Injection Molding Cost: All Factors and How to Reduce It

- 1. Introduction

- 2. What Determines Injection Molding Costs?

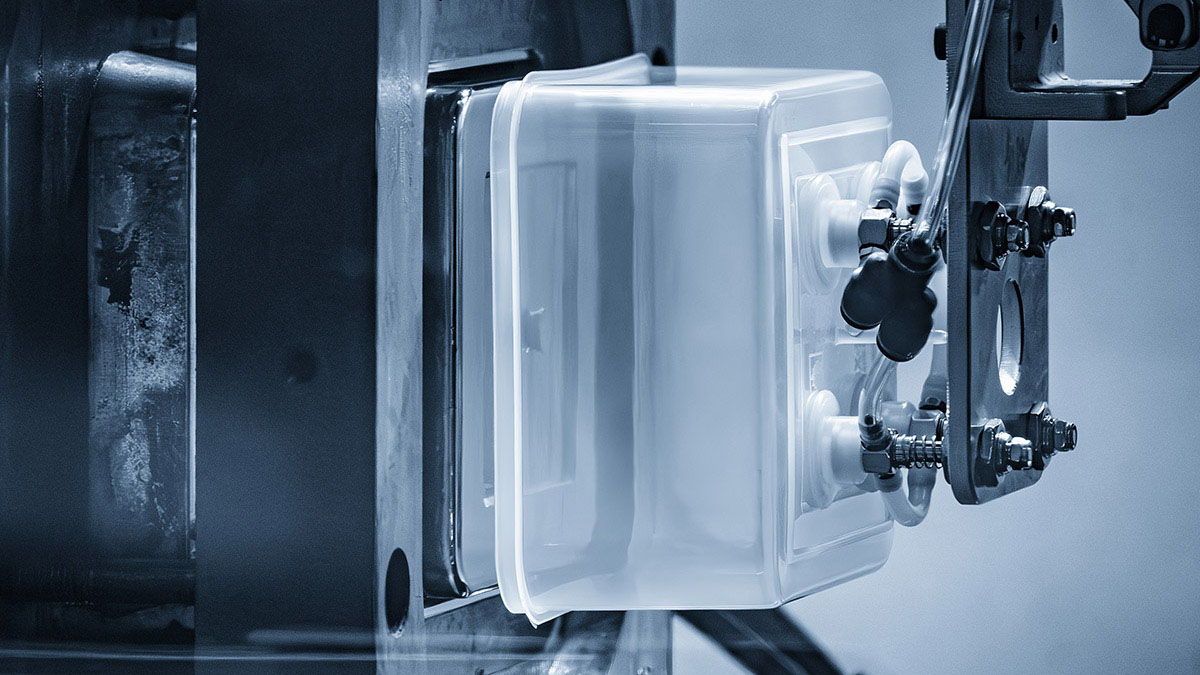

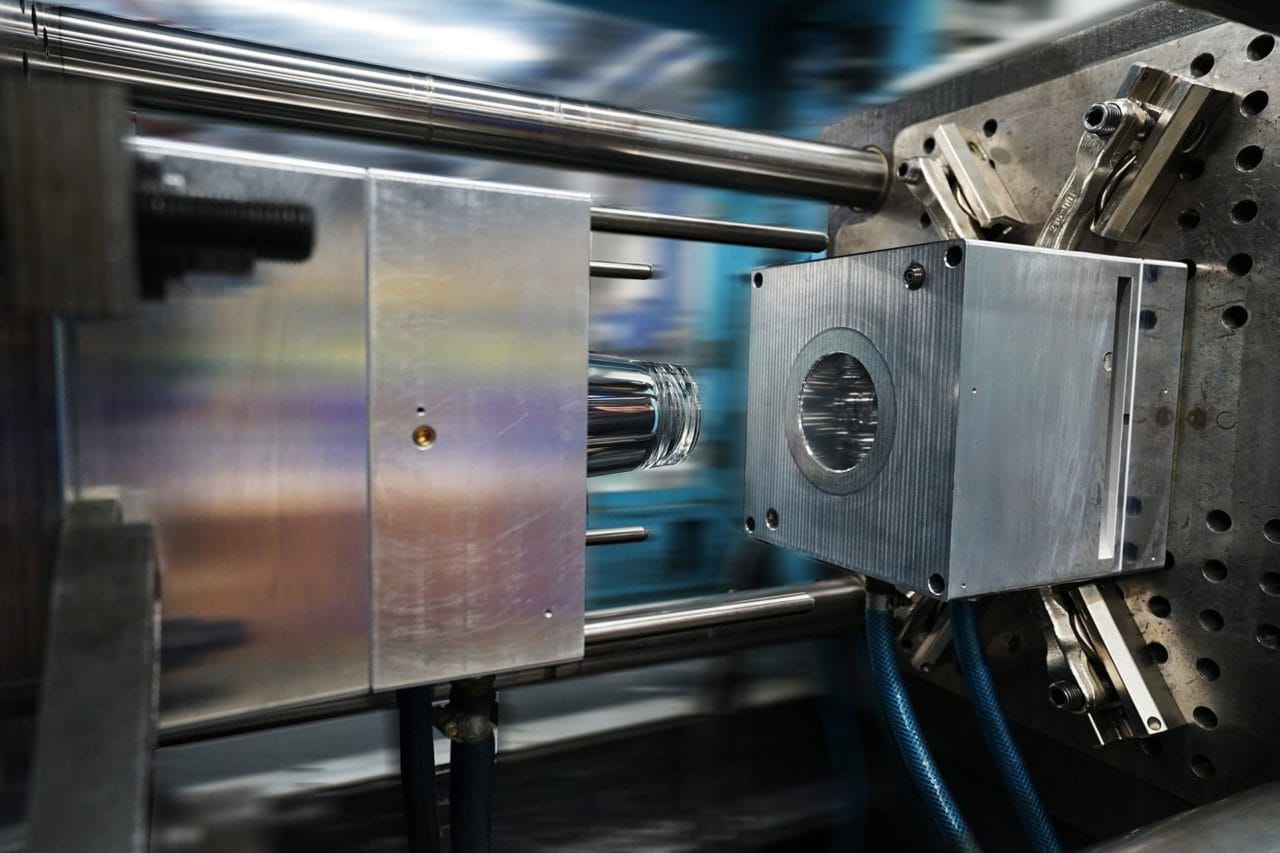

- 3. Mold Tooling Costs: The Foundation of Injection Molding Expenses

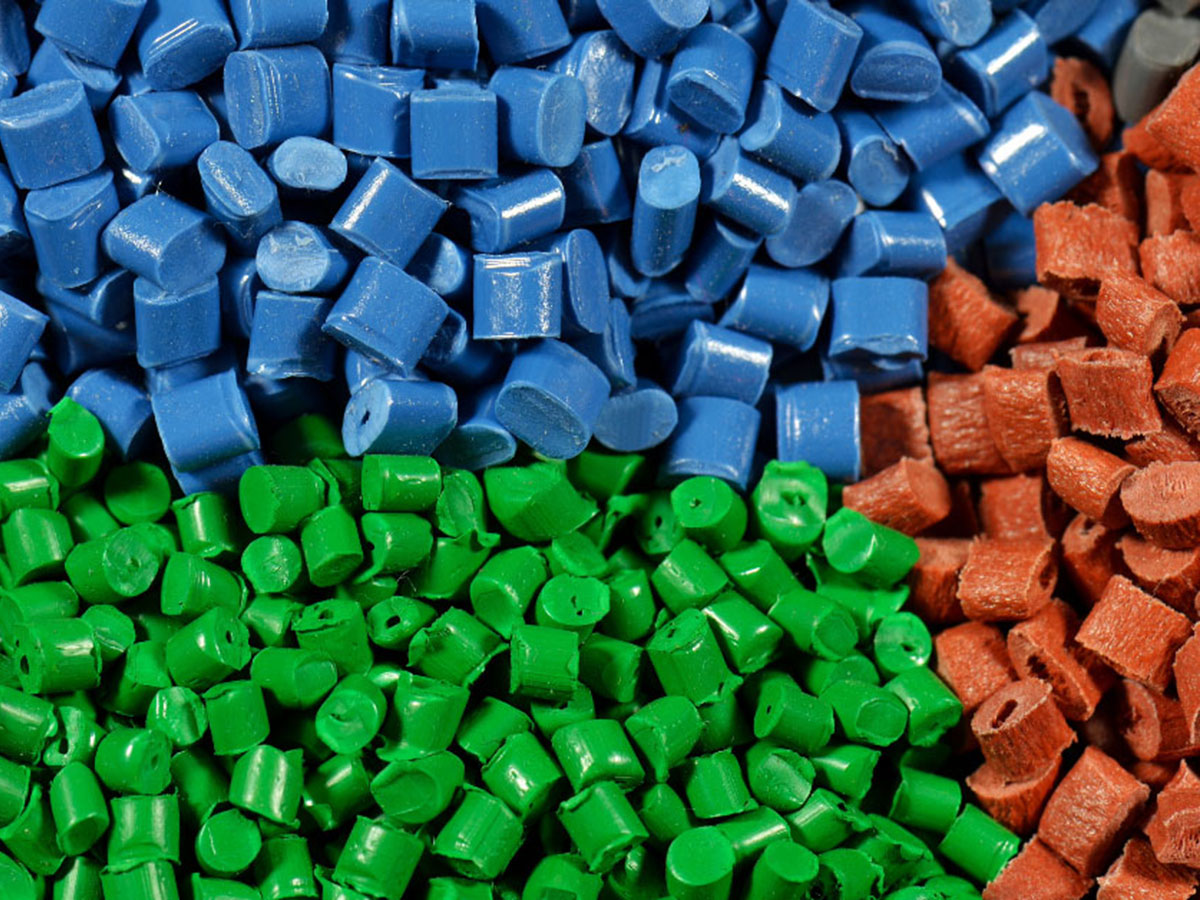

- 4. Material Costs

- 5. Injection Molding Machine and Equipment Costs

- 6. Labor and Setup Costs: The Hidden Expenses

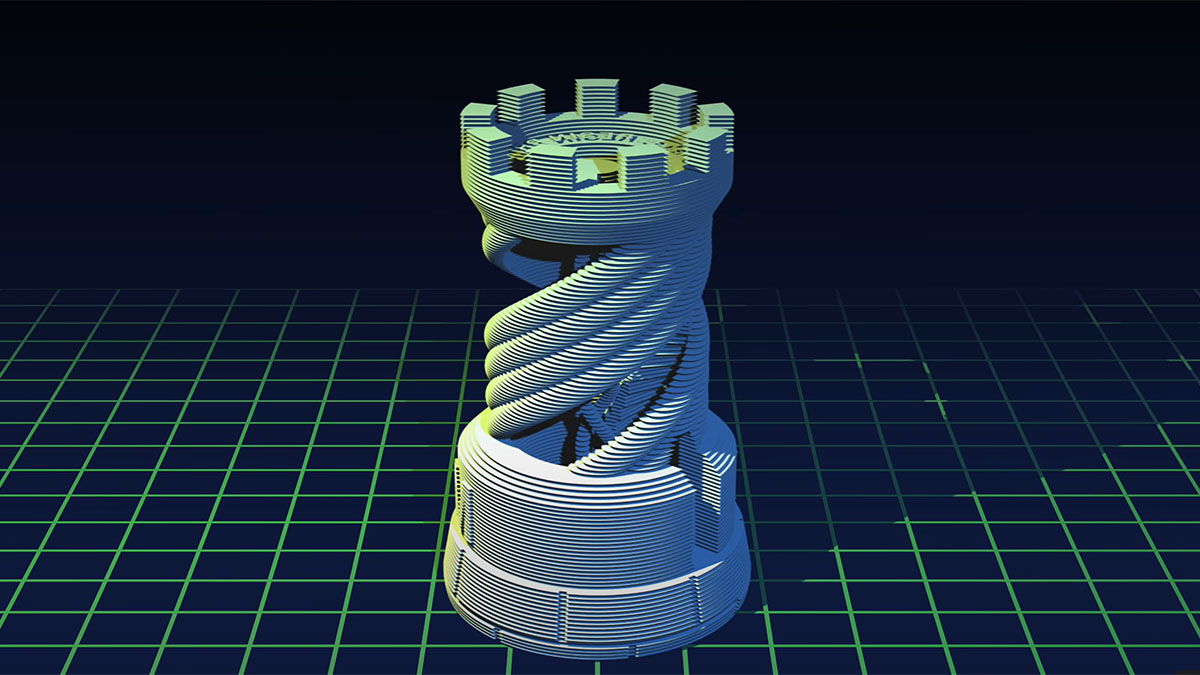

- 7. How Part Design Influences Injection Molding Costs

- 8. Injection Molding Costs Across Different Production Volumes

- 9. Strategies to Reduce Injection Molding Costs

- Implementing Design for Manufacturing (DfM) Practices

- Simplifying Product Design to Minimize Mold Complexity

- Reducing the Number of Cavities in the Mold

- Strategic Material Selection Tactics

- The Advantages of Insert Molding and Overmolding

- How Self-Mating Parts Can Simplify Design and Reduce Costs

- Leveraging Rapid Tooling to Speed Up Production and Reduce Costs

- Adopting New Technologies to Reduce Costs

1. Introduction

Injection molding has become one of the most widely used manufacturing processes, especially for producing high-volume, complex plastic parts. It’s an cost-effective method that allows for precise replication of parts, making it ideal for industries like automotive, electronics, medical devices, and consumer goods. However, despite its advantages, injection […]

Every week we receive emails and phone calls from customers asking about Low-volume injection molding. Most of the questions are about mold material selection, production cycle, cost, etc. As [...]

