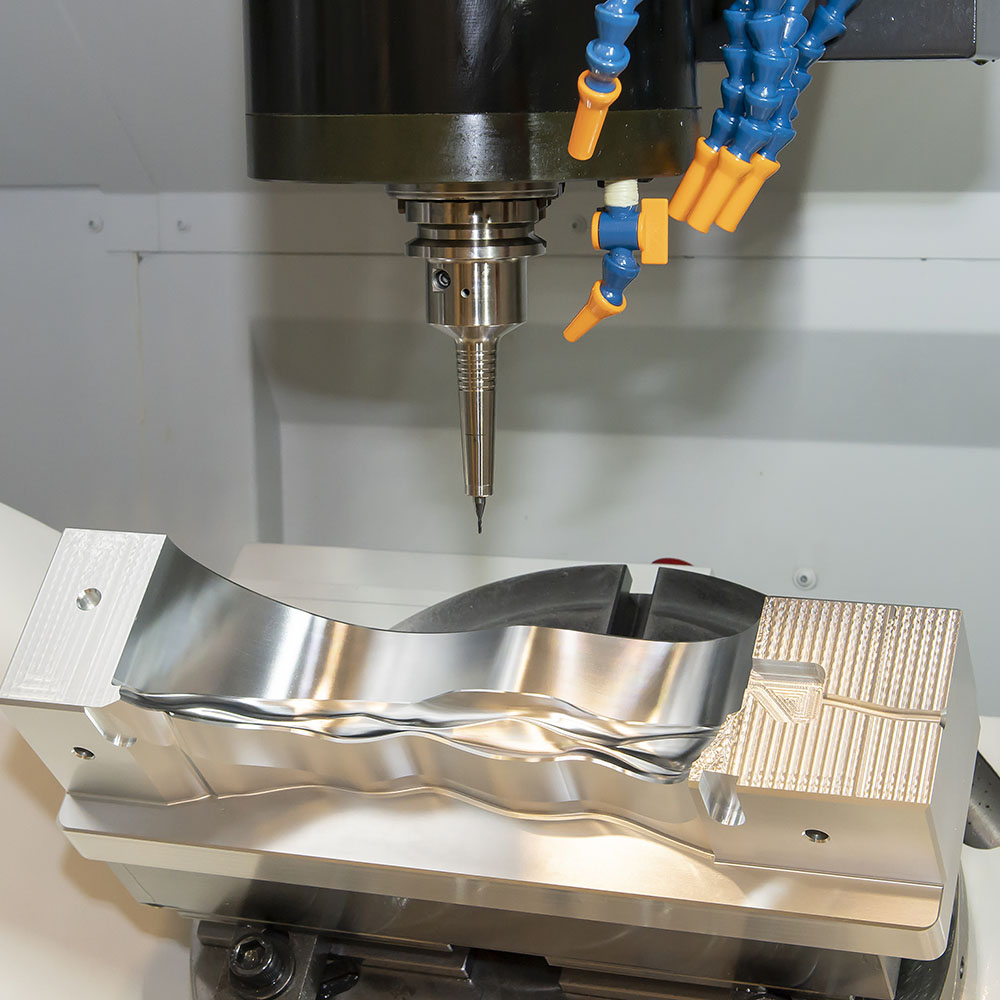

KingStar Mold CNC Precision Machining Service: Excellence in Detail

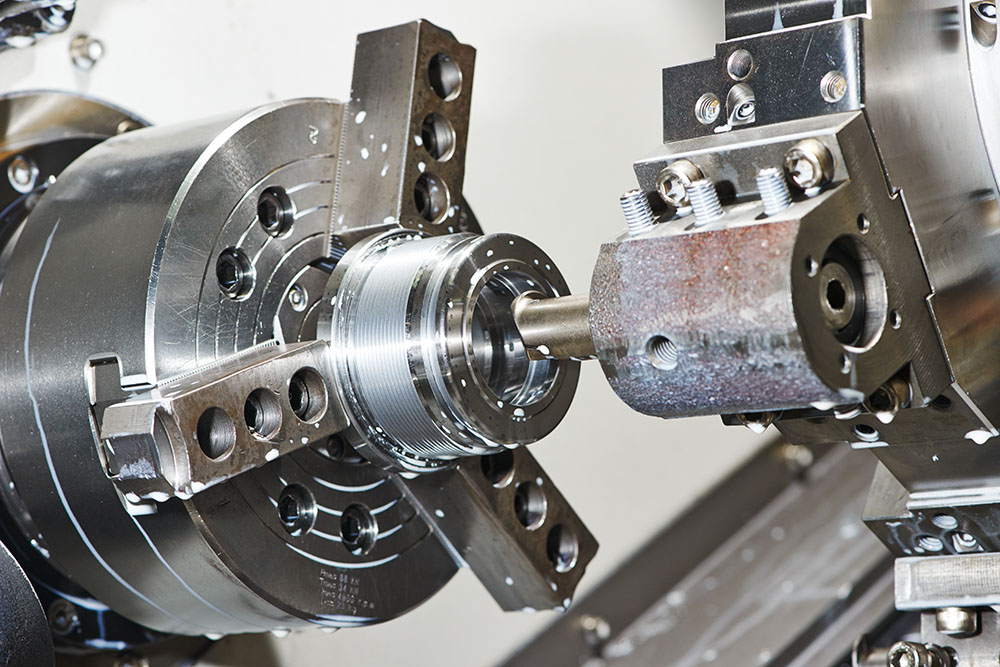

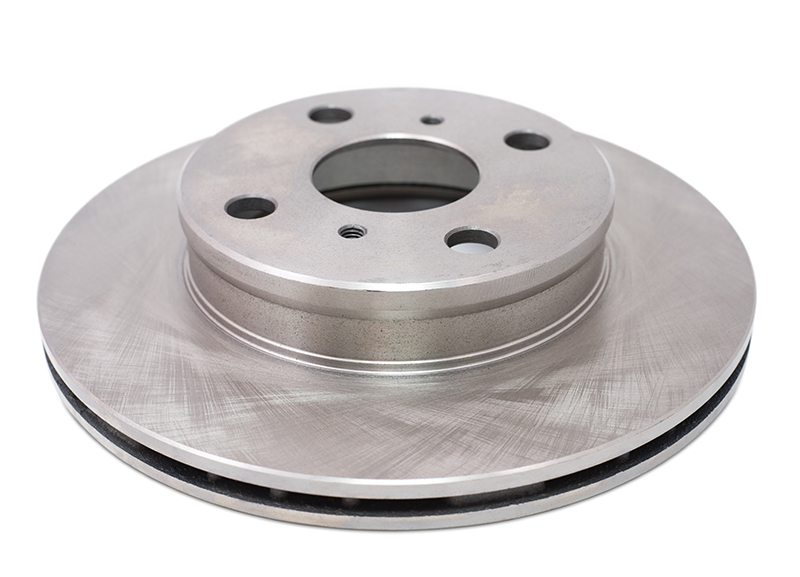

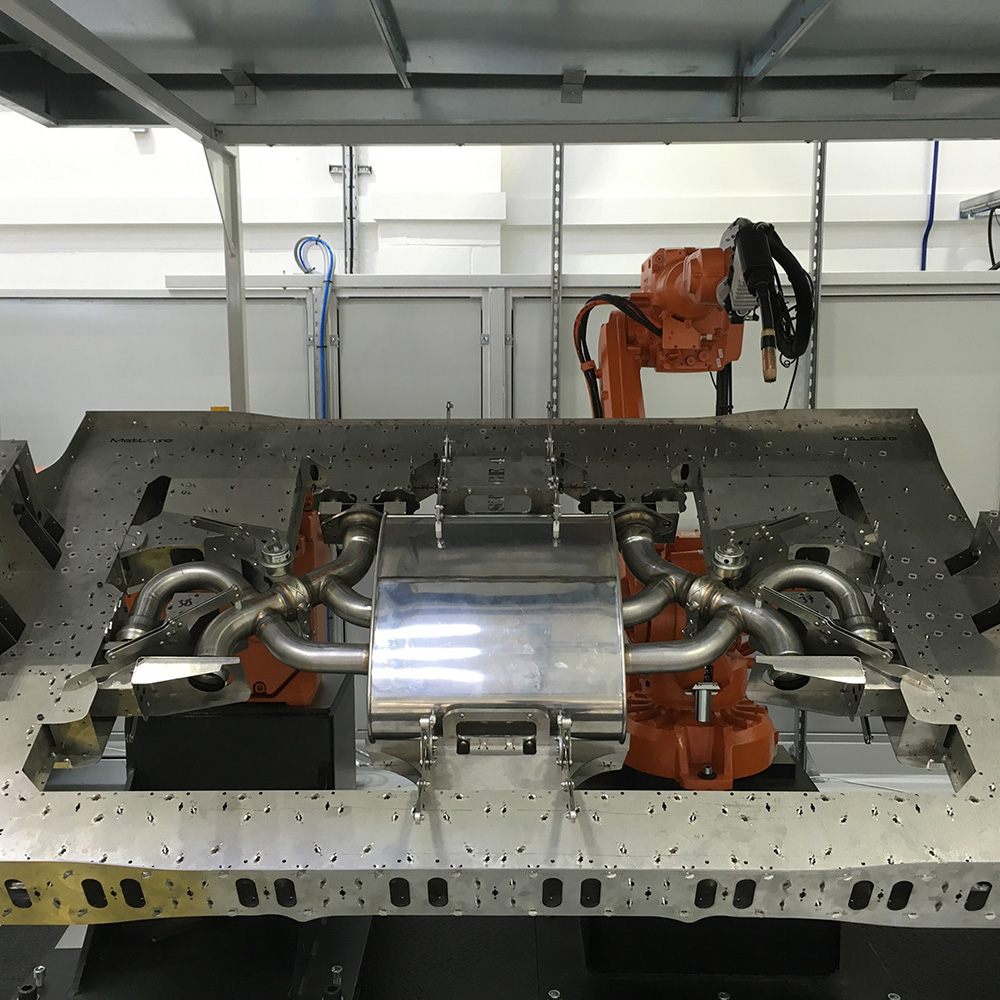

At KingStar Mold, we specialize in CNC precision machining, offering high-accuracy solutions for custom parts with stringent tolerance requirements. Our advanced CNC equipment and skilled technicians ensure that each part is crafted with exceptional precision, whether for prototyping, low-volume production, or complex assemblies. With capabilities ranging from micro-machining to large-scale parts, we deliver parts that meet the most demanding standards for industries such as aerospace, automotive, medical, and electronics.

