Best Mold Manufacturers In China

When it comes to custom plastic injection molding, choosing the right manufacturer can significantly impact both the quality and cost of your project. China is home to a range of world-class mold manufacturers that offer precision, efficiency, and innovative solutions to meet diverse industry needs. In this post, we […]

Keeping an injection molding machine running smoothly isn't just about fixing problems when they happen — it's about preventing them in the first place. To ensure their regular operation, [...]

Apparently, plastics products have become fundamental in modern lifestyles, regardless of regions and lands. However, how could plastics become so widely applied, while only 20 to 30 types of [...]

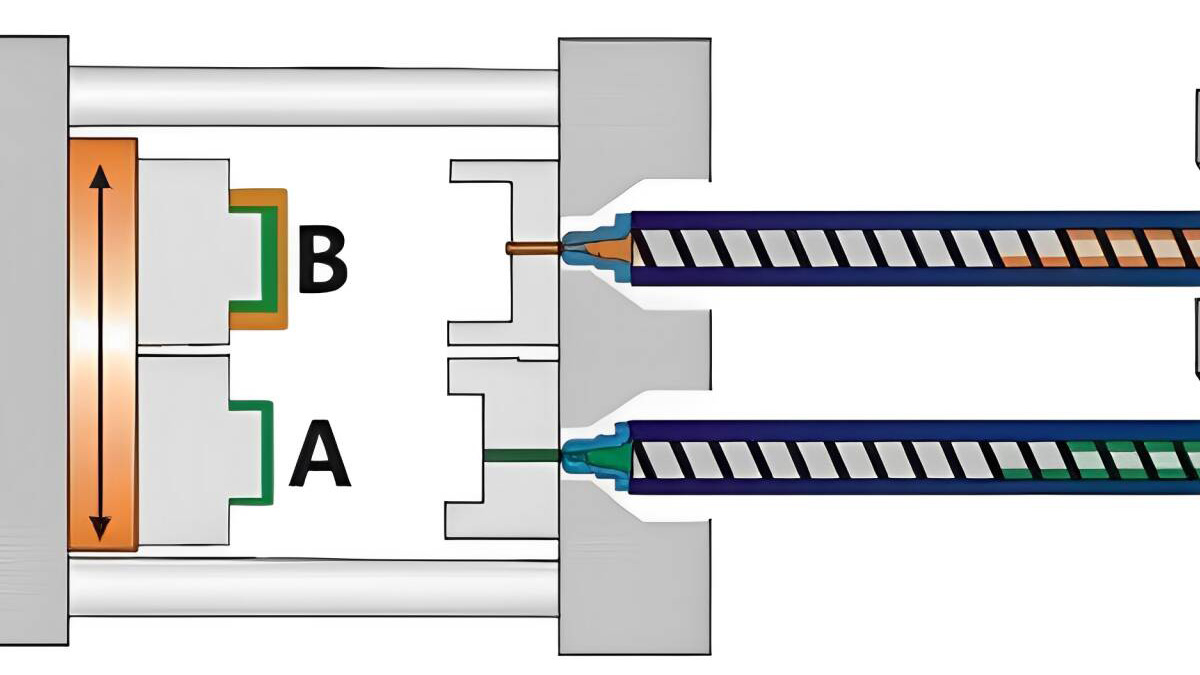

Most plastic products with colorful patterns are manufactured with two shot injection molding technique. Briefly, it’s about manufacturing one product with two types of plastic. But choosing the perfect [...]

Plastic products are everywhere in modern lifestyle, especially those with colorful appearance. When you see colorful bottles or ornaments, it’s likely that they’re made by two-shot injection molding technique. [...]

Sheet metal fabrication is a manufacturing process that involves cutting, punching, stamping, and bending flat metal sheets into functional parts. Using 3D CAD models, machine code is generated to [...]

