TPE (Thermoplastic Elastomer) overmolding is a commonly used overmolded material that provides excellent tactile and visual effects while protecting products. However, common defects often arise during the production and use of TPE overmolding. This post will introduce these common issues and offer solutions to help designers better address them.

1. Common Issues

In industrial production, overmolding is a commonly used process. Simply put, it involves wrapping a material (such as TPE elastomer) onto the surface of another substrate (such as plastic or metal parts) through a mold. This not only enhances the feel of the product, but also strengthens its protective performance. It is commonly used in the manufacturing of home appliance handles, electronic device casings, medical device accessories, and other products. However, in the actual production process, it is easy to encounter some problems due to the influence of material characteristics, equipment parameters, environmental factors, etc. Below are several typical problems to be explained in detail:

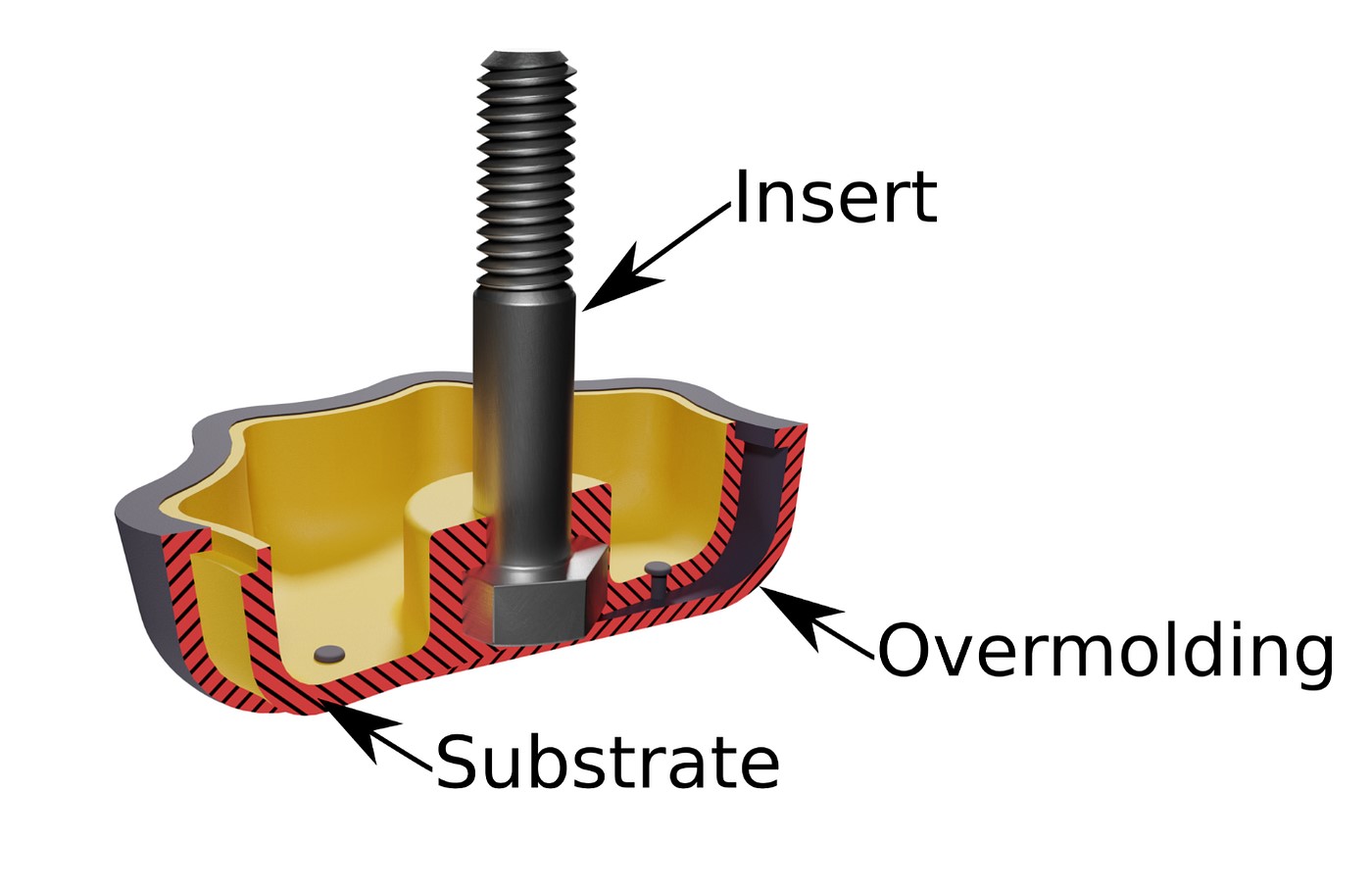

Part Structure Involving Insert Molding and Overmolding

1.1 Blisters in Overmolding

In the process of overmolding, “blistering” is a particularly common problem – blisters of different sizes appear on the surface of the molded product, which not only seriously affects the appearance and aesthetics (such as if there are bubbles on the handle of a household appliance, consumers will feel that the product quality is poor), but also damages the structural integrity of the packaging material, leading to a decrease in its protective performance (such as the original anti drop shell, which may crack as soon as there are bubbles).

For these reasons, the corresponding solutions are also very clear:

(1) Before formal molding, dry the raw materials first – for example, use a dryer to dry TPE particles for 4-6 hours, control the moisture content below 0.1%, and reduce the bubbles caused by moisture from the source;

(2) Strictly monitor and control the processing temperature during the manufacturing process, set appropriate temperature ranges based on the characteristics of the materials used (such as different types of TPE having different melting temperatures), and avoid material decomposition or volatilization caused by high temperatures;

(3) Regularly inspect the air treatment system in the workshop, including filters, ventilation equipment, etc., to ensure that there are no excessive dust, oil, or other aerosol pollutants in the air. At the same time, keep the molds clean and reduce the possibility of pollutant mixing.

1.2 Poor Adhesion of Adhesive

