Post-Processing Options for Metal 3D-Printed Parts

Metal 3D printing has transformed modern manufacturing, enabling the creation of highly complex, lightweight, and customized parts. However, while 3D printing offers incredible design freedom, it’s important to note that the parts usually require post-processing to enhance their performance, surface finish, and dimensional accuracy.

In this post, we will explore […]

In the fields of precision manufacturing such as home appliance panels and vehicle exterior panels, AL5052 aluminum sheet stamped parts have become the core components due to their excellent [...]

The quality of injection molded products is the cornerstone for enterprises to establish themselves in the market, and quality managers are the core guardians of this quality defense line. [...]

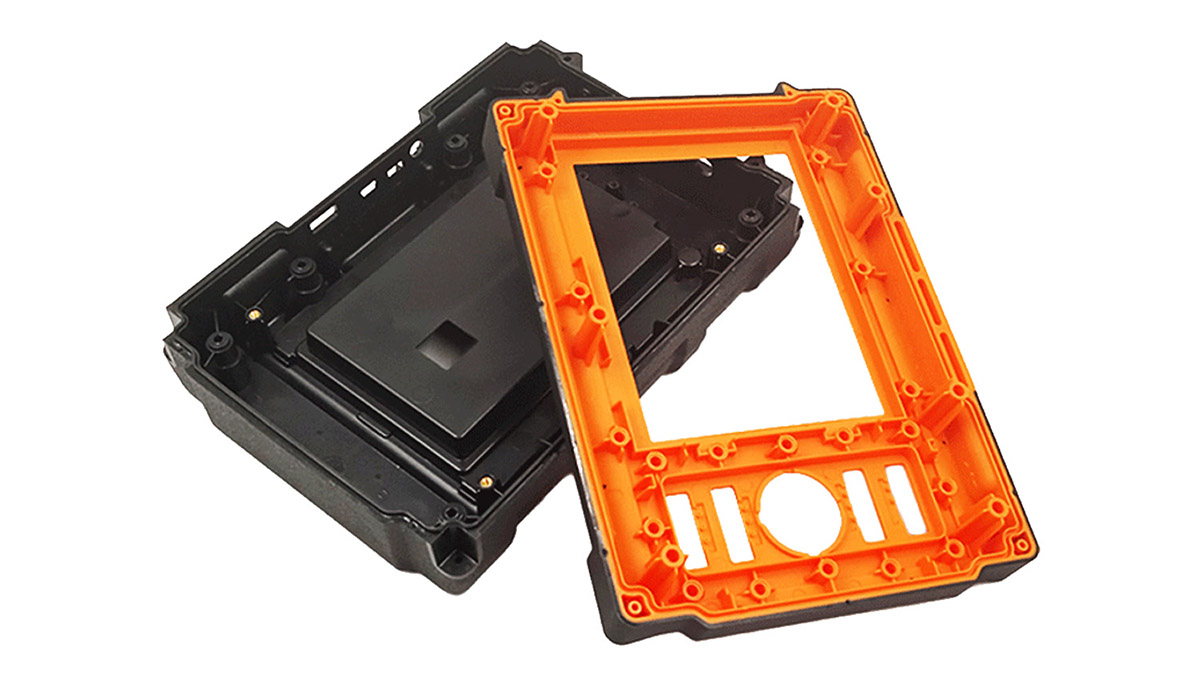

In modern manufacturing, thermoplastic injection molding technology, with its advantages of efficient mass production and controllable precision, can stably produce complex shaped components. In addition, the material itself has [...]

