How Are Plastic Storage Bins Made? A Comprehensive Guide to the Manufacturing Process

Plastic storage bins are everywhere—from your garage to warehouse shelves. But have you ever wondered why some bins last for years while others crack after a few months? The secret lies in how they’re made. As a leading custom wholesale plastic storage box manufacturer, we provide this guide for:

-

[…]

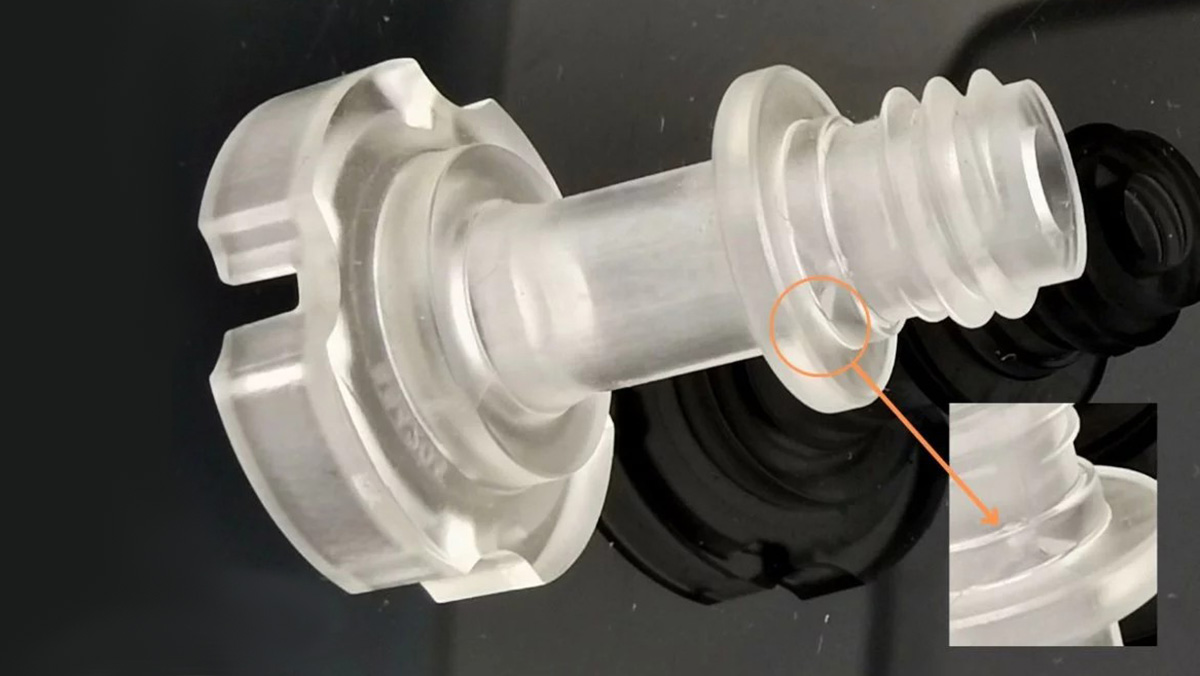

Air bubbles are a common defect in injection molding, occurring when gas pockets or voids become trapped within the molded part. These bubbles can significantly impact the product's appearance, [...]

