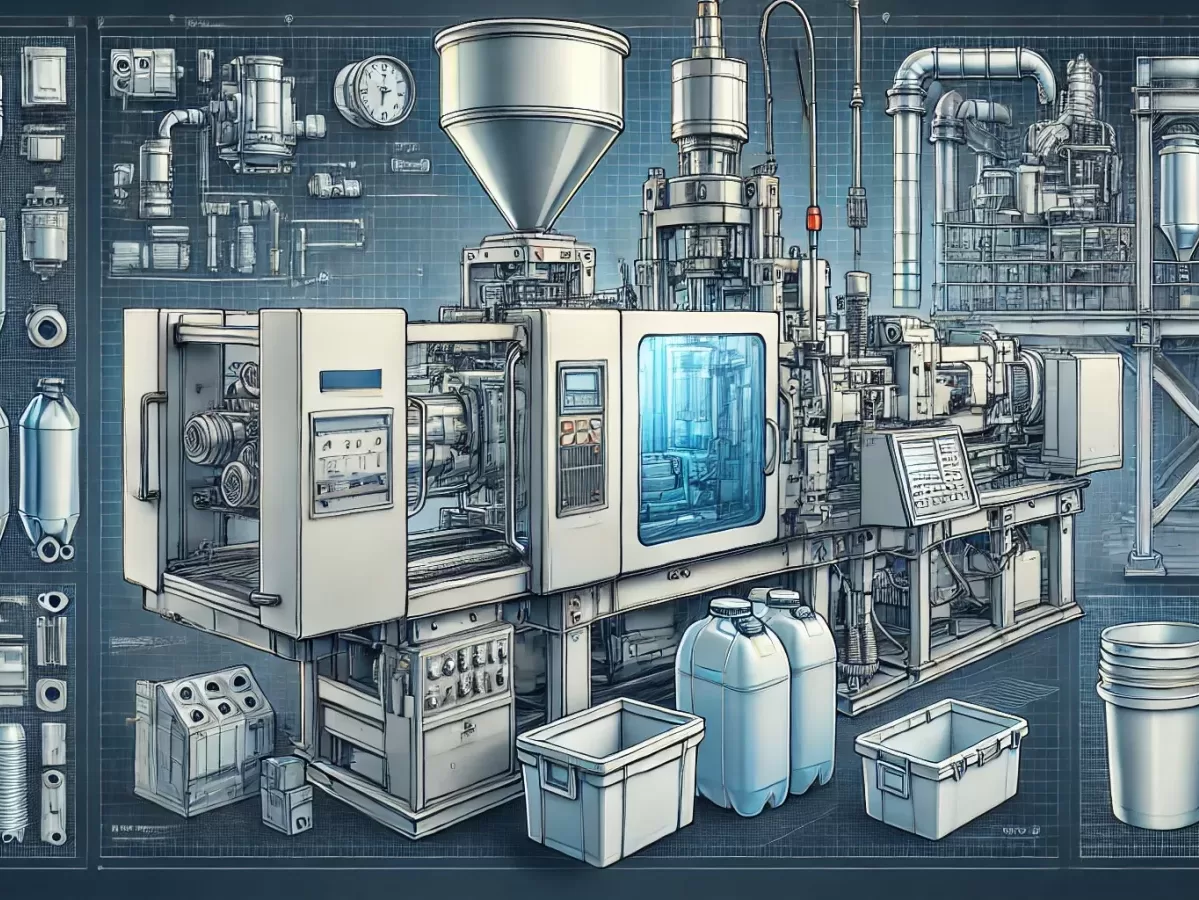

What is Plastic Injection Molding?

