Electric Scooter Wheel Hubs Producing by Insert Molding

| Parts Material | PA6+30%GF, Steel |

| Application Industry | Tools & Equipment |

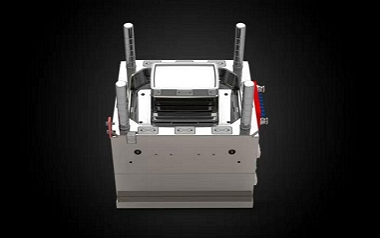

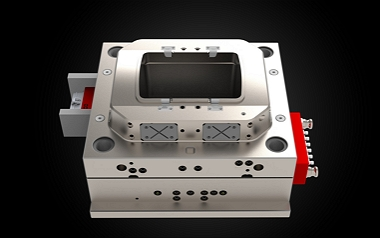

| Manufacturing Process | Plastic Mold Making Service & Insert Molding Service |

| Mold Type | Production Tooling |

| Tolerance(Accuracy) | Parts: ±0.1mm(±0.004″) |

| Surface Treatment | Standard Smooth |

Designing and Manufacturing PA Material Wheel Hubs for Electric Scooters

The design and production of PA material wheel hubs for electric scooters incorporate several critical factors to ensure optimal performance, durability, and cost efficiency:

- Material Properties Analysis

PA material offers excellent mechanical properties and wear resistance. Key considerations include its glass transition temperature (Tg), melting point (Tm), and water absorption rate, as these affect injection molding and product performance under varying conditions. - Optimization of Injection Molding Process

Precise control of melt temperature, mold temperature, injection speed, and holding time is essential to prevent material degradation and ensure proper molecular chain alignment. This enhances strength and dimensional stability. - Refined Mold Design

Mold design addresses flow paths, cooling rates, and shrinkage to minimize warping and internal stress. Surface treatments also play a role in achieving a high-quality product finish. - Structural Strength Analysis

Stress and fatigue life predictions are conducted using CAE tools like finite element analysis (FEA) to ensure the wheel hub withstands repetitive loads and impacts. - Surface Treatment Technology

Special surface treatments, such as coatings or chemical enhancements, improve wear resistance, corrosion protection, and aesthetics while ensuring compatibility with PA material. - Environmental Adaptability

Outdoor use demands resistance to UV rays, temperature fluctuations, and humidity for long-term stability. - Production Efficiency and Cost Control

Automation and lean manufacturing techniques enhance production efficiency, reduce defect rates, and control costs. - Quality Assurance System

Stringent quality control processes, including online inspections and performance testing, guarantee that every wheel hub meets specifications. - Sustainability

Efforts are made to select recyclable or bio-based materials, reduce energy use, and minimize waste, supporting environmentally friendly production.

By addressing these factors, the PA material wheel hubs achieve a balance of performance, cost-effectiveness, and sustainability, ensuring their suitability for modern electric scooters.

Apologies, but the customer requirements for the Electric Scooter Wheel Hub remain confidential.

Q1. How can clients get started with a project for wheel hub production at KingStar Mold?

Clients can contact us with their project details to begin. Our team will schedule an initial consultation to discuss the project scope, design needs, and create a roadmap for mold development, production, and assembly.

Q2. Can KingStar Mold manufacture wheel hubs according to specific industry standards?

Absolutely. We have the capacity and expertise to produce wheel hubs that meet various industry standards, ensuring they meet the required safety, performance, and durability criteria.

Q3. How does KingStar Mold ensure timely delivery for wheel hub projects?

With efficient project management, optimized manufacturing processes, and continuous communication with our clients, we ensure that all projects are delivered on time.

Q4. What is insert molding, and how is it applied to wheel hub production?

Insert molding is a process where plastic is injected around pre-placed metal inserts in the mold. In wheel hub production, this technique is used to integrate metal components such as bearing races and mounting points directly into the plastic hub.

Q5. Does KingStar Mold offer assembly services for wheel hubs?

Yes, we offer comprehensive product assembly services, including integrating components such as bearings and fasteners, ensuring that the finished wheel hubs are ready for installation.

Q6. How does KingStar Mold maintain mold longevity for high-volume production of wheel hubs?

Our molds are designed with high-quality tool steels and incorporate features like cooling channels and ejector systems to reduce wear, extend mold life, and ensure consistent, high-quality production.

Q7. Can clients provide feedback or request changes during the wheel hub production process at KingStar Mold?

We maintain open communication throughout the project, encouraging clients to provide feedback or request changes at any point. Our flexible manufacturing processes allow us to accommodate adjustments to meet client expectations.

Q8. Can KingStar Mold integrate RFID chips or other electronic components into wheel hubs during the molding process?

Yes, using insert molding and other advanced techniques, we can incorporate RFID chips, sensors, and other electronic components into the wheel hubs to enable smart functionalities.

Q9. Can KingStar Mold accommodate custom designs for wheel hubs?

Yes, we specialize in custom mold design and can create bespoke molds based on your specific wheel hub requirements, including patterns, sizes, and material properties.