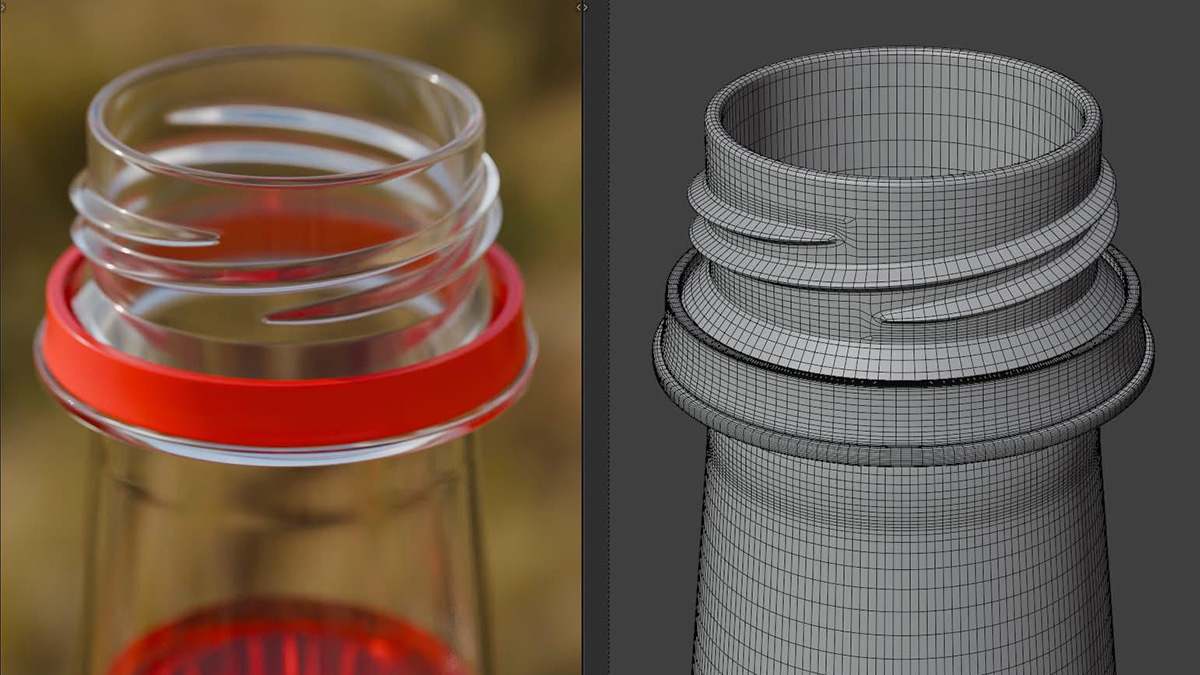

Have you ever wondered why the threads on the plastic bottle necks are on the outside instead of the inside, though the functions would be exactly the same? Many [...]

Plastics have become fundamental components in contemporary life, serving critical functions in nearly every sector from healthcare to consumer goods. Their ubiquitous nature demands rigorous quality assurance measures to [...]

This plastic parts inspection specification applies to all plastic components produced by KingStar Mold, including those made through injection molding, as well as externally sourced plastic accessories and products [...]

When choosing the right cooler, it’s not just about the size or color. You’ve probably heard brands and manufacturers mention terms like “rotomolded” and “injection molded,” and you might [...]