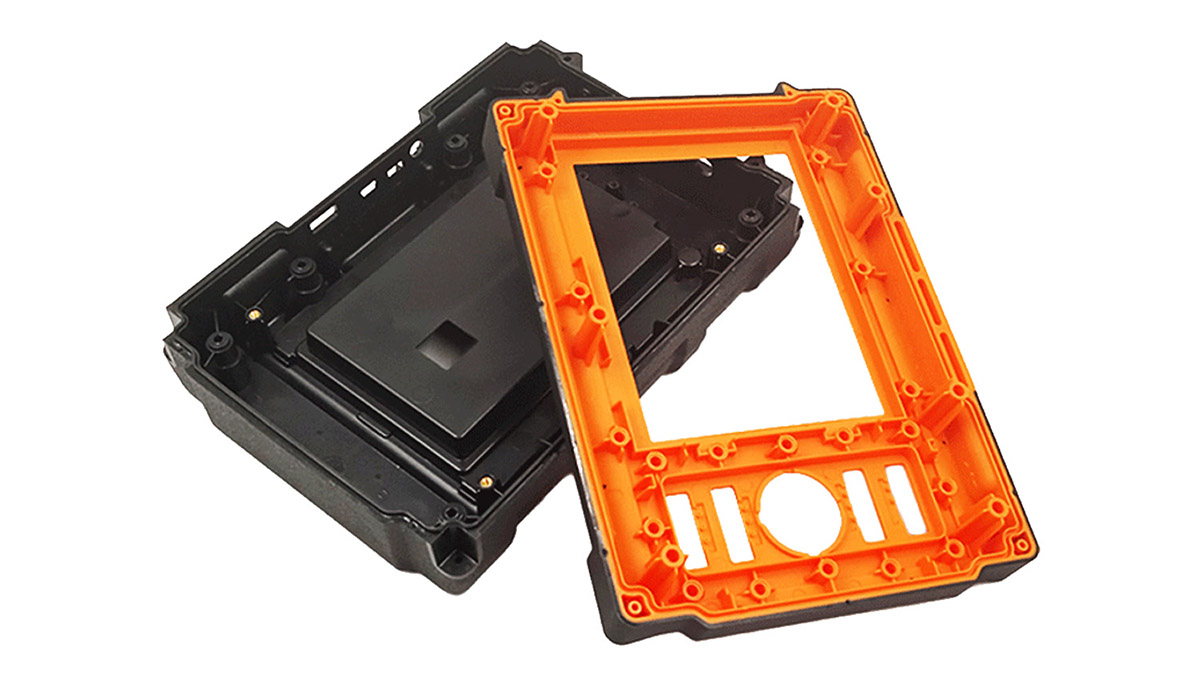

Plastic injection molding is a transformative manufacturing process that injects melted plastic into precisely designed molds. Through centuries, this technique has revolutionized the production of everyday items, from simple products like bottles to automotive parts with complex design. As more and more industries seek efficient, cost-effective solutions, plastic injection […]

In current industrial production, thin-wall injection molding materials are widely used in various fields such as packaging and electronics due to their unique advantages. From daily food packaging to [...]

Plastic storage boxes have become indispensable for both daily life and industrial use, and their quality and performance depend heavily on the materials they’re made of. Different types of [...]

1. Process Background: New Exploration of IMD Technology In recent years, in-mold decoration (IMD) has actually gained significant popularity in the field of product exterior processing—it enhances surface [...]

Nowadays, many products are trending towards being “light, small, and thin,” such as mobile phones, headphones, and even disposable food containers. Thin-wall injection molding is the key technology supporting [...]

1. Preface As the leading injection molding factory in China, KingStar has extensive experience in overmolding design. This specification is formulated based on the needs of our company’s [...]

As a key component for enhancing the fire safety of polymer materials (especially PVC), flame retardants play an indispensable role in many industries, such as construction, electronics, automotive, and [...]

Whether the overmolding mold is qualified is crucial, as the design of the mold structure and the mold fitting(FIT) process during manufacturing are extremely important. All personnel involved in [...]

TPE overmolding is a key technology that involves encapsulating a soft thermoplastic elastomer (TPE) onto a hard substrate (such as plastic or metal) through injection molding. It is far [...]