Note:

We maintain pre-market confidentiality agreements and sign NDA/NNN with all our customers. Every case you see has been shared with client approval. To protect sensitive information, some details have been blurred or modified. All photos were taken internally by KingStar Mold. Thank you for your support and cooperation.

Why Choose Us

We Believe You Will Choose Us Again

Only companies with extensive market experience and a deep understanding of customer needs can offer the best service.

Skilled

High-precision production equipment, skilled production staff, and guaranteed delivery times.

Experienced

Over ten years of industry experience, with a mature quotation system and technical support.

Thoughtful

Customized processing options that save time and effort, with active support throughout pre-sales and post-sales.

Equipped

Engineers review designs to identify and resolve potential issues, backed by advanced testing equipment.

Related Manufacturing Case Studies

Plastic Household Products

Partnering with KingStar Mold offers you a range of plastic household product services. By utilizing advanced injection molding processes, we help enhance your plastic household items business and meet your specific needs.

Plastic Household Products

Partnering with KingStar Mold offers you a range of plastic household product services. By utilizing advanced injection molding processes, we help enhance your plastic household items business and meet your specific needs.

Plastic Household Products

Partnering with KingStar Mold offers you a range of plastic household product services. By utilizing advanced injection molding processes, we help enhance your plastic household items business and meet your specific needs.

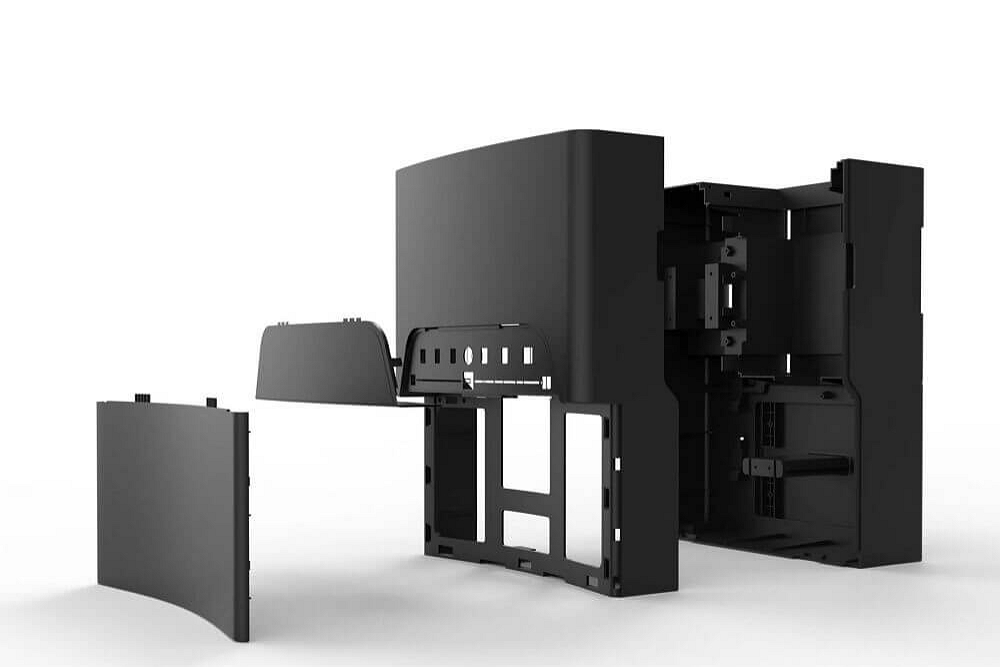

Plastic Household Products Mold Manufacturing & Injection Molding

As a leading manufacturer of plastic home items, KingStar Mold is your one-stop solution provider for all plastic household product needs.

We handle everything under one roof, using injection molding technology to design and develop molds and injection-molded plastic household products tailored to your specifications. Our designs are innovative, reliable, and offer both uniqueness and high functionality.

Injection Molding Services for Plastic Household Items

Plastic Household Items Design

Plastic Home Items Mold Design

With our advanced expertise in mold design, we create the perfect mold to shape your plastic household items. Through streamlined processes, we deliver a mold design that meets your needs, no matter how complex or intricate the requirements may be.

