Overview of Our Custom Coloring Service

Custom coloring plays a critical role in enhancing both the appearance and functionality of manufactured components across 3D printing, injection molding, CNC machining, and sheet metal fabrication. The process involves advanced techniques tailored to different materials, ensuring high-quality, durable finishes. For plastics, options include in-mold coloring, masterbatch compounding, and post-processing methods such as painting or hydrographics. Metals can be treated with anodizing, powder coating, electroplating, or specialized coatings to enhance corrosion resistance and wear properties. Precision color matching ensures consistency with industry standards, Pantone references, or customer specifications. Rigorous testing is conducted to verify adhesion, durability, and environmental resistance, ensuring long-term performance in demanding applications.

Coloring Methods

Raw Material Coloring (Pre-selected Color Options)

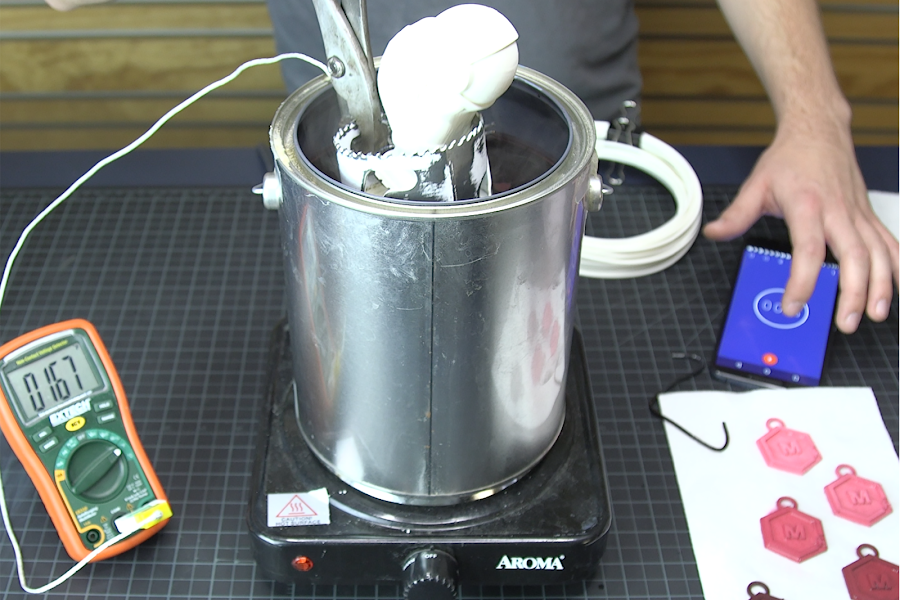

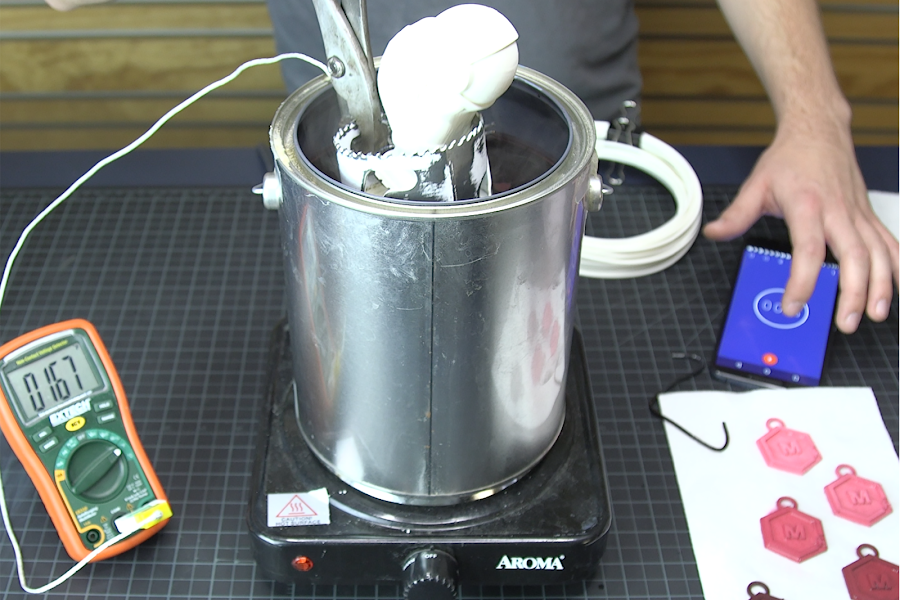

Dyeing (For SLS, MJF, and Resin 3D Printing)