If you’ve ever shopped for a high-performance cooler, you’ve probably noticed Yeti coolers' price tag stands out—and for good reason. These coolers have built a reputation for lasting through [...]

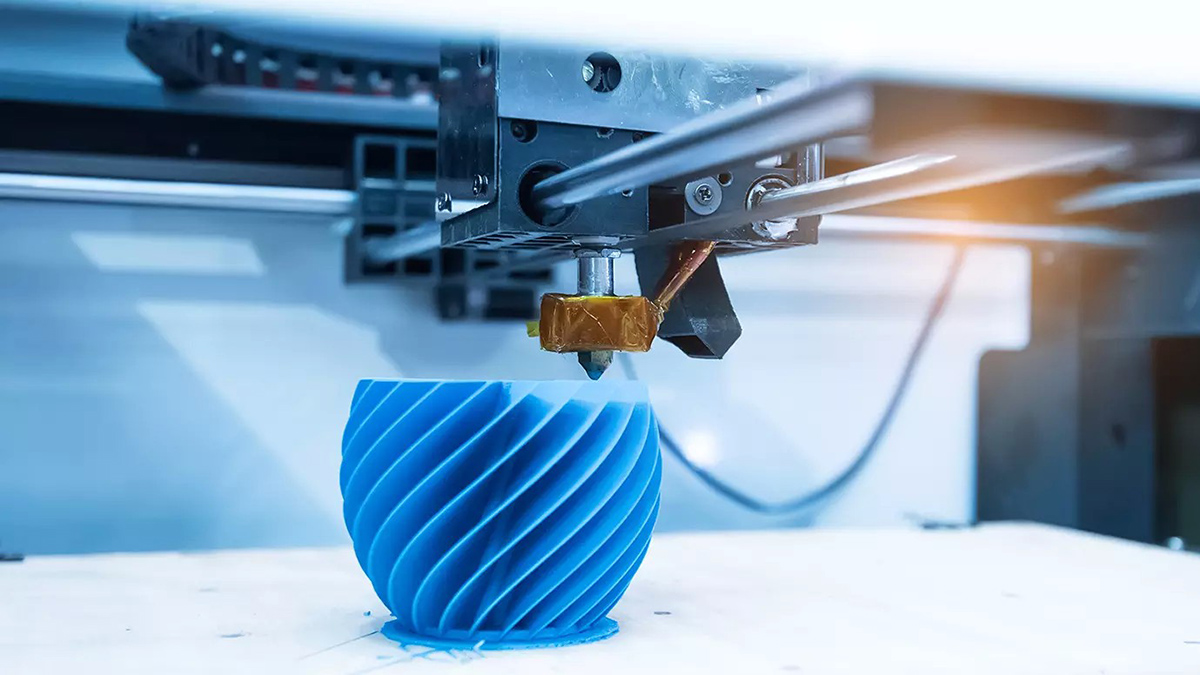

Fused Deposition Modeling (abbreviated as FDM) is one of the most widely used 3D printing technologies. It uses a heated nozzle to extrude thermoplastic filaments, depositing layers of material [...]

Have you ever looked at a product and thought, “I could’ve made something better”? Maybe it's a tool you wish worked differently, or a daily annoyance you’re convinced no [...]

Selecting the right sheet metal material is a crucial step in product design, especially for sheet metal fabrication, as it directly impacts various aspects of manufacturing and the performance [...]

In today’s competitive manufacturing landscape, producing high-quality products isn't just a goal—it’s a measurable discipline. At the heart of this discipline lies CTQ, or Critical to Quality, a framework [...]

