1. What is IMD Technology?

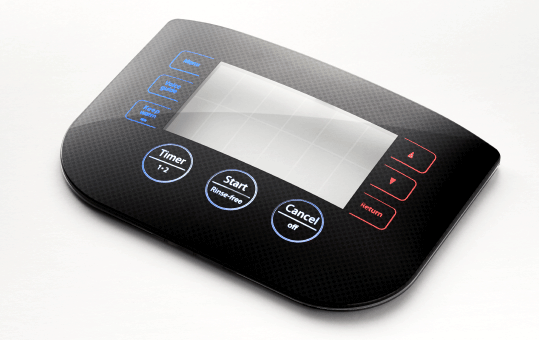

As a popular surface decoration technology internationally, IMD(In-Mold Decoration) is mainly applied to the surface decoration and various functional panels of home appliances, covering different areas such as mobile phone casing and window lense, refrigerator control panel, washing machine control panel, air conditioning control panel, car instrument panel, rice cooker control panel, and other external components such as panels and logos.

In terms of conceptual definition, IMD is a technical system that includes specific process types such as IML (In-Mold Labeling), IMF (In-Mold Film), IMR (In-Mold Transfer), etc. Among them, IMF and IML processes are essentially the same, with only slight differences in naming and expression. At KingStar, a leading IMD injection molding company, today, we will provide a detailed introduction of this internationally popular technology, leading you to a clear understanding of the characteristics and differences of IMD and its core branch processes, and providing reference for your production selection.

2. Core Differences Between IML and IMR Processes

- IML: In-Mold Labeling. What defines this technique is a hardened and transparent film on the outer side, a printed design layer in the center, and a plastic substrate at the rear. Due to the ink being sandwiched in the middle, the product can prevent scratches and abrasion on the surface, and can maintain a bright color for a long time without fading easily.

- IMR: In-Mold Transfer. This process involves printing patterns on a thin film, followed by attaching the film to the mold cavity via a film feeder for the injection molding process. After injection molding, the ink layer with patterns separates from the film, leaving the ink layer on the plastic part to obtain a decorative pattern on the surface. In the final product, there is no transparent protective film on the surface, and the film is just a carrier in the production process.

IML and IMR are the two most common processes in IMD systems, and the biggest difference between the two is whether there is a transparent protective film on the surface of the final product. Below is a detailed comparison from the four core dimensions of mold, sheet, printing, and process:

| Comparison Dimension | IMR (In-Mold Release) | IML (In-Mold Labeling) |

|---|---|---|

| Mold Configuration | Only one set of inverted injection mold | Includes three sets of molds: forming mold, punching mold, and injection mold |

| Sheet Material Selection | Usually PET film | Various sheet materials can be selected, such as PC, PET, PMMA, etc. |

| Printing Method | Uses roller printing, which allows for printing a large area at once | Employs CMYK color matching system, combined with screen printing and pad printing processes |

| Production Process | Printed patterns are placed into the injection mold, aligned, and directly injected; the process is simple, enabling full automation and reducing manual labor | Printed sheets first undergo forming, then punching, and finally injection molding; the process is more complex compared to IMR |

3. What is IML Process?

3.1 Process Definition and Core Structure

IML, In-Mold Labeling, its core is to achieve a tight combination of printed sheet material and plastic. The significant structural feature of this process is “three-layer composite”: A hardened transparent film forms the exterior, while the middle part is a printed pattern layer and the rear is a plastic layer.

3.2 Technological Advantages and Material Selection

Due to the ink pattern layer being encapsulated between the transparent film and plastic layer, products produced by IML technology have outstanding advantages: they can effectively prevent surface scratches, resist abrasion, and maintain bright colors for a long time without fading easily.

In terms of material selection, besides the commonly used PET, IML can also choose sheet materials such as PC and PMMA; The plastic pellets used in injection molding generally include PMMA, ABS, PC, PP, TPU, ABS+PC, etc. However, the specific selection of sheets may vary depending on the technical level of each company.

3.3 Process Limitations

The biggest drawback of IML technology is that it cannot achieve the overall application of IML technology, and its decorative scope is usually limited to a specific area of the product, which is difficult to meet the needs of full surface decoration.

4. What is IMR Process?

4.1 Process Definition and Core Principle

IMR is In-Molding Roller. The core of the process lies in the design of the release layer on the rubber material. Japan refers to this process as Thermal Transfer, and the production equipment uses the ROLL TO ROLL method, with precise control of alignment achieved through CCD computers. The focus is on the release layer on the adhesive material. PET FILM → Release agent → Printing ink → Adhesive → Injection of inner plastic → Ink and plastic bonding → After mold opening, the adhesive material will automatically release from the ink.

4.2 Process Advantages

The outstanding advantages of IMR technology are reflected in production efficiency and cost control: the high degree of automation in the production process can effectively reduce labor costs; Simultaneously suitable for large-scale production, it can significantly reduce the unit product cost.

4.3 Process Limitations

The disadvantages of IMR technology are quite obvious, mainly focusing on product durability and development flexibility:

- Poor Wear Resistance of Patterns: The printed pattern layer is directly exposed on the surface of the product, with a thickness of only a few microns. After a period of use, it is easy to wear and fade, affecting the aesthetic appearance of the product;

- High Development Cost: The development cycle for new products is long, and the initial development expenses are high;

- Lack of Flexibility: Pattern colors lack the flexibility for changes when it comes to small-batch manufacturing, making it difficult to meet personalized or small batch production needs.

5. Summary

Currently, some individuals in China refer to IMR as IMD and separate IML from IMD. The fundamental difference lies in the surface of the lens between IML and IMR. IML has PET or PC sheets on its surface, while IMR only has ink on its surface. IMD is a relatively complex process, and there are only a few manufacturers in China with relatively mature technology. As some of the technologies are trade secrets of each factory, we can only provide a superficial introduction. We ask for understanding.

IML’s sheet materials include PET, as well as PC, PMMA, PET. I don’t think I need to explain the material issues of PET and PC. Plastic injection molding generally uses PMMA and ABS, PP, PC, TPU, ABS+PC. IML and IMR each have their own advantages. IMR is not very durable, and some Nokia and Moto phones use IMR technology, which can cause scratches even if used for a longer period of time; The biggest drawback of IML is that it cannot implement IML technology as a whole, only limited to a certain area.

Due to the different technological levels of various companies, the selection of sheet materials, ink application, and machine selection are all different. A product may not be able to be manufactured by some small factories, but can be produced in factories with stronger technology. Moreover, IMD technology involves multiple considerations such as printing, injection molding, molds, injection molding raw materials, sheet materials, and product design. The application of IMD technology involves multi link collaboration. If you have any needs in process selection, production implementation, etc., please feel free to contact KingStar, the best custom manufacturing company in China, at sales@kingstarmold.com at any time. We will rely on professional technology to provide you with customized solutions.