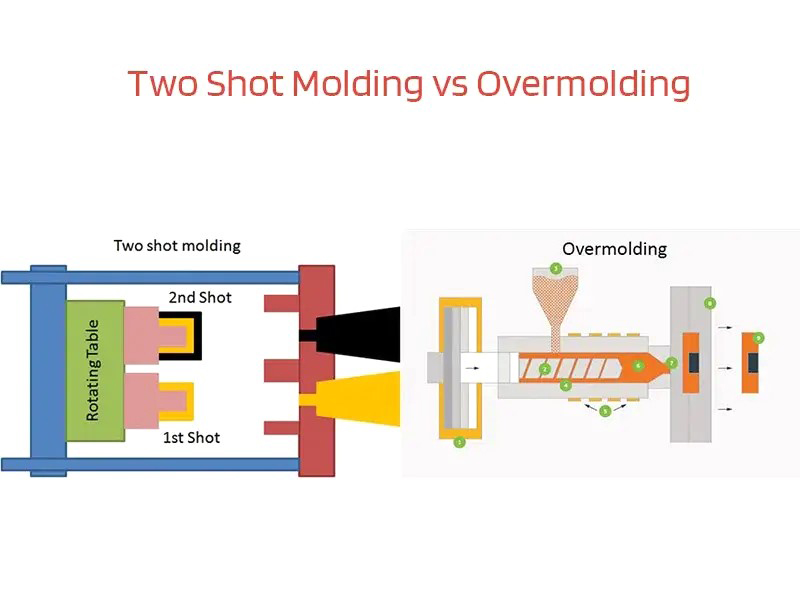

1.2 Forming Principle of Two-shot Injection Molding

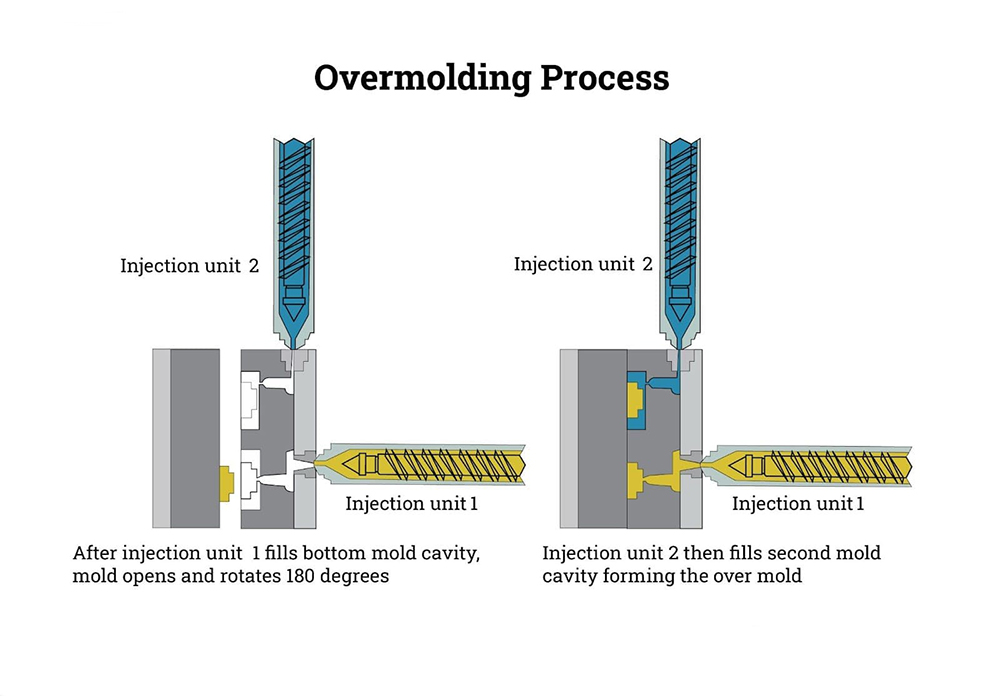

Two-shot injection molding is specifically designed for the molding needs of two colors or different types of plastics, and its technical core lies in the special structure of the two-shot injection molding machine. The device is equipped with two independent separate injection units and nozzles to ensure that the two types of plastics do not mix during the molding process, and the two-color boundary of the finished product is clear. Compared with ordinary injection molding machines, the key difference of two-shot machines lies in the design of movable platen-they must have a rotating mechanism. Common designs include adding a rotary or shaft mechanism, which can achieve 180° reciprocating rotation and drive the mold to complete cyclic alternating actions; Some special two-shot molds do not require such mechanisms, and can be formed by sliding alternately or horizontally rotating the mold.

1.3 Production Process Characteristics

- Equipment Configuration: The two-shot machine includes two sets of plasticizing injection devices with completely identical structures and specifications. The nozzle needs to be designed with a special structure according to production needs, or matched with two sets of molding molds of the same specifications that can rotate to ensure precise injection of two types of plastics.

- Parameter Requirements: Due to the longer flow channel and more complex structure of the two-shot mold, the flow resistance of the injected melt is relatively high. Therefore, the temperature and pressure of the melt during injection must be higher than those of ordinary injection molding processes to ensure smooth filling of the mold cavity with the melt.

- Material Selection: Plastic materials with good thermal stability as well as low melt viscosity, such as polystyrene, polyolefin resins, ABS materials, etc., should be preferred to avoid degradation of the melt due to high temperature environment and prolonged residence in the runner, which may affect product quality.

- Molding Control: In order to achieve good bonding of two different colored melts in the mold, ensure the molding quality and structural stability of injection molded products, it is necessary to use higher melt temperature, mold temperature, injection pressure, and injection rate to optimize the bonding effect of the two materials.

1.4 Mold Structure Types

Traditional two-shot injection molds are mainly divided into two types: “Punch-pin Slide” and “Punch-pin Rotate”, which have significant differences in workflow and production efficiency:

