KingStar CNC Prototyping Service: Speed and Precision

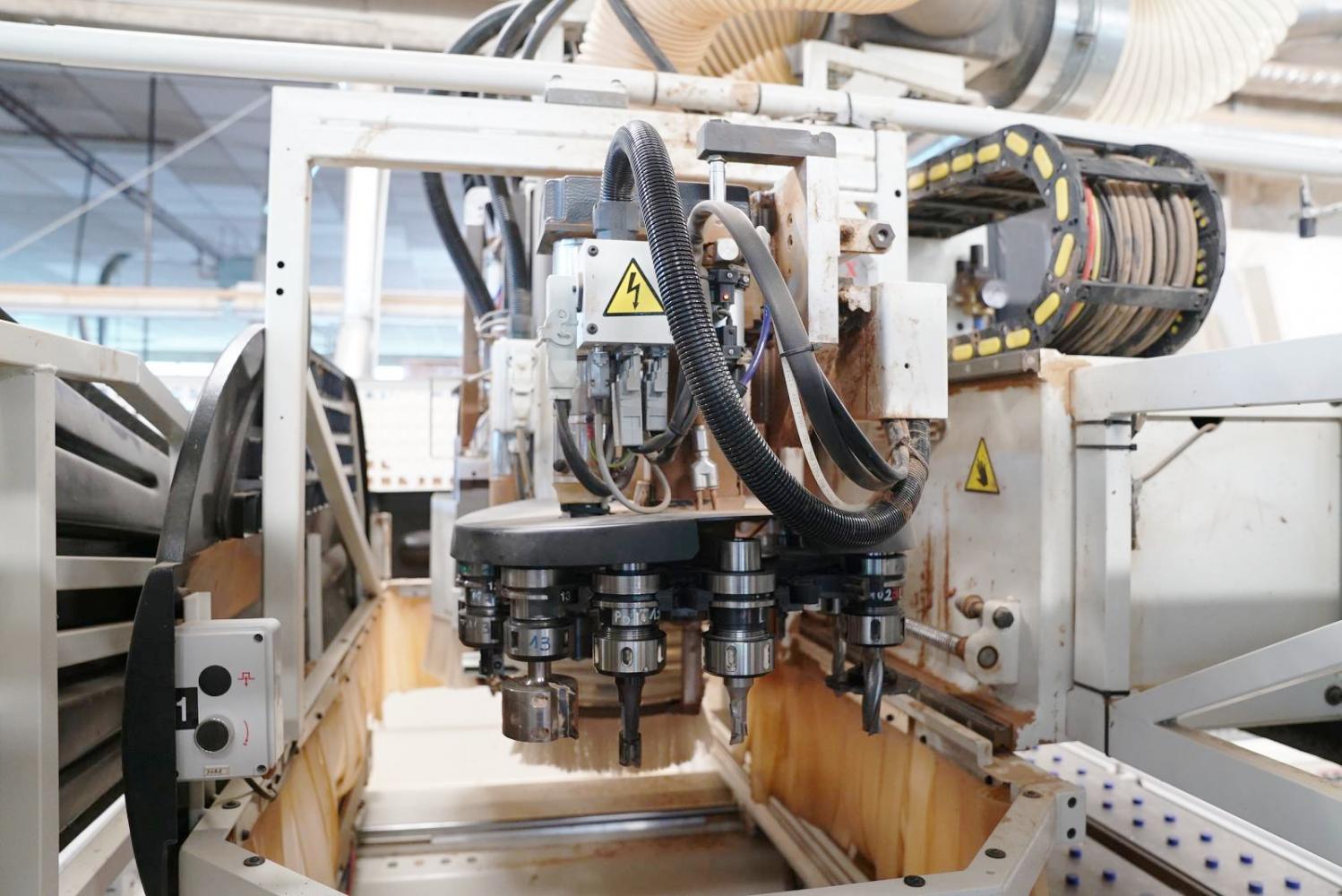

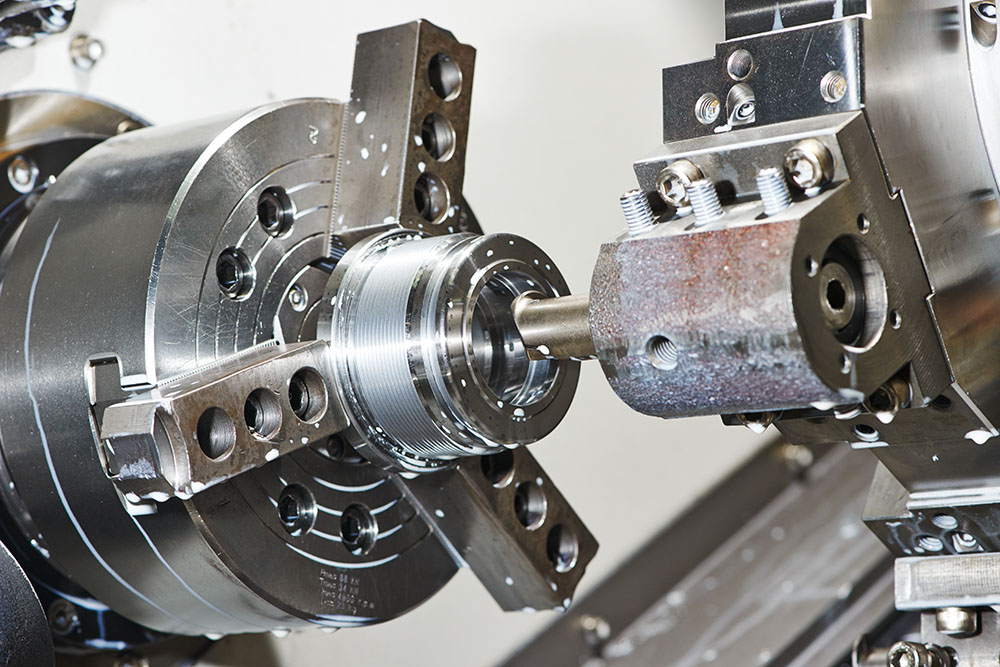

At KingStar, we specialize in rapid CNC prototyping services, allowing you to bring your designs to life quickly and accurately. Using advanced CNC machines, we can produce high-quality prototypes in a variety of materials, ensuring they meet the exact specifications required for testing and evaluation. Our service is perfect for both simple and complex parts, enabling quick iterations to refine your design before mass production.

Our team of experienced engineers works closely with you to select the best material and manufacturing process for your prototype. With tight tolerances and quick turnaround times, we ensure that your prototype is ready for testing or production in no time. Whether you need one-off prototypes or small batches, KingStar’s CNC prototyping service provides cost-effective, reliable, and high-precision results for your product development process.