Surface Coatings

Coloring Methods

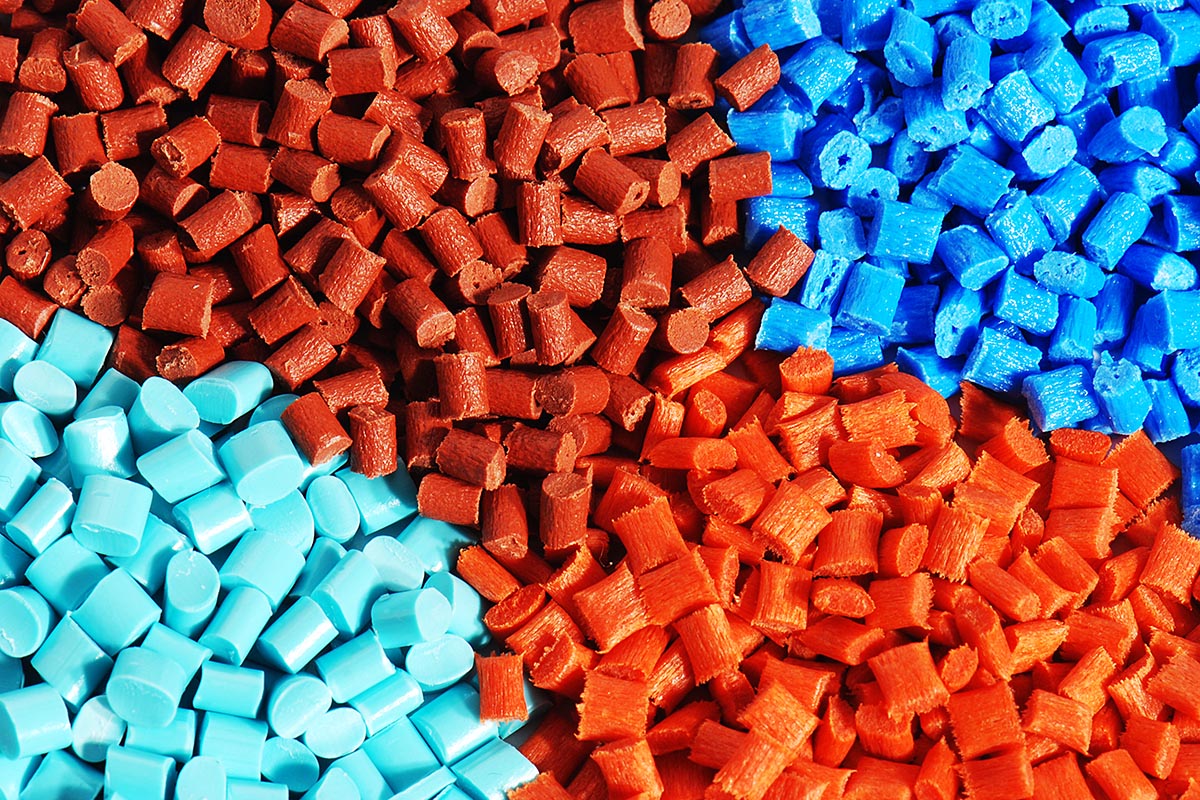

Pre-Coloring (For High-Volume Production)