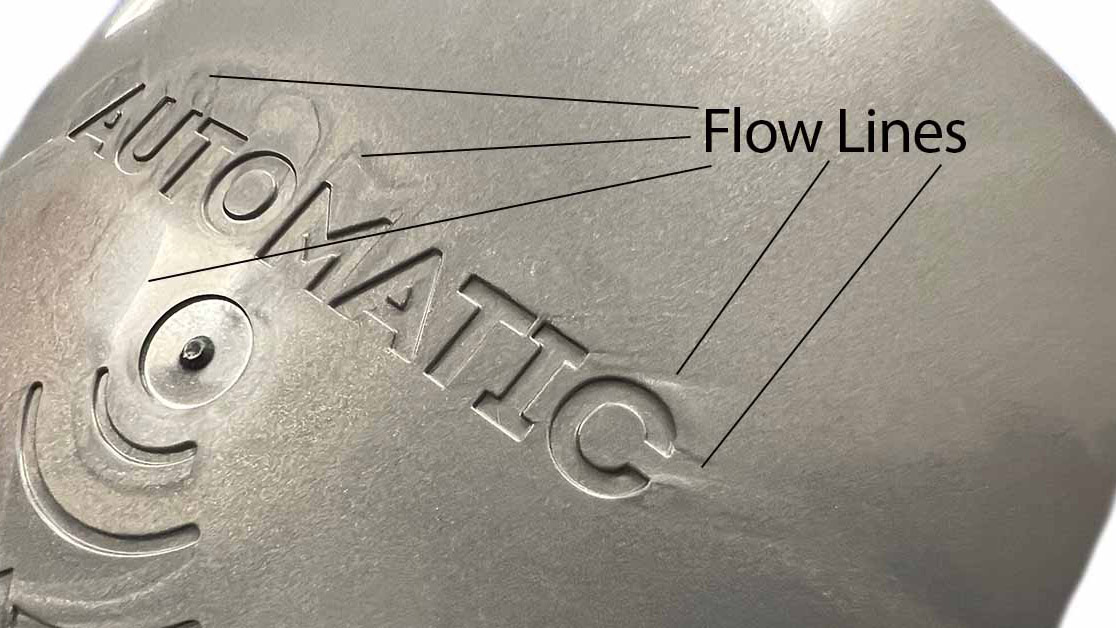

Flash and burrs are common defects in injection molding, characterized by excess material protruding from the edges or surfaces of molded parts. These imperfections typically occur at the parting [...]

Clamping force is the pressure applied by an injection molding machine to hold the mold closed during the injection and cooling phases. It counteracts the internal cavity pressure generated [...]