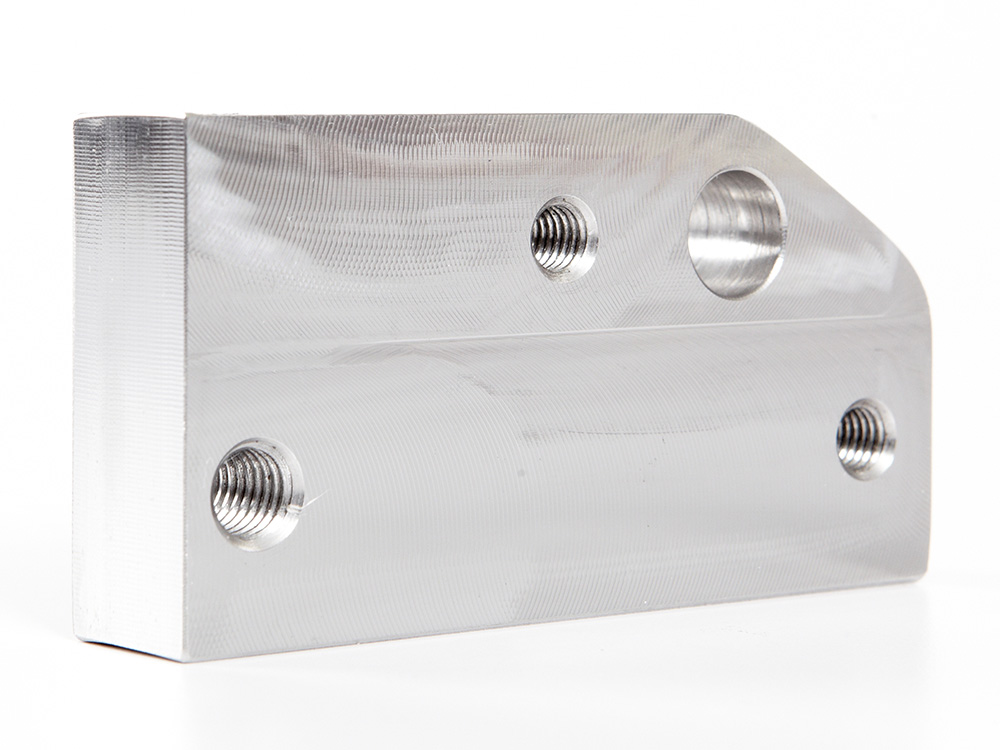

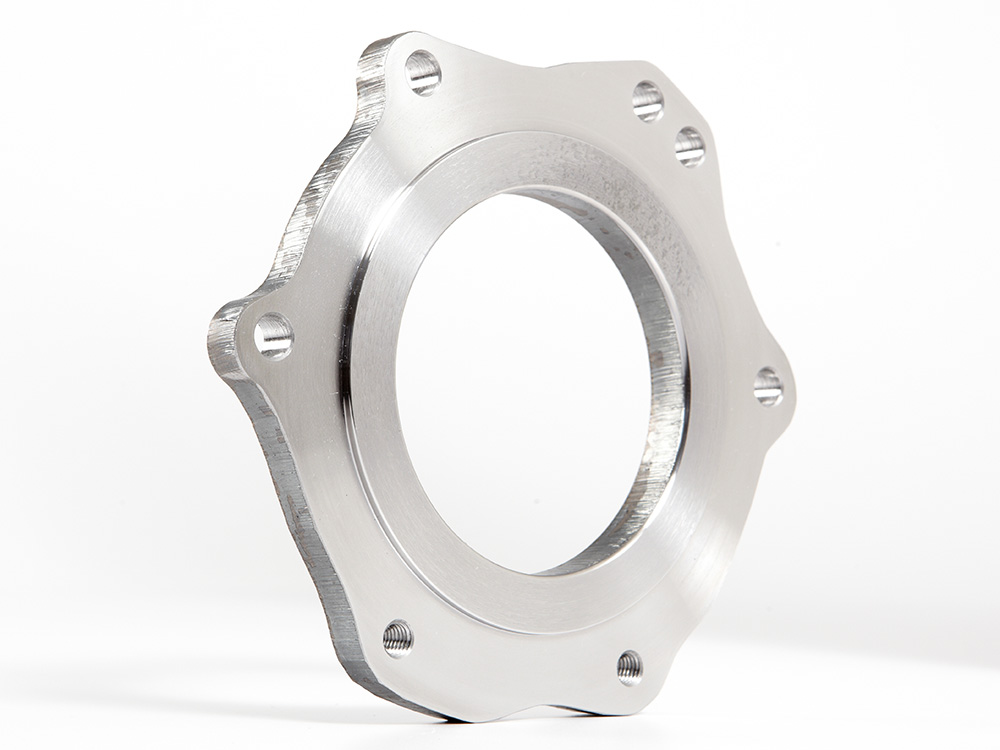

CNC Prototypes Gallery

KingStar’s Advantages On CNC Prototyping Service

High Precision

Our advanced CNC machines ensure precise manufacturing, achieving tight tolerances and intricate details. This level of accuracy helps you identify any design flaws early in the process, ensuring a smoother transition to mass production.

Rapid Turnaround

We understand the importance of speed in product development. KingStar’s CNC prototyping service offers quick production times, allowing you to test and refine your design faster, keeping your project on track and reducing time to market.

Versatile Material Options

KingStar offers a wide range of materials, including metals, plastics, and composites. Whether your prototype requires lightweight plastic or durable metal, we provide the flexibility to choose the best material for performance and cost-effectiveness.

Cost-Effective Prototyping

Our CNC prototyping service balances precision and affordability. By optimizing materials and processes, we deliver high-quality prototypes at competitive prices, allowing you to test multiple iterations without exceeding your budget.

01

Receive Design File

02

Review Design Specifications

03

Select Material for Prototype

04

Generate CNC Program

05

Set Up CNC Machine

06

Load Material and Tools

07

Begin Milling Process

08

Monitor Machining Progress

09

Perform Quality Inspections

10

Post-Processing (if needed)

11

Final Inspection and Testing

12

Deliver Prototype to Client

We offer a wide variety of materials, including metals (like aluminum and stainless steel), plastics (such as POM, nylon, and acrylic), and composites, allowing us to meet diverse prototyping needs.

CNC prototyping is ideal for industries such as aerospace, automotive, medical, consumer electronics, and industrial equipment, where functional testing of prototypes is critical before full-scale manufacturing.