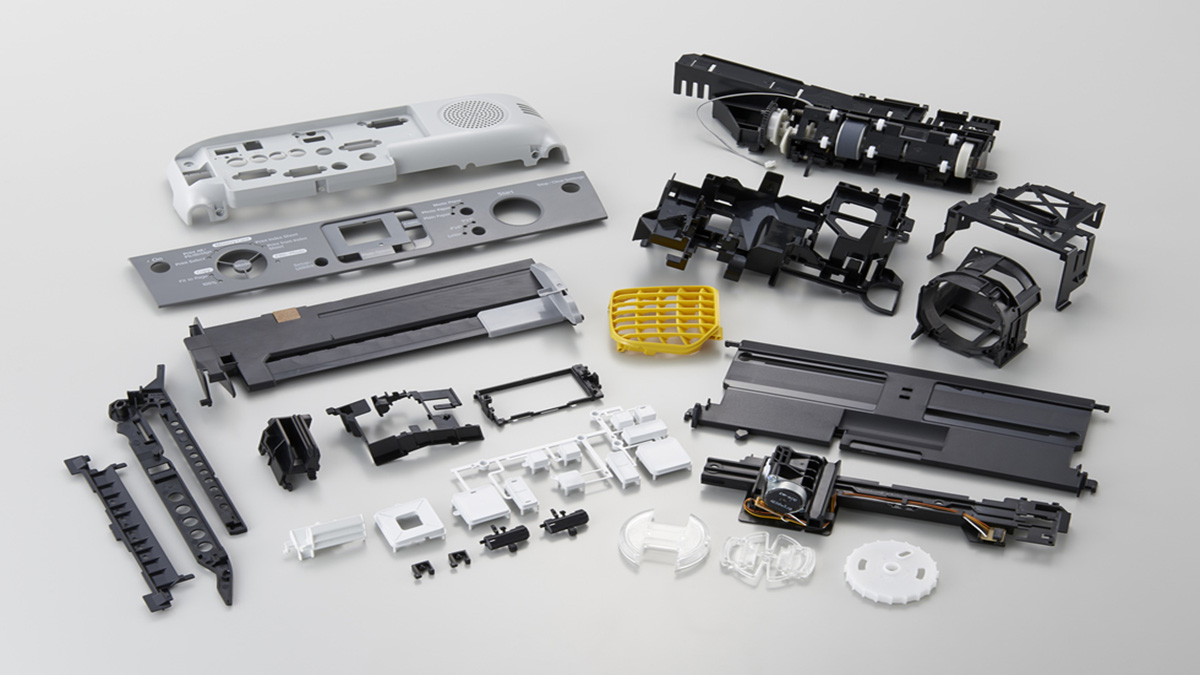

In the modern injection molding industry, thin-walled products have gained widespread application in sectors such as electronics, medical devices, and packaging due to their advantages of lightweight design, material [...]

In current industrial production, thin-wall injection molding materials are widely used in various fields such as packaging and electronics due to their unique advantages. From daily food packaging to [...]

Plastic storage boxes have become indispensable for both daily life and industrial use, and their quality and performance depend heavily on the materials they’re made of. Different types of [...]

1. Process Background: New Exploration of IMD Technology In recent years, in-mold decoration (IMD) has actually gained significant popularity in the field of product exterior processing—it enhances surface [...]

Nowadays, many products are trending towards being “light, small, and thin,” such as mobile phones, headphones, and even disposable food containers. Thin-wall injection molding is the key technology supporting [...]

1. Preface As the leading injection molding factory in China, KingStar has extensive experience in overmolding design. This specification is formulated based on the needs of our company’s [...]

Polyvinyl chloride (PVC) possesses outstanding corrosion resistance, flame retardancy, and high mechanical properties, and is thus widely used in industries such as construction, electronics, packaging, and pipe manufacturing. However, [...]

TPU (Thermoplastic Polyurethane Elastomer), with its outstanding wear resistance, elasticity and weather resistance, is widely used in automotive, electronic, medical, packaging and other fields. However, different types of TPU [...]

For manufacturers and engineers working with products made through PVC injection molding(especially wire and cable compounds, flexible films, and consumer goods) choosing the right plasticizer is critical to achieving [...]

If you are engaged in an industry related to the manufacturing of plastic products (injection molding, 3D printing, etc.), then you are likely to have encountered a common problem: [...]

As a leading custom manufacturing company having tens of years' experiences in plastic injection molding, I’ve always believed that "choosing the right plasticizer is half the battle." Whether it’s [...]

Apparently, plastics products have become fundamental in modern lifestyles, regardless of regions and lands. However, how could plastics become so widely applied, while only 20 to 30 types of [...]

Compared with traditional glass and metal materials, plastic has demonstrated irreplaceable advantages in the medical field. It is cost-effective and particularly suitable for manufacturing disposable medical devices, effectively reducing [...]

Most plastic products with colorful patterns are manufactured with two shot injection molding technique. Briefly, it’s about manufacturing one product with two types of plastic. But choosing the perfect [...]

Selecting the right sheet metal material is a crucial step in product design, especially for sheet metal fabrication, as it directly impacts various aspects of manufacturing and the performance [...]

Sandblasting is a technique that bridges the old and the new. Dating back to the early 1870s, its core idea - using a stream of abrasive material to clean [...]

As a leading custom manufacturing company having tens of years' experiences in plastic injection molding, I’ve always believed that "choosing the right plasticizer is half the battle." Whether it’s [...]

When you're planning a camping trip, a long fishing day, or a beach getaway, keeping your food and drinks cold is more than just a luxury—it’s a necessity. In [...]

Keeping an injection molding machine running smoothly isn't just about fixing problems when they happen — it's about preventing them in the first place. To ensure their regular operation, [...]

Compared with traditional glass and metal materials, plastic has demonstrated irreplaceable advantages in the medical field. It is cost-effective and particularly suitable for manufacturing disposable medical devices, effectively reducing [...]