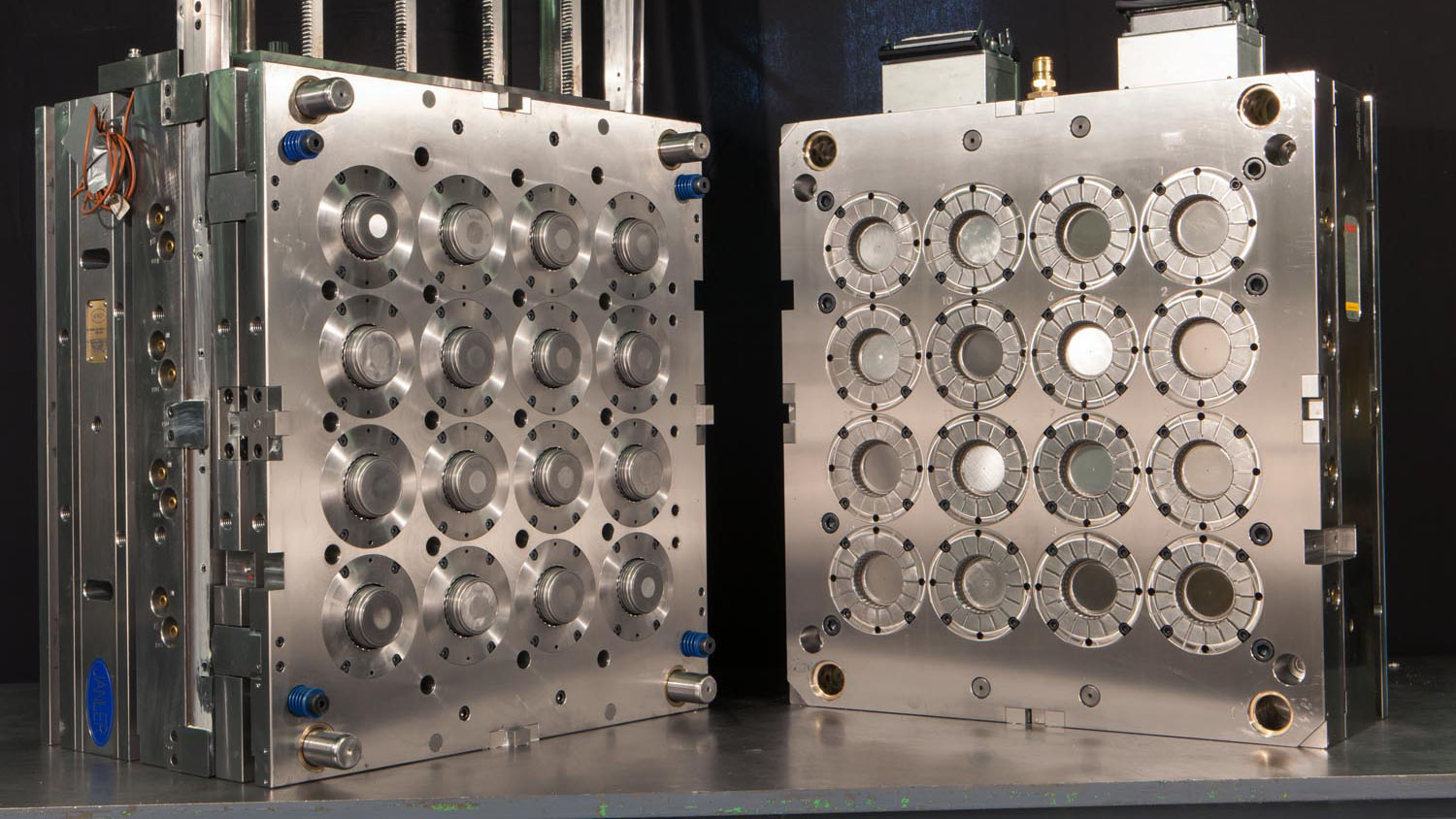

Molds play an essential role in injection molding and die-casting process, and should be designed for continuous, frequent use. A durable mold could bring manufacturing efficiency and production effectiveness. Whether in injection or [...]

There are many different creative ways of using plastic storage boxes. Thanks to their versatility and accessibility, they have become an essential companion of maintaining a clean and tidy [...]

