Two color plastic products have a wide range of applications in people’s daily lives and industrial production, such as two-color toothbrush handles, pen holders, and toy case. They all have a comfortable soft and hard touch and a dazzling color effects, increasing people’s life satisfaction. For example, the door pillar plastic shell in automotive parts uses hard plastic to meet mechanical strength. And it uses soft materials to provide sealing performance to achieve specific structural or sealing properties. Under specific conditions, Using cheap plastic for local filling can reduce the consumption of premium materials and lower production costs. Two color or multi-color products integrated molding, reduces post-processing processes such as painting, coloring and assembly, saving labor, energy saving and environmental protection.

1. Clarify Two Core Concepts

- Two-shot Plastic Products: Refer to two colors, including two different plastic materials, or products of the same material in different colors;

- Two-shot Injection Molding Machine: An injection molding equipment capable of molding products of two or more materials/colors, and its structural design is completely adapted to dual color molds.

2. Matching Characteristics of 4 Mainstream Types and Molds

2.1 Parallel Type: Dual Molds Parallel Installation

- Mold Installation: Two sets of molds are installed in parallel on both sides of the center of the injection molding machine template, one for molding the first color semi-finished product and the other for molding the second color finished product;

- Core Requirement: The center of the two nozzles of the two molds should align with the center of the two nozzles of the injection molding machine, and follow the principle of “same moving mold, different fixed molds” (the mold core/cavity of the moving mold is completely consistent);

- Mold Design: Two sets of split molds can be used, or they can be designed as a whole (or the mold frame can be split and the bottom plate can be integrated). The key is to ensure that the center distance between the one color and two-color nozzles of the mold is consistent with the center distance between the two nozzles of the injection molding machine;

- Compatible Equipment: Two-color machines with wide platens and parallel injection units.

2.2 Horizontal Right Angle Type: 90° Horizontal Layout

- Mold Features: The first-color nozzle is located at the center of the fixed mold side, the second-color nozzle is on the non operating side of the fixed mold horizontal plane. Two nozzle axes are perpendicular at a 90° angle (horizontal right angle two-color mold);

- Compatible Equipment: Horizontal right-angle two-color injection molding machines where the first and second material barrel axes are also at 90°, and the second injection unit is positioned on the non-operator side of the machine.

2.3 Vertical Right Angle Type: 90° Vertical Layout

- Mold Features: The first-color nozzle is at the center of the fixed mold side, the second-color nozzles are at the top of the fixed mold vertical plane. The axes of two nozzles are perpendicular at a 90° angle (vertical right angle two-color mold);

- Compatible Equipment: Vertical right-angle two-color injection molding machines where the first and second material barrel axes are at 90°, and the second injection unit is mounted on top of the machine’s fixed platen.

2.4 Backpack Type: Parallel Vertical Layout

- Mold Features: The first-color nozzle is at the center of the fixed mold side; the second-color nozzle is above the first one. Axes of the two nozzles are parallel and at a certain distance from each other in the vertical plane;

- Compatible Equipment: The two-shot injection table unit is installed above the first color, with the axis of the material barrel inclined. The corner of the head flange restores axis of the second-color nozzle to horizontal. It is parallel to the axis of the first color nozzle in the vertical plane of the backpack two-shot injection molding machine.

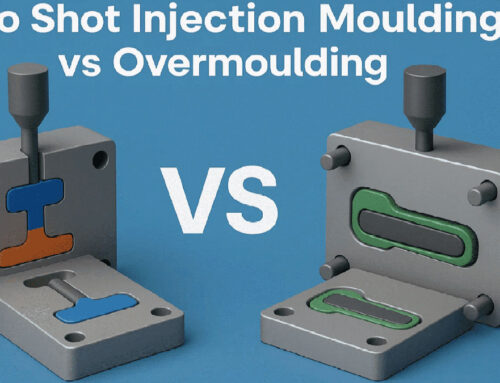

3. Core Application Differences: Parallel vs Right Angle Type

According to the angle of the nozzle axis, the four models can be classified into two categories: parallel and right angle (horizontal right angle, vertical right angle, backpack type), with significant differences in application characteristics:

| Comparison Dimension | Parallel Type | Right Angle Type (Horizontal+Vertical+Backpack) |

|---|---|---|

| Floor Area | Compact (1.2-1.4 times the size of a regular single-color machine) | Horizontal type: 1.5-2 times the machine position; Vertical type: 1x machine position (requires high factory building); Backpack style: minimum footprint and height |

| Retrofit/Adaptability | Dedicated two-color design, can be retrofitted and converted into three color/four color | Horizontal type is easy to retrofit from older single-color machines; Can operate as single-color by shutting down 2nd unit; High versatility |

| Shot Size Combination | Two shooting platforms are parallel, limited space, and the amount of glue injected in one color cannot be too large | Horizontal type offers ample space for 2nd unit; virtually no limit on 2nd shot size, can be equal to 1st |

| Mold Compatibility | Wide Template+large pull rod spacing; can accommodate large molds, with multiple mold cavities | The distance between the pull rods is small, the size of the compatible mold is limited, and the number of mold cavities is small |

| Manufacturing Cost | Separate mold has a simple runner system, saving 20-30% of mold costs (vs right angle type) | The mold runners require corners, resulting in higher manufacturing costs |

| Product Accuracy | Flat, elongated, and wide template with slightly poor four-direction force balance, suitable for general precision products | Square template, balanced four-direction force, suitable for high-precision products |

| Convenience of operation | Install code mold clips on the upper and lower sides of the mold, unobstructed and easy to operate | Horizontal type: rear installation code clip is obstructed and inconvenient to operate |

Conclusion:

Parallel, horizontal right angle, vertical right angle, and backpack are the four most common basic two-color structures on the market. They can also be combined to create more than ten types of three or four-color injection molding machines. For example, on the basis of parallel two-color, horizontal and vertical right angle shooting units can be added to form a three or four-color machine;

On the basis of the horizontal right angle type, vertical right angle and backpack shooting platform units can be added to form a three color or four-color machine, which can be customized by the user through negotiation with the supplier. When it comes to the production of products that are matched with molds, they have their own advantages, disadvantages, and characteristics, and it is not said which style is the best. When users choose or suppliers recommend, they need to consider various factors such as factory space, equipment availability, investment cost, product accuracy, production efficiency, and usage habits in combination with the actual situation. The one that meets the actual situation is the best choice.

Want to source a reliable injection molding company in China for your project? Welcome to contact us at sales@kingstarmold.com or leave online message at any time.