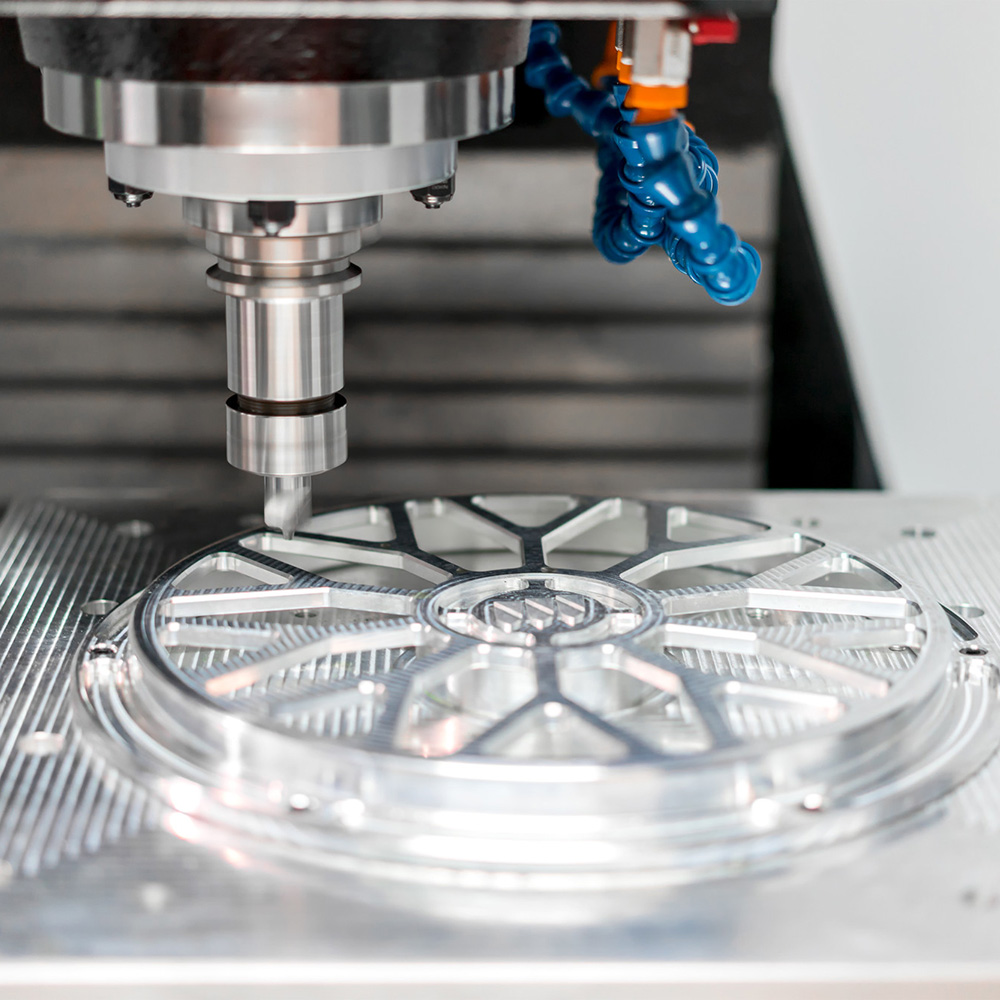

KingStar Mold CNC Milling Service: Precision and Performance

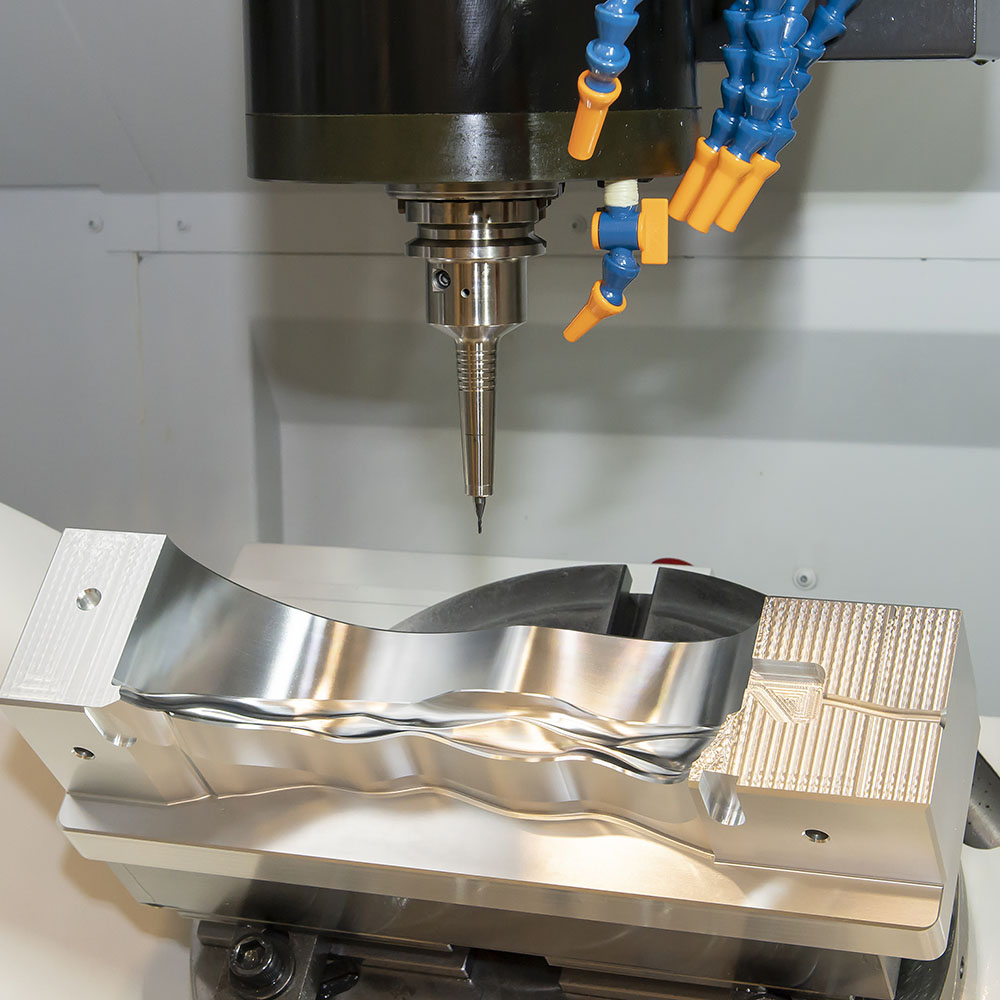

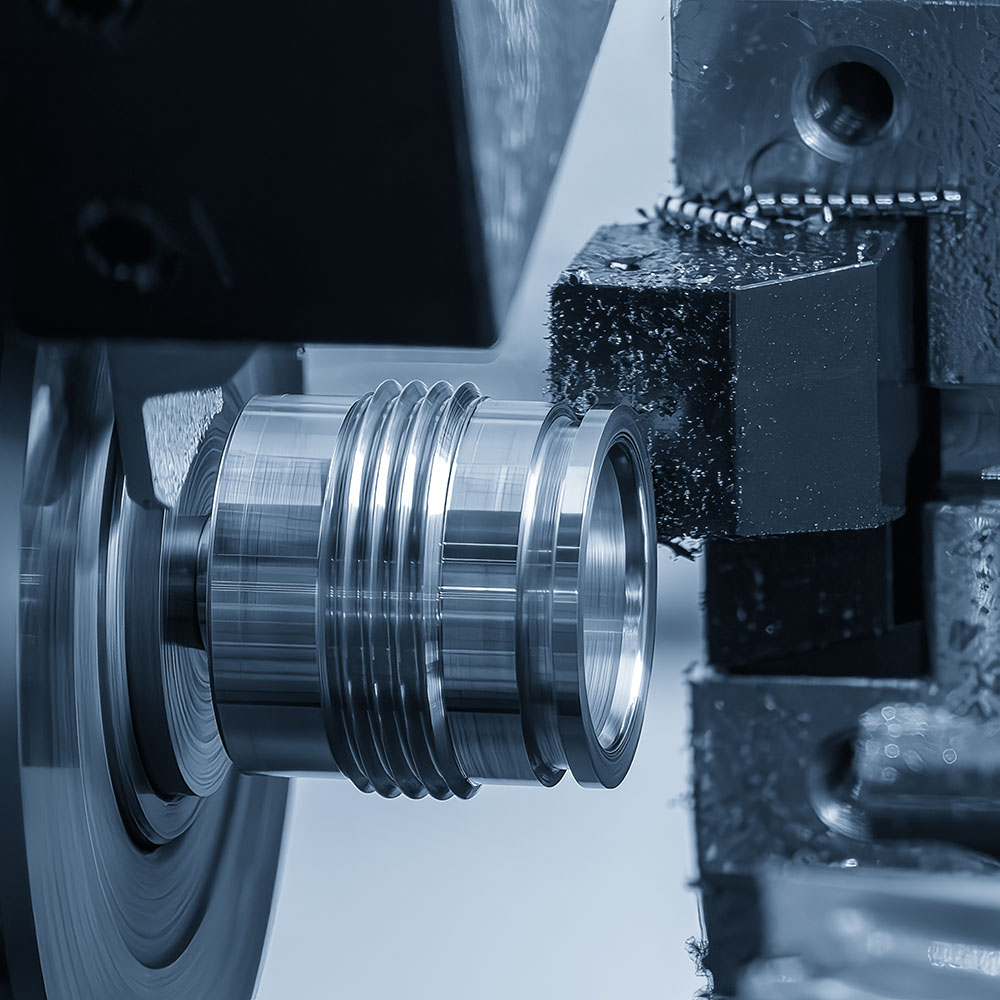

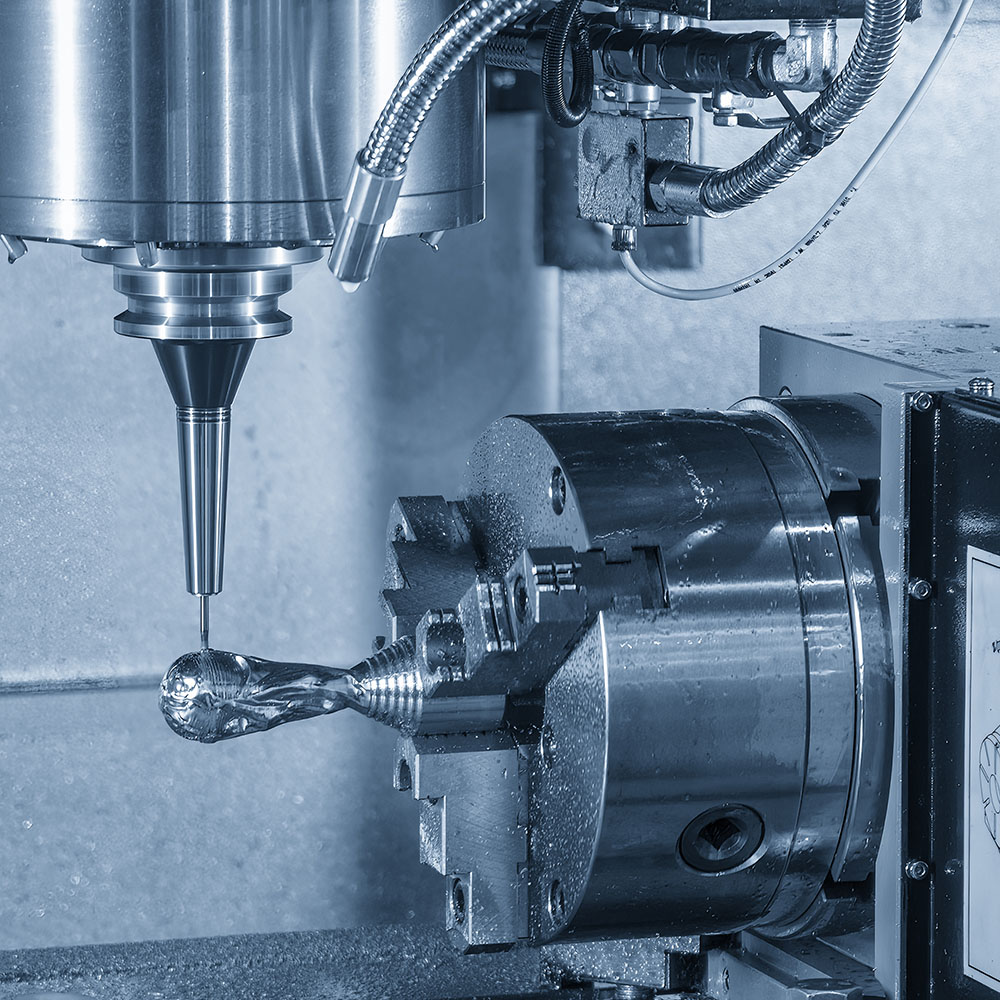

At KingStar Mold, we offer high-quality CNC milling services that provide exceptional precision and efficiency for a wide range of applications. Our state-of-the-art milling machines, combined with advanced multi-axis capabilities, allow us to machine complex geometries and tight tolerances in a variety of materials, including metals, plastics, and composites. Whether you’re producing prototypes, small batches, or large-scale production runs, we ensure consistent, accurate results with every project.

Our experienced team at KingStar Mold works closely with you to understand your specific requirements, ensuring that each part meets your exact specifications. With a focus on quality control, we use advanced inspection tools to monitor and verify each step of the machining process. From design to delivery, our CNC milling service guarantees precision, reliability, and fast turnaround times to meet the demands of even the most intricate projects.