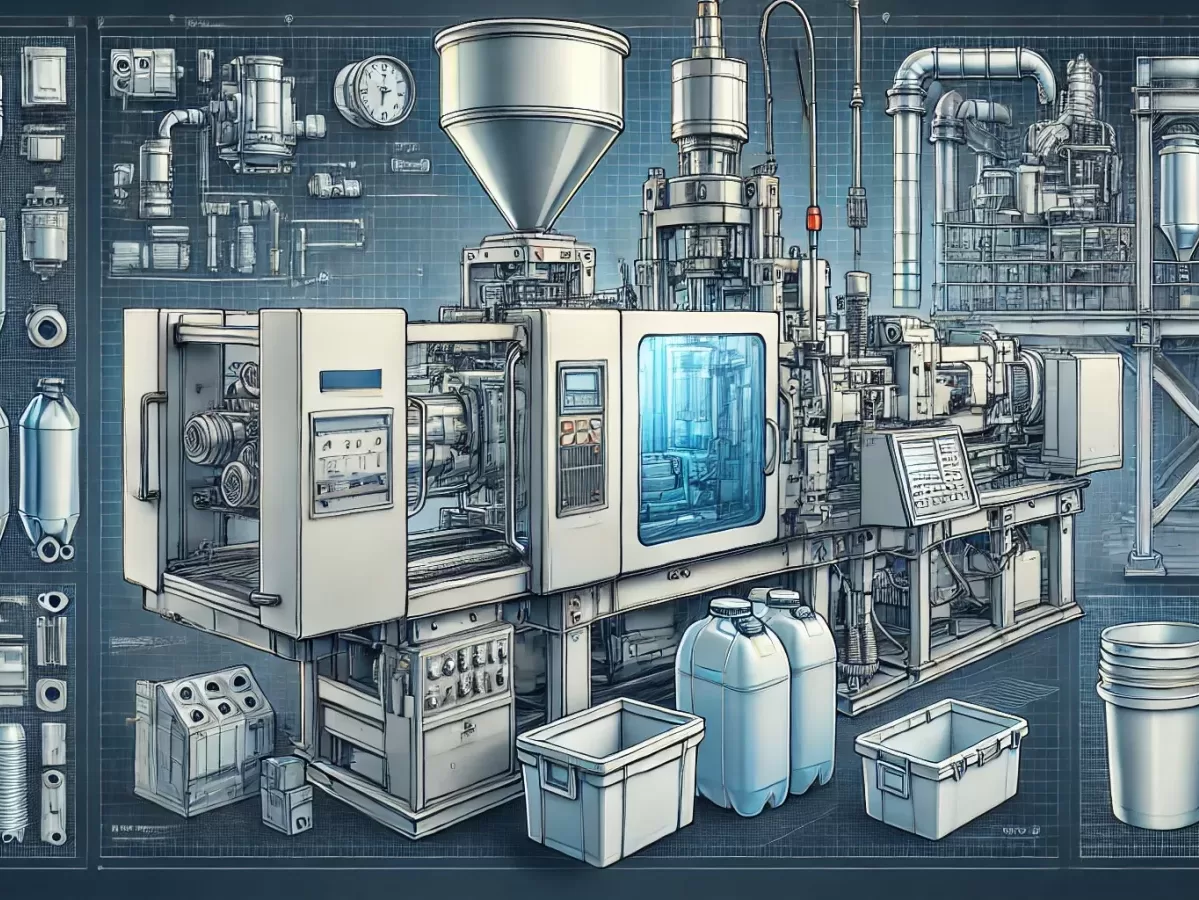

Plastic storage bins are everywhere—from your garage to warehouse shelves. But have you ever wondered why some bins last for years while others crack after a few months? The [...]

As a leading custom plastic injection molding company, KingStar Mold receives multiple inquiries daily from various industries regarding mold building and injection molding projects. Some projects have incomplete designs, [...]

