Almost all plastic products have varying degrees of internal stress, especially the internal stress of plastic injection products is more pronounced. The presence of internal stress not only causes stress cracking and warpage during storage and use, but also affects the mechanical, optical, electrical, and appearance quality of plastic products. The necessary condition for stress cracking is the presence of stress within the specimen or part, and the presence of certain stress concentration factors such as notches, surface scratches, etc. So, where does the stress in plastic parts come from?

KingStar, as a leading injection molding company, has in-depth research and rich practical experience in the mechanism of internal stress generation and cracking problems of materials such as PC/ABS. We now summarize and analyze the relevant points and response plans of internal stress in plastic parts, providing reference for industry processing and production.

1. Causes of Internal Stress in Plastic Parts

Based on the different causes of internal stress, it can be divided into the following categories:

1.1 Orientation Internal Stress

Orientation internal stress is a type of internal stress generated by the freezing of the oriented conformation of polymer chains along the flow direction during the process of flow filling and pressure filling of plastic melts. The freezing condition of oriented polymer chains within plastic products implies the presence of unrelaxed reversible highly elastic deformation, so orientation stress is the internal force that causes the polymer chains to transition from an oriented conformation to an unoriented conformation. The orientation internal stress distribution of plastic products decreases from the surface layer to the inner layer and follows a parabolic trend.

1.2 Cooling Internal Stress

Cooling internal stress is a type of internal stress generated during the melting process of plastic products due to uneven shrinkage during cooling and solidification. Especially for thick walled plastic products, the outer layer first cools, solidifies, and shrinks, while the inner layer may still be a molten melt. The core layer will limit the shrinkage of the surface layer, resulting in the core layer being in a compressive stress state and the surface layer being in a tensile stress state. The distribution of internal stress during cooling increases from the surface to the inner layer of the product, and also follows a parabolic trend. In addition, plastic products with metal inserts are prone to uneven shrinkage due to the significant difference in thermal expansion coefficients between metal and plastic.

1.3 Environmental Stress

Environmental stress cracking is a unique phenomenon of polyolefin plastics. When products come into contact with active media such as detergents, water, acids, and alkalis under stress, brittle cracks or even product damage may occur. Raw materials mixed with impurities, improper or excessive additives can also cause cracks at stress concentration sites. Under damp heating conditions, water vapor can trigger a catalytic cracking reaction in certain plastics like ABS, leading to significant part failure.

1.4 Others

The different crystal structures and degrees of crystallinity in various parts of crystalline plastic products can generate internal stresses, as well as configuration internal stresses and demolding internal stresses, which account for a relatively small proportion.

