A Small Batch Production Project for Table Connectors by KingStar Mold

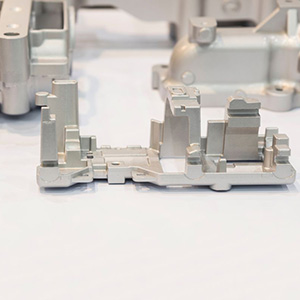

In 2019, KingStar Mold received a small batch production project focused on table connector manufacturing for a client. The project was aimed at producing 300 pieces per quarter using rapid tooling to meet the client’s specific needs.

Understanding the Customer’s Needs

Our client came to us with precise requirements for their table connectors:

- Small Batch Production: The client needed 300 pieces per quarter to meet their production schedules.

- High Durability: Since the table connectors played a structural role, durability and strength were critical.

- Precision Fit: The connectors needed to fit precisely, ensuring easy assembly and long-term stability.

Despite the modest batch size, KingStar Mold committed to delivering top-tier quality and value, fully addressing the client’s requirements.

Challenges in Insert Molding for Table Connectors

Insert molding is the process of placing a pre-formed insert (such as metal components) into a mold, followed by the injection of plastic to form a unified part. While ideal for creating sturdy, reliable table connectors, this method posed certain challenges:

- Thick Sections Leading to Sink Marks: The table connectors had thick sections, increasing the risk of shrinkage, which could lead to dimensional inaccuracies and weakened structural integrity.

- Maintaining Precision: Ensuring each connector met the exact specifications required stringent control over the molding process.

- Cost Efficiency for Small Batches: Offering cost-effective solutions for small-batch production without compromising on quality presented an additional challenge.

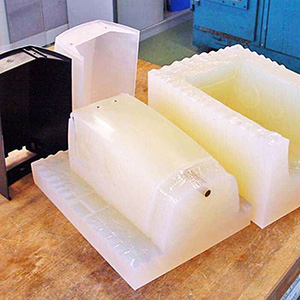

KingStar Mold’s Solution

- Advanced Mold Design: Our team of engineers designed custom molds to address sink marks. By incorporating optimized cooling channels and precise control over the molding parameters, we minimized shrinkage risks and ensured consistent quality across all connectors.

- High-Quality Materials: We used high-grade, low-shrinkage plastic materials and sourced metal inserts to meet the client’s stringent standards. This ensured the durability and reliability of the final product.

- Process Optimization: Rigorous testing allowed us to fine-tune injection parameters such as speed, pressure, and cooling time, ensuring optimal results.

- Cost-Effective Small Batch Production: Despite the small order size, KingStar Mold’s efficient manufacturing processes allowed us to deliver the required quality at a competitive price, maintaining value for the client.

- Quality Assurance: Each batch of connectors underwent thorough quality checks, including dimensional accuracy, structural integrity tests, and fit assessments, ensuring they met the client’s exact specifications.

Summary

This partnership lasted for three years, concluding when the project came to an end.

KingStar Mold’s expertise in insert molding and commitment to meeting customer needs has earned us the trust of our clients in producing table connectors. Whether small-batch or large-scale production is required, we ensure exceptional quality and value. Contact us today to find out how we can meet your manufacturing needs.

Quality Control Standards for KingStar Mold’s Manufacturing Process

- Dimensional Accuracy

Maintaining dimensional tolerances of ±0.1 mm to ensure precise fitting and high-quality production. - Surface Finish

Achieving a surface roughness (Ra) of less than 1.6 µm, ensuring smooth and aesthetically pleasing finishes. - Structural Integrity

Ensuring the product’s tensile strength meets at least 30 MPa and impact resistance is 20 kJ/m² for superior durability. - Absence of Injection Molding Defects

Products are rigorously tested to be free of defects like voids, bubbles, and flash, with a defect rate kept below 0.2%. - Color Consistency

Maintaining color variance (ΔE) of less than 1.0, ensuring uniform appearance and quality across all parts. - Consistency Across Batches

Ensuring batch-to-batch variation remains under 0.5%, guaranteeing consistency and reliability across all production runs.

Q1. What materials are commonly used in the production of dining table connectors?

Dining table connectors are usually made from high-strength plastics such as polyamide (Nylon), polypropylene, or polycarbonate. These materials are chosen for their excellent mechanical properties, durability, and resistance to environmental factors. Metal inserts are also commonly incorporated to provide added strength and secure connections.

Q2. How does KingStar Mold ensure high dimensional accuracy in its connectors?

KingStar Mold achieves high dimensional accuracy through precise mold manufacturing, stringent process controls, and regular calibration of injection molding machines. We maintain dimensional tolerances within ±0.05 mm to ensure a perfect fit and optimal functionality for each connector.

Q3. What quality control measures are implemented to ensure the absence of defects in connectors?

Our comprehensive quality control process at KingStar Mold includes visual inspections, dimensional checks, and non-destructive testing to detect and eliminate defects like voids, bubbles, and flash. We maintain a defect rate below 0.2%, ensuring the highest standards in every product.

Q4. How does KingStar Mold achieve consistent color in its connectors?

To achieve consistent color, KingStar Mold uses precise colorant formulations and maintains stable processing conditions. This involves controlling key variables such as temperature, pressure, and mixing times during the injection molding process to ensure uniform color distribution across all parts.

Q5. How does KingStar Mold handle small batch production cost-effectively?

We leverage efficient manufacturing processes and flexible production systems at KingStar Mold to keep costs low. By optimizing material usage, reducing setup times, and employing cost-effective production techniques, we offer competitive pricing even for small batch orders.

Q6. What are the key benefits of using insert molding for dining table connectors?

Insert molding offers several advantages, including enhanced strength and durability by combining plastic and metal components, improved mechanical properties, and better performance in structural applications. It also allows the integration of multiple materials into a single part, reducing assembly time and injection molding costs.

Note:

We maintain pre-market confidentiality agreements and sign NDA/NNN with all our customers. Every case you see has been shared with client approval. To protect sensitive information, some details have been blurred or modified. All photos were taken internally by KingStar Mold. Thank you for your support and cooperation.

Custom Manufacturing that Fits Your Product Life Cycle

Our Custom Manufacturing Services

Your one-stop solution for enhancing your product’s market potential.

Injection Molding

We offer comprehensive services of injection molding, producing a wide range of parts through two-shot molding, overmolding and custom molding techniques.

Mold Making

At KingstarMold, we develop and produce precision die-casting molds, injection molds, stack molds, and two-color molds using state-of-the-art equipment.

Sheet Metal Fabrication

We provide precise sheet metal fabrication solutions, offering custom-made parts with exceptional durability, tailored to meet the specific requirements of your project.

CNC Machining

Our CNC machining includes both 4-axis and 5-axis capabilities, with a focus on optimizing equipment arrangement to enhance efficiency.

Die Casting

Our die casting service ensures high-precision, high-volume production of metal parts with excellent surface finishes and tight tolerances.

Vacuum Casting

With vacuum casting, we produce high-quality, detailed prototypes and low-volume parts with exceptional accuracy.