In the process of overmolding, the role of adhesive is to firmly stick the overmolded material (such as TPE) and the substrate (such as ABS plastic) together. If the adhesion is poor, the two materials will layer and fall off – for example, by gently breaking the handle with your hand, the outer TPE of the handle will separate from the inner plastic substrate, which not only affects the normal use of the product, but also may bring safety hazards (such as medical device accessories falling off, which may cause equipment failure).

There are two common reasons for this problem: on the one hand, there is contamination on the surface of the material (such as oil stains, fingerprints on the substrate before processing, or dust on the surface of the overmolded material, which can act as a “barrier” and hinder the contact between the adhesive and the material); On the other hand, the adhesion between the overmolded material and the substrate itself is relatively weak (for example, some rigid plastic substrates have poor compatibility with flexible TPE materials, and even if adhesive is applied, the adhesion force is not enough).

To solve this problem, the key is to start from two aspects: “cleaning” and “matching”:

(1) Before the start of overmolding, the surfaces of the overmolded material and substrate must be thoroughly cleaned – the substrate surface can be wiped with alcohol to remove oil stains, and the dust on the overmolded material surface can be blown off with compressed air to ensure that both surfaces are clean and free of impurities, allowing the adhesive to fully contact the material;

(2) Select the appropriate adhesive type based on the characteristics of the overmolded material and substrate – for example, polyurethane adhesives can be used for the combination of TPE and ABS plastics; If the substrate is metal, choose epoxy adhesive to improve the adhesion between the two by selecting the right adhesive. If necessary, the surface of the substrate can also be polished to increase surface roughness and further enhance adhesion.

1.3 Fading During Overmolding

For overmolded products that require long-term exposure to the external environment (such as tool handles for outdoor use, car interior accessories), fading is a headache – originally bright colors (such as red and blue) will gradually become lighter, yellow, and even develop color spots, directly causing the product to lose its original aesthetic appeal and reduce its market competitiveness (consumers are usually more willing to choose products with intact appearance).

The main reasons for fading are related to material characteristics and usage environment: Firstly, the stability of the material itself is poor (such as some cheap TPE materials, the weather resistance of the coloring agent inside is poor, and it is easy to decompose after long-term use); The second is that the product is exposed to ultraviolet radiation for a long time (such as outdoor products often being exposed to sunlight, which can damage the pigment molecules in the material and cause color loss).