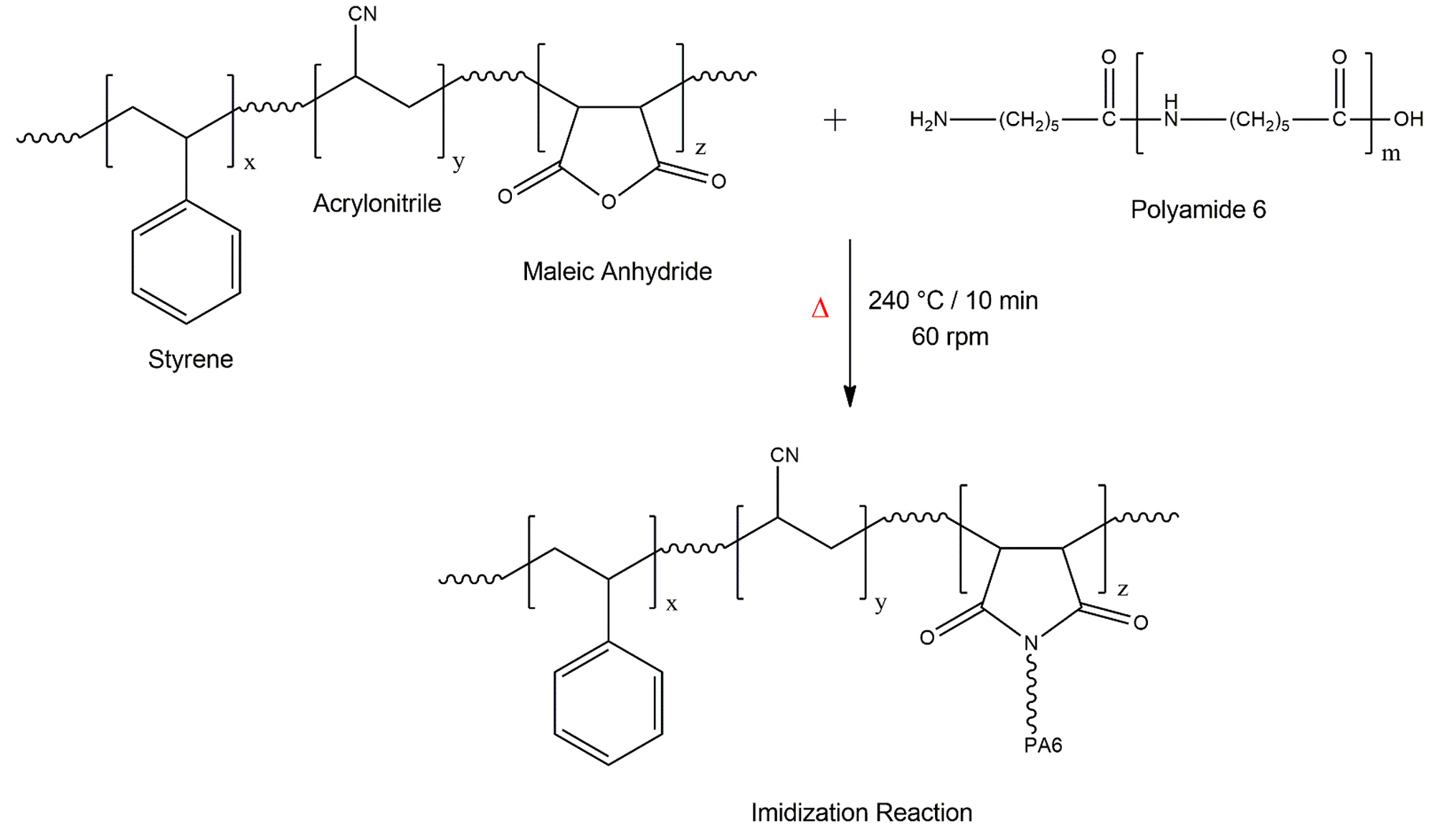

2. Micro-Analysis of Internal Stress Cracking in PC/ABS

The greater the rigidity of the molecular chain, the higher the viscosity of the melt, the poorer the activity of the polymer molecular chain, the weaker the reversible high elastic deformation recovery, and the easier it is to generate residual internal stress, such as in PC, PPO, PPS and other polymer products containing benzene rings, where the internal stress is relatively high.

The internal stress cracking of PC materials is determined by their own molecular structure. And the presence of phenyl rings in their molecular chains makes orientation difficult. After molding, the oriented chain links tend to return to their natural state, and are limited by molecular chain freezing and intermolecular forces, resulting in stress and ultimately leading to cracking. Recycled PC is prone to cracking due to a decrease in relative molecular weight, wider distribution, and the presence of moisture, impurities, etc.

The order of internal stress of several common polymers is: PPO>PSF>PC>ABS>PA 6>PP>HDPE.

3. Reduction & Dispersion of Internal Stress in Plastics

3.1 Selection of Raw Materials in the Early Stage

(1) Select resins with high molecular weight and narrow molecular weight distribution to enhance the stress cracking resistance of the product, reduce micro tearing and stress concentration;

(2) Select resins with low impurity content to reduce the risk of stress concentration and ensure the original strength of the plastic;

(3) Blending modification involves blending easily stress cracking resins with suitable resins, such as PS and PE mixed into PC, to disperse and relieve internal stress;

(4) Enhanced modification, using reinforced fibers to entangle large molecular chains, such as 30% GF PC, which has a stress cracking resistance 6 times higher than pure PC;

(5) Nucleation modification involves adding nucleating agents to crystalline plastics to form small spherical crystals that disperse internal stress.

3.2 Control of Molding Process Conditions

During the molding process, factors such as reducing molecular orientation, achieving uniform cooling, and facilitating smooth demolding can all reduce corresponding internal stresses. Key control points for core processing conditions:

- Barrel Temperature: Moderate is appropriate, too high can lead to insufficient cooling, and too low can result in severe molecular orientation and high orientation stress;

- Mold Temperature: Avoid being too low, otherwise uneven cooling, sudden increase in melt viscosity, and increased cooling and orientation stress will occur;

- Injection Pressure: Reduce appropriately to minimize the shear effect of the melt and lower the probability of orientation stress generation;

- Holding Pressure: High pressure can easily cause forced orientation of molecular chains, resulting in greater orientation stress, which needs to be controlled reasonably;

- Injection Speed: Moderate is preferred, and variable speed injection is preferred. The mold filling is completed at a reduced speed to avoid exacerbating the orientation too quickly and forming melting marks too slowly;

- Holding Time: It should not be too long, otherwise the shear effect of the melt will increase and freeze more orientation stress;

- Residual Pressure During Mold Opening: Adjust parameters to make the residual pressure inside the mold close to atmospheric pressure, avoiding the generation of internal stress during demolding.