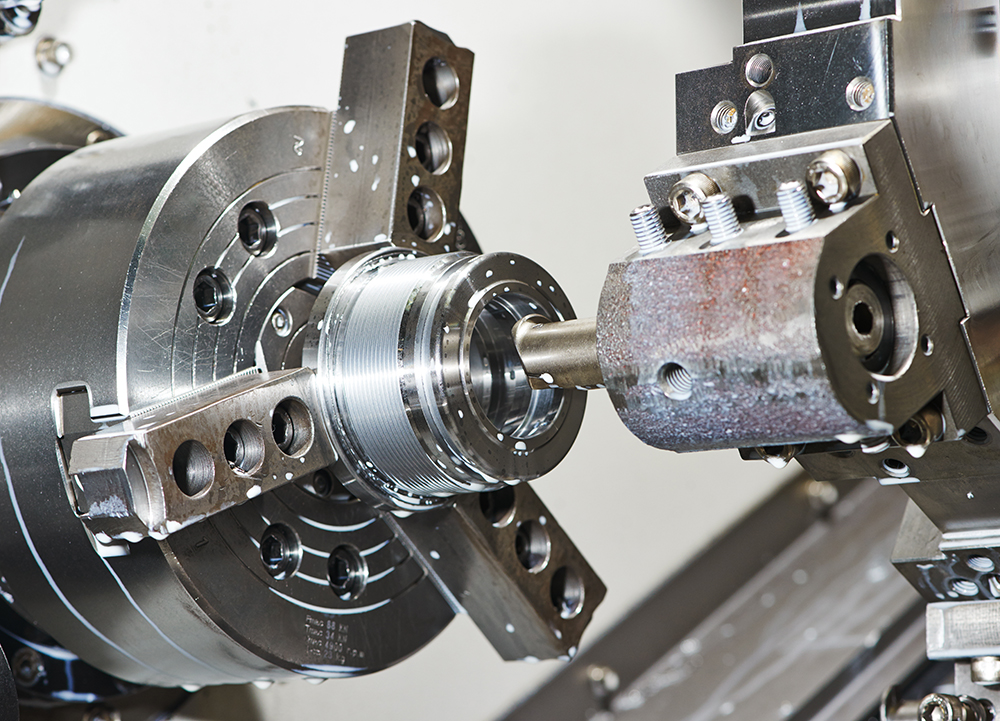

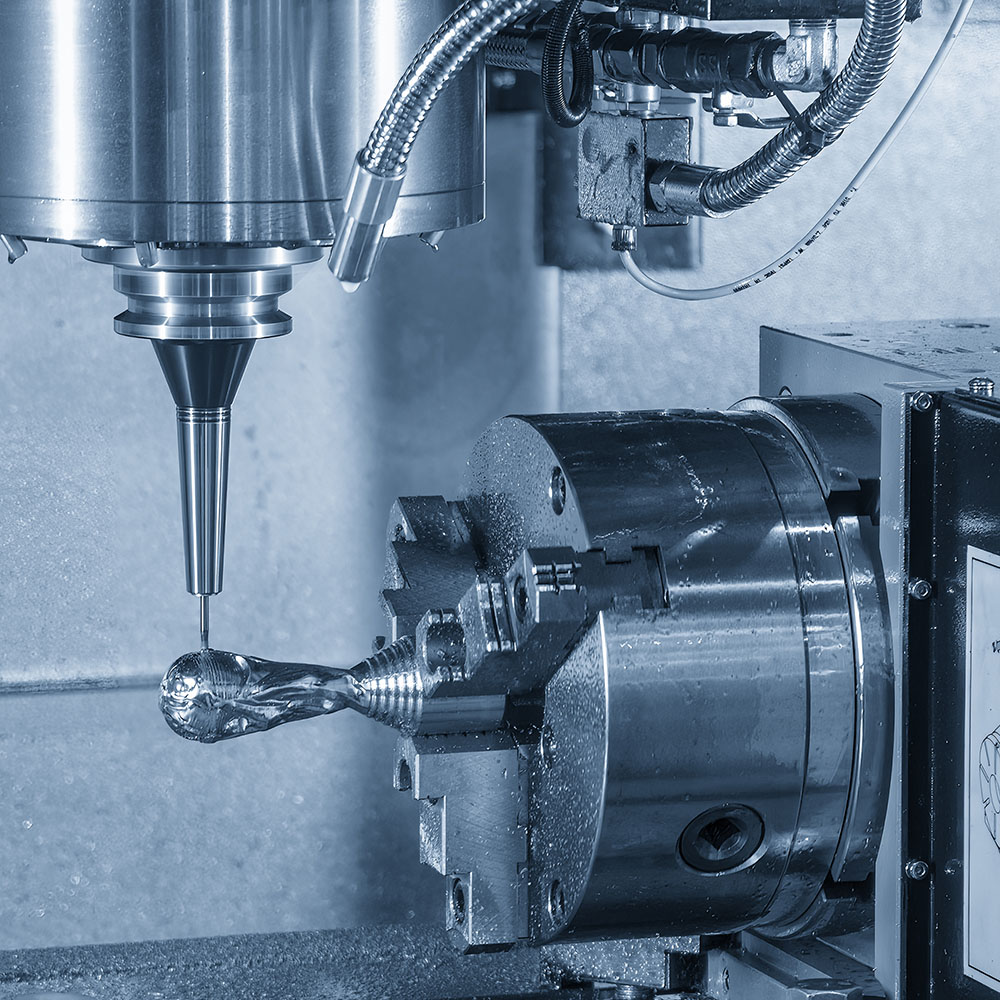

We use cutting-edge technology to perform precise milling, turning, and grinding operations, ensuring flawless results every time. By combining state-of-the-art machinery with a commitment to quality, KingStar Mold guarantees reliable, high-performance parts tailored to your exact specifications. Whether you need complex geometries or high-strength materials, our CNC precision machining service provides the quality and accuracy you need to bring your designs to life.

