Typical Part Properties

| Property | As Built | Stress Relieved (1150°C for 6h) |

|---|---|---|

| Tensile Strength (XY) | 1350±100 MPa (196±15 ksi) | 1100±100 MPa (160±15 ksi) |

| Tensile Strength (Z) | 1200±150 MPa (174±22 ksi) | 1100±100 MPa (160±15 ksi) |

| Yield Strength (Rp0.2%, XY) | 1060±100 MPa (154±15 ksi) | 600±50 MPa (87±7 ksi) |

| Yield Strength (Rp0.2%, Z) | 800±100 MPa (116±15 ksi) | 600±50 MPa (87±7 ksi) |

| Elongation at Break (XY) | (11±3)% | min. 20% |

| Elongation at Break (Z) | (24±4)% | min. 20% |

| Modulus of Elasticity (XY) | 200±20 GPa (29±3 Msi) | 200±20 GPa (29±3 Msi) |

| Modulus of Elasticity (Z) | 190±20 GPa (28±3 Msi) | 200±20 GPa (29±3 Msi) |

*From our supplier, click here to download full material datasheet of Cobalt Chrome.

Post-Processing for Cobalt Chrome Printed Parts

Necessary

Optional

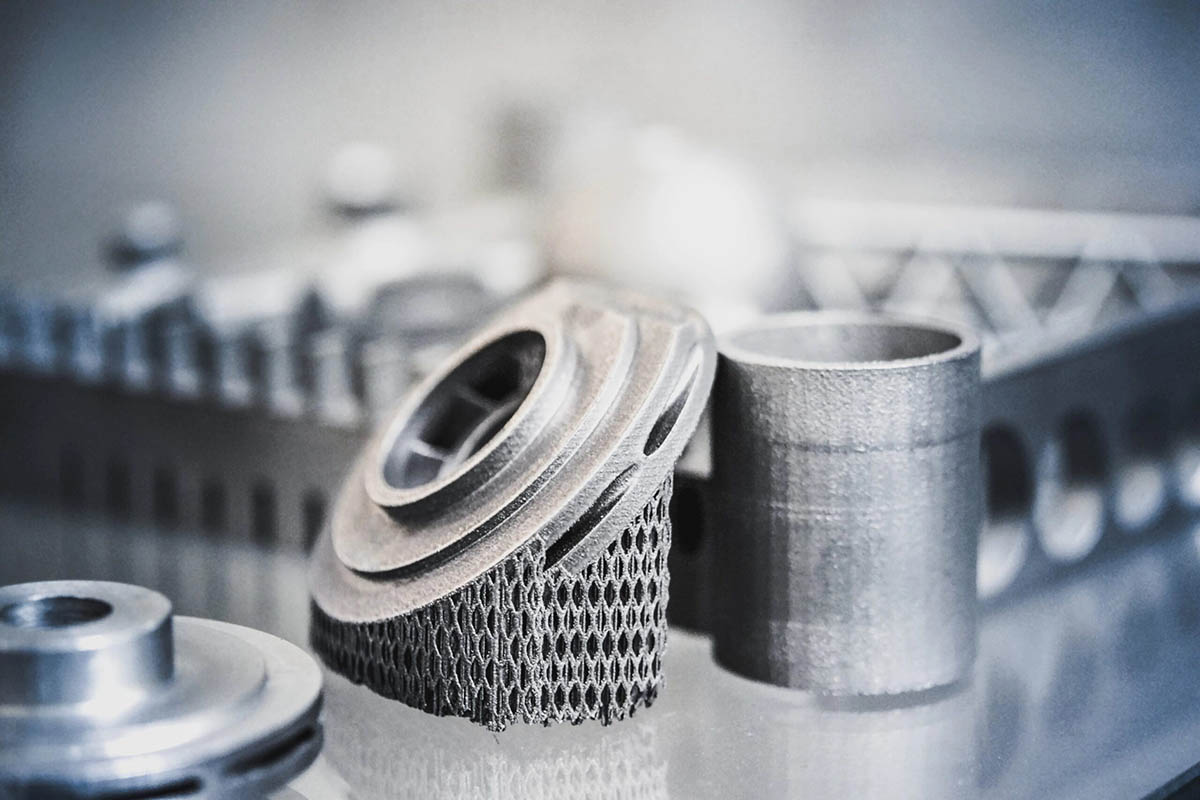

Cobalt Chrome 3D Printing Design Tips

While our previous post: Design Guide for DMLS Metal 3D Printing provide foundational principles for metal additive manufacturing, certain materials—like Cobalt Chrome—demand specialized considerations due to their unique properties. The table below highlights key differences and material-specific recommendations for Cobalt Chrome 3D printing, ensuring optimal results when working with this high-performance alloy.

| Factor | Cobalt Chrome Recommendation | DMLS General Rule |

|---|---|---|

| Minimum Wall Thickness | 1.0 mm (0.5 mm non-structural) | 0.8 mm (1.0 mm unsupported) |

| Minimum Hole Size | 1.0 mm (post-machining for smaller holes) | 1.0 mm |

| Surface Roughness (As-Printed) | 2–5 μm Ra (polishable to <0.1 μm Ra) | 2–5 μm Ra |

| Shrinkage | 0.3–0.5% (design oversized accordingly) | Tolerances: ±0.2 mm for dimensions ≤100 mm; +±0.1 mm/100 mm thereafter |

| Minimum Clearance (Moving Parts) | 0.5 mm | 0.5 mm |

| Overhang Angle | Supports required for angles <45° | Supports required for angles <35° |

| Support Density | 30–50% lattice density | 20–30% lattice density |

| Heat Treatment | Mandatory stress relief annealing (1150°C/6h) | Optional (depends on alloy) |

| Threaded Features | Tap threads post-print (add 0.5–1 mm clearance) | Printed threads (M3+) acceptable in softer metals |

| Thermal Conductivity | 13–33 W/m·K (varies with temperature) | Varies by alloy (e.g., titanium: ~7–22 W/m·K) |

| Thermal Expansion | 13.6×10⁻⁶ m/m·°C (20–500°C) | Varies by alloy (e.g., titanium: ~8.6×10⁻⁶ m/m·°C) |

*Note: Cobalt Chrome guidelines reflect material-specific properties (e.g., higher hardness, thermal conductivity) while aligning with DMLS process constraints. Always verify with your manufacturer for alloy-specific adjustments.