Precision Machining

Customized Solutions

Scalable Production

We Can Provide CNC Milling Service to These Industries

Automotive

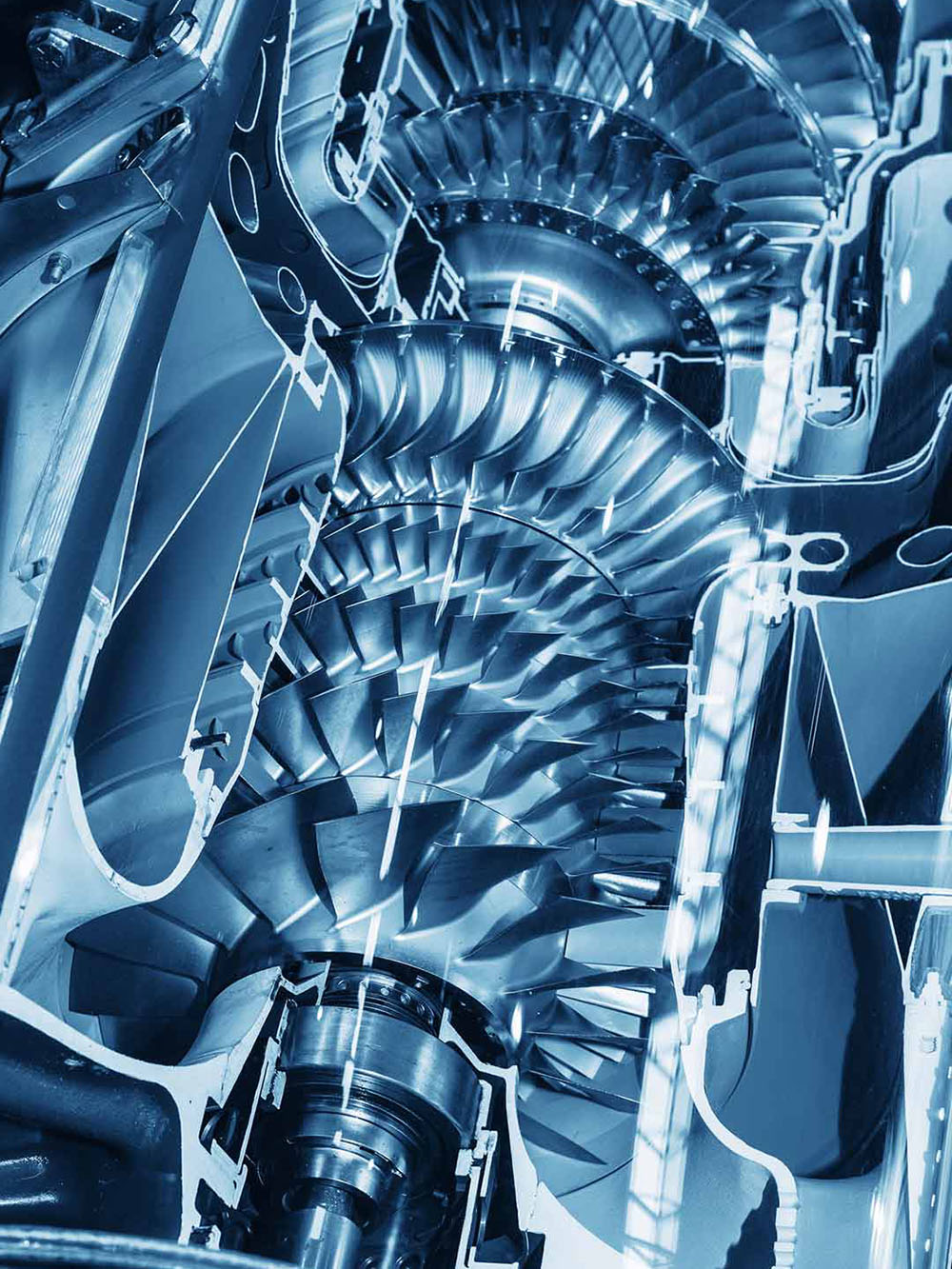

Aerospace

Automotive

Appliances

Why KingStar Mold

Our Advantages in CNC Milling

High Precision

Our CNC milling services ensure tight tolerances and precise dimensions, meeting the most exacting requirements. Whether it’s small, intricate parts or large, complex components, we guarantee accuracy throughout the entire production process.

Rapid Turnaround

Our advanced CNC milling technology, combined with efficient workflow management, enables quick turnaround times. This means faster prototyping, reduced lead times, and quicker time-to-market for your products.

Versatile Material Options

We work with a wide range of materials, from metals like aluminum and titanium to plastics and composites. This flexibility allows us to cater to diverse industries, providing tailored solutions for each specific application.

Consistent Quality

With strict quality control processes in place, we maintain a high standard of production across all orders. From initial design to final inspection, we ensure that every part meets the necessary specifications and performance standards.

Cost-Effective Production

Our CNC milling service balances precision with efficiency, optimizing material usage and minimizing waste. This cost-effective approach allows us to deliver high-quality parts without exceeding your budget.

Scalable Capacity

Whether you need a single prototype or a large batch of parts, we can scale our operations to meet your needs. Our CNC milling services can handle small runs and mass production, adapting to your project size and timelines.

| Parameter | Specification |

|---|---|

| Max Part Size | Up to 1000 mm x 500 mm x 500 mm |

| Max Machining Speed | 20,000 RPM (depending on material) |

| Tolerance | ± 0.01 mm |

| Material Types | Metals (Aluminum, Steel, Titanium), Plastics (POM, Nylon), Composites |

| Axis Capabilities | 3-Axis, 4-Axis, 5-Axis |

| Max Cutting Tool Diameter | Up to 200 mm |

| Surface Finish | Ra 0.8 to Ra 1.6 |

| Max Load on Workpiece | 100 kg |

| Max Tool Changing Speed | 2 seconds/tool |

| Software Used | CAD/CAM (SolidWorks, AutoCAD, Fusion 360) |

Our Satisfied Clients

Order Processing Workflow

01

Upload Your Design File

Submit your design file to kickstart the process and get started on your custom part.