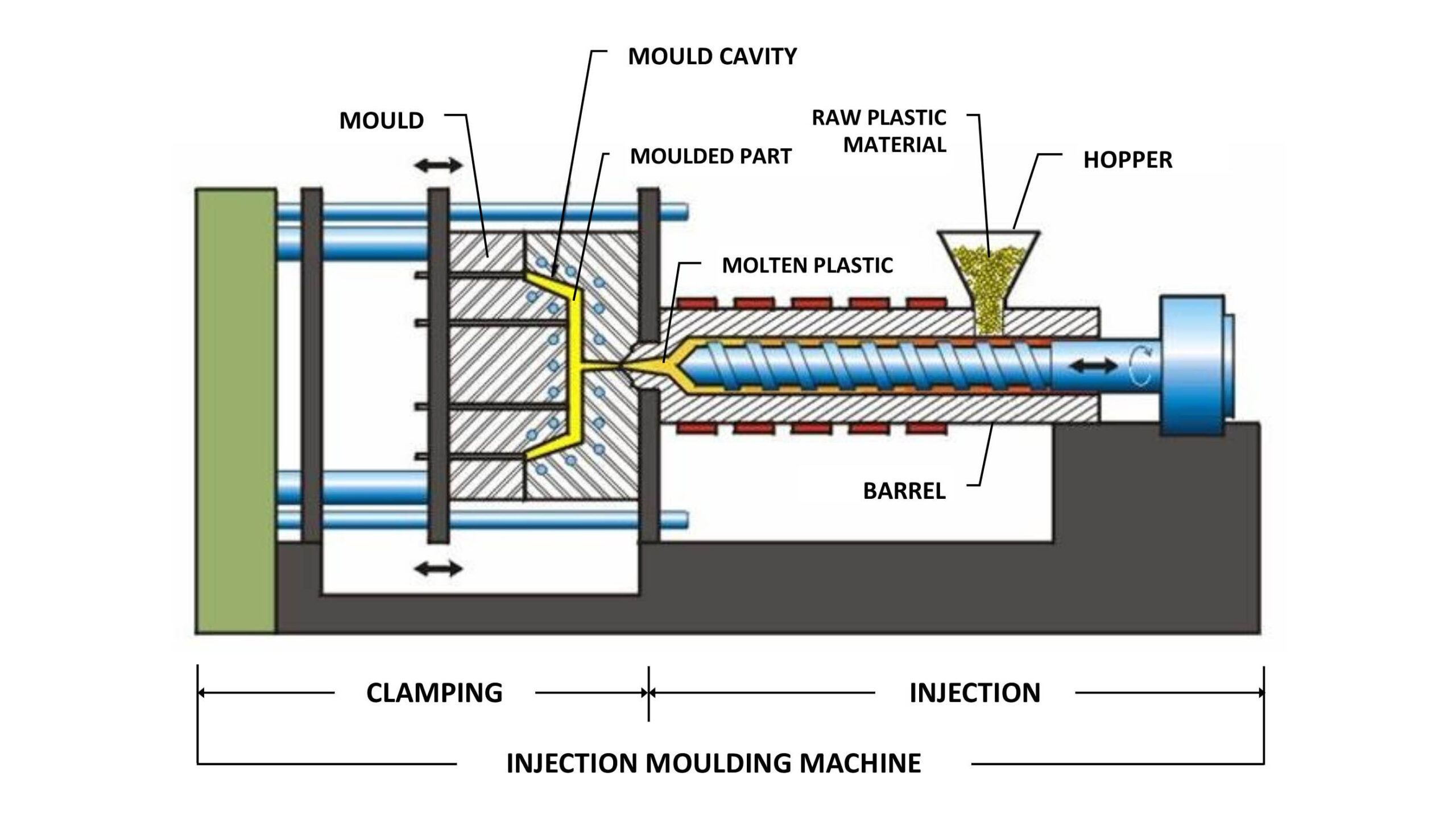

Injection molding is one of the most widely used manufacturing processes in producing plastic parts across various industries, including automotive, electronics, and consumer goods. Its efficiency, precision, and ability [...]

Selecting the appropriate mold steel is a crucial strategic decision that will have an impact on various aspects ranging from part quality, production efficiency to mold lifespan and total [...]