Yes! KingStar Mold’s advanced CNC machines, including multi-axis capabilities, can handle intricate, complex designs with ease, ensuring your prototype meets all your design requirements.

Our CNC machines achieve high precision, typically within ±0.01 mm tolerances, ensuring that your prototypes match your exact design specifications with exceptional accuracy.

At KingStar Mold, we offer fast turnaround times. Depending on complexity, we can produce prototypes within a few days to a couple of weeks, allowing you to move your project forward without unnecessary delays.

CNC prototyping is the process of creating precise, functional prototypes using CNC (Computer Numerical Control) machines. This allows designers and engineers to quickly validate and test their designs before full-scale production.

If the prototype doesn’t meet the specifications or functional requirements, we will work with you to refine the design and make necessary adjustments until it aligns with your expectations.

Yes! CNC prototyping is ideal for small batch production as well. KingStar Mold can scale up from prototypes to small production runs with the same level of precision and quality.

While both are rapid prototyping methods, CNC prototyping offers higher precision, better surface finish, and the ability to work with a wider range of materials, including metals, that 3D printing cannot match.

CNC prototyping costs depend on factors like material choice, complexity, and quantity. KingStar Mold offers competitive pricing, and we provide a detailed quote once we review your design.

Absolutely! If any adjustments are needed during the prototyping phase, our team can modify the design to accommodate changes, ensuring the final prototype matches your evolving requirements.

Yes, we require a CAD file (such as STEP, IGES, or STL) for CNC prototyping. This file allows us to precisely translate your design into a machine-readable format to create the prototype.