02

Select Materials & Specifications

Choose the materials and specify any key features or tolerances for your product.

03

Review & Approve Quote

Receive an instant quote based on your design and confirm your order details.

04

Precision Machining Begins

Choose the materials and specify any key features or tolerances for your product.

05

Quality Control Inspection

We thoroughly inspect each part to ensure it meets your exact requirements and quality standards.

06

Timely Delivery

Receive your fully finished product on time, ready for use or assembly.

Supported Milling Materials

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Machinability | Common Applications |

|---|---|---|---|---|---|---|

| Aluminum | 2.70 | 310 | 275 | 95 | High | Aerospace, automotive, structural parts |

| Stainless Steel | 7.93 | 520 | 215 | 150 | Medium | Food processing, medical, marine |

| Titanium | 4.43 | 900 | 880 | 330 | Low | Aerospace, medical implants, high-performance parts |

| Brass | 8.49 | 345 | 150 | 65 | High | Plumbing, electrical connectors |

| Copper | 8.92 | 210 | 70 | 40 | Medium | Electrical wiring, heat exchangers |

| Carbon Steel | 7.85 | 570 | 350 | 120 | Medium | Machinery, automotive, tooling |

| POM (Acetal) | 1.41 | 65 | 55 | 70 | High | Gears, bearings, automotive components |

| Nylon | 1.15 | 75 | 50 | 80 | Medium | Mechanical parts, automotive, electrical insulation |

| Acrylic (PMMA) | 1.19 | 70 | 90 | 20 | High | Optical lenses, signage, automotive |

| Carbon Fiber Composites | 1.60 | 800 | 600 | 150 | Low | Aerospace, sports equipment, automotive |

CNC milling is widely used across industries such as aerospace, automotive, medical, electronics, and consumer products. It’s ideal for creating prototypes, low-volume production, and intricate custom parts.

Lead time can vary depending on the complexity of the part and material. However, KingStar Mold offers rapid turnaround times, often completing milling projects in as little as a few days for simple parts, or a couple of weeks for more complex designs.

Yes, CNC milling is ideal for machining complex geometries. Our multi-axis milling capabilities allow for intricate shapes and features to be precisely machined, ensuring accurate results for even the most complicated designs.

At KingStar Mold, we combine advanced CNC technology with skilled craftsmanship to deliver high-precision, high-quality parts. We also offer flexible lead times, competitive pricing, and a wide range of material options tailored to your specific needs.

CNC milling offers high precision, typically achieving tolerances of ±0.01 mm. The exact tolerance depends on the material and complexity of the part.

CNC milling can work with a wide variety of materials, including metals like aluminum, steel, and titanium, as well as plastics such as POM, acrylic, and nylon. The choice of material depends on the part’s functionality and application requirements.

You can get an instant quote by submitting your design file through our website. After reviewing your specifications, our team will provide a detailed cost estimate based on material, complexity, and quantity.

Yes, we offer post-processing services such as heat treatment, surface finishing, coating, and assembly, ensuring that your CNC-milled parts meet all functional and aesthetic requirements.

Consider factors like strength, weight, corrosion resistance, and machinability. Our team at KingStar Mold can help you choose the right material based on your part’s requirements and application.

Yes, we can scale CNC milling for both small batch and large production runs. Our equipment and team are equipped to handle both high-volume manufacturing and custom, one-off prototypes.

You can submit your design files through our easy online platform or directly by email. We accept various formats, including CAD files (DXF, STEP, IGES), and our team will review them for manufacturability.