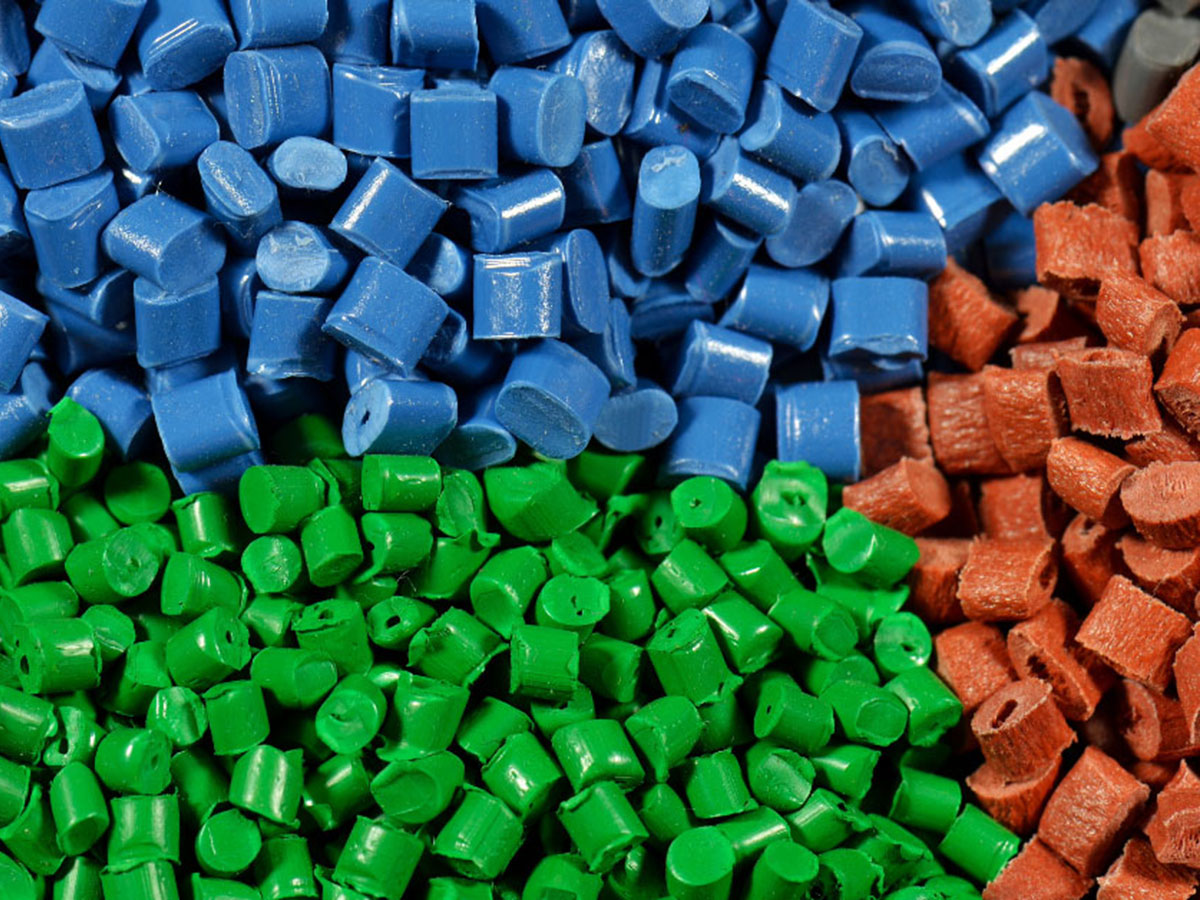

In today’s world, plastics play an integral role in countless products we use daily, from packaging and toys to automotive components and medical devices. Custom plastic parts are specialized [...]

Plastic injection molding is a transformative manufacturing process that injects melted plastic into precisely designed molds. Through centuries, this technique has revolutionized the production of everyday items, from simple [...]

Against the backdrop of the global wave of “plastic limitation and ban” policies, such as the EU Single-Use Plastics Directive and China’s “Plastic Reduction 2.0,” the injection molding industry [...]

This plastic parts inspection specification applies to all plastic components produced by KingStar Mold, including those made through injection molding, as well as externally sourced plastic accessories and products [...]

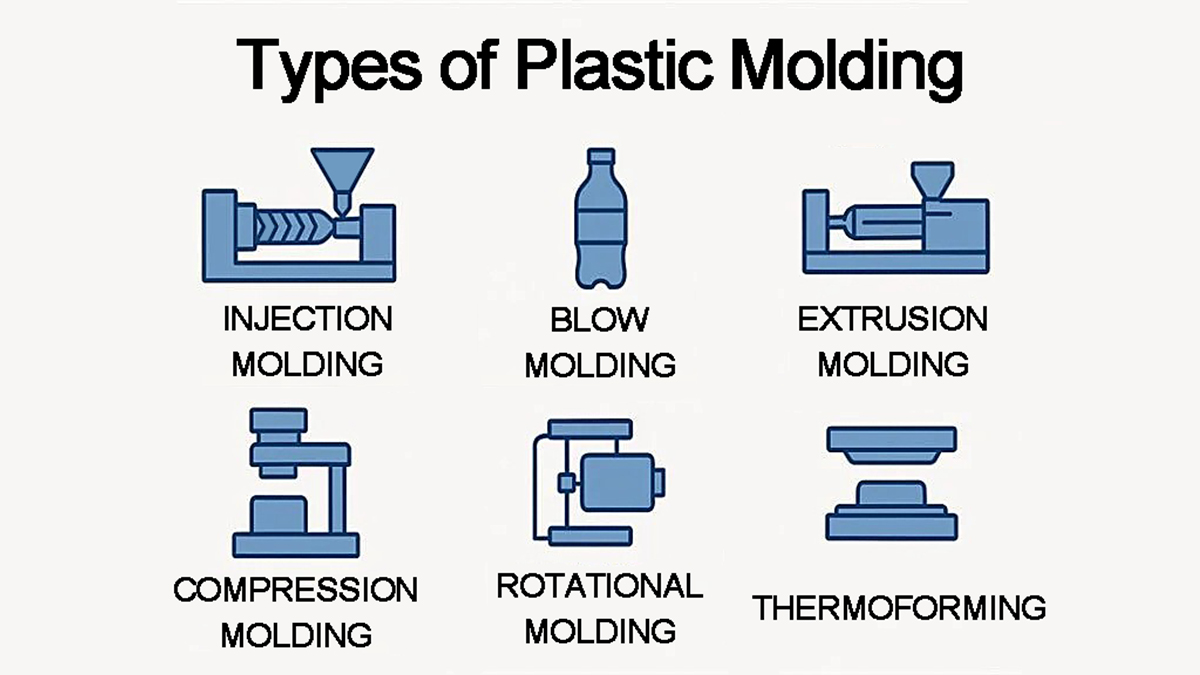

When choosing the right cooler, it’s not just about the size or color. You’ve probably heard brands and manufacturers mention terms like “rotomolded” and “injection molded,” and you might [...]