Extreme Accuracy

Achieve tight tolerances and detailed precision for every part

Material Versatility

Machine a wide range of materials for diverse applications

Efficient Production

Reduce lead times and boost productivity with advanced technology

Consistent Quality

Ensure flawless results with strict quality control and inspections

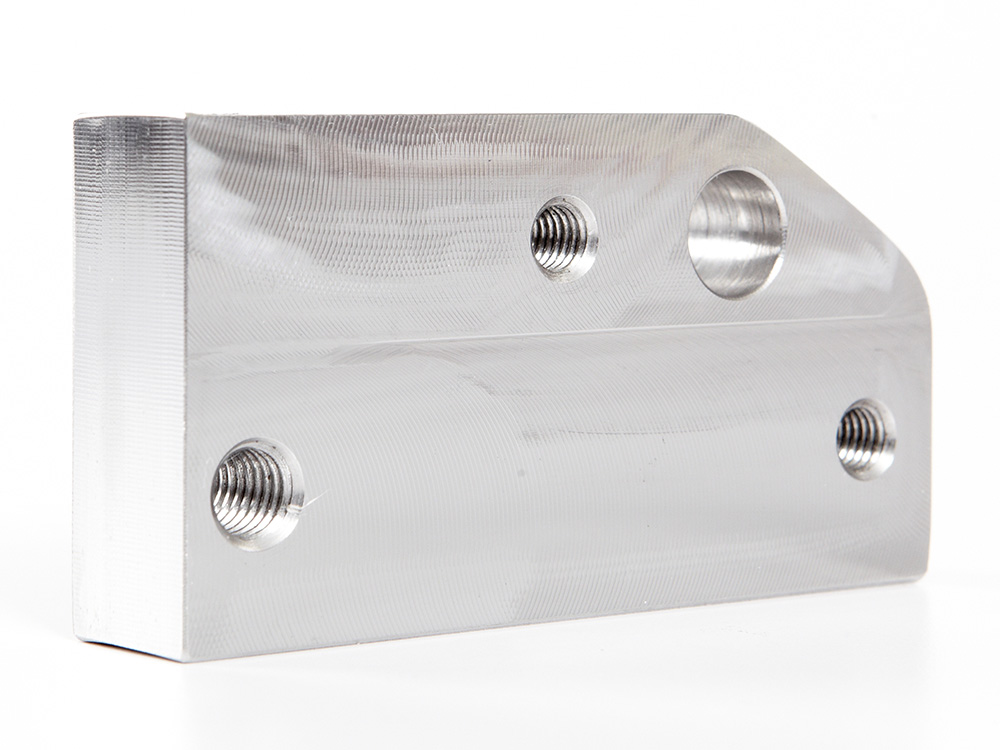

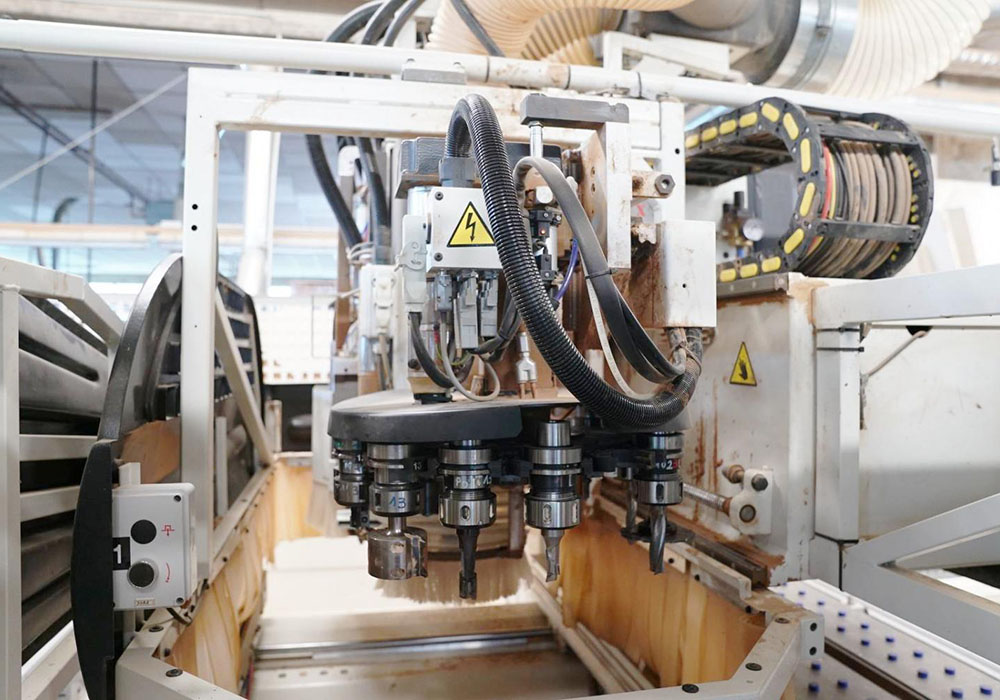

CNC machined part Gallery

KingStar Mold’s Advantages On CNC Precision Machining Service

Cutting-Edge Technology

KingStar Mold uses the latest CNC machining technology to achieve the highest levels of precision and efficiency, ensuring superior results for every project.

Experienced Team

Our skilled engineers and machinists bring years of expertise to the table, enabling us to handle complex designs and challenging tolerances with ease.

Custom Solutions

We offer tailored CNC machining services to meet your specific requirements, providing flexible solutions for both prototyping and production in a variety of industries.

Order Processing Workflow

01

Upload Your Design File

The process begins by receiving your design file in formats like CAD or CAM to understand the part specifications.

02

Review and Plan Machining Process

Our engineers analyze the design and determine the best machining methods and tools to achieve optimal results.

03

Select Materials and Tools

Based on the part requirements, we choose the appropriate materials and machining tools to ensure precision and quality.

04

Set Up CNC Machine

The CNC machine is calibrated, and the workpiece is loaded, preparing for the machining process.

05

Machining and Quality Checks

The part is machined, with ongoing inspections to ensure it meets the required tolerances and quality standards.

06

Post-Processing and Delivery

After machining, parts undergo post-processing, such as finishing, and are then packaged for timely delivery to you.

Our Satisfied Clients

4 Tips for Your Design

To optimize CNC machining, simplify your design to reduce complexity and cost. Use standard tooling to minimize setup time and incorporate fillets or radii to improve part strength and tool life. Ensure your design allows for easy fixturing to maintain accuracy, and specify only necessary tolerances to control costs. Finally, consider the material’s machinability and thermal properties to ensure efficient production. These tips will help streamline your design for cost-effective and precise machining.

Use Standard Tooling

Opt for standard tools and shapes wherever possible to minimize tool changes and setup time.