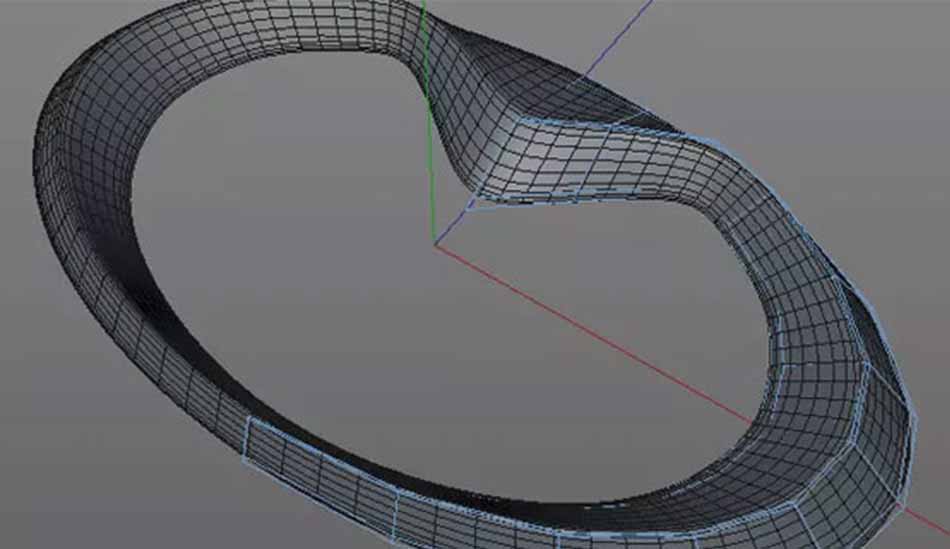

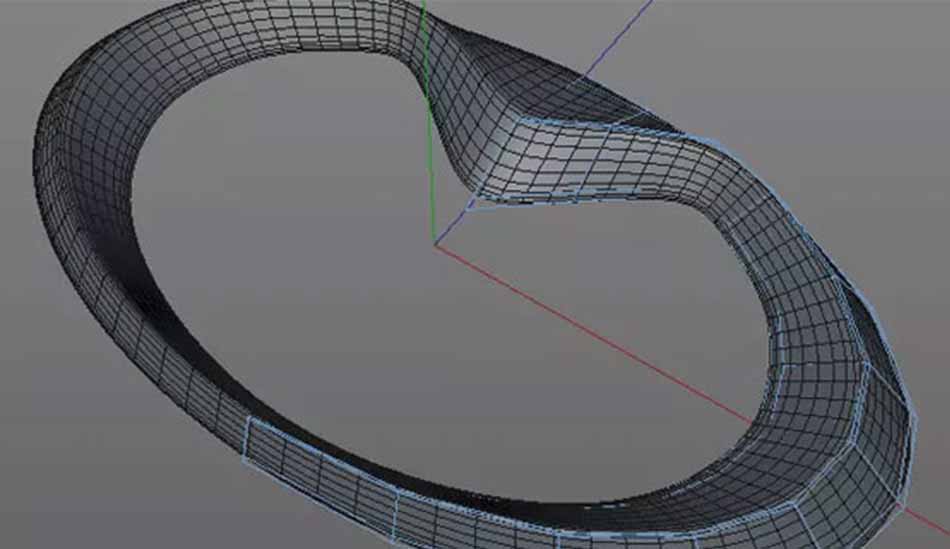

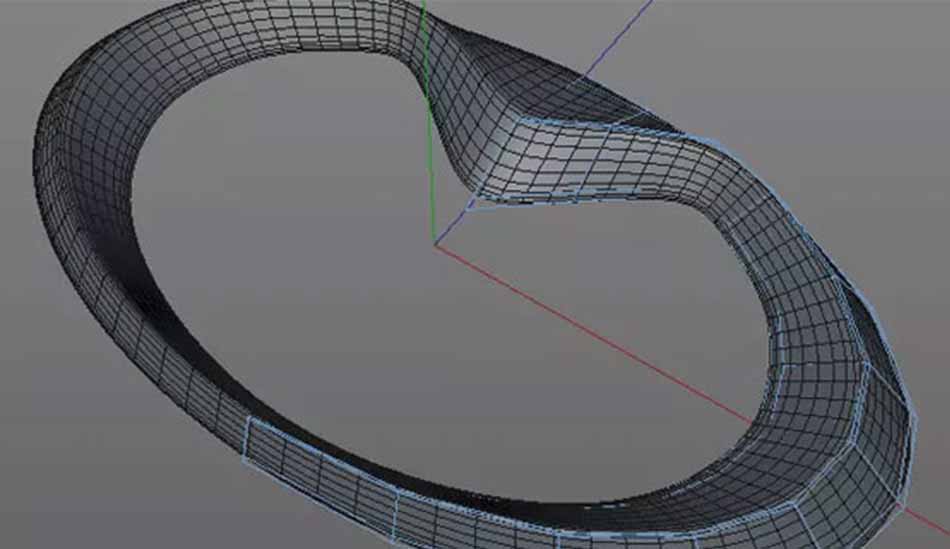

3D Printing

Using 3D printing, we quickly produce high-definition prototypes at a cost-effective price. This significantly reduces the turnaround time for producing complex parts, while maintaining high precision and consistent repeatability, ensuring no compromise on quality.

CNC Machining

By utilizing CNC machining to remove layers of material from existing components, we enhance the injection molding of household products. This manufacturing method supports quick turnaround times, custom finishes, and high scalability, ensuring efficiency and flexibility in production.

