KingStar Mold CNC Turning Service: Precision and Efficiency

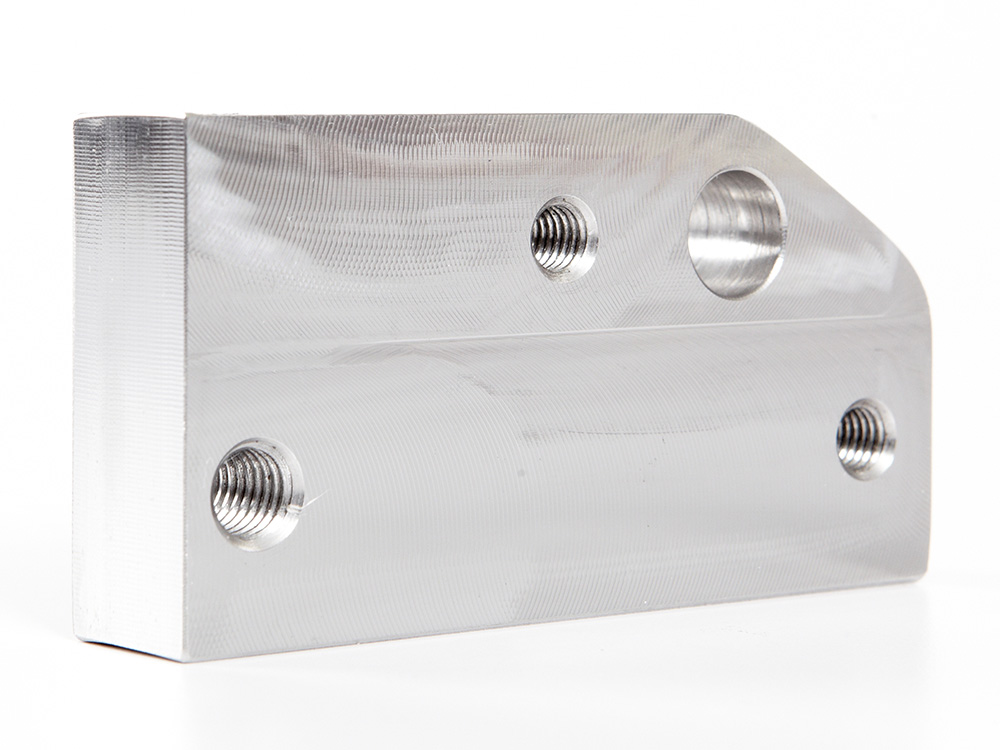

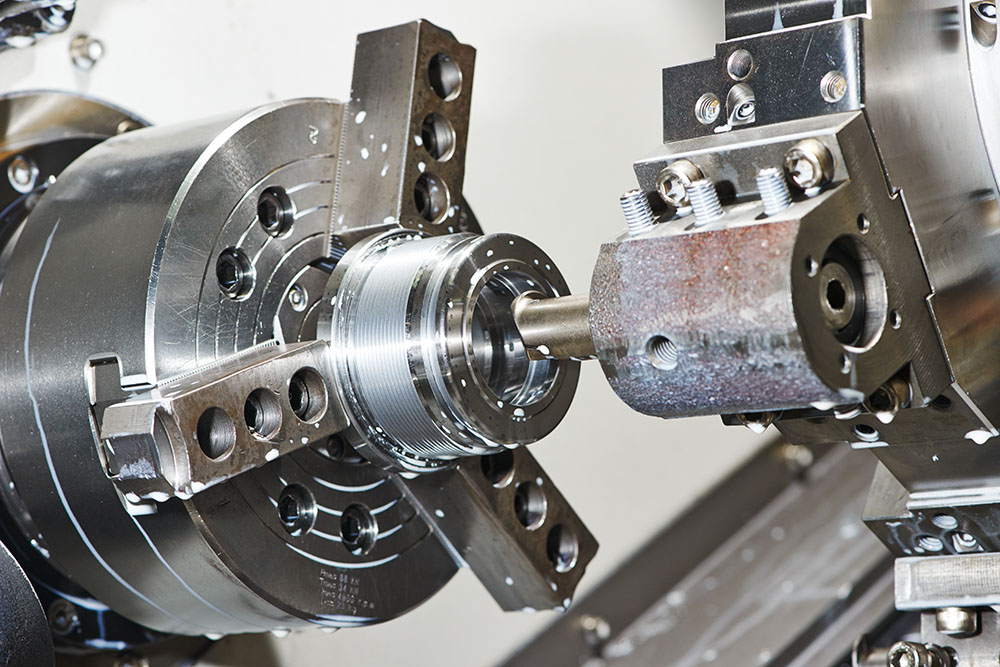

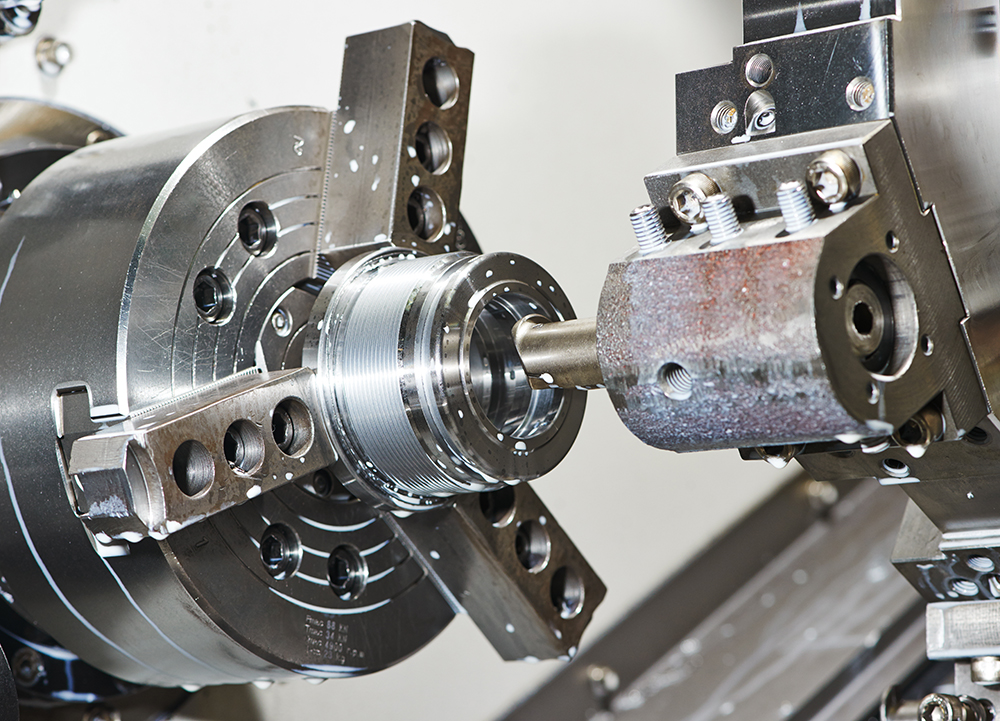

At KingStar Mold, our CNC turning service delivers exceptional precision and efficiency for manufacturing high-quality, complex parts. Using state-of-the-art CNC lathe machines, we can create cylindrical components with intricate features, achieving tight tolerances and superior surface finishes. Whether you need small or large quantities, our advanced turning capabilities ensure consistent results across a wide variety of materials, including metals, plastics, and composites.

Our experienced team works closely with clients to ensure that each turned part meets exact specifications. With capabilities ranging from simple cylindrical shapes to more complex profiles, KingStar Mold’s CNC turning service is ideal for industries such as automotive, aerospace, and medical. We offer quick turnaround times, reliable production processes, and a focus on quality to help bring your parts from design to reality with precision.

CNC Prototypes Gallery

KingStar Mold’s Advantages On CNC Turning & Milling Service

Enhanced Precision and Versatility

With our advanced turn-mill machines, we can combine both turning and milling operations in a single setup, ensuring high-precision machining for complex geometries. This reduces the need for multiple machine setups, improving accuracy and consistency across your parts.

Improved Efficiency and Reduced Lead Time

Our turn-mill technology allows us to perform both operations simultaneously, significantly reducing cycle times and streamlining the manufacturing process. This leads to faster production and quicker delivery without sacrificing quality.

Cost-Effective Production for Complex Parts

By consolidating multiple machining processes into one, we minimize material handling, setup time, and tool changes. This cost-effective approach is ideal for producing intricate components and parts with both turning and milling requirements.

Order Processing Workflow

01

Upload Your Design File

Submit your design file to kickstart the process and get started on your custom part.

02

Select Materials & Specifications

Choose the materials and specify any key features or tolerances for your product.

03

Review & Approve Quote

Receive an instant quote based on your design and confirm your order details.

04

Precision Machining Begins

Choose the materials and specify any key features or tolerances for your product.

05

Quality Control Inspection