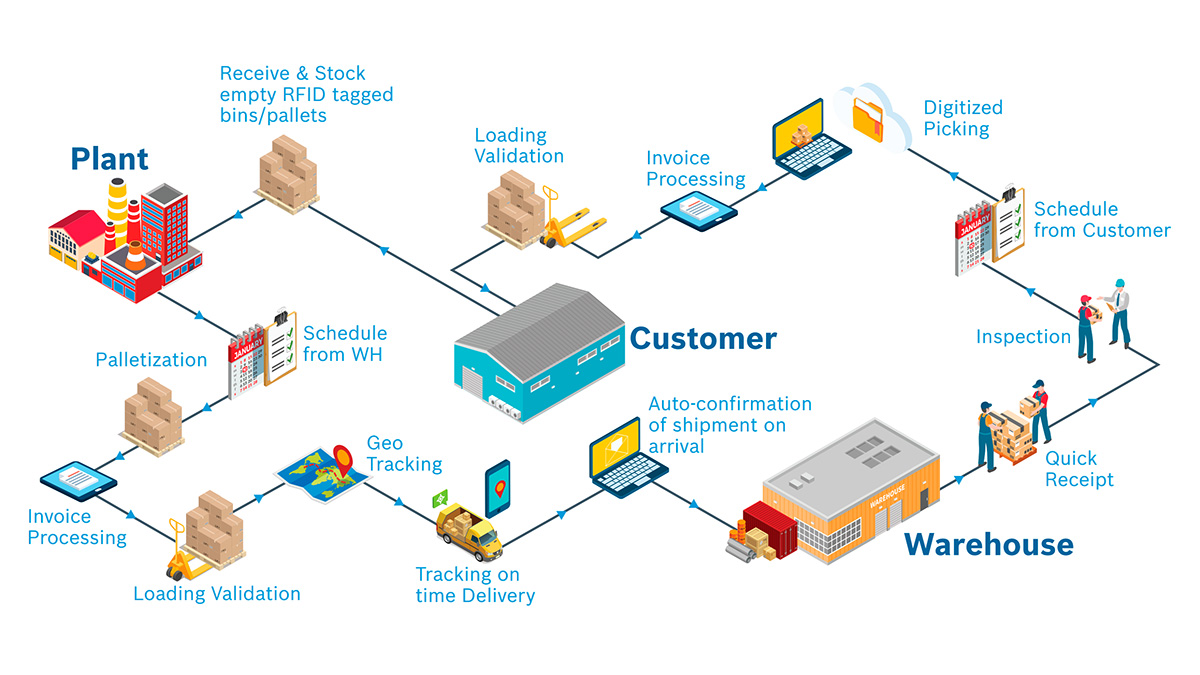

In today’s highly competitive and regulated manufacturing landscape, ensuring product quality and transparency throughout the production process is crucial. Traceability is a key concept that allows manufacturers to track [...]