3.3 Heat Treatment (Annealing) of Plastic Products

Heat treatment is the best method to eliminate orientation stress, and immediate treatment after demolding yields better results. Parts with high molecular chain rigidity, large wall thickness, metal inserts, and high dimensional accuracy requirements all require heat treatment. The commonly used temperature is 10-20 ℃ higher than the operating temperature or 5-10 ℃ lower than the thermal deformation temperature. Generally, the parts are kept warm for 1-2 hours and then slowly cooled. Liquid medium or oven heating can be used. It should be noted that heat treatment can only reduce internal stress to the allowable range for use and is difficult to completely eliminate.

3.4 Design of Plastic Products

- Shape and Dimensions: The outer shape should be kept continuous, and the edges should be rounded. The inner corner radius should be greater than 70% of the thickness of the thinner adjacent walls; The wall thickness should be as uniform as possible, and gradual transitions should be used if necessary;

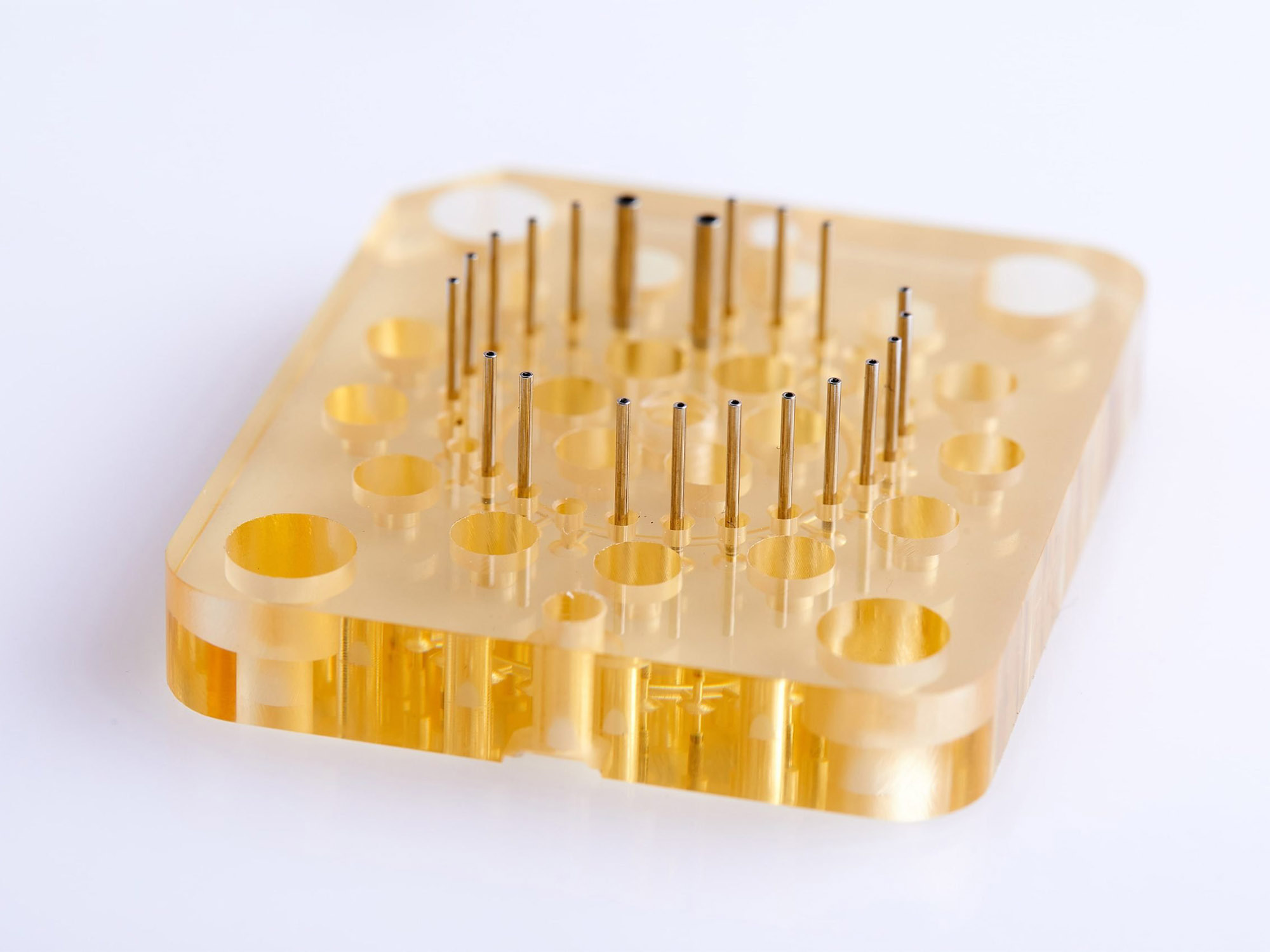

- Metal inserts: Priority should be given to plastic inserts, using metals with similar thermal expansion coefficients such as aluminum and copper. The inserts should be degreased, preheated, and coated with an elastic buffer layer on the surface to ensure the thickness of the surrounding plastic (aluminum inserts h≥0.8D, copper inserts h≥0.9D). The inserts should be designed in a smooth and rolled pattern style;

- Hole Design: Avoid polygonal holes and prioritize circular and elliptical holes (with the long axis parallel to the direction of external force). Opening a circular hole can increase the number of process circular holes or create symmetrical slot holes to disperse internal stress.

3.5 Design of Plastic Molds

- Gate Size: Reduce it appropriately to avoid excessive freezing and more orientation stress, and reduce it too small to cause short shots in the product;

- Gate Position: Priority should be given to the area with the largest wall thickness, and the gate wall thickness should be increased at thin-walled areas. Thick walled and long-flow-length products adopt a multi gate distribution, and ear guard gates can also be designed. After demolding, the ear guard can be removed to reduce internal stress;

- Runner Design: Using short and thick channels to reduce melt pressure loss and temperature drop;

- Cooling System: The distribution of cooling water channels is reasonable to ensure uniform and slow cooling of all parts of the product;

- Ejection System: Design suitable draft angles, highly polished cores, and large-area ejection points to prevent demolding stress caused by forced demolding.