We thoroughly inspect each part to ensure it meets your exact requirements and quality standards.

06

Timely Delivery

Receive your fully finished product on time, ready for use or assembly.

Our Satisfied Clients

6 Tips for Your Design

01

Optimize Geometries for Machinability

02

Incorporate Tolerances Wisely

03

Use Draft Angles for Easier Extraction

04

Consider Material Properties

05

Minimize Tool Changes

06

Ensure Sufficient Clearance

Yes! With our advanced CNC lathe machines, KingStar Mold can handle both simple and complex turning operations, including threading, grooving, and contouring.

Lead times vary depending on part complexity and quantity. However, KingStar Mold offers fast turnaround, typically completing simple parts within a few days and more complex parts in one to two weeks.

CNC turning is ideal for parts with rotational symmetry, including shafts, bushings, spindles, pulleys, and custom cylindrical components used in industries such as automotive, aerospace, and medical.

CNC turning offers high precision, typically achieving tolerances of ±0.01 mm, making it suitable for parts requiring tight dimensional accuracy and smooth finishes.

CNC turning can be performed on a wide range of materials, including metals (such as aluminum, steel, brass, and titanium), plastics, and composites, depending on your part’s requirements.

CNC turning is a manufacturing process where a rotating workpiece is machined using a cutting tool to create cylindrical shapes and complex features. It’s ideal for producing parts like shafts, rings, and bolts with high precision.

The cost of CNC turning depends on factors like material, part complexity, and order quantity. KingStar Mold offers cost-effective pricing tailored to meet your project needs.

Simply submit your design file to KingStar Mold, and our team will provide a fast and competitive quote based on the part complexity, material, and quantity.

Yes, KingStar Mold offers various post-processing services such as surface finishing, heat treatment, and coating to ensure that the final part meets your specifications.

Yes, we can handle both low-volume production runs and high-volume manufacturing, offering flexibility for prototyping as well as large-scale production.

CNC turning is widely used in automotive, aerospace, medical, electronics, and manufacturing industries, where precision and high-quality cylindrical parts are essential.

You can submit your design file in CAD formats like STEP, IGES, or DXF through our website or email. Our team will review it and provide a quote based on your specifications.