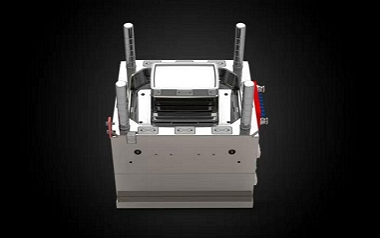

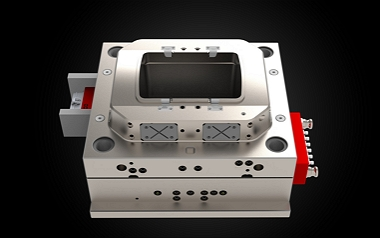

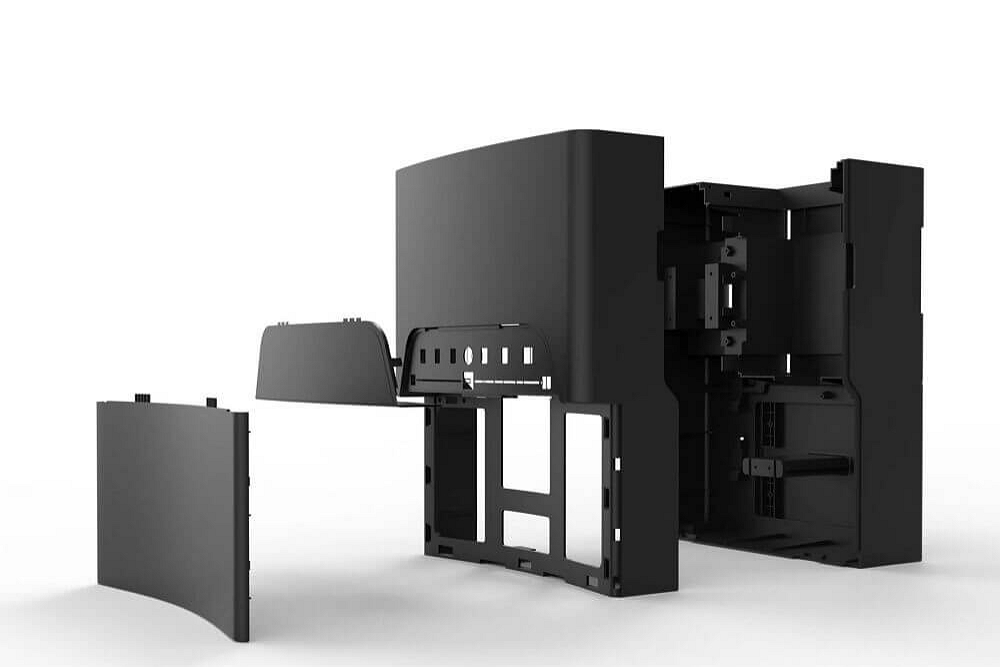

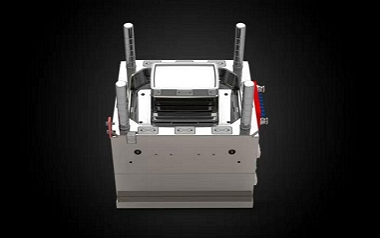

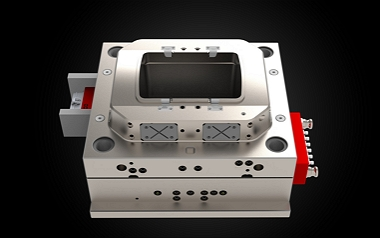

Plastic Mold Making

At KingStar Mold, we understand that the quality of plastic molds directly impacts the outcome of the injection molding process. That’s why we prioritize our mold-making process, ensuring top-notch quality in every aspect.

Injection Molding Plastic Household Products

Custom Plastic Household Products Mold by Experts

We understand that each client is unique, and we approach every demand with customized solutions. Our experts excel in offering custom mold services across various areas, including:

Injection Mold Design

Injection Mold Engineering

Injection Mold Machining

Fast Prototyping

Effective Cost Control

Scalability

Quality Control

Why KingStar Mold for Plastic Daily Necessities Injection Molding

With our injection molding technology, we create plastic storage drawers on wheels that provide you with a seamless storage system.

We have a wide selection of plastic shoe boxes with lids, offering you a lightweight packaging and safety from dust and other impurities.