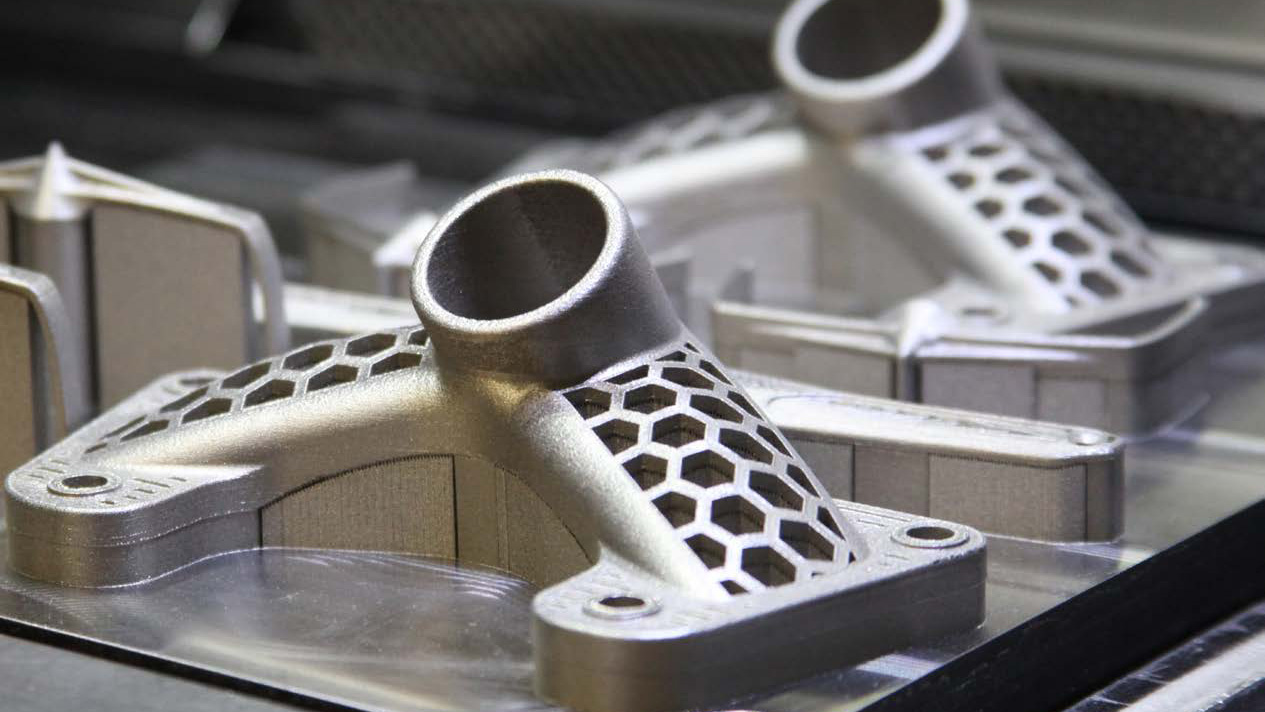

Metal 3D printing has transformed modern manufacturing, enabling the creation of highly complex, lightweight, and customized parts. However, while 3D printing offers incredible design freedom, it’s important to note [...]

Direct Metal Laser Sintering (DMLS) is a powerful additive manufacturing technology that uses a high-powered laser to fuse fine metal powders into solid metal parts, layer by layer. This [...]