Maintain Adequate Tolerances

Specify only the necessary tolerances, as tighter tolerances increase machining time and cost.

Account for Material Behavior

Design with the material’s properties in mind, considering factors like machinability, strength, and thermal expansion.

Design for Easy Fixturing

Ensure your part can be securely fixtured during machining to avoid movement or misalignment during the process.

Lead times vary depending on part complexity and volume, but KingStar Mold typically delivers prototypes within a few days and production parts in one to two weeks.

You can submit your design file in CAD formats such as STEP, IGES, or STL through our website or via email. Our team will review it and provide a detailed quote.

Industries like aerospace, automotive, medical, electronics, and defense rely on CNC precision machining for producing parts that require high accuracy and reliability.

CNC precision machining offers exceptional accuracy, with tolerances typically ranging from ±0.01 mm to ±0.05 mm, making it suitable for high-precision applications across various industries.

CNC precision machining can handle a wide range of materials, including metals (aluminum, steel, titanium), plastics (acrylic, nylon, POM), and composites, based on the part’s functional requirements.

CNC precision machining is a manufacturing process where computer-controlled machines use cutting tools to create high-precision parts with tight tolerances and complex geometries, ideal for industries requiring exact specifications.

If any part does not meet the specified requirements, we will review the issue and work with you to make adjustments, ensuring that the final product meets your exact needs.

Yes, KingStar Mold offers post-processing services like surface finishing, anodizing, heat treatment, and coating to meet specific part requirements.

The cost depends on factors like material, part complexity, and quantity. KingStar Mold provides competitive and transparent pricing based on your specific project requirements.

Yes, CNC precision machining is versatile and suitable for both one-off prototypes and large-scale production runs, offering consistent quality across all quantities.

CNC precision machining offers high accuracy, repeatability, and the ability to work with a wide range of materials. It also reduces human error and speeds up the production process compared to manual methods.

Yes, CNC precision machining is perfect for complex parts with intricate geometries, including holes, slots, and custom shapes that traditional machining methods can’t easily achieve.