- Punch-pin Slide Type: The mold consists of two cavities and one Punch-pin. When the first barrel injects, the Punch-pin and the first cavity are closed, completing the injection of the first type of plastic; After the first type of plastic solidifies, the Punch-pin and cavity separate, and the semi-finished product formed by the first plastic moves horizontally with the core to align with the position of the second cavity; The injection molding machine closes again, and the second barrel injects the second type of plastic. After the plastic solidifies, the mold opens and the complete product is ejected.

- Punch-pin Rotate Type: The mold is equipped with two cavities and a rotatable Punch-pin composed of two back-to-back combinations. The matching two-shot injection molding machine is equipped with two barrels, and the second barrel is preferably designed in the vertical direction of the injection molding machine’s movement direction, which can achieve simultaneous injection of two types of plastics. After both types of plastics solidify, injection molding machine opened and automatically ejected the complete product; After removing the product, the rotatable core rotates 180°, the injection molding machine closes, and enters the next production cycle.

- Efficiency Comparison: Due to the fact that the two barrels inject alternately in the “Punch-pin Slide” mode, while the two barrels inject simultaneously in the “Punch-pin Rotate” mode, the production efficiency of the “Punch-pin Rotate” mode is twice that of the “Punch-pin Slide” mode when producing the same product.

1.5 Application of New Technologies

The new technology in the field of two-shot injection molding has achieved significant breakthroughs, with its core feature being the use of a single-cavity mold. This mold has a common cavity required for both the first type of plastic (“hard plastic”) and the second type of plastic (“soft plastic”), and only requires one set of cavity and core plates, which is fundamentally different from the structure of traditional two-shot molds. The specific process flow is as follows: After the first barrel completes the injection of the first plastic (hard plastic), wait for the hard plastic to partially or completely solidify; A control mechanism activates a power cylinder to retract an isolating blade until it is flush with the core plate’s molding surface. Subsequently, the second barrel injects the second plastic (soft plastic); After the soft plastic has completely solidified, the injection molding machine opens to remove the complete product, and then the machine closes to enter the next production cycle.