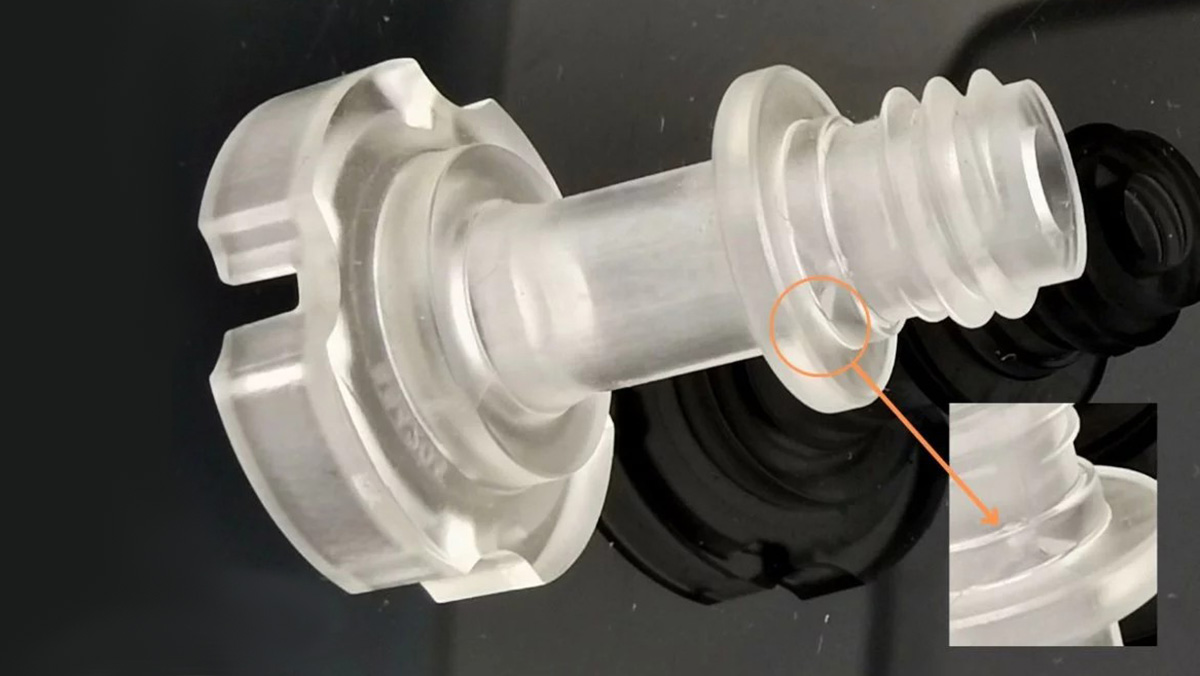

Air bubbles are a common defect in injection molding, occurring when gas pockets or voids become trapped within the molded part. These bubbles can significantly impact the product's appearance, [...]

Flash and burrs are common defects in injection molding, characterized by excess material protruding from the edges or surfaces of molded parts. These imperfections typically occur at the parting [...]

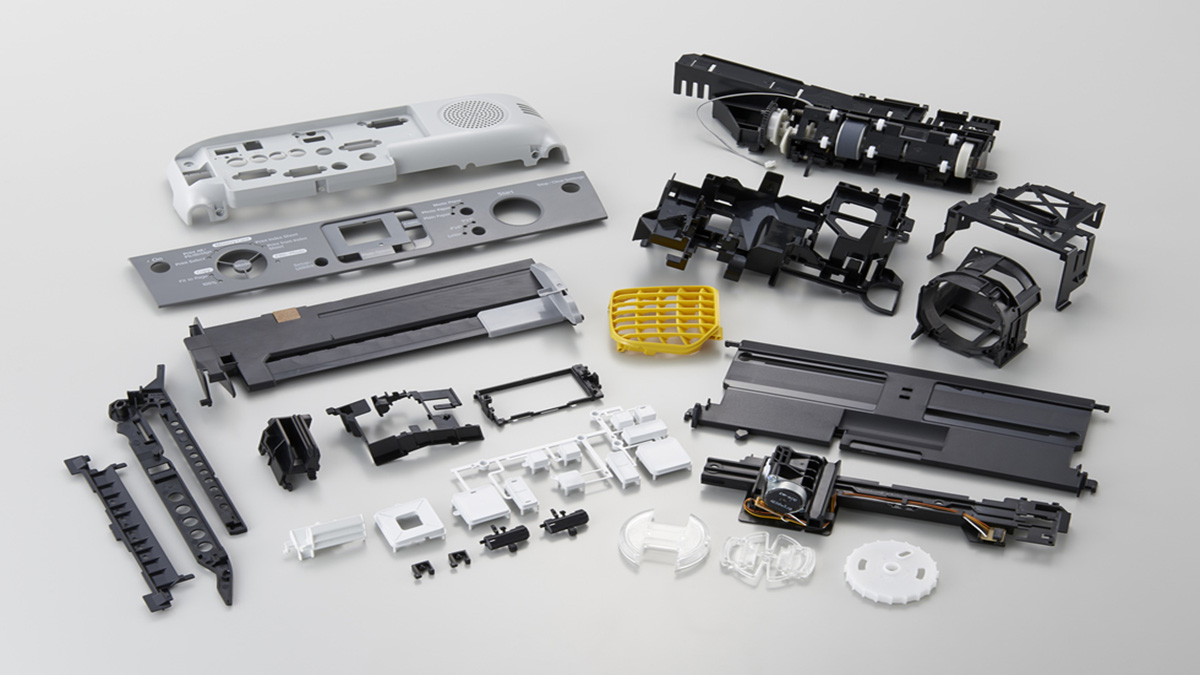

In the field of precision manufacturing, the combination of metal inserts and plastic components has long been a core solution for enhancing product durability. This design not only addresses [...]