Selective Laser Sintering (SLS) is a powerful additive manufacturing technology that uses a laser to selectively sinter powdered material, fusing it into a solid structure. This process is ideal [...]

When it comes to custom plastic injection molding, choosing the right manufacturer can significantly impact both the quality and cost of your project. China is home to a range [...]

Stereolithography (SLA) is a precision 3D printing technique that utilizes a laser to solidify liquid photopolymer resin, building up a model layer by layer. One of the earliest 3D [...]

1. Introduction Injection molding has become one of the most widely used manufacturing processes, especially for producing high-volume, complex plastic parts. It's an cost-effective method that allows for [...]

That moment when a perfectly designed sheet metal component fails – not due to the metal itself, but because an integrated nut strips, a clip snaps, or a mounting [...]

Overview of cost-effective injection molding Plastic injection molding is one of the most widely used manufacturing processes for producing high-precision plastic parts, especially in industries such as automotive, [...]

In today’s world, plastics play an integral role in countless products we use daily, from packaging and toys to automotive components and medical devices. Custom plastic parts are specialized [...]

Plastic injection molding is a commonly employed manufacturing technique that consists of injecting heated plastic into a mold to produce various components and products. This technique is known for [...]

Whether you're gearing up for a weekend camping adventure, a fun-filled day at the beach, a peaceful fishing trip, or a lively backyard barbecue, cooler boxes and ice chests [...]

When it comes to outdoor events, sports tournaments, construction sites, or large family gatherings, a reliable beverage dispenser can make all the difference. Among the many options available, Igloo [...]

When planning an outdoor adventure or hosting a backyard gathering, keeping drinks cold and easy to serve is essential. Among all other options, the most popular options are insulated [...]

Have you ever looked at a product and thought, “I could’ve made something better”? Maybe it's a tool you wish worked differently, or a daily annoyance you’re convinced no [...]

Selecting the right sheet metal material is a crucial step in product design, especially for sheet metal fabrication, as it directly impacts various aspects of manufacturing and the performance [...]

In today’s competitive manufacturing landscape, producing high-quality products isn't just a goal—it’s a measurable discipline. At the heart of this discipline lies CTQ, or Critical to Quality, a framework [...]