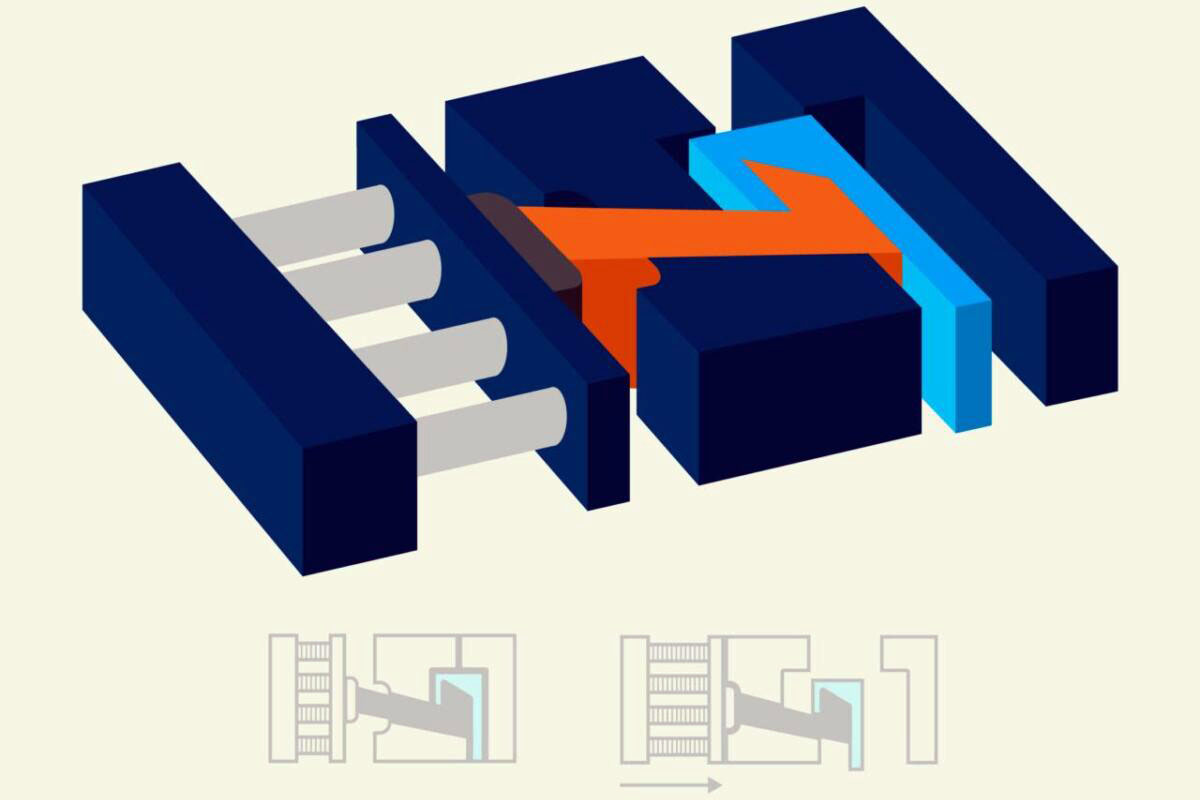

Two-Shot (Dual-Color) Molding

Post-Processing Coating

Coloring Methods

Raw Material Selection (Pre-selected Material Options)

Custom Machining and Dyeing (For Unique Color Requests)