In the fields of precision manufacturing such as home appliance panels and vehicle exterior panels, AL5052 aluminum sheet stamped parts have become the core components due to their excellent [...]

The quality of injection molded products is the cornerstone for enterprises to establish themselves in the market, and quality managers are the core guardians of this quality defense line. [...]

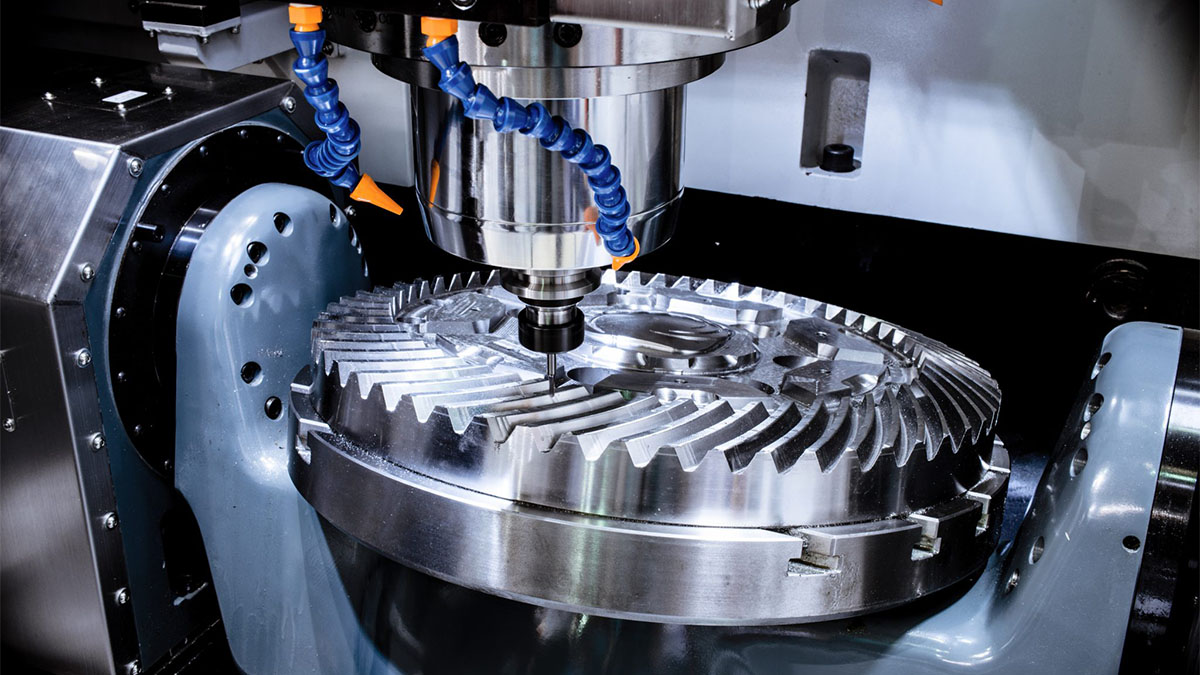

In the field of CNC machining, standardization is the core support for ensuring production safety, controlling product accuracy, and improving operational efficiency. In order to effectively avoid machining risks, [...]

Hey there, party planners and camping enthusiasts! Most buyers of coolers, including you who are reading this article, probably think that the typical use of coolers is to keep [...]

In modern manufacturing, thermoplastic injection molding technology, with its advantages of efficient mass production and controllable precision, can stably produce complex shaped components. In addition, the material itself has [...]

In the modern injection molding industry, thin-walled products have gained widespread application in sectors such as electronics, medical devices, and packaging due to their advantages of lightweight design, material [...]

In current industrial production, thin-wall injection molding materials are widely used in various fields such as packaging and electronics due to their unique advantages. From daily food packaging to [...]

Plastic storage boxes have become indispensable for both daily life and industrial use, and their quality and performance depend heavily on the materials they’re made of. Different types of [...]