4. Internal Stress Cracking Test Method (Acetic Acid Immersion Test)

Internal stress cracking of PC/ABS can be tested by immersion in acetic acid or carbon tetrachloride: the injection molded parts with screws that have not been annealed are immersed in a solvent at room temperature, and the time when the crack appears is recorded as the stress cracking time.

Test example: Soak a PC product with screw slots/columns completely in ice cold acetic acid at 25 ℃ for 30 seconds, take it out and dry it, and inspect it. If small and dense cracks appear, it indicates the presence of internal stress. The more cracks there are, the greater the internal stress.

4.1 Key Points of PC Injection Molding Process

- Drying of Raw Materials: Dry at 100-120 ℃ for at least 4 hours to reduce the moisture content to below 0.02%;

- Temperature Control: The temperature of the material barrel is 250-320 ℃ (not exceeding 350 ℃), and the mold temperature is 85-120 ℃;

- Injection Parameters: High-pressure injection, medium wall thickness, high wall thickness;

- Annealing Treatment: If necessary, hold in an oven at 125-135 ℃ for 2 hours and cool naturally to room temperature;

- Mold Requirements: The runner should be thick and short, with few bends, circular cross-section and polished, and the diameter of the water level entering the gate should be ≥1.5mm;

- Post-Processing: Use PE material to pass through the machine.

4.2 Common Testing Items for Polymer Materials

- Physical Properties: Tensile/elongation, flexural strength/modulus, impact strength, hardness, water absorption, etc;

- Thermal Properties: DSC analysis, TGA analysis TMA, thermal resistance/thermal conductivity, combustion performance, etc;

- Electrical Properties: Insulation resistance, surface/volume resistivity, withstand voltage/breakdown voltage, etc;

- Climate Environment: High temperature, low temperature, constant temperature and humidity, thermal shock, photoaging, etc;

- Other: Solvent resistance, plastic cracking failure analysis, etc.

Conclusion

The control of internal stress and the solution to cracking problems in plastic parts are the core issues in the field of plastic processing, which need to be integrated throughout the entire process of raw materials, processing, design, and testing. Only with professional technical control and mature process systems can the quality of products be improved.

KingStar is deeply engaged in the field of plastic processing and has professional skills and rich experience in PC/ABS internal stress control. If you encounter any technical issues or want to seek a precision part manufacturer, please feel free to contact KingStar at sales@kingstarmold.com or leave online message at any time and we will reply to you within 24 hours.