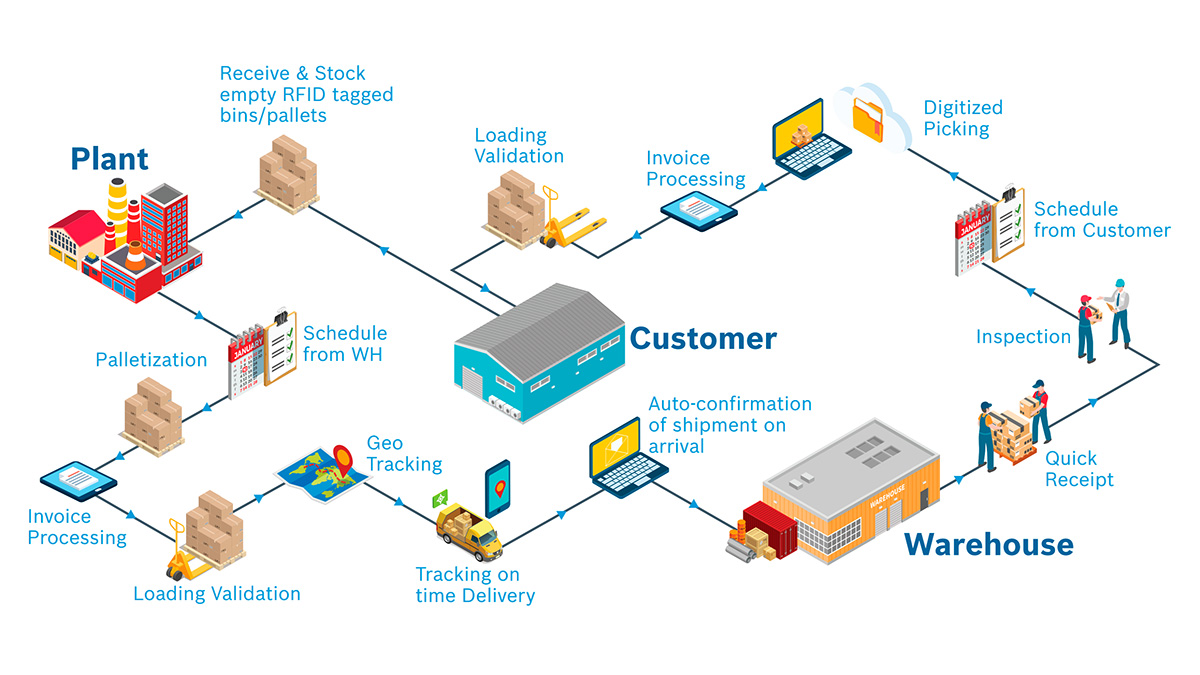

In today’s highly competitive and regulated manufacturing landscape, ensuring product quality and transparency throughout the production process is crucial. Traceability is a key concept that allows manufacturers to track [...]

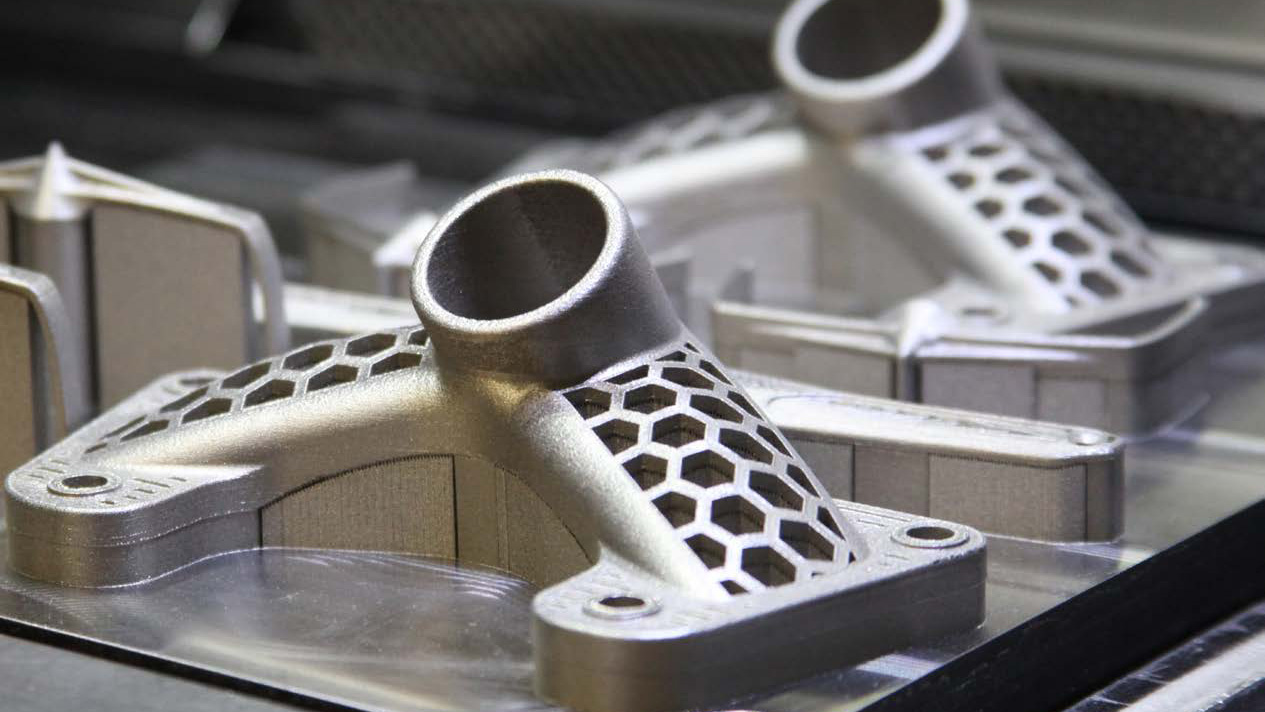

Metal 3D printing has transformed modern manufacturing, enabling the creation of highly complex, lightweight, and customized parts. However, while 3D printing offers incredible design freedom, it’s important to note [...]

Direct Metal Laser Sintering (DMLS) is a powerful additive manufacturing technology that uses a high-powered laser to fuse fine metal powders into solid metal parts, layer by layer. This [...]