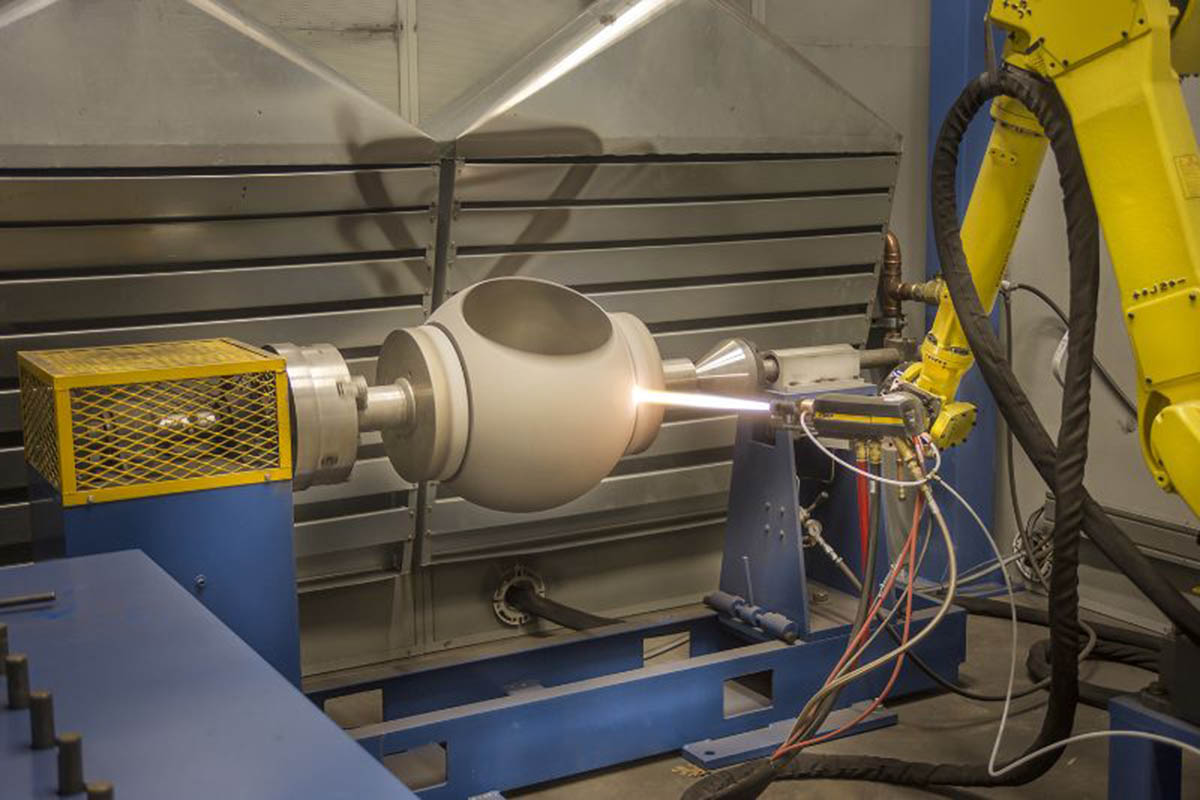

Surface Finishing and Coatings

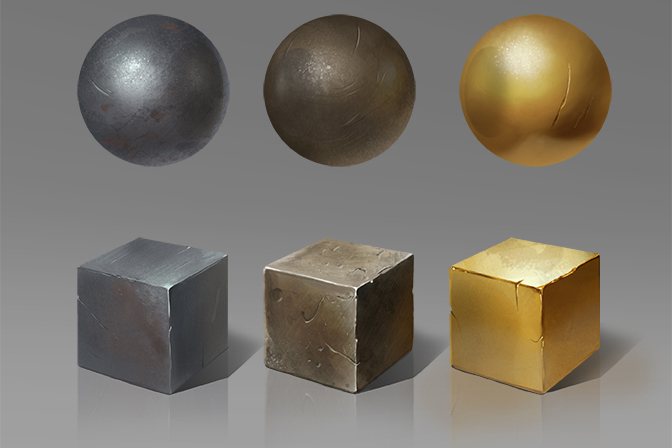

Heat Treatment Coloring (For Metallic Finishes)

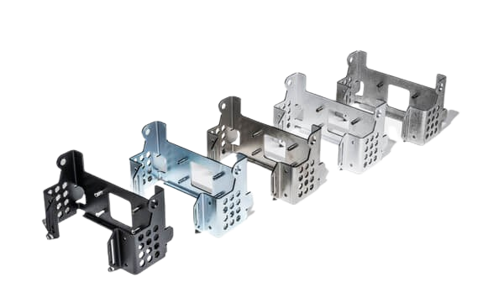

Coloring Methods

Raw Material Coloring (Pre-selected Color Options)

Anodizing (Specifically for Aluminum)

Powder Coating

Surface Coatings (Additional Finishes)

Yes, we welcome customer-provided color specifications, using advanced color-matching technology for precision.

Turnaround time varies, but we strive for efficiency. We offer expedited options and keep our production lines running smoothly to minimize wait times.

Quality assurance is our priority. We use advanced equipment and rigorous testing, with quality control specialists inspecting every stage of the process.

We offer a range of customize coloring services tailored to your needs, bringing your vision to life in plastic molding, cnc machining, 3d printing and other materials.

Our process begins with a consultation to understand your needs and goals. We’ll discuss color specifications, material type, and any other relevant details. From there, we’ll create a sample for your approval and, once confirmed, proceed with production. To get started, simply reach out to us via our contact form, email, or phone number, and we’ll schedule a consultation at your earliest convenience.

Absolutely! Our team of experts can provide guidance on choosing the right color for your product, considering factors such as target audience, brand identity, and market trends. We can offer color swatches, mockups, and advice to ensure your product stands out and appeals to your customers.

Pricing varies based on the project’s complexity, material type, and quantity. We offer competitive rates and can provide a detailed quote upon request.

We can color a variety of materials, including plastics, metals, elastomers and composites, tailored to your specific needs and applications.