Plastic products are everywhere in modern lifestyle, especially those with colorful appearance. When you see colorful bottles or ornaments, it’s likely that they’re made by two-shot injection molding technique. [...]

A lukewarm drink or a soggy sandwich can ruin even the best outdoor trip—and it all comes down to how you pack your cooler. Get it right, and ice [...]

Did your last camping trip leave your cooler looking like something out of a science lab? Maybe there’s a sticky residue clinging to the bottom, a mysterious odor that [...]

Sheet metal fabrication is a manufacturing process that involves cutting, punching, stamping, and bending flat metal sheets into functional parts. Using 3D CAD models, machine code is generated to [...]

In the field of precision manufacturing, the combination of metal inserts and plastic components has long been a core solution for enhancing product durability. This design not only addresses [...]

In the fields of precision manufacturing such as home appliance panels and vehicle exterior panels, AL5052 aluminum sheet stamped parts have become the core components due to their excellent [...]

The quality of injection molded products is the cornerstone for enterprises to establish themselves in the market, and quality managers are the core guardians of this quality defense line. [...]

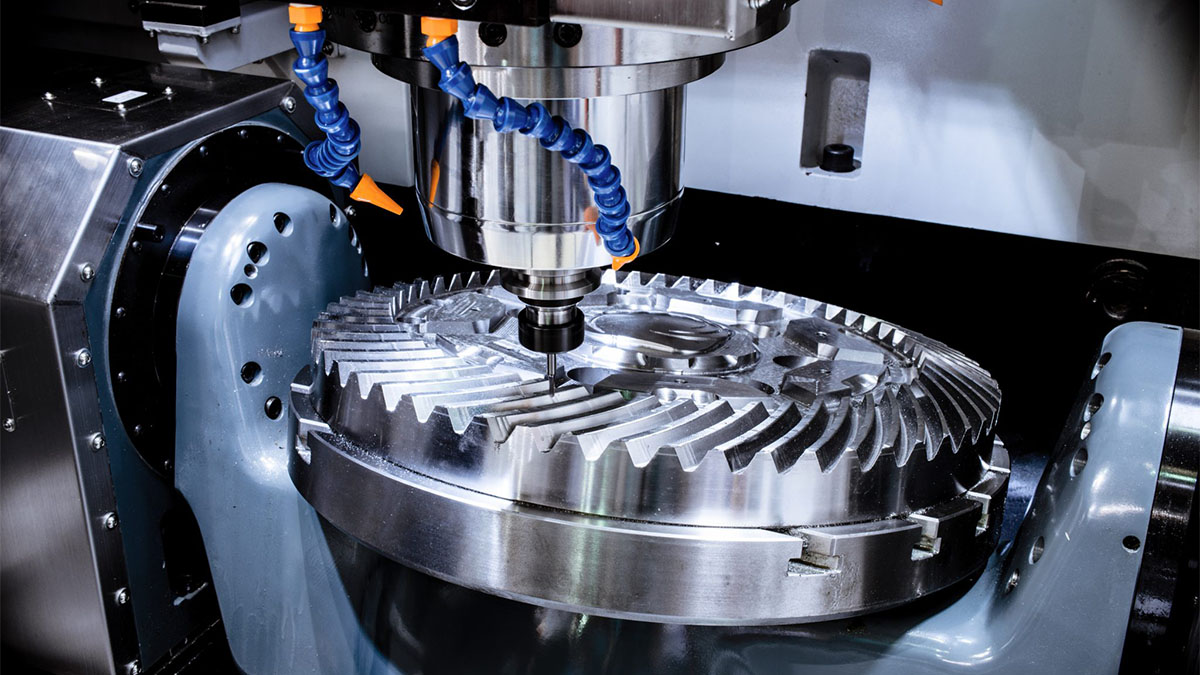

In the field of CNC machining, standardization is the core support for ensuring production safety, controlling product accuracy, and improving operational efficiency. In order to effectively avoid machining risks, [...]

Hey there, party planners and camping enthusiasts! Most buyers of coolers, including you who are reading this article, probably think that the typical use of coolers is to keep [...]

In modern manufacturing, thermoplastic injection molding technology, with its advantages of efficient mass production and controllable precision, can stably produce complex shaped components. In addition, the material itself has [...]

In the modern injection molding industry, thin-walled products have gained widespread application in sectors such as electronics, medical devices, and packaging due to their advantages of lightweight design, material [...]

In current industrial production, thin-wall injection molding materials are widely used in various fields such as packaging and electronics due to their unique advantages. From daily food packaging to [...]

Plastic storage boxes have become indispensable for both daily life and industrial use, and their quality and performance depend heavily on the materials they’re made of. Different types of [...]