The main solution to the fading problem is to “choose the right materials” and “enhance protection”:

(1) Priority should be given to selecting overmolded materials with good UV resistance, such as TPE materials labeled as “UV resistant” on the market. These materials have been added with UV resistant components during production, which can effectively resist the damage of UV to color;

(2) If the selected base material has average UV resistance, additional stabilizers (such as light stabilizers and antioxidants) can be added during the material processing. These additives can slow down the aging rate of the material under UV irradiation, thereby reducing the occurrence of fading and extending the overall service life of the product.

1.4 Deformation During Overmolding

If the overmolded product undergoes deformation, it can lead to irregular appearance – for example, the handle, which should have been cylindrical, becomes bent, or the flat shell has protrusions or indentations, which not only looks unsightly but also affects the user experience (such as uncomfortable grip of the deformed handle, or inability to assemble with other components properly).

There are two common reasons for deformation: one is uneven temperature during the manufacturing process (such as high temperature in some areas of the mold and low temperature in some areas, different shrinkage rates of the material at different temperatures, and deformation after cooling); The second reason is that the thickness of the overmolded layer is too thin (the structural strength of the thin overmolded layer is insufficient, and it is easy to deform due to external forces or internal stresses during the cooling process or subsequent use).

To solve the deformation problem, adjustments need to be made from two aspects: temperature control and structural design.

(1) During the processing, use heating equipment that can uniformly control temperature, such as injection molding machines with multi zone temperature control systems, and regularly check the temperature distribution of the mold to ensure that the temperature of each part of the mold is consistent, so that the material is heated evenly and shrinks uniformly, reducing deformation caused by temperature differences;

(2) In the product design phase, the thickness of the overmolded layer should be appropriately increased according to the usage requirements – for example, the original thickness of the overmolded layer was 0.5mm, which can be adjusted to 1mm. By increasing the thickness, the structural strength and deformation resistance of the material can be improved. However, it is also important to note that the thickness should not be too thick to avoid affecting the weight and cost of the product.

2. Additional Considerations

TPE overmolding products may encounter common issues such as blistering, poor adhesion, color fading, and warpage during production and service life. Understanding the root causes of these defects and implementing targeted solutions can assist manufacturers in enhancing product quality and cosmetic appeal. By continuously optimizing processing techniques and material selection, we can effectively address these recurring challenges and manufacture more competitive products. Beyond the common issues and solutions mentioned above, there are other problems and approaches worthy to explore and apply.

- The environmental performance of TPE overmolding: More and more consumers and businesses are paying attention to the environmental performance of their products, including degradability and recyclability. By selecting environmentally friendly TPE materials, improving the overmolding process, and introducing biodegradable overmolding materials, the environmental performance of the product can be improved.

- Abrasion resistance of overmolding: In certain applications, the overmolded layer may be subjected to friction and wear, leading to diminished aesthetics and functional degradation. Potential solutions include incorporating wear-resistant additives and optimizing the thickness and quality of the overmolded layer.

- Chemical resistance issue of overmolding: Certain chemicals may corrode overmolded materials, leading to a decrease in material performance. The solution includes selecting TPE materials with good chemical resistance, adding chemical resistance agents, etc.

- Customization of overmolding: With the intensification of market competition, consumers’ demand for personalized and customized products is also increasing. By improving the overmolding process and technology, more diverse overmolding designs and effects can be achieved to meet the needs of different consumers.

Conclusion

Understanding the common issues and solutions of TPE overmolding is crucial for creators. Preventing and resolving these issues in advance can not only improve the competitiveness and quality of products, but also reduce production costs and product rework rates. Through continuous thinking and improvement, we can fully utilize the advantages of TPE overmolding and address potential challenges and issues, providing consumers with a better product experience.

To gain systematic information of the common issues and solutions for TPE overmolding defects, theoretical support is needed to facilitate the summarization and discovery in practice. As the top injection molding company, KingStar welcomes any corrections or discussions, and please feel free to send us an email(sales@kingstarmold.com) for professional suggestions on the solutions for TPE overmolding defects for your project or general injection molding services inquiry.