China plays a dominant role in the global cooler market, supplying a vast range of products from rugged hard coolers to portable cooler jugs. With its extensive manufacturing infrastructure, [...]

At KingStar Mold, as a leading custom plastic molding service provider in China, we understand that selecting the right plastic molding process is critical to delivering high-quality, cost-effective parts. [...]

How Are Cooler Boxes Made? As the world's leading hard cooler manufacturer, KingStar receives emails asking this question every week. This question is raised by our customers, consumers, and [...]

When it comes to getting the most out of your cooler, it's not just about loading it with ice and hoping for the best. The way you use ice—how [...]

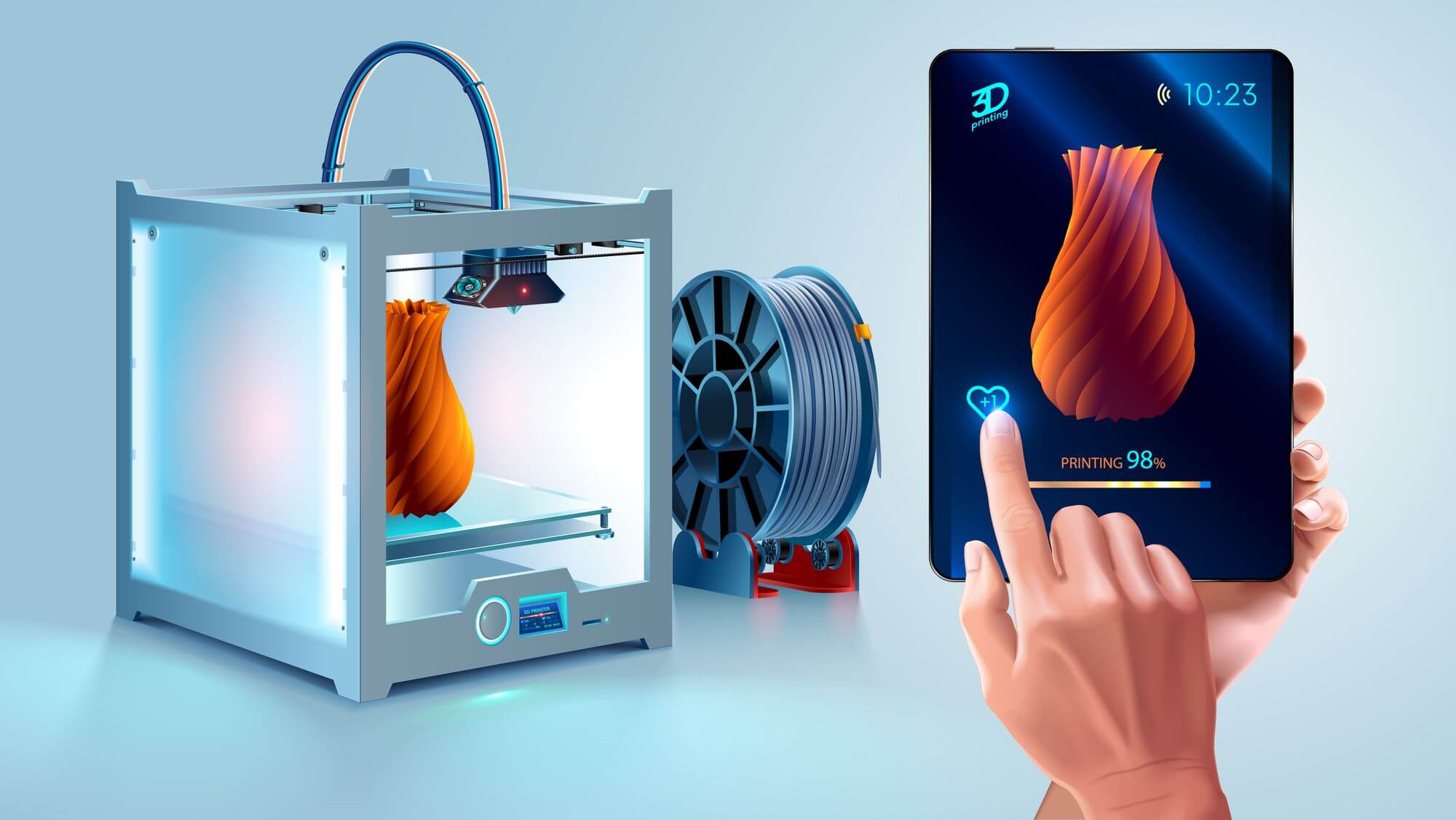

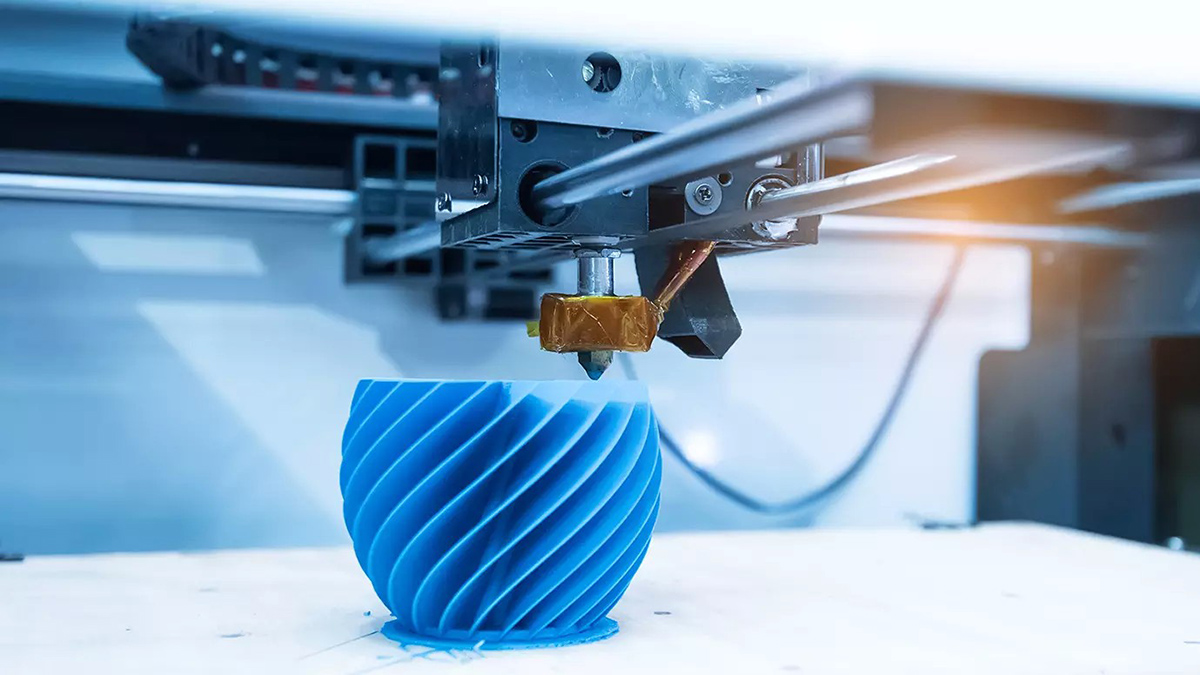

FDM (Fused Deposition Modeling) is one of the most widely used 3D printing technologies at present. Due to its low cost and wide range of material options, it is [...]

Fused Deposition Modeling (abbreviated as FDM) is one of the most widely used 3D printing technologies. It uses a heated nozzle to extrude thermoplastic filaments, depositing layers of material [...]

Is there anything more disappointing than reaching for a refreshing sip of your drink, only to find it has turned into a sad, lukewarm puddle halfway through your picnic [...]