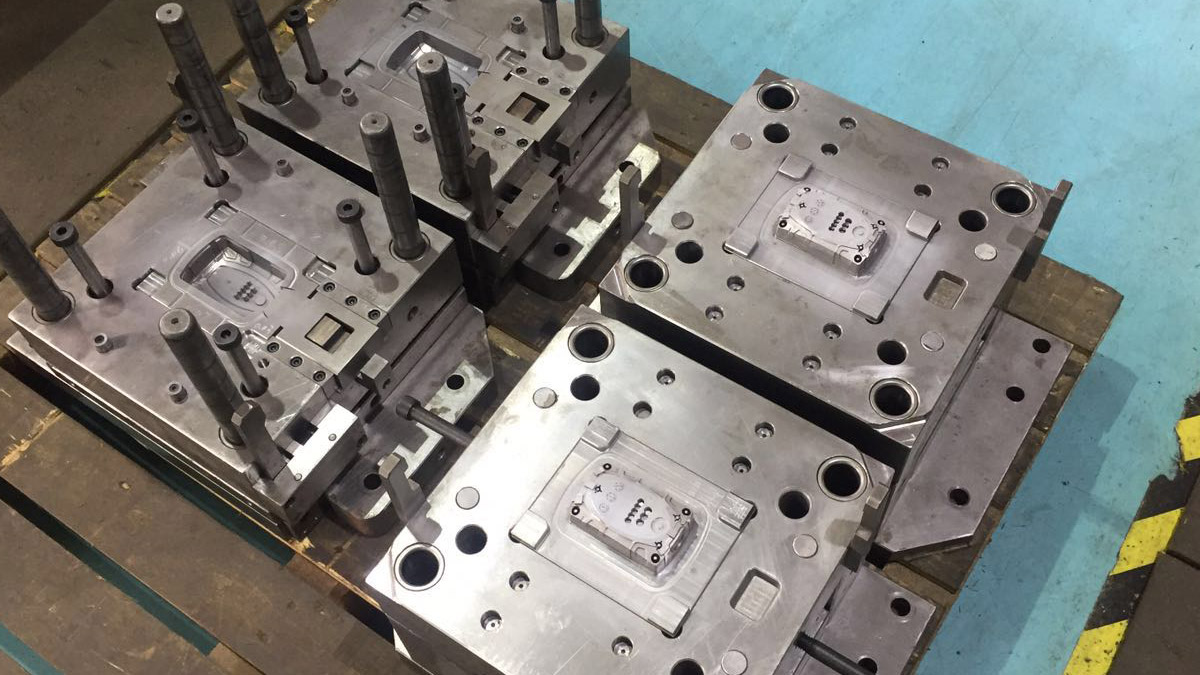

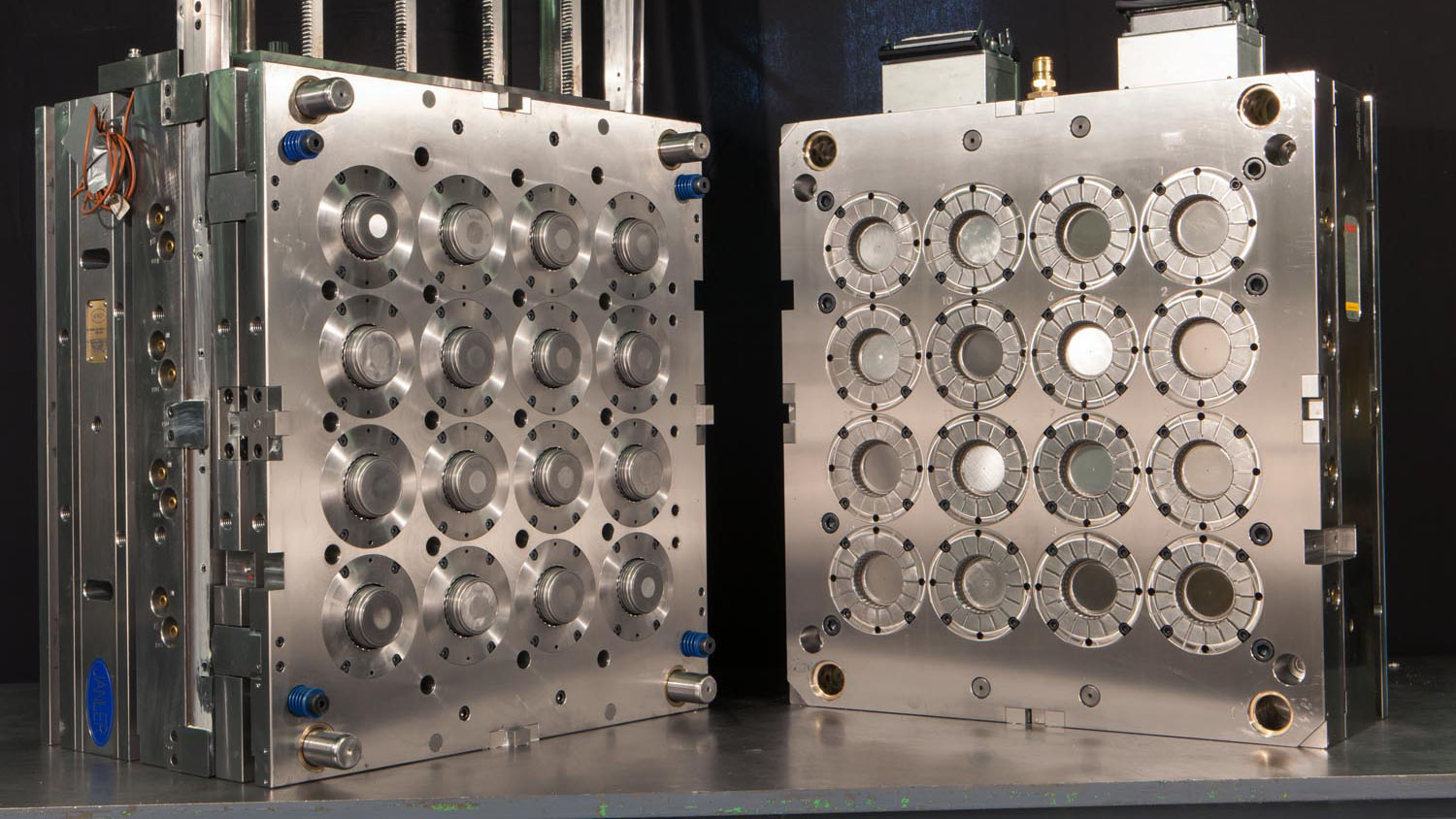

Molds play an essential role in injection molding and die-casting process, and should be designed for continuous, frequent use. A durable mold could bring manufacturing efficiency and production effectiveness. Whether in injection or [...]

There are many different creative ways of using plastic storage boxes. Thanks to their versatility and accessibility, they have become an essential companion of maintaining a clean and tidy [...]

Plastic storage bins are everywhere—from your garage to warehouse shelves. But have you ever wondered why some bins last for years while others crack after a few months? The [...]