The advantages of this new technology are very significant:

1) It simplifies the mold structure and reduces the cost of mold design and manufacturing;

2) It reduces the demand for workspace of injection molding machines, allowing for the use of smaller two-shot injection molding machines, thereby reducing equipment investment costs and energy consumption during the production process;

3) Production efficiency has been significantly improved, and the output has doubled compared to the traditional “overmolding method”;

4) It fundamentally avoids the defective products caused by the traditional process of putting the “hard plastic” that has undergone shrinkage and deformation back into the mold cavity for secondary molding, significantly improving the product qualification rate.

2. Introduction of Overmolding

Overmolding, also known as secondary molding, is a core logic that completes product manufacturing through two-step injection molding. The specific process is as follows: two types of plastic materials may not necessarily be injected on the same machine, but are molded in two stages; Firstly, the first injection molding is completed in the first set of molds. After the product is ejected, it is then placed in the second set of molds for a second injection molding, ultimately forming a finished product combining the two materials.

1) In terms of equipment and mold requirements, the overmolding process usually requires two sets of molds and does not require a specialized two-shot injection molding machine. The structure of the mold used is completely consistent with that of the single-color injection mold, mainly by adjusting the flow rate in the injection parameters to control the bonding point of the two materials and ensure a tight fit between the two materials.

2) In terms of material matching, the main form of plastic injection molding is “soft plastic over hard plastic”. Soft plastic is commonly made of artificial rubber, TPR, TPU, etc., while hard plastics can be ABS, PP, PC, etc. By combining soft and hard materials, the structural strength and tactile experience of the product can be taken into account.

3. Core Differences Between Two-Shot Molds and Overmolds

| Comparison Dimension | Two-Shot Mold | Overmold (Secondary Molding) |

|---|---|---|

| Injection Machine Requirement | Requires a dedicated two-shot injection molding machine. | No special equipment required; standard injection molding machines suffice. |

| Number of Molds | 1 mold set (with special structural design). | 2 mold sets (identical in structure to single-color injection molds). |

| Molding Process | Two injections, one part ejection. | Two injections, two part ejections (requires manual/mechanical transfer). |

| Material Injection Location | Both materials injected on the same machine. | Materials can be injected on the same or different machines. |

| Mold Structure Characteristic | Contains special mechanisms (rotation/slide), complex design. | No special mechanisms, simple structure, identical to single-color molds. |

| Material Bonding Control Method | Relies on precise machine parameter control and mold structure design. | Primarily controlled by adjusting injection parameters like speed at the bonding point. |

| Production Waste | Low waste, 7%-10% lower than overmolding. | Relatively higher waste, influenced by transfer and secondary positioning. |

| Product Manufacturing Cost | Lower cost, 20%-30% lower than overmolding. | Higher cost, includes investment for two mold sets and secondary processing costs. |

| Product Quality Stability | Stable quality, easy deformation control, low defect rate. | Slightly lower stability due to secondary positioning in the mold, relatively higher defect rate. |

| Core Applicable Scenarios | High-efficiency, low-cost, high-quality integrated dual-color/dual-material products for mass production. | Small-batch production, products with complex structures, or scenarios with limited equipment investment. |

In summary, two-shot injection molding and overmolding each have their own technical characteristics and applicable scenarios. Two-shot injection molding, with its advantages of high efficiency, low cost, and high quality, is more suitable for large-scale production of products with high requirements for appearance, feel, and stability; And overmolding is characterized by low equipment investment and structural flexibility, suitable for the manufacturing needs of small batch production or complex structural products. Companies can choose the most suitable molding process based on their own production scale, product characteristics, and cost budget.

If you would like further information or to source reliable custom manufacturer for your project, please feel free to reach out to the KingStar team at sales@kingstarmold.com or online message anytime. We will reply to you within 24 hours!