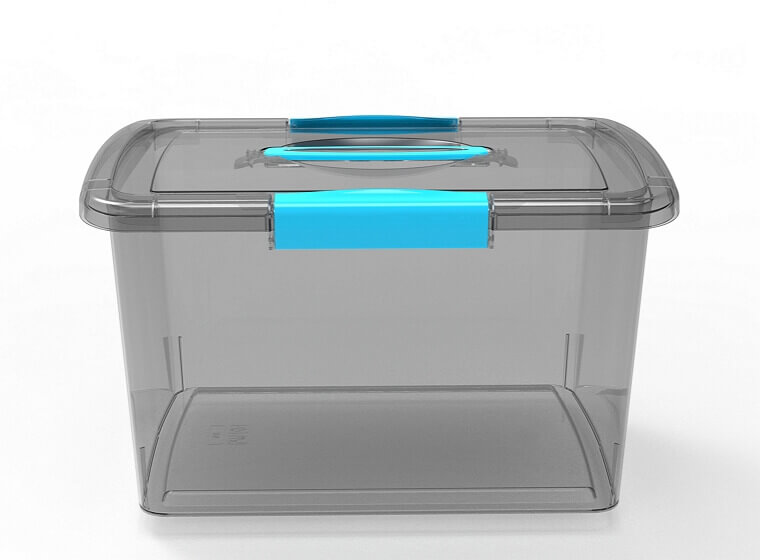

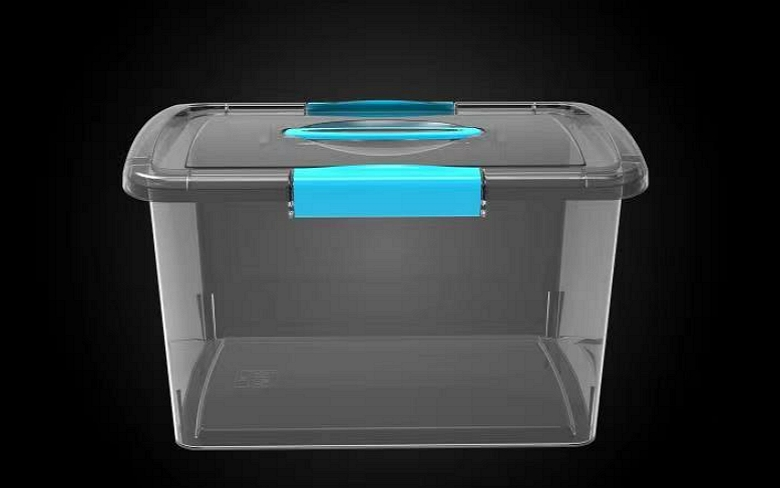

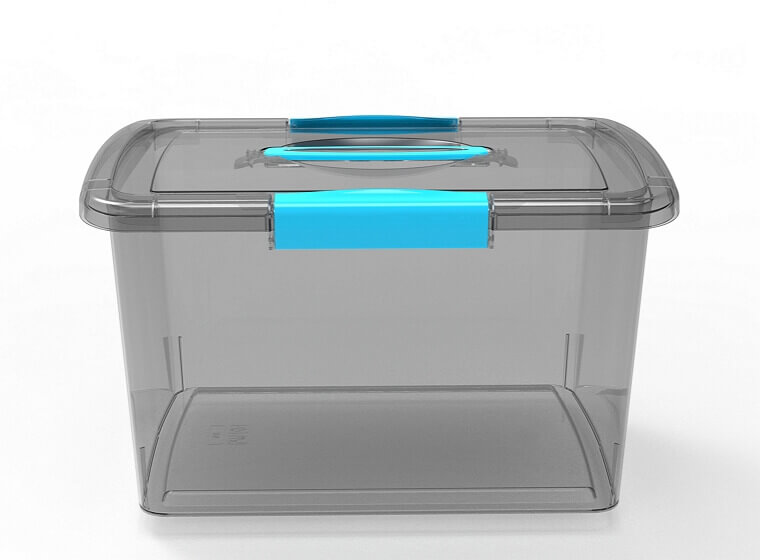

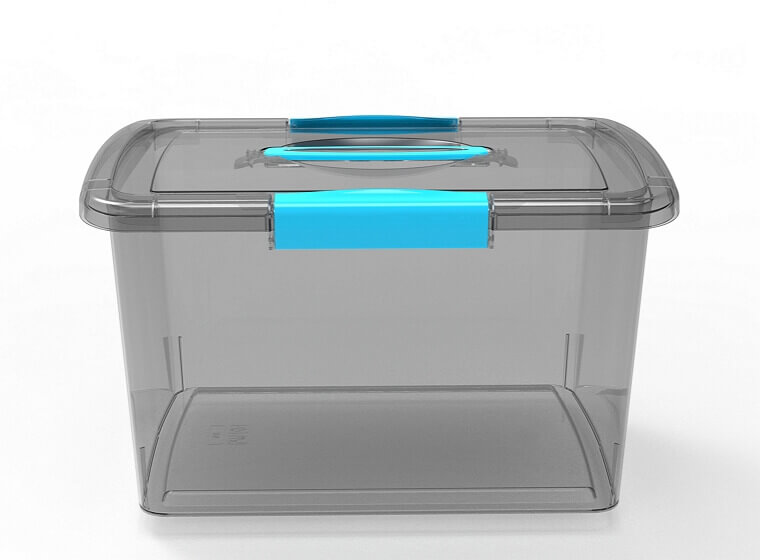

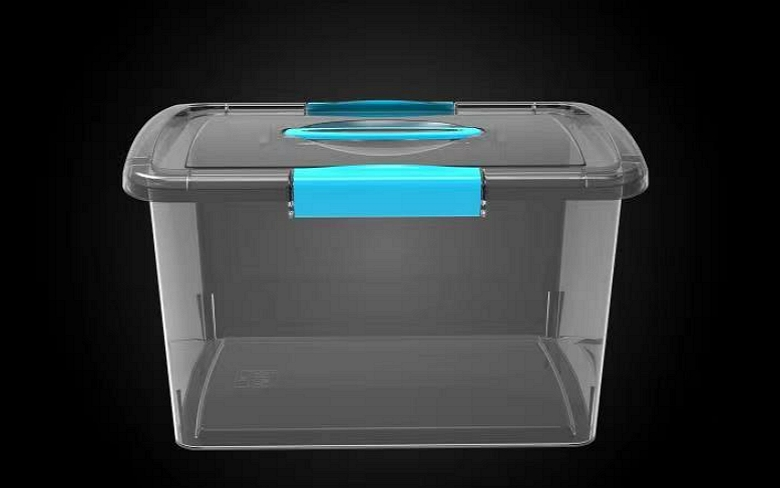

KingStar Mold creates top-quality plastic containers with lids for household applications. With this lightweight and portable storage system, items will be perfectly preserved.