As a global leader in wholesale custom storage bin manufacturing, KingStar Mold receives daily inquiries about production timelines and costs. This article highlights the key cost factors involved in [...]

As a leading custom plastic injection molding company, KingStar Mold receives multiple inquiries daily from various industries regarding mold building and injection molding projects. Some projects have incomplete designs, [...]

Injection molding is one of the most widely used manufacturing processes in producing plastic parts across various industries, including automotive, electronics, and consumer goods. Its efficiency, precision, and ability [...]

Selecting the appropriate mold steel is a crucial strategic decision that will have an impact on various aspects ranging from part quality, production efficiency to mold lifespan and total [...]

Every week we receive emails and phone calls from customers asking about Low-volume injection molding. Most of the questions are about mold material selection, production cycle, cost, etc. As [...]

Selective Laser Sintering (SLS) is a powerful additive manufacturing technology that uses a laser to selectively sinter powdered material, fusing it into a solid structure. This process is ideal [...]

For manufacturers and engineers working with products made through PVC injection molding(especially wire and cable compounds, flexible films, and consumer goods) choosing the right plasticizer is critical to achieving [...]

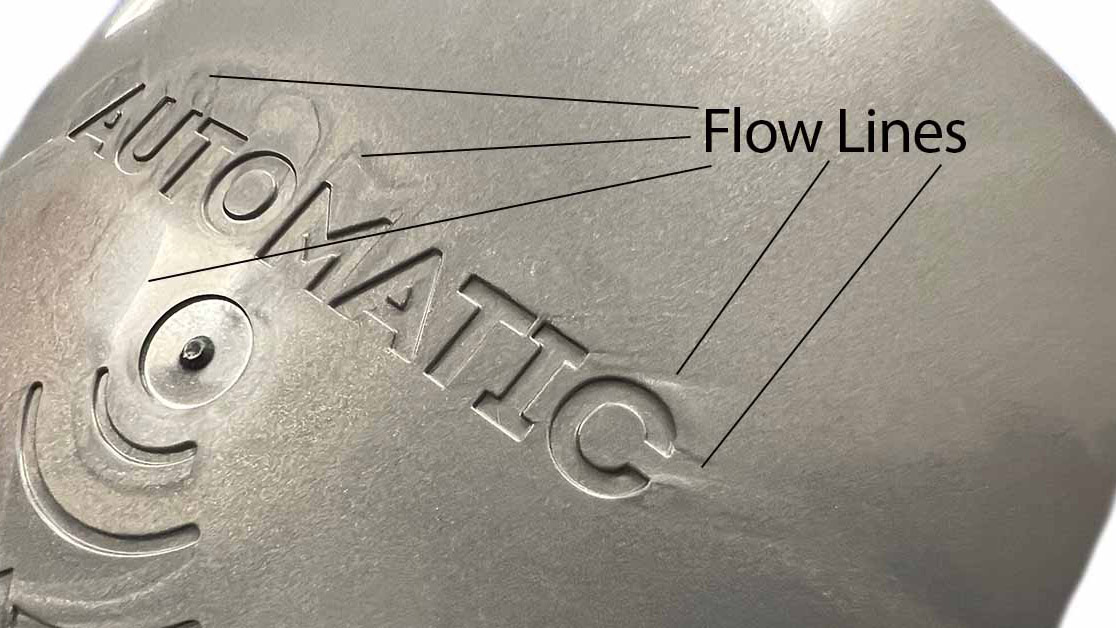

If you are engaged in an industry related to the manufacturing of plastic products (injection molding, 3D printing, etc.), then you are likely to have encountered a common problem: [...]

Whether you’re an R&D engineer refining plastic blends for injection molding, a QA specialist checking consistency in silicone rubber molding parts, or a procurement pro verifying material specs, Shore [...]

Whether you’re gearing up for a weekend camping trip, a backyard BBQ, or a long road trip, a cooler is your best friend for keeping food fresh and drinks [...]

Sandblasting is a technique that bridges the old and the new. Dating back to the early 1870s, its core idea - using a stream of abrasive material to clean [...]

Investing in high-quality hard-sided coolers is a significant decision for businesses, especially those in the outdoor, catering, or event - planning industries. As a leading hard cooler ice box [...]

As a leading custom manufacturing company having tens of years' experiences in plastic injection molding, I’ve always believed that "choosing the right plasticizer is half the battle." Whether it’s [...]

When you're planning a camping trip, a long fishing day, or a beach getaway, keeping your food and drinks cold is more than just a luxury—it’s a necessity. In [...]

Keeping an injection molding machine running smoothly isn't just about fixing problems when they happen — it's about preventing them in the first place. To ensure their regular operation, [...]