Injection Molding Cost: All Factors and How to Reduce It

- 1. Introduction

- 2. What Determines Injection Molding Costs?

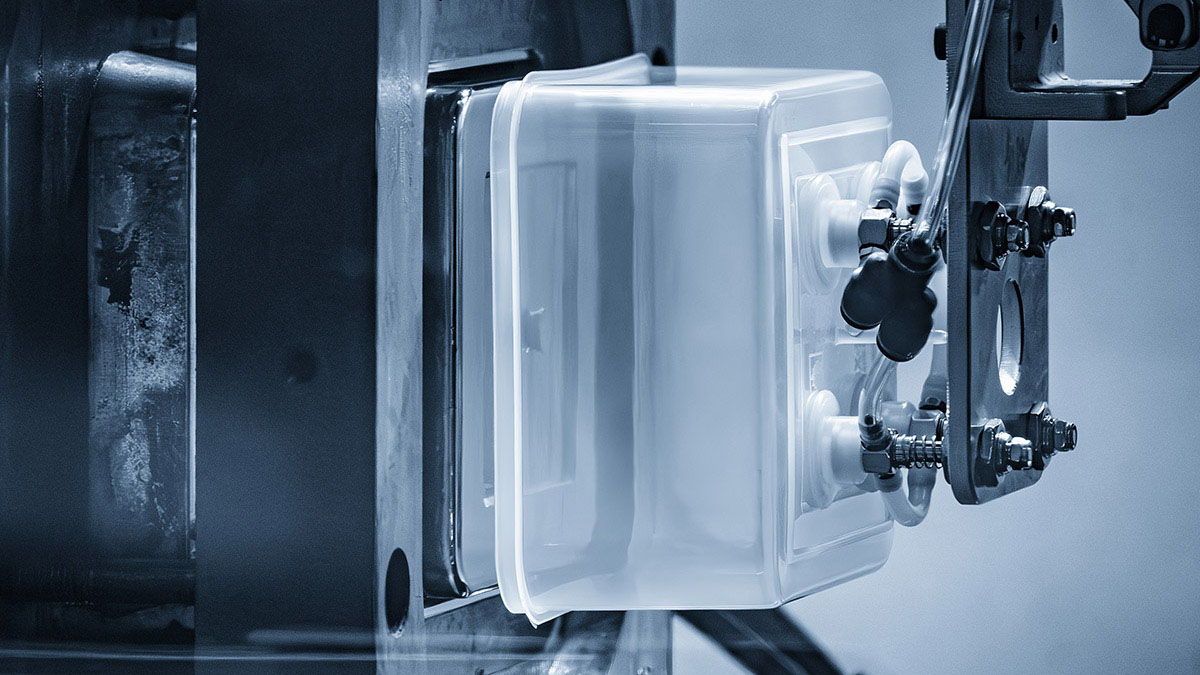

- 3. Mold Tooling Costs: The Foundation of Injection Molding Expenses

- 4. Material Costs

- 5. Injection Molding Machine and Equipment Costs

- 6. Labor and Setup Costs: The Hidden Expenses

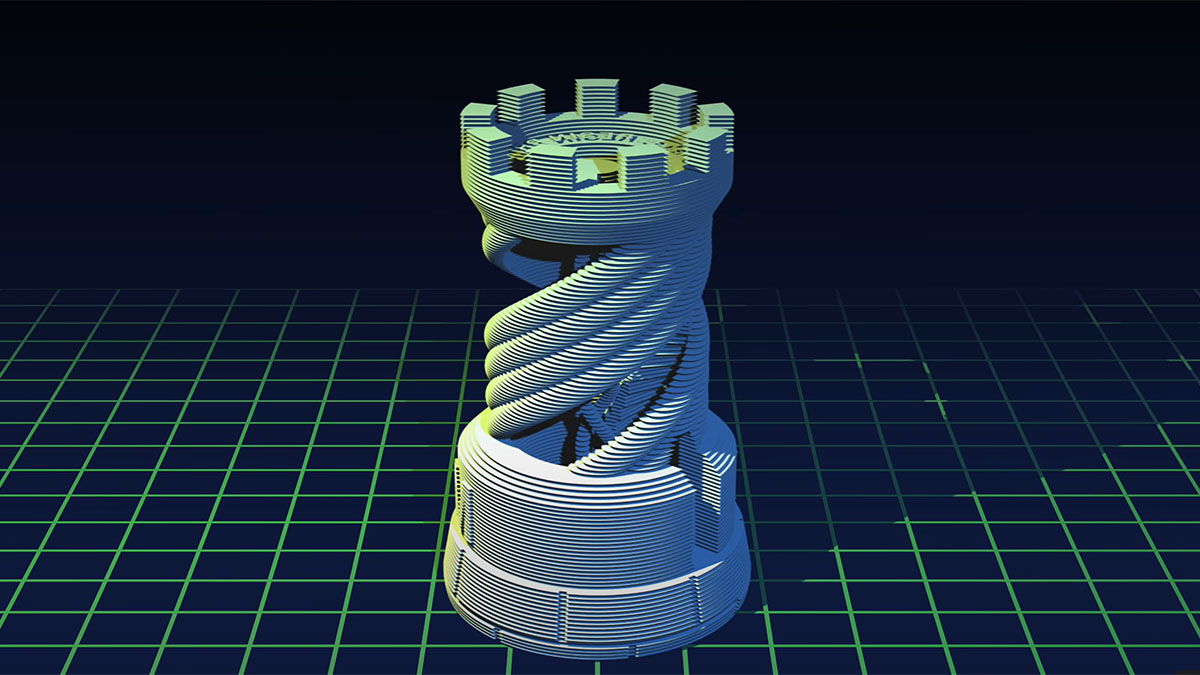

- 7. How Part Design Influences Injection Molding Costs

- 8. Injection Molding Costs Across Different Production Volumes

- 9. Strategies to Reduce Injection Molding Costs

- Implementing Design for Manufacturing (DfM) Practices

- Simplifying Product Design to Minimize Mold Complexity

- Reducing the Number of Cavities in the Mold

- Strategic Material Selection Tactics

- The Advantages of Insert Molding and Overmolding

- How Self-Mating Parts Can Simplify Design and Reduce Costs

- Leveraging Rapid Tooling to Speed Up Production and Reduce Costs

- Adopting New Technologies to Reduce Costs

1. Introduction

Injection molding has become one of the most widely used manufacturing processes, especially for producing high-volume, complex plastic parts. It’s an cost-effective method that allows for precise replication of parts, making it ideal for industries like automotive, electronics, medical devices, and consumer goods. However, despite its advantages, injection […]

Selecting the appropriate mold steel is a crucial strategic decision that will have an impact on various aspects ranging from part quality, production efficiency to mold lifespan and total [...]

Every week we receive emails and phone calls from customers asking about Low-volume injection molding. Most of the questions are about mold material selection, production cycle, cost, etc. As [...]

Selective Laser Sintering (SLS) is a powerful additive manufacturing technology that uses a laser to selectively sinter powdered material, fusing it into a solid structure. This process is ideal [...]

When it comes to custom plastic injection molding, choosing the right manufacturer can significantly impact both the quality and cost of your project. China is home to a range [...]

Stereolithography (SLA) is a precision 3D printing technique that utilizes a laser to solidify liquid photopolymer resin, building up a model layer by layer. One of the earliest 3D [...]

1. Introduction Injection molding has become one of the most widely used manufacturing processes, especially for producing high-volume, complex plastic parts. It's an cost-effective method that allows for [...]

In the world of injection molding, in most circumstances, the choice of materials is not a one-time decision. The selection of materials involves many considerations, including cost, properties, supply [...]

Dear customers: Considering the national statutory holiday schedule and the actual situation of our company, our company will start the Chinese New Year holiday on January 28, 2025 (Tuesday), [...]

That moment when a perfectly designed sheet metal component fails – not due to the metal itself, but because an integrated nut strips, a clip snaps, or a mounting [...]