Plastic Storage Drawers on Wheels

Plastic Shoe Boxes with Lids

Plastic Containers with Lids

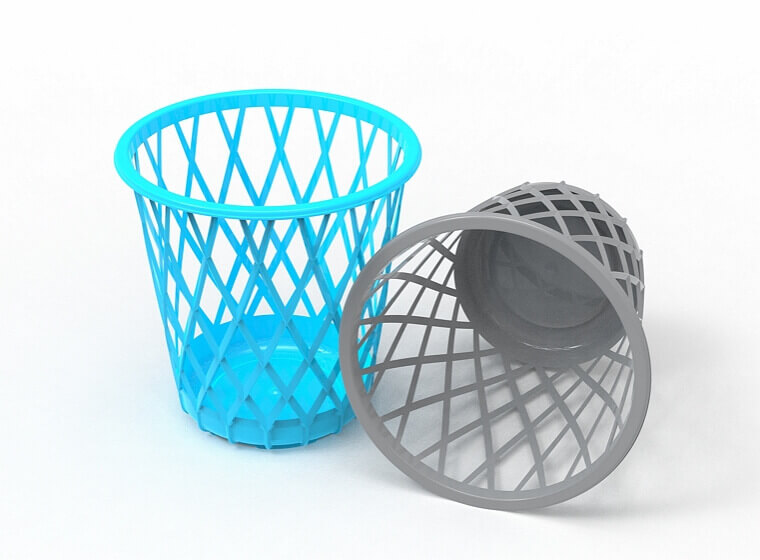

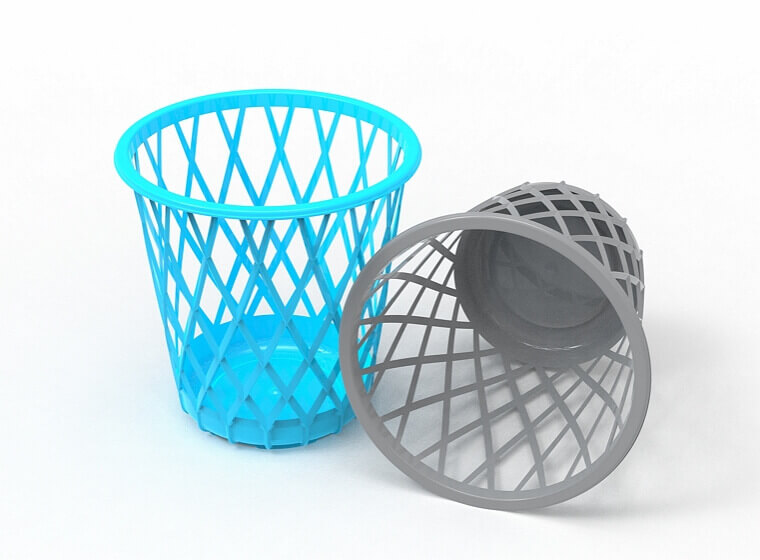

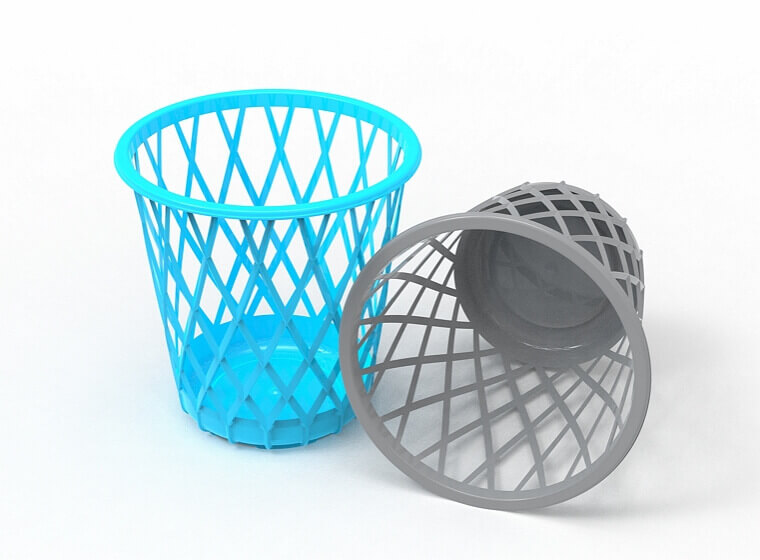

Our extensive collection of products includes plastic trash cans with lids. Serving as a collector of waste till final disposal, they are made with lids that prevent odor.

With our injection molding technology, we provide the best set of plastic step stools. At KingStar Mold, we implement our wide range of capabilities in manufacturing durable plastic step stools that stand the test of time.

Our plastic flower pots are highly efficient and strong, standing firmly with sand and flowers inside. They are also built to be eco-friendly and support the growth of flowers.

Plastic Trash Cans with Lids

Plastic Step Stool

Plastic Flower Pot

Having a high strength-to-weight ratio and a high resistance to acids, solvents, and other chemicals, Polyethylene is used for making storage containers, beverage bottles, toiletry bottles, and so many more.

A soft flexible plastic widely used in making clear plastic household items. It can be stretched and deformed without cracking or ripping.

With a good resistance to acids and solvents, as well as fatigue, Polypropylene can be repeatedly strained without cracking. Its varied applications include food storage containers, living hinges on lids, and so on.

Your Content Goes Here

Polystyrene for Plastic Household ItemsYour Content Goes Here

Having two main advantages: stiffness and rigidity, Polystyrene is used for making tough home plastic items like casings for kitchen appliances, seed trays, disposable cutlery, and so on.

Previous Injection Molded Plastic Household Item Projects

With an annual capability to produce 900-1000 molds, KingStar Mold specializes in fabricating quality molds that are used in household products injection molding. Supported by our experienced engineers, we offer one-stop solutions to our clients, starting from plastic household items design, mold design, to production and delivery.

In addition to manufacturing all kinds of injection molded household products, we also cater to other needs like warehouse storage boxes, home appliances, baby products, furniture, and automobile products.

Plastic Household Products Mold Manufacturing & Injection Molding

As a leading manufacturer of plastic home items, KingStar Mold is your one-stop solution provider for all plastic household product needs.

We handle everything under one roof, using injection molding technology to design and develop molds and injection-molded plastic household products tailored to your specifications. Our designs are innovative, reliable, and offer both uniqueness and high functionality.

Injection Molding Services for Plastic Household Items

Plastic Household Items Design

Plastic Home Items Mold Design

With our advanced expertise in mold design, we create the perfect mold to shape your plastic household items. Through streamlined processes, we deliver a mold design that meets your needs, no matter how complex or intricate the requirements may be.

3D Printing

Using 3D printing, we quickly produce high-definition prototypes at a cost-effective price. This significantly reduces the turnaround time for producing complex parts, while maintaining high precision and consistent repeatability, ensuring no compromise on quality.

CNC Machining

By utilizing CNC machining to remove layers of material from existing components, we enhance the injection molding of household products. This manufacturing method supports quick turnaround times, custom finishes, and high scalability, ensuring efficiency and flexibility in production.

Plastic Mold Making

At KingStar Mold, we understand that the quality of plastic molds directly impacts the outcome of the injection molding process. That’s why we prioritize our mold-making process, ensuring top-notch quality in every aspect.

Injection Molding Plastic Household Products

Custom Plastic Household Products Mold by Experts

We understand that each client is unique, and we approach every demand with customized solutions. Our experts excel in offering custom mold services across various areas, including:

Injection Mold Design

Injection Mold Engineering

Injection Mold Machining

Fast Prototyping

Effective Cost Control

Scalability

Quality Control

Why KingStar Mold for Plastic Daily Necessities Injection Molding

With our injection molding technology, we create plastic storage drawers on wheels that provide you with a seamless storage system.

We have a wide selection of plastic shoe boxes with lids, offering you a lightweight packaging and safety from dust and other impurities.

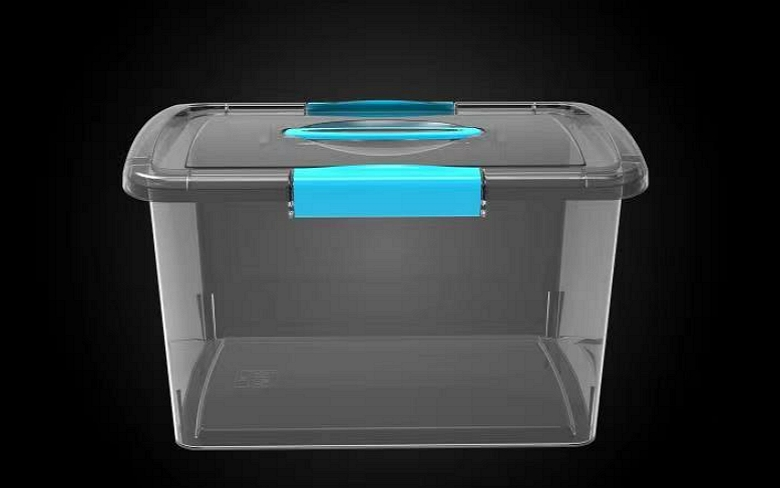

KingStar Mold creates top-quality plastic containers with lids for household applications. With this lightweight and portable storage system, items will be perfectly preserved.

Plastic Storage Drawers on Wheels

Plastic Shoe Boxes with Lids

Plastic Containers with Lids

Our extensive collection of products includes plastic trash cans with lids. Serving as a collector of waste till final disposal, they are made with lids that prevent odor.

With our injection molding technology, we provide the best set of plastic step stools. At KingStar Mold, we implement our wide range of capabilities in manufacturing durable plastic step stools that stand the test of time.

Our plastic flower pots are highly efficient and strong, standing firmly with sand and flowers inside. They are also built to be eco-friendly and support the growth of flowers.

Plastic Trash Cans with Lids

Plastic Step Stool

Plastic Flower Pot

Having a high strength-to-weight ratio and a high resistance to acids, solvents, and other chemicals, Polyethylene is used for making storage containers, beverage bottles, toiletry bottles, and so many more.

A soft flexible plastic widely used in making clear plastic household items. It can be stretched and deformed without cracking or ripping.

With a good resistance to acids and solvents, as well as fatigue, Polypropylene can be repeatedly strained without cracking. Its varied applications include food storage containers, living hinges on lids, and so on.

Your Content Goes Here

Polystyrene for Plastic Household ItemsYour Content Goes Here

Having two main advantages: stiffness and rigidity, Polystyrene is used for making tough home plastic items like casings for kitchen appliances, seed trays, disposable cutlery, and so on.

Previous Injection Molded Plastic Household Item Projects

With an annual capability to produce 900-1000 molds, KingStar Mold specializes in fabricating quality molds that are used in household products injection molding. Supported by our experienced engineers, we offer one-stop solutions to our clients, starting from plastic household items design, mold design, to production and delivery.

In addition to manufacturing all kinds of injection molded household products, we also cater to other needs like warehouse storage boxes, home appliances, baby products, furniture, and automobile products.

Plastic Household Products Mold Manufacturing & Injection Molding

As a leading manufacturer of plastic home items, KingStar Mold is your one-stop solution provider for all plastic household product needs.

We handle everything under one roof, using injection molding technology to design and develop molds and injection-molded plastic household products tailored to your specifications. Our designs are innovative, reliable, and offer both uniqueness and high functionality.

Injection Molding Services for Plastic Household Items

Plastic Household Items Design

Plastic Home Items Mold Design

With our advanced expertise in mold design, we create the perfect mold to shape your plastic household items. Through streamlined processes, we deliver a mold design that meets your needs, no matter how complex or intricate the requirements may be.

3D Printing

Using 3D printing, we quickly produce high-definition prototypes at a cost-effective price. This significantly reduces the turnaround time for producing complex parts, while maintaining high precision and consistent repeatability, ensuring no compromise on quality.

CNC Machining

By utilizing CNC machining to remove layers of material from existing components, we enhance the injection molding of household products. This manufacturing method supports quick turnaround times, custom finishes, and high scalability, ensuring efficiency and flexibility in production.

Plastic Mold Making

At KingStar Mold, we understand that the quality of plastic molds directly impacts the outcome of the injection molding process. That’s why we prioritize our mold-making process, ensuring top-notch quality in every aspect.

Injection Molding Plastic Household Products

Custom Plastic Household Products Mold by Experts

We understand that each client is unique, and we approach every demand with customized solutions. Our experts excel in offering custom mold services across various areas, including:

Injection Mold Design

Injection Mold Engineering

Injection Mold Machining

Fast Prototyping

Effective Cost Control

Scalability

Quality Control

Why KingStar Mold for Plastic Daily Necessities Injection Molding

With our injection molding technology, we create plastic storage drawers on wheels that provide you with a seamless storage system.

We have a wide selection of plastic shoe boxes with lids, offering you a lightweight packaging and safety from dust and other impurities.

KingStar Mold creates top-quality plastic containers with lids for household applications. With this lightweight and portable storage system, items will be perfectly preserved.

Plastic Storage Drawers on Wheels

Plastic Shoe Boxes with Lids

Plastic Containers with Lids

Our extensive collection of products includes plastic trash cans with lids. Serving as a collector of waste till final disposal, they are made with lids that prevent odor.

With our injection molding technology, we provide the best set of plastic step stools. At KingStar Mold, we implement our wide range of capabilities in manufacturing durable plastic step stools that stand the test of time.

Our plastic flower pots are highly efficient and strong, standing firmly with sand and flowers inside. They are also built to be eco-friendly and support the growth of flowers.

Plastic Trash Cans with Lids

Plastic Step Stool

Plastic Flower Pot

Having a high strength-to-weight ratio and a high resistance to acids, solvents, and other chemicals, Polyethylene is used for making storage containers, beverage bottles, toiletry bottles, and so many more.

A soft flexible plastic widely used in making clear plastic household items. It can be stretched and deformed without cracking or ripping.

With a good resistance to acids and solvents, as well as fatigue, Polypropylene can be repeatedly strained without cracking. Its varied applications include food storage containers, living hinges on lids, and so on.

Your Content Goes Here

Polystyrene for Plastic Household ItemsYour Content Goes Here

Having two main advantages: stiffness and rigidity, Polystyrene is used for making tough home plastic items like casings for kitchen appliances, seed trays, disposable cutlery, and so on.

Previous Injection Molded Plastic Household Item Projects

With an annual capability to produce 900-1000 molds, KingStar Mold specializes in fabricating quality molds that are used in household products injection molding. Supported by our experienced engineers, we offer one-stop solutions to our clients, starting from plastic household items design, mold design, to production and delivery.

In addition to manufacturing all kinds of injection molded household products, we also cater to other needs like warehouse storage boxes, home appliances